relay INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2030 of 5598

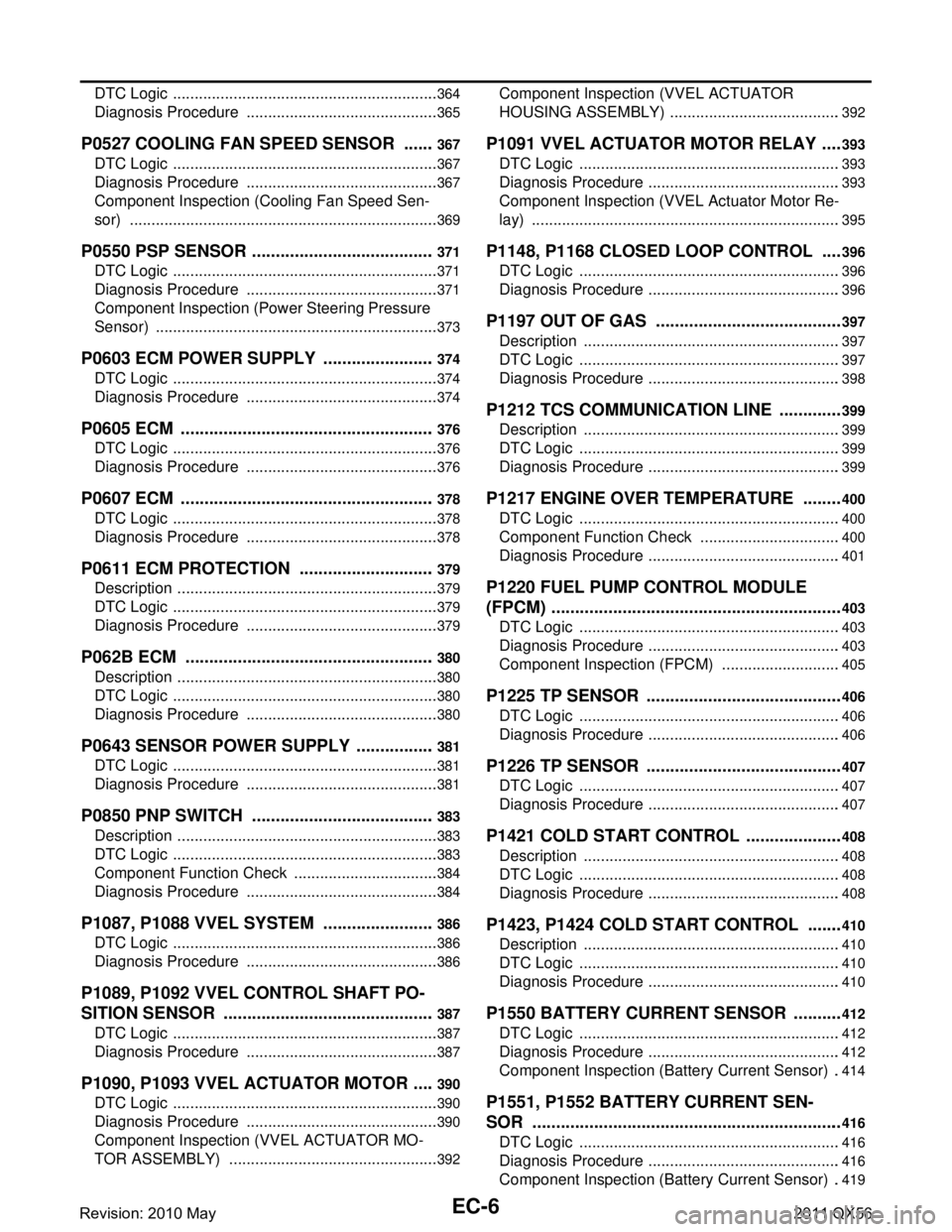

EC-6

DTC Logic ..............................................................364

Diagnosis Procedure .............................................365

P0527 COOLING FAN SPEED SENSOR .......367

DTC Logic ............................................................ ..367

Diagnosis Procedure .............................................367

Component Inspection (Cooling Fan Speed Sen-

sor) ........................................................................

369

P0550 PSP SENSOR .......................................371

DTC Logic ............................................................ ..371

Diagnosis Procedure .............................................371

Component Inspection (Power Steering Pressure

Sensor) ..................................................................

373

P0603 ECM POWER SUPPLY ........................374

DTC Logic ............................................................ ..374

Diagnosis Procedure .............................................374

P0605 ECM ......................................................376

DTC Logic ............................................................ ..376

Diagnosis Procedure .............................................376

P0607 ECM ......................................................378

DTC Logic ............................................................ ..378

Diagnosis Procedure .............................................378

P0611 ECM PROTECTION .............................379

Description ........................................................... ..379

DTC Logic ..............................................................379

Diagnosis Procedure .............................................379

P062B ECM .....................................................380

Description ........................................................... ..380

DTC Logic ..............................................................380

Diagnosis Procedure .............................................380

P0643 SENSOR POWER SUPPLY .................381

DTC Logic ............................................................ ..381

Diagnosis Procedure .............................................381

P0850 PNP SWITCH .......................................383

Description ........................................................... ..383

DTC Logic ..............................................................383

Component Function Check ..................................384

Diagnosis Procedure .............................................384

P1087, P1088 VVEL SYSTEM ........................386

DTC Logic ............................................................ ..386

Diagnosis Procedure .............................................386

P1089, P1092 VVEL CONTROL SHAFT PO-

SITION SENSOR .............................................

387

DTC Logic ............................................................ ..387

Diagnosis Procedure .............................................387

P1090, P1093 VVEL ACTUATOR MOTOR .....390

DTC Logic ............................................................ ..390

Diagnosis Procedure .............................................390

Component Inspection (VVEL ACTUATOR MO-

TOR ASSEMBLY) .................................................

392

Component Inspection (VVEL ACTUATOR

HOUSING ASSEMBLY) ......... ...............................

392

P1091 VVEL ACTUATOR MOTOR RELAY ... ..393

DTC Logic ............................................................ .393

Diagnosis Procedure .............................................393

Component Inspection (VVEL Actuator Motor Re-

lay) ....................................................................... .

395

P1148, P1168 CLOSED LOOP CONTROL .....396

DTC Logic ............................................................ .396

Diagnosis Procedure .............................................396

P1197 OUT OF GAS ........................................397

Description ........................................................... .397

DTC Logic .............................................................397

Diagnosis Procedure .............................................398

P1212 TCS COMMUNICATION LINE ..............399

Description ........................................................... .399

DTC Logic .............................................................399

Diagnosis Procedure .............................................399

P1217 ENGINE OVER TEMPERATURE .........400

DTC Logic ............................................................ .400

Component Function Check .................................400

Diagnosis Procedure .............................................401

P1220 FUEL PUMP CONTROL MODULE

(FPCM) ..............................................................

403

DTC Logic ............................................................ .403

Diagnosis Procedure .............................................403

Component Inspection (FPCM) ............................405

P1225 TP SENSOR ..........................................406

DTC Logic ............................................................ .406

Diagnosis Procedure .............................................406

P1226 TP SENSOR ..........................................407

DTC Logic ............................................................ .407

Diagnosis Procedure .............................................407

P1421 COLD START CONTROL .....................408

Description ........................................................... .408

DTC Logic .............................................................408

Diagnosis Procedure .............................................408

P1423, P1424 COLD START CONTROL ........410

Description ........................................................... .410

DTC Logic .............................................................410

Diagnosis Procedure .............................................410

P1550 BATTERY CURRENT SENSOR ...........412

DTC Logic ............................................................ .412

Diagnosis Procedure .............................................412

Component Inspection (Battery Current Sensor) ..414

P1551, P1552 BATTERY CURRENT SEN-

SOR ..................................................................

416

DTC Logic ............................................................ .416

Diagnosis Procedure .............................................416

Component Inspection (Battery Current Sensor) ..419

Revision: 2010 May2011 QX56

Page 2031 of 5598

EC-7

C

DE

F

G H

I

J

K L

M

EC A

N

O P

P1553 BATTERY CURRENT SENSOR ......... ..420

DTC Logic ........................................................... ..420

Diagnosis Procedure .............................................420

Component Inspection (Battery Current Sensor) ..423

P1554 BATTERY CURRENT SENSOR ...........424

DTC Logic ........................................................... ..424

Component Function Check ..................................424

Diagnosis Procedure .............................................425

Component Inspection (Battery Current Sensor) ..427

P1556, P1557 BATTERY TEMPERATURE

SENSOR ...........................................................

428

DTC Logic ........................................................... ..428

Diagnosis Procedure .............................................428

Component Inspection (Battery Temprature Sen-

sor) ........................................................................

430

P1564 ASCD STEERING SWITCH ..................431

DTC Logic ........................................................... ..431

Diagnosis Procedure .............................................431

Component Inspection (ASCD Steering Switch) ...433

P1564 ICC STEERING SWITCH ......................434

DTC Logic ........................................................... ..434

Diagnosis Procedure .............................................434

Component Inspection (ICC Steering Switch) .......436

P1568 ICC FUNCTION .....................................437

DTC Logic ........................................................... ..437

Diagnosis Procedure .............................................437

P1572 ASCD BRAKE SWITCH .......................438

DTC Logic ........................................................... ..438

Diagnosis Procedure .............................................439

Component Inspection (ASCD Brake Switch) .......442

Component Inspection (Stop Lamp Switch) ..........442

P1572 ICC BRAKE SWITCH ...........................443

DTC Logic ........................................................... ..443

Diagnosis Procedure .............................................444

Component Inspection (ICC Brake Switch) ...........445

Component Inspection (Stop Lamp Switch) ..........446

P1574 ASCD VEHICLE SPEED SENSOR ......447

Description .......................................................... ..447

DTC Logic .............................................................447

Diagnosis Procedure .............................................447

P1574 ICC VEHICLE SPEED SENSOR ..........449

Description .......................................................... ..449

DTC Logic .............................................................449

Diagnosis Procedure .............................................449

P1606 VVEL CONTROL MODULE ..................451

DTC Logic ........................................................... ..451

Diagnosis Procedure .............................................451

P1607 VVEL CONTROL MODULE ..................452

DTC Logic ........................................................... ..452

Diagnosis Procedure .............................................452

P1608 VVEL SENSOR POWER SUPPLY ......453

DTC Logic ............................................................ ..453

Diagnosis Procedure .............................................453

P1805 BRAKE SWITCH .................................455

DTC Logic ..............................................................455

Diagnosis Procedure .............................................455

Component Inspection (Stop Lamp Switch) ..........456

P2100, P2103 THROTTLE CONTROL MO-

TOR RELAY ....................................................

458

DTC Logic ..............................................................458

Diagnosis Procedure .............................................458

P2101 ELECTRIC THROTTLE CONTROL

FUNCTION ......................................................

460

Description ........................................................... ..460

DTC Logic ..............................................................460

Diagnosis Procedure .............................................460

Component Inspection ...........................................462

Special Repair Requirement ..................................463

P2118 THROTTLE CONTROL MOTOR .........464

DTC Logic ..............................................................464

Diagnosis Procedure .............................................464

Component Inspection (Electric Throttle Control

Motor) ....................................................................

465

P2119 ELECTRIC THROTTLE CONTROL

ACTUATOR .....................................................

466

DTC Logic ..............................................................466

Diagnosis Procedure .............................................466

P2122, P2123 APP SENSOR .........................468

DTC Logic ..............................................................468

Diagnosis Procedure .............................................468

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

470

P2127, P2128 APP SENSOR .........................471

DTC Logic ..............................................................471

Diagnosis Procedure .............................................471

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

474

P2135 TP SENSOR .........................................475

DTC Logic ..............................................................475

Diagnosis Procedure .............................................475

Component Inspection (Throttle Position Sensor) ..476

P2138 APP SENSOR ......................................478

DTC Logic ..............................................................478

Diagnosis Procedure .............................................478

Component Inspection (Accelerator Pedal Posi-

tion Sensor) ...........................................................

481

P2539, P2541, P2542 LOW FUEL PRES-

SURE SENSOR ...............................................

483

DTC Logic ..............................................................483

Diagnosis Procedure .............................................483

Component Inspection ...........................................485

Revision: 2010 May2011 QX56

Page 2043 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fu INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fu](/img/42/57033/w960_57033-2042.png)

COMPONENT PARTSEC-19

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Component DescriptionINFOID:0000000006217657

1. ASCD steering switch

ICC steering switch 2. Snow mode switch 3. Fuel level sensor unit and fuel pump

assembly (with fuel tank temperature

sensor)

4. Fuel pump control module (FPCM) 5. EVAP canister vent control valve 6. EVAP canister

7. EVAP control system pressure sen- sor 8. Stop lamp switch 9. ASCD brake switch

ICC brake switch

10. Accelerator pedal position sensor

JSBIA0606ZZ

Component Reference

ECM EC-23, "

ECM"

Malfunction indicator lamp (MIL)EC-30, "Malfunction Indicator Lamp (MIL)"

Ignition coil with power transistorEC-29, "Ignition Coil With Power Transistor"

Accelerator pedal position sensorEC-21, "Accelerator Pedal Position Sensor"

Mass air flow sensor

EC-31, "Mass Air Flow Sensor (With Intake Air Temperature Sen-

sor)"Intake air temperature sensor

Electric throttle control actuator

EC-23, "

Electric Throttle Control Actuator"Throttle control motor relay

Throttle control motor

Throttle position sensor

Crankshaft position sensorEC-23, "

Crankshaft Position Sensor"

Camshaft position sensorEC-22, "Camshaft Position Sensor"

Engine coolant temperature sensorEC-25, "Engine Coolant Temperature Sensor"

Revision: 2010 May2011 QX56

Page 2044 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-2 INFINITI QX56 2011 Factory Service Manual

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-2](/img/42/57033/w960_57033-2043.png)

EC-20

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

High pressure fuel pump

EC-28, "High Pressure Fuel Pump"

Low pressure fuel pumpEC-30, "Low Pressure Fuel Pump"

Fuel pump control module (FPCM)EC-27, "Fuel Pump Control Module"

Fuel rail pressure sensorEC-27, "Fuel Rail Pressure Sensor"

Low fuel pressure sensorEC-30, "Low Fuel Pressure Sensor"

Fuel injectorEC-26, "Fuel Injector"

Fuel level sensorEC-26, "Fuel Level Sensor"

Fuel tank temperature sensorEC-27, "Fuel Tank Temperature Sensor"

A/F sensor 1

EC-21, "Air Fuel Ratio (A/F) Sensor 1"A/F sensor 1 heater

Heated oxygen sensor 2EC-27, "

Heated Oxygen Sensor 2"Heated oxygen sensor 2 heater

Manifold absolute pressure sensorEC-31, "

Manifold Absolute Pressure Sensor"

Knock sensorEC-30, "Knock Sensor"

Engine oil temperature sensorEC-25, "Engine Oil Temperature Sensor"

Power steering pressure sensorEC-31, "Power Steering Pressure (PSP) Sensor"

Electrically-controlled cooling fan coupling EC-24, "Electrically-controlled cooling fan coupling"

Intake valve timing control solenoid valveEC-29, "Intake Valve Timing Control Solenoid Valve"

VVEL control moduleEC-32, "VVEL Control Module"

VVEL actuator motor relayEC-32, "VVEL Actuator Motor Relay"

VVEL actuator motorEC-32, "VVEL Actuator Motor"

VVEL control shaft position sensor EC-32, "VVEL Control Shaft Position Sensor"

EVAP control system pressure sensor EC-26, "EVAP Control System Pressure Sensor"

EVAP canister vent control valveEC-26, "EVAP Canister Vent Control Valve"

EVAP canister purge volume control solenoid valveEC-26, "EVAP Canister Purge Volume Control Solenoid Valve"

Battery current sensor (with battery temperature sensor)EC-22, "Battery Current Sensor (With Battery Temperature Sen-

sor)"

Refrigerant pressure sensor

EC-32, "Refrigerant Pressure Sensor"

Stop lamp switch

EC-21, "ASCD Brake Switch & Stop Lamp Switch"ASCD brake switch

ASCD steering switchEC-21, "

ASCD Steering Switch"

Information displayEC-49, "AUTMATIC SPEED CONTROL DEVICE (ASCD) : Switch

Name and Function"

Stop lamp switch

EC-29, "ICC Brake Switch & Stop Lamp Switch"ICC brake switch

ICC steering switchEC-29, "

ICC Steering Switch"

Component Reference

Revision: 2010 May2011 QX56

Page 2056 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-32

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

Refrigerant Pressure Sensor

INFOID:0000000006217690

The refrigerant pressure sensor is installed at the c ondenser of the air conditioner system. INFINITI QX56 2011 Factory Service Manual

EC-32

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

Refrigerant Pressure Sensor

INFOID:0000000006217690

The refrigerant pressure sensor is installed at the c ondenser of the air conditioner system.](/img/42/57033/w960_57033-2055.png)

EC-32

< SYSTEM DESCRIPTION >[VK56VD]

COMPONENT PARTS

Refrigerant Pressure Sensor

INFOID:0000000006217690

The refrigerant pressure sensor is installed at the c ondenser of the air conditioner system. The sensor uses an

electrostatic volume pressure transducer to convert refrigerant pressure to voltage. The voltage signal is sent

to ECM, and ECM controls cooling fan system.

VVEL Actuator MotorINFOID:0000000006217691

The VVEL actuator motor rotates the control shaft acco rding to the control signal from the VVEL control mod-

ule. The VVEL control module judges whether the VVEL actuator motor controls the angle properly by the

VVEL control shaft position sensor signal.

VVEL Actuator Motor RelayINFOID:0000000006217692

Power supply for the VVEL actuator motor is provided to the VVEL control module via VVEL actuator motor

relay. VVEL actuator motor relay is ON/OFF controll ed by the VVEL control module. In addition, when the

VVEL actuator motor relay cannot be controlled by the VVEL control module for some reason, it ON/OFF con-

trolled by ECM.

VVEL Control ModuleINFOID:0000000006217693

The VVEL control module consists of a microcomputer and connec-

tors for signal input and output and for power supply. The VVEL con-

trol module controls VVEL system.

VVEL Control Shaft Position SensorINFOID:0000000006217694

VVEL control shaft position sensor detects the control shaft position

angle.

A magnet is installed to the tip of the control shaft.

The magnetic field changes as the control shaft rotates. This

changes output voltage of the VVEL control shaft position sensor.

VVEL control module detects the actual position angle through the

voltage change and sends the signal to ECM.

PBIB2657E

JMBIA0879ZZ

JSBIA0466ZZ

Revision: 2010 May2011 QX56

Page 2071 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMEC-47

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR CONDITIONING CUT CONTROL : System DiagramINFOID:0000000006217713

AIR CONDITIONING CUT CONTROL : System DescriptionINFOI INFINITI QX56 2011 Factory Service Manual

SYSTEMEC-47

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR CONDITIONING CUT CONTROL : System DiagramINFOID:0000000006217713

AIR CONDITIONING CUT CONTROL : System DescriptionINFOI](/img/42/57033/w960_57033-2070.png)

SYSTEMEC-47

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

AIR CONDITIONING CUT CONTROL : System DiagramINFOID:0000000006217713

AIR CONDITIONING CUT CONTROL : System DescriptionINFOID:0000000006217714

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM via the CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

This system improves engine operation when the air conditioner is used.

Under the following conditions, the air conditioner is turned OFF.

When the accelerator pedal is fully depressed.

When cranking the engine.

At high engine speeds.

When the engine coolant temperature becomes excessively high.

When operating power steering during low engine speed or low vehicle speed.

When engine speed is excessively low.

When refrigerant pressure is excessively low or high.

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

JMBIA1457GB

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor

Camshaft position sensor Engine speed*

2

Air conditioner cut

controlIPDM E/R

↓

A/C relay

↓

Compressor

Engine coolant temperature sensor Engine coolant temperature

Accelerator pedal position sensor Accelerator pedal position

Battery

Battery voltage*

2

Refrigerant pressure sensor Refrigerant pressure

Power steering pressure sensor Power steering operation

A/C auto amp.A/C ON signal*

1

A/C evaporator temperature*1

Target A/C evaporator temperature*1

Blower fan ON signal

Combination meter Vehicle speed*

1

Revision: 2010 May2011 QX56

Page 2091 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger](/img/42/57033/w960_57033-2090.png)

DIAGNOSIS SYSTEM (ECM)EC-67

< SYSTEM DESCRIPTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

Indicates [ON/OFF] condition from the electrical

load signal.

ON: Rear window defogger switch is ON and/or

lighting switch is in 2nd position.

OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFF Indicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the blower fan

ON signal.

BRAKE SW ON/OFF Indicates [ON/OFF] condition from the stop lamp

switch signal.

IGN TIMING BTDC Indicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped,

a certain value is indicated.

COMBUSTION — These items are displayed but are not applicable to

this model.

CAL/LD VALUE % “Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/s Indicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V % Indicates the EVAP canister purge volume control

solenoid valve control value computed by the ECM

according to the input signals.

The opening becomes larger as the value increas-

es.

INT/V SOL (B1)

% The control value of the intake valve timing control

solenoid valve (determined by ECM according to

the input signals) is indicated.

The advance angle becomes larger as the value increases.

INT/V SOL (B2)

AIR COND RLY ON/OFF

The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

VENT CONT/V ON/OFF The control condition of the EVAP canister vent

control valve (determined by ECM according to the

input signals) is indicated.

ON: Closed

OFF: Open

THRTL RELAY ON/OFF Indicates the throttle co

ntrol motor relay control

condition determined by the ECM according to the

input signals.

A/F S1 HTR (B1)

% Air fuel ratio (A/F) sensor 1 heater control value

computed by ECM according to the input signals.

The current flow to the heater becomes larger as the value increases.

A/F S1 HTR (B2)

HO2S2 HTR (B1)

ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

HO2S2 HTR (B2)

ALT DUTY SIG ON/OFF The control condition of the power generation volt-

age variable control (determined by ECM accord-

ing to the input signals) is indicated.

ON: Power generation voltage variable control is

active.

OFF: Power generation voltage variable control is

inactive.

I/P PULLY SPD rpm Indicates the engine speed computed from the in-

put speed sensor signal.

Monitored item Unit Description Remarks

Revision: 2010 May2011 QX56

Page 2094 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the displa INFINITI QX56 2011 Factory Service Manual

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the displa](/img/42/57033/w960_57033-2093.png)

EC-70

< SYSTEM DESCRIPTION >[VK56VD]

DIAGNOSIS SYSTEM (ECM)

*: The item is indicated, but not used.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

Test Item

ECM TEMP 1

°C or °F Displays a temperature calculated from a signal of

ECM temperature sensor 1.

ECM TEMP 2 °C or °F Displays a temperature calculated from a signal of

ECM temperature sensor 2.

FUEL PUMP DUTY % The control condition of the fuel pump control mod-

ule (FPCM) (determined by ECM according to the

input signals) is indicated.

Monitored item Unit Description Remarks

TEST ITEM CONDITION JUDGMENT CHECK ITEM (REMEDY)

VENT CON-

TROL/V Ignition switch: ON (Engine

stopped)

Turn solenoid valve ON and OFF with the CONSULT-III and listen

to operating sound. Solenoid valve makes an operating

sound.

Harness and connectors

Solenoid valve

ENG COOLANT

TEMP Engine: Return to the original

non-standard condition

Change the engine coolant tem- perature using CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM. Harness and connectors

Engine coolant temperature sen-

sor

Fuel injector

FUEL INJEC-

TION Engine: Return to the original

non-standard condition

Change the amount of fuel injec- tion using CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM.

Harness and connectors

Fuel injector

Air fuel ratio (A/F) sensor 1

FUEL/T TEMP

SEN Change the fuel tank temperature using CONSULT-III.

PURG VOL

CONT/V Engine: After warming up, run en-

gine at 1,500 rpm.

Change the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-III. Engine speed changes according to

the opening percent.

Harness and connectors

Solenoid valve

FAN DUTY CON-

TROL* Ignition switch: ON

Change duty ratio using CON-

SULT-III. Cooling fan speed changes. Harness and connectors

Cooling fan motor

Cooling fan relay

Cooling fan control module

IPDM E/R

ALTERNATOR

DUTY Engine: Idle

Change duty ratio using CON-

SULT-III. Battery voltage changes. Harness and connectors

IPDM E/R

Alternator

POWER BAL-

ANCE Engine: After warming up, idle the

engine.

A/C switch OFF

Selector lever: P or N

Cut off each injector signal one at a time using CONSULT-III. Engine runs rough or stops.

Harness and connectors

Compression

Fuel injector

Power transistor

Spark plug

Ignition coil

IGNITION TIM-

ING Engine: Return to the original

non-standard condition

Timing light: Set

Retard the ignition timing using

CONSULT-III. If malfunctioning symptom disap-

pears, see CHECK ITEM.

Perform Idle Air Volume Learning.

Revision: 2010 May2011 QX56

Page 2098 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-74

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

INT/V SOL (B2) Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 0 - 2%

2,000 rpm Approx. 0 - 50%

AIR COND RL INFINITI QX56 2011 Factory Service Manual

EC-74

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

INT/V SOL (B2) Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 0 - 2%

2,000 rpm Approx. 0 - 50%

AIR COND RL](/img/42/57033/w960_57033-2097.png)

EC-74

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

INT/V SOL (B2) Engine: After warming up

Selector lever: P or N position

A/C switch: OFF

No load Idle 0 - 2%

2,000 rpm Approx. 0 - 50%

AIR COND RLY Engine: After warming up, idle

the engine A/C switch: OFF OFF

A/C switch: ON

(Compressor operates)

ON

VENT CONT/V Ignition switch: ON OFF

THRTL RELAY Ignition switch: ON ON

A/F S1 HTR (B1) Engine: After warming up, idle the engine

(More than 140 seconds after starting engine) 4 - 100%

A/F S1 HTR (B2) Engine: After warming up, idle the engine

(More than 140 seconds after starting engine) 4 - 100%

HO2S2 HTR (B1) Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load ON

Engine speed: Above 3,600 rpm OFF

HO2S2 HTR (B2) Engine speed: Below 3,600 rpm after the following conditions are met.

- Engine: After warming up

- Keeping the engine speed between 3,500 and 4,000 rpm for 1 minute and at

idle for 1 minute under no load ON

Engine speed: Above 3,600 rpm OFF

ALT DUTY SIG Power generation voltage variable control: Operating ON

Power generation voltage variable control: Not operating OFF

I/P PULLY SPD Vehicle speed: More than 20 km/h (12 MPH) Almost the same speed as

the tachometer indication

VEHICLE SPEED Turn drive wheels and compare CONSULT-III value with the speedometer in-

dication. Almost the same speed as

the speedometer indication

IDL A/V LEARN Engine: Running Idle air volume learning has not been per-

formed yet.

YET

Idle air volume learning has already been

performed successfully. CMPLT

TRVL AFTER MIL Ignition switch: ON Vehicle has traveled after MIL has illumi-

nated.0 - 65,535 km

(0 - 40,7

23 miles)

SNOW MODE SW Ignition switch: ON Snow mode switch: ON ON

Snow mode switch: OFF OFF

ENG OIL TEMP Engine: After warming up More than 70 °C (158 °F)

MAIN SW Ignition switch: ON MAIN switch: Pressed ON

MAIN switch: Released OFF

CANCEL SW Ignition switch: ON CANCEL switch: Pressed ON

CANCEL switch: Released OFF

RESUME/ACC SW Ignition switch: ON RESUME/ACCELERATE switch:

Pressed

ON

RESUME/ACCELERATE switch: Re-

leased OFF

SET SW Ignition switch: ON SET/COAST switch: Pressed ON

SET/COAST switch: Released OFF

BRAKE SW1

(ASCD/ICC brake

switch) Ignition switch: ON

Brake pedal: Fully released ON

Brake pedal: Slightly depressed OFF

Monitor Item Condition Values/Status

Revision: 2010 May2011 QX56

Page 2114 of 5598

![INFINITI QX56 2011 Factory Service Manual

EC-90

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

111

(R) 175

(B) Fuel injector driver power supply Input [Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14 V)

11 2

(SB) 175

(B) Fuel injector driver powe INFINITI QX56 2011 Factory Service Manual

EC-90

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

111

(R) 175

(B) Fuel injector driver power supply Input [Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14 V)

11 2

(SB) 175

(B) Fuel injector driver powe](/img/42/57033/w960_57033-2113.png)

EC-90

< ECU DIAGNOSIS INFORMATION >[VK56VD]

ECM

111

(R) 175

(B) Fuel injector driver power supply Input [Ignition switch: ON]

BATTERY VOLTAGE

(11 - 14 V)

11 2

(SB) 175

(B) Fuel injector driver power supply Input [Ignition switch: ON] BATTERY VOLTAGE

(11 - 14 V)

11 4 (B) — ECM ground — — —

11 5 (B) — ECM ground — — —

120 (Y) 175

(B) EVAP canister vent control valve Output [Ignition switch: ON] BATTERY VOLTAGE

(11 - 14 V)

122

(BR/ W) 175

(B) VVEL actuator motor relay abort

signal (VVEL control module)

Input [Ignition switch: ON] 0 V

123

(V/R) 175

(B) Throttle control mo

tor relay Output [Ignition switch: ON

→ OFF] 0 - 1.0 V

↓

BATTERY VOLTAGE

(11 - 14 V)

↓

0 V

[Ignition switch: ON] 0 - 1.0 V

125

(GR) 175

(B) Fuel pump control module

(FPCM)

Output[When cranking engine] 0 - 0.5 V

[Engine is running]

Warm-up condition

0 - 4.0 V

126 (O) 129

(P/L) Accelerator pedal position sen-

sor 2

Input[Ignition switch: ON]

Engine: Stopped

Accelerator pedal: Fully released

0.28 - 0.48 V

[Ignition switch: ON]

Engine: Stopped

Accelerator pedal: Fully depressed 2.0 - 2.5 V

128 (Y) 130

(R) ASCD steering switch Input [Ignition switch: ON]

ASCD steering switch: OFF

4 V

[Ignition switch: ON]

MAIN switch: Pressed 0 V

[Ignition switch: ON]

CANCEL switch: Pressed 1 V

[Ignition switch: ON]

RESUME/ACCELERATE switch: Pressed 3 V

[Ignition switch: ON]

SET/COAST switch: Pressed 2 V

Te r m i n a l N o .

(Wire color) Description

ConditionVa l u e

(Approx.)

+ – Signal name Input/

Output

JPBIA3344ZZ

Revision: 2010 May2011 QX56