sensor INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3271 of 5598

INL-4

< SYSTEM DESCRIPTION >

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006216048

Component DescriptionINFOID:0000000006216049

1. BCMRefer to BCS-4, "

BODY CONTROL

SYSTEM : Componen t Parts Loca-

tion"

2. Personal lamp 3. Luggage room lamp

4. Remote keyless entry receiver Refer to DLK-11, "

DOOR LOCK

SYSTEM :

ComponentPartsLocation"

5. Back door lock assembly

(back door switch) 6. Automatic back door close switch

7. Door request switch 8. Door switch 9. Step lamp

10. Paddle lamp 11. Optical sensor 12. IPDM E/R Refer to PCS-4, "

Component Parts

Location"

13. Vanity mirror lamp 14. Combination meter 15. Combination switch

16. Front door lock assembly (driver

side) (door key cylinder switch, un-

lock sensor) 17. Door lock and unlock switch 18. Foot lamp

19. Push-button ignition switch 20. AV control unit Refer to AV- 9 , "

Component Parts Lo-

cation"

21. Map lamp

JMLIA0837ZZ

Part Description

BCM Controls the interior lighting system.

IPDM E/R Controls the integrated relay according to the request signal from BCM (via CAN com-

munication).

Remote keyless entry receiver Refer to DLK-12, "

DOOR LOCK SYSTEM : ComponentDescription".

AV control uni Receives the dimmer signal from BCM via CAN communication.

Optical sensor Refer to EXL-7, "

EXTERIOR LIGHTING SYSTEM : ComponentDescription".

Unlock sensor Detects door lock condition of driver side door.

Revision: 2010 May2011 QX56

Page 3278 of 5598

SYSTEMINL-11

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

AUTO LIGHT ADJUSTMENT SYSTEM : System DiagramINFOID:0000000006216056

AUTO LIGHT ADJUSTMENT SYSTEM : System DescriptionINFOID:0000000006216057

OUTLINE

Auto light adjustment system is controlled by each f unction of BCM, combination meter and AV control unit

Control by BCM Auto light system

Auto light adjustment system

AUTO LIGHT ADJUSTMENT SYSTEM

Description

BCM supplies voltage to the optical sensor when the ignition switch is turned ON or ACC.

Optical sensor converts outside brightness (lux) to voltage and transmits the optical sensor signal to BCM.

BCM judges dimming/brightening of combination meter and display according to brightness outside the vehi- cle, when ignition switch is ON.

BCM transmits dimmer signal to combination meter via CAN communication, according to auto light adjust- ment conditions. Dimmer signal is also transmitted to AV control unit.

NOTE:

As to dimming/brightening timing, the sensitivity depends on settings. The settings can be changed with CON-

SULT-III. Refer to EXL-23, "

HEADLAMP : CONSULT-III F unction (BCM - HEAD LAMP)".

Auto Light Adjustment Timing Table

When the ignition switch is ON, the illumination of co mbination meter and display switches dimming/brighten-

ing in the following condition.

BCM switches the illumination of combination me ter and display to dimming when outside brightening

obtained from the optical sensor signal is 1250 lx or le ss for 3 seconds or more. And BCM switches the illumi-

nation of combination meter and display to brightening when outside brightening from the optical sensor signal

is 2500 lx or more for 5 seconds or more.

JMLIA0967GB

Combination meter and display Dimming/brightening timing

Dimming Outside brightness is 1250 lx or less for 3 seconds or more.

Brightening Outside brightness is 2500 lx or more for 5 seconds or more.

Revision: 2010 May2011 QX56

Page 3282 of 5598

DIAGNOSIS SYSTEM (BCM)INL-15

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

ACTIVE TEST

BATTERY SAVER

BATTERY SAVER : CONSULT-III Function (BCM - BATTERY SAVER)INFOID:0000000006216060

WORK SUPPORT

*:Factory setting PUSH SW

[On/Off]

The switch status input from push-button ignition switch

UNLK SEN -DR

[On/Off] Driver door unlock status input from unlock sensor

DOOR SW-DR

[On/Off] The switch status input from door switch (driver side)

DOOR SW-AS

[On/Off] The switch status input from door switch (passenger side)

DOOR SW-RR

[On/Off] The switch status input from rear door switch RH

DOOR SW- RL

[On/Off] The switch status input from rear door switch LH

DOOR SW- BK

[On/Off] The switch status input from back door switch

CDL LOCK SW

[On/Off] Lock switch status input from door lock and unlock switch

CDL UNLOCK SW

[On/Off] Unlock switch status input from door lock and unlock switch

KEY CYL LK-SW

[On/Off] Lock switch status received from door key cylinder switch

KEY CYL UN-SW

[On/Off] Unlock switch status received from door key cylinder switch

TRNK/HAT MNTR

[On/Off] NOTE:

The item is indicated, but not monitored.

RKE-LOCK

[On/Off] Lock signal status received from remote keyless entry receiver

RKE-UNLOCK

[On/Off] Unlock signal status received from remote keyless entry receiver

Monitor item

[Unit] Description

Test item Operation Description

INT LAMP OnOutputs the interior room lamp control signal to turn the interior room lamps ON.

[Map lamp, personal lamp, foot lamp (when applicable lamps switch is in DOOR po-

sition.)]

Off Stops the interior room lamp control signal to turn the interior room lamps OFF.

STEP LAMP TEST On Outputs the step lamp control signal to turn the step lamps ON.

Off Stops the step lamp control signal to turn the step lamps ON.

Service item Setting item Setting

ROOM LAMP TIMER SET MODE 1

*30 min.

Sets the interior room lamp battery saver timer operating

time.

MODE 2 60 min.

BATTERY SAVER SET On

*With the exterior lamp battery saver function

Off Without the exterior lamp battery saver function

Revision: 2010 May2011 QX56

Page 3283 of 5598

![INFINITI QX56 2011 Factory Service Manual

INL-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

*: Each lamp switch is in ON position.Monitor item

[Unit] Description

REQ SW-DR

[On/Off] The switch status input from doo INFINITI QX56 2011 Factory Service Manual

INL-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

*: Each lamp switch is in ON position.Monitor item

[Unit] Description

REQ SW-DR

[On/Off] The switch status input from doo](/img/42/57033/w960_57033-3282.png)

INL-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

DATA MONITOR

ACTIVE TEST

*: Each lamp switch is in ON position.Monitor item

[Unit] Description

REQ SW-DR

[On/Off] The switch status input from door request switch (driver side)

REQ SW-AS

[On/Off] The switch status input from door request switch (passenger side)

REQ SW-RR

[On/Off] NOTE:

The item is indicated, but not monitored.

REQ SW-RL

[On/Off]

PUSH SW

[On/Off] The switch status input from push-button ignition switch

UNLK SEN-DR

[On/Off] Driver door unlock status input from unlock sensor

DOOR SW-DR

[On/Off] The switch status input from door switch (driver side)

DOOR SW-AS

[On/Off] The switch status input from door switch (passenger side)

DOOR SW-RR

[On/Off] The switch status input from rear door switch RH

DOOR SW- RL

[On/Off] The switch status input from rear door switch LH

DOOR SW- BK

[On/Off] The switch status input from back door switch

CDL LOCK SW

[On/Off] Lock switch status input from door lock and unlock switch

CDL UNLOCK SW

[On/Off] Unlock switch status input from door lock and unlock switch

KEY CYL LK-SW

[On/Off] Lock switch status received from door key cylinder switch

KEY CYL UN-SW

[On/Off] Unlock switch status received from door key cylinder switch

TRNK/HAT MNTR

[On/Off] NOTE:

The item is indicated, but not monitored.

RKE-LOCK

[On/Off] Lock signal status received from remote keyless entry receiver

RKE-UNLOCK

[On/Off] Unlock signal status received from remote keyless entry receiver

Test item Operation Description

BATTERY SAVER Off Cuts the interior room lamp power supply to turn interior room lamps OFF.

On Outputs the interior room lamp power supply to turn interior room lamps ON.*

Revision: 2010 May2011 QX56

Page 3352 of 5598

PRECAUTIONSINT-3

< PRECAUTION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006415653

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006415652

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3375 of 5598

INT-26

< REMOVAL AND INSTALLATION >

FLOOR TRIM

10. Remove the following parts after removing the center console assembly. Remove ground bolt (G).

Disconnect floor harness connectors (A) and (E).

Disconnect yaw rate/side/decel G sensor harness connector (C). Refer to BRC-138, "

Exploded View".

Disconnect diagnosis sensor unit harness connector (D). Refer to SR-26, "

Exploded View".

Remove floor harness clamps (B) and (F).

11. Remove A/T shift selector assembly mounting bolts. Refer to TM-176, "

Removal and Installation".

12. Remove floor duct 1 (LH and RH). Refer to VTL-11, "

FLOOR DUCT 1 : Removal and Installation".

13. Disconnect drain hose (1) and remove instrument stay mounting nuts (A), and then remove instrument stay (2) (LH and RH).

14. Disengage front floor carpet from front floor carpet fixing clips (A).

JMJIA4226ZZ

JMJIA4225ZZ

JMJIA1560ZZ

Revision: 2010 May2011 QX56

Page 3378 of 5598

HEADLININGINT-29

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Removal and InstallationINFOID:0000000006220257

REMOVAL

1. Remove sun visor cap (1) using a remover tool (A), and then remove sunvisor assembly fixing TORX screws.

2. Disconnect vanity mirror lamp harness connector, and then remove sun visor assembly (LH and RH).

3. Rotate sun visor holder (1) (LH and RH) at approximately 90 degrees, and then pull it out to remove.

4. Insert a remover tool (A) into the gap between lane camera fin- isher (1), and then remove lane camera finisher (if equipped).

5. Remove light & rain sensor cover / rain sensor cover. Refer to WW-72, "

Removal and Installation".

10. Sun visor cover LH 11. Map lamp bracket 12. Dual lock fastener

13. Rear ventilator base LH 14. Rear ventilator grille LH 15. Roof garnish

16. Headlining assembly 17. Dual lock fastener 18. Dual lock fastener

19. Map lamp assembly 20. Sum visor holder RH 21. Rain sensor cover

22. Front camera finisher 23. Sum visor holder LH 24. Rear ventilator garnish A LH

25. Rear ventilator garnish B LH 26. Front camera finisher

(with LDP/LDW)

: Clip

: Pawl

: Metal clip

JMJIA4055ZZ

JMJIA4061ZZ

: Pawl

JMJIA4053ZZ

Revision: 2010 May2011 QX56

Page 3379 of 5598

INT-30

< REMOVAL AND INSTALLATION >

HEADLINING

6. Disconnect harness connectors. Lane camera unit harness connector (1) (if equipped).

Inside mirror harness connector (2).

Light & rain sensor harness connector / rain sensor harness

connector (3).

7. Remove assist grips Insert a small flat-bladed screwdriver (A) into the gap between

assist grip cap (1), and then remove assist grip cap.

Remove assist grip mounting bolts, and then remove assist grips (2).

8. Insert a remover tool (A) between luggage room lamp (1) and roof garnish to disengage the fixing metal clips, and then discon-

nect luggage room lamp harness connector.

CAUTION:

Apply protective tape (B) to the roof garnish to protect from

damage.

9. Insert a remover tool (A) between roof garnish (1) and body panel to disengage the fixing clips and pawls, and then remove

roof garnish.

10. Remove front pillar garnish (LH and RH). Refer to INT-19, "

FRONT PILLAR GARNISH : Removal and

Installation".

11. Remove front kicking plate inner (LH and RH) and rear kicking plate inner (LH and RH). Refer to INT-20,

"KICKING PLATE INNER : Removal and Installation".

12. Remove dash side finisher (LH and RH). Refer to INT-18, "

DASH SIDE FINISHER : Removal and Installa-

tion".

13. Remove center pillar lower garnish (LH and RH). Refer to INT-22, "

CENTER PILLAR LOWER GARNISH :

Removal and Installation".

JMJIA4054ZZ

JMJIA4063ZZ

: Metal clip

JMLIA1059ZZ

: Clip

: Pawl

JMJIA4066ZZ

Revision: 2010 May2011 QX56

Page 3392 of 5598

IP-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006113088

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006113089

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 3404 of 5598

IP-14

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

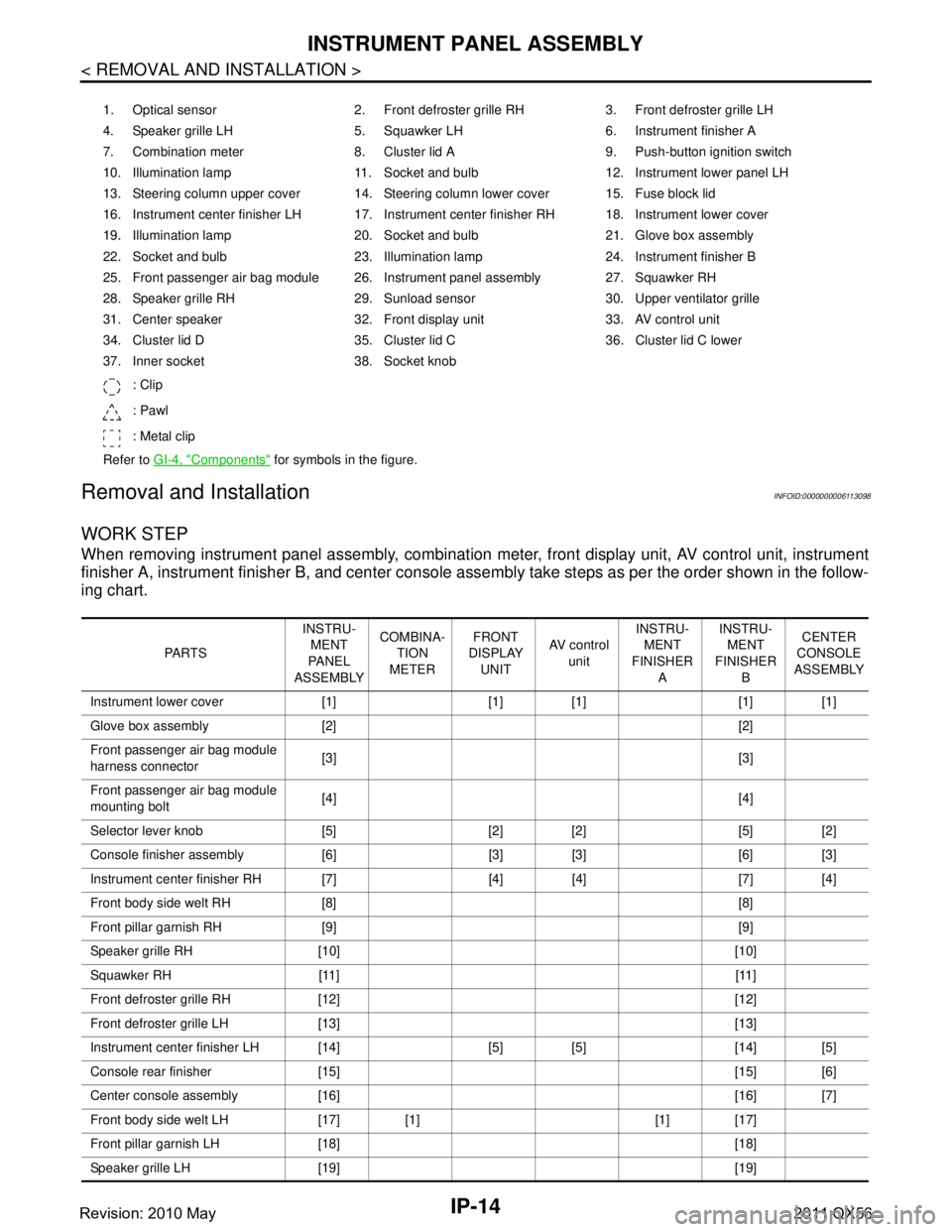

Removal and Installation

INFOID:0000000006113098

WORK STEP

When removing instrument panel assembly, combination meter, front display unit, AV control unit, instrument

finisher A, instrument fini sher B, and center console assembly take st eps as per the order shown in the follow-

ing chart.

1. Optical sensor 2. Front defroster grille RH 3. Front defroster grille LH

4. Speaker grille LH 5. Squawker LH 6. Instrument finisher A

7. Combination meter 8. Cluster lid A 9. Push-button ignition switch

10. Illumination lamp 11. Socket and bulb 12. Instrument lower panel LH

13. Steering column upper cover 14. Steering column lower cover 15. Fuse block lid

16. Instrument center finisher LH 17. Instrument center finisher RH 18. Instrument lower cover

19. Illumination lamp 20. Socket and bulb 21. Glove box assembly

22. Socket and bulb 23. Illumination lamp 24. Instrument finisher B

25. Front passenger air bag module 26. Instrument panel assembly 27. Squawker RH

28. Speaker grille RH 29. Sunload sensor 30. Upper ventilator grille

31. Center speaker 32. Front display unit 33. AV control unit

34. Cluster lid D 35. Cluster lid C 36. Cluster lid C lower

37. Inner socket 38. Socket knob

: Clip

: Pawl

: Metal clip

Refer to GI-4, "

Components" for symbols in the figure.

PA R T S INSTRU-

MENT

PA N E L

ASSEMBLY COMBINA-

TION

METER FRONT

DISPLAY

UNIT AV c o n t r o l

unit INSTRU-

MENT

FINISHER A INSTRU-

MENT

FINISHER B CENTER

CONSOLE

ASSEMBLY

Instrument lower cover [1] [1] [1] [1] [1]

Glove box assembly [2] [2]

Front passenger air bag module

harness connector [3] [3]

Front passenger air bag module

mounting bolt [4] [4]

Selector lever knob [5] [2] [2] [5] [2]

Console finisher assembly [6] [3] [3] [6] [3]

Instrument center finisher RH [7] [4] [4] [7] [4]

Front body side welt RH [8] [8]

Front pillar garnish RH [9] [9]

Speaker grille RH [10] [10]

Squawker RH [11] [11]

Front defroster grille RH [12] [12]

Front defroster grille LH [13] [13]

Instrument center finisher LH [14] [5] [5] [14] [5]

Console rear finisher [15] [15] [6]

Center console assembly [16] [16] [7]

Front body side welt LH [17] [1] [1] [17]

Front pillar garnish LH [18] [18]

Speaker grille LH [19] [19]

Revision: 2010 May2011 QX56