relay INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1524 of 5598

DEF-32

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER RELAY

WIPER DEICER RELAY

Component Function CheckINFOID:0000000006299451

1.CHECK WIPER DEICER RELAY POWER SUPPLY CIRCUIT

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer relay power supply circuit function is OK.

NO >> Refer to DEF-32, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000006299452

1.CHECK WIPER DEICER CIRCUIT 1

1. Turn ignition switch ON.

2. Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK WIPER DEICER CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay and IPDM E/R connector.

3. Check continuity between wiper deicer relay terminal connector and IPDM E/R harness connector.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace harness.

3.CHECK WIPER DEICER CIRCUIT 3

Check voltage between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK WIPER DEICER RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector.

3. Check continuity between wiper deicer relay terminal connector and ground.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal

E23 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer relay IPDM E/R

Continuity

Connector Terminal Connector Terminal

E23 1 E11 14 Existed

(+) (–)Voltage (V)

(Approx.)

Wiper deicer relay

Connector Terminal E23 3 Ground Battery voltage

Revision: 2010 May2011 QX56

Page 1525 of 5598

WIPER DEICER RELAYDEF-33

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness.

5.CHECK WIPER DEICER RELAY

Check wiper deicer relay.

Refer to DEF-33, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace wiper deicer relay.

6.CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component InspectionINFOID:0000000006299453

1.CHECK WIPER DEICER RELAY

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay.

3. Check wiper deicer relay.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace wiper deicer relay.

Wiper deicer relay

GroundContinuity

Connector Terminal

E23 2 Existed

Wiper deicer relay Condition Continuity

Te r m i n a l

35 12 V direct current supply between termi-

nals 1 and 2

Existed

No current supply Not existed

SEF497Y

Revision: 2010 May2011 QX56

Page 1526 of 5598

DEF-34

< DTC/CIRCUIT DIAGNOSIS >

WIPER DEICER

WIPER DEICER

Component Function CheckINFOID:0000000006299454

1.CHECK WIPER DEICER

1. Select Active Test (“REAR DEFOGGER”) mode of “BCM” using CONSULT-III.

2. Touch “ON”.

3. Check that the front window heating wire is getting warmer.

Is the inspection result normal?

YES >> Wiper deicer is OK.

NO >> Refer to DEF-34, "

Diagnosis Procedure"

Diagnosis ProcedureINFOID:0000000006299455

1.CHECK FUSE

1. Turn ignition switch OFF.

2. Check 15 A fuse [No.75, located in fuse block (J/B)]

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace the blown fuse after repairing the affected circuit if a fuse is blown.

2.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 4.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer connector.

3. Check continuity between wiper deicer harness connector and ground.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace harness between rear window defogger and ground.

4.CHECK WIPER DEICER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect wiper deicer relay connector and wiper deicer connector.

3. Check continuity between wiper deicer relay harness connector and wiper deicer harness connector.

(+)

(–) Condition Voltage (V)

(Approx.)

Wiper deicer

Connector Terminal

E40 1 Ground Rear window defogger switch: ON Battery voltage

Rear window defogger switch: OFF 0

Wiper deicer

GroundContinuity

Connector Terminal

E40 2 Existed

Revision: 2010 May2011 QX56

Page 1527 of 5598

WIPER DEICERDEF-35

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

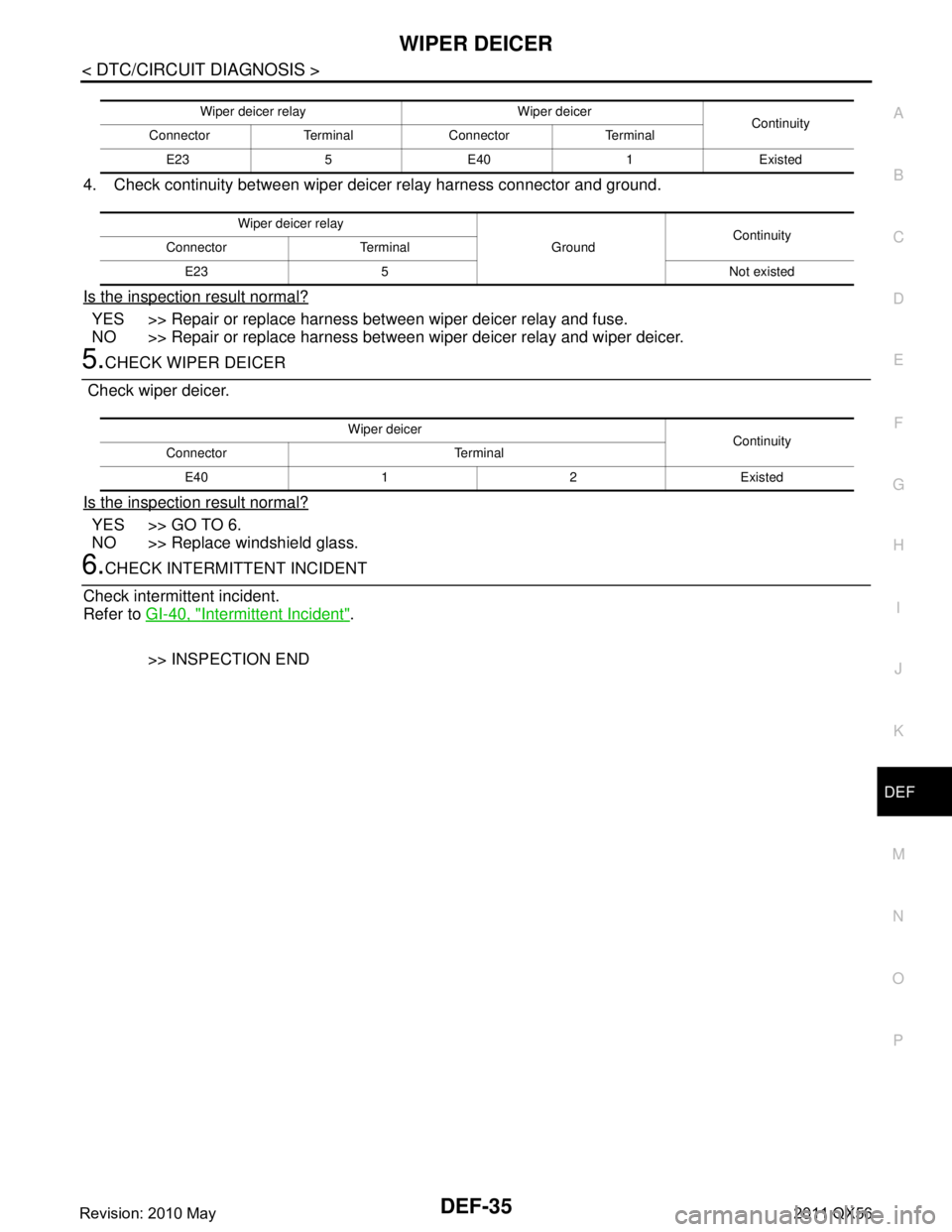

4. Check continuity between wiper deicer relay harness connector and ground.

Is the inspection result normal?

YES >> Repair or replace harness between wiper deicer relay and fuse.

NO >> Repair or replace harness between wiper deicer relay and wiper deicer.

5.CHECK WIPER DEICER

Check wiper deicer.

Is the inspection result normal?

YES >> GO TO 6.

NO >> Replace windshield glass.

6.CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Wiper deicer relay Wiper deicer Continuity

Connector Terminal Connector Terminal

E235E401Existed

Wiper deicer relay GroundContinuity

Connector Terminal

E23 5 Not existed

Wiper deicer Continuity

Connector Terminal

E40 1 2 Existed

Revision: 2010 May2011 QX56

Page 1528 of 5598

DEF-36

< SYMPTOM DIAGNOSIS >

REAR WINDOW DEFOGGER DOES NOT OPERATE

SYMPTOM DIAGNOSIS

REAR WINDOW DEFOGGER DOES NOT OPERATE

Diagnosis ProcedureINFOID:0000000006299456

1.CHECK REAR WINDOW DEFOGGER SWITCH

Check rear window defogger switch.

Refer to DEF-25, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK REAR WINDOW DEFOGGER RELAY

Check rear window defogger relay.

Refer to DEF-26, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK REAR WINDOW DEFOGGER

Check rear window defogger.

Refer to DEF-27, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 1529 of 5598

REAR WINDOW DEFOGGER AND DOOR MIRROR DEFOGGER DO NOT OPER-

ATE.

DEF-37

< SYMPTOM DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER AND DO OR MIRROR DEFOGGER DO NOT

OPERATE.

Diagnosis ProcedureINFOID:0000000006299457

1.CHECK REAR WINDOW DEFOGGER SWITCH

Check rear window defogger switch.

Refer to DEF-25, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK REAR WINDOW DEFOGGER RELAY

Check rear window defogger relay.

Refer to DEF-26, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK REAR WINDOW DEFOGGER

Check rear window defogger.

Refer to DEF-27, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 1533 of 5598

WIPER DEICER DOSE NOT OPERATEDEF-41

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

WIPER DEICER DOSE NOT OPERATE

Diagnosis ProcedureINFOID:0000000006299465

1.CHECK WIPER DEICER RELAY

Check wiper deicer relay.

Refer to DEF-32, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK WIPER DEICER

Check wiper deicer.

Refer to DEF-34, "

Component Function Check".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 1578 of 5598

DLK-42

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (BCM)

SELF-DIAG RESULT

Refer to BCS-57, "DTCIndex".

DATA MONITOR

AUTO LOCK SET Auto door lock operation time can be changed in this mode

MODE 1: OFF

MODE 2: 30 sec

MODE 3: 1 minute

MODE 4: 2 minutes

MODE 5: 3 minutes

MODE 6: 4 minutes

MODE 7: 5 minutes

HORN WITH KEYLESS LOCK Horn reminder function mode by Intelligent Key button can be selected from the following with

this mode

On: Operate

Off: Non-operation

PW DOWN SET Unlock button pressing time on Intelligent Key button can be selected from the following with

this mode

MODE 1: 3 sec

MODE 2: Non-operation

MODE 3: 5 sec

WELCOME LIGHT SELECT Welcome light function mode can be selected from the following with this mode

Puddle/Outside Handle

Room lamp

Head & Tail Lamps (this item is displayed, but cannot be used)

Heart Beat

WELCOME LIGHT OP SET Welcome light function mode can be changed to operation with this mode

On: Operate

Off: Non-operation

Monitor item Description

Monitor Item Condition

REQ SW -DR Indicates [On/Off] condition of door request switch (driver side)

REQ SW -AS Indicates [On/Off] condition of door request switch (passenger side)

REQ SW -BD/TR Indicates [On/Off] condition of back door request switch

PUSH SW Indicates [On/Off] condition of push-button ignition switch

CLUTCH SW NOTE:

This item is displayed, but cannot be monitored

BRAKE SW 1 Indicates [On/Off]* condition of stop lamp switch power supply

BRAKE SW 2 Indicates [On/Off] condition of stop lamp switch

DETE/CANCL SW Indicates [On/Off] condition of P position

SFT PN/N SW Indicates [On/Off] condition of P or N position

S/L -LOCK Indicates [On/Off] condition of steering lock unit (LOCK)

S/L -UNLOCK Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY -F/B Indicates [On/Off] condition of steering lock relay

UNLK SEN -DR Indicates [On/Off] condition of driver door UNLOCK status

PUSH SW -IPDM Indicates [On/Off] condition of push-button ignition switch

IGN RLY1 -F/B Indicates [On/Off] condition of ignition relay 1

DETE SW -IPDM Indicates [On/Off] condition of P position

SFT PN -IPDM Indicates [On/Off] condition of P or N position

SFT P -MET Indicates [On/Off] condition of P position

SFT N -MET Indicates [On/Off] condition of N position

ENGINE STATE Indicates [Stop/Stall/Crank/Run] condition of engine states

Revision: 2010 May2011 QX56

Page 1579 of 5598

DIAGNOSIS SYSTEM (BCM)DLK-43

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

*: OFF is displayed when brake pedal is depressed while brake switch power supply is OFF.

ACTIVE TEST

S/L LOCK-IPDM Indicates [On/Off] condition of steering lock unit (LOCK)

S/L UNLK-IPDM Indicates [On/Off] condition of steering lock unit (UNLOCK)

S/L RELAY-REQ Indicates [On/Off] condition of steering lock relay

VEH SPEED 1 Display the vehicle speed signal received from combination meter by numerical value [Km/h]

VEH SPEED 2 Display the vehicle spee d signal received from ABS or VDC or TCM by numerical value [Km/h]

DOOR STAT-DR Indicates [LOCK/READY/UNLK] condition of unlock sensor

DOOR STAT-AS Indicates [LOCK/READY/UNLK] condition of passenger side door status

ID OK FLAG Indicates [Set/Reset] condition of key ID

PRMT ENG STRT Indicates [Set/Reset] condition of engine start possibility

PRMT RKE STRT NOTE:

This item is displayed, but cannot be monitored

TRNK/HAT MNTR NOTE:

This item is displayed, but cannot be monitored

RKE-LOCK Indicates [On/Off] condition of LOCK signal from Intelligent Key

RKE-UNLOCK Indicates [On/Off] condition of UNLOCK signal from Intelligent Key

RKE-TR/BD NOTE:

This item is displayed, but cannot be monitored

RKE-PANIC Indicates [On/Off] condition of PANIC button of Intelligent Key

RKE-MODE CHG Indicates [On/Off] condition of MODE CHANGE signal from Intelligent Key

RKE OPE COUN1 When remote keyless entry receiver receives the signal transmitted while operating on Intelli-

gent Key, the numerical value start changing

RKE OPE COUN2 NOTE:

This item is displayed, but cannot be monitored

Monitor Item Condition

Test item Description

BATTERY SAVER This test is able to check interior room lamp operation

On: Operate

Off: Non-operation

OUTSIDE BUZZER This test is able to check Intelligent Key warning buzzer operation

On: Operate

Off: Non-operation

INSIDE BUZZER This test is able to check warning chime in combination meter operation

Take Out: Take away warning chime sounds when CONSULT-III screen is touched

Key: Key warning chime sounds when CONSULT-III screen is touched

Knob: OFF position warning chime sounds when CONSULT-III screen is touched

Off: Non-operation

INDICATOR This test is able to check warning lamp operation

KEY ON: “KEY” Warning lamp illuminates when CONSULT-III screen is touched

KEY IND: “KEY” Warning lamp blinks when CONSULT-III screen is touched

Off: Non-operation

INT LAMP This test is able to check interior room lamp operation

On: Operate

Off: Non-operation

Revision: 2010 May2011 QX56

Page 2025 of 5598

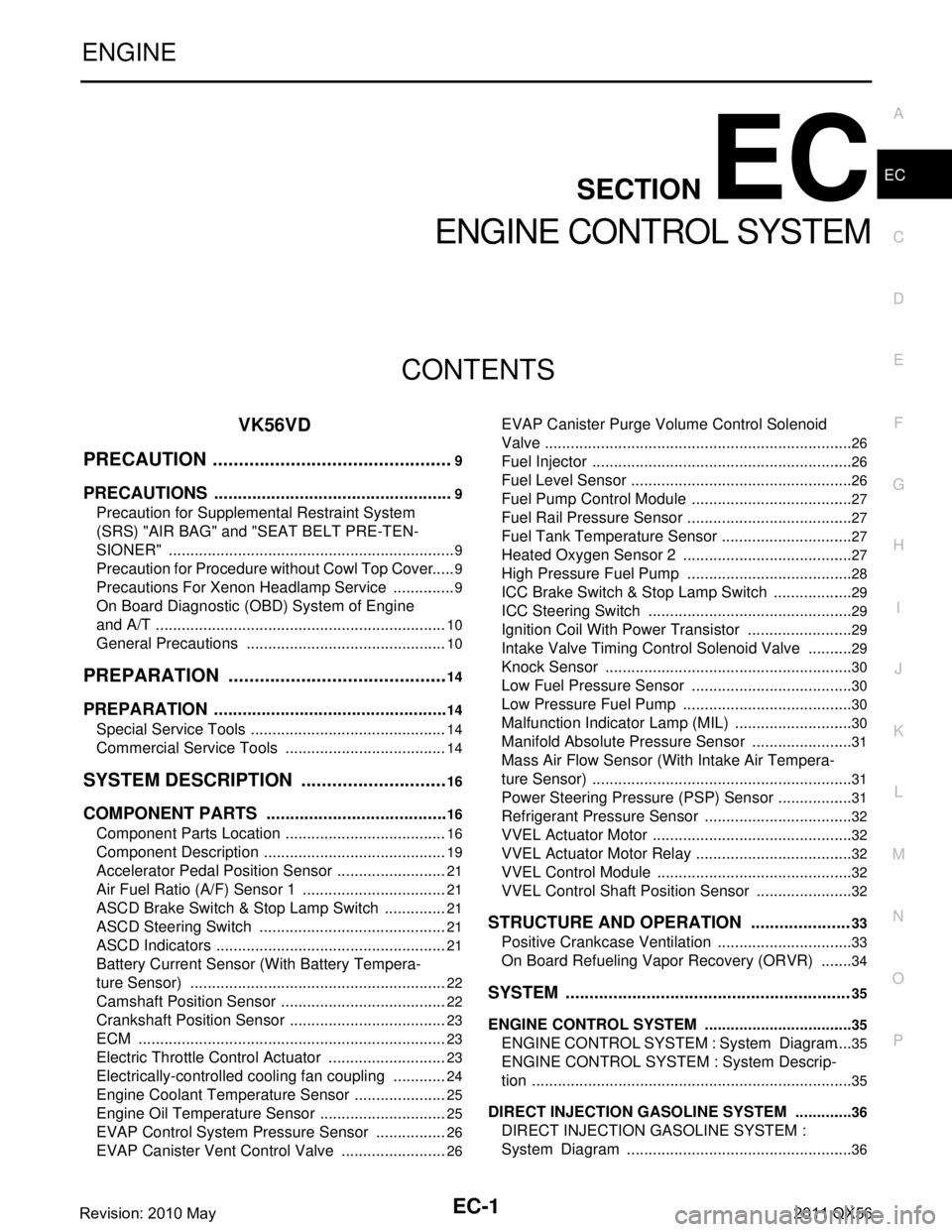

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

VK56VD

PRECAUTION ................ ...............................

9

PRECAUTIONS .............................................. .....9

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

9

Precaution for Procedure without Cowl Top Cover ......9

Precautions For Xenon Headlamp Service ...............9

On Board Diagnostic (OBD) System of Engine

and A/T ....................................................................

10

General Precautions ...............................................10

PREPARATION ...........................................14

PREPARATION .............................................. ....14

Special Service Tools .......................................... ....14

Commercial Service Tools ......................................14

SYSTEM DESCRIPTION .............................16

COMPONENT PARTS ................................... ....16

Component Parts Location .................................. ....16

Component Description ...........................................19

Accelerator Pedal Position Sensor ..........................21

Air Fuel Ratio (A/F) Sensor 1 ..................................21

ASCD Brake Switch & Stop Lamp Switch ...............21

ASCD Steering Switch ............................................21

ASCD Indicators ......................................................21

Battery Current Sensor (With Battery Tempera-

ture Sensor) ............................................................

22

Camshaft Position Sensor .......................................22

Crankshaft Position Sensor .....................................23

ECM ........................................................................23

Electric Throttle Control Actuator ............................23

Electrically-controlled cooling fan coupling .............24

Engine Coolant Temperature Sensor ......................25

Engine Oil Temperature Sensor ..............................25

EVAP Control System Pressure Sensor .................26

EVAP Canister Vent Control Valve .........................26

EVAP Canister Purge Volume Control Solenoid

Valve .................................................................... ....

26

Fuel Injector .............................................................26

Fuel Level Sensor ....................................................26

Fuel Pump Control Module ......................................27

Fuel Rail Pressure Sensor .......................................27

Fuel Tank Temperature Sensor ...............................27

Heated Oxygen Sensor 2 ........................................27

High Pressure Fuel Pump .......................................28

ICC Brake Switch & Stop Lamp Switch ...................29

ICC Steering Switch ................................................29

Ignition Coil With Power Transistor .........................29

Intake Valve Timing Control Solenoid Valve ...........29

Knock Sensor ...................................................... ....30

Low Fuel Pressure Sensor ......................................30

Low Pressure Fuel Pump ........................................30

Malfunction Indicator Lamp (MIL) ............................30

Manifold Absolute Pressure Sensor ........................31

Mass Air Flow Sensor (With Intake Air Tempera-

ture Sensor) .............................................................

31

Power Steering Pressure (PSP) Sensor ..................31

Refrigerant Pressure Sensor ............................... ....32

VVEL Actuator Motor ...............................................32

VVEL Actuator Motor Relay .....................................32

VVEL Control Module ..............................................32

VVEL Control Shaft Position Sensor .......................32

STRUCTURE AND OPERATION .....................33

Positive Crankcase Ventilation ................................33

On Board Refueling Vapor Recovery (ORVR) ........34

SYSTEM ............................................................35

ENGINE CONTROL SYSTEM ........................ ...........35

ENGINE CONTROL SYSTEM : System Diagram ....35

ENGINE CONTROL SYSTEM : System Descrip-

tion ...........................................................................

35

DIRECT INJECTION GASOLINE SYSTEM .......... ....36

DIRECT INJECTION GASOLINE SYSTEM :

System Diagram .....................................................

36

Revision: 2010 May2011 QX56