INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1781 of 5598

REAR DOOR LOCKDLK-245

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

7. Remove front gasket and rear gasket.

8. Slide toward rear of vehicle to remove outside handle bracket.

9. Disconnect door lock cable from outside handle bracket.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check door lock cable is properly engaged with outside handle bracket.

After installation, check door op en/close, lock/unlock operation.

JMKIA2652ZZ

Revision: 2010 May2011 QX56

Page 1782 of 5598

DLK-246

< REMOVAL AND INSTALLATION >

BACK DOOR LOCK

BACK DOOR LOCK

Exploded ViewINFOID:0000000006226105

DOOR LOCK

DOOR LOCK : Removal and InstallationINFOID:0000000006226106

REMOVAL

1. Remove back door finisher lower. Refer to INT-39, "Removal and Installation".

2. Disconnect back door lock assembly harness connector.

3. Remove back door lock mounting bolts, and then remove back door lock assembly.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check back door open/close, lock/unlo ck operation after installation.

TOUCH SENSOR

TOUCH SENSOR : Removal and InstallationINFOID:0000000006226107

CAUTION:

Take care not to bend touch sensor.

REMOVAL

1. Remove back door finisher side. Refer to INT-39, "Removal and Installation".

2. Disconnect touch sensor connector.

1. Back door support rod 2. Touch sensor 3. Automatic back door control module

4. Back door lock assembly 5. Back door assembly 6. Stud ball

7. Screw grommet

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5484GB

Revision: 2010 May2011 QX56

Page 1783 of 5598

BACK DOOR LOCKDLK-247

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

3. Remove clips and TORX screws of touch sensor.

4. Pull harness of touch sensor out of back door and remove touch sensor.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check back door open/close operation after installation.

BACK DOOR SUPPORT ROD

BACK DOOR SUPPORT ROD : Removal and InstallationINFOID:0000000006226108

REMOVAL

1. Remove cap of back door finisher side (LH). Refer to INT-39, "Exploded View".

2. Remove stud ball (1) of back door support rod (3) from back door assembly (2).

3. Remove automatic back door control module. Refer to DLK-262, "

Removal and Installation".

NOTE:

When replacing back door support rod, replace stud ba ll and automatic back door control module as a set,

since back door support rod is engaged and connected to stud ball and automatic back door control mod-

ule.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

When reusing stud ball, always a pply locking sealant before installing stud ball to back door.

Check back door open/close opera tion after installation.

EMERGENCY LEVER

EMERGENCY LEVER : Unlock proceduresINFOID:0000000006226109

UNLOCK PROCEDURES

NOTE:

If back door lock cannot be unlocked due to a malfuncti on or battery discharge, follow the procedures to

unlock back door.

1. Remove the emergency handle mask. Refer to INT-39, "

Exploded View".

2. From inside the vehicle, rotate emergency lever toward lower direction and unlock.

JMKIA5442ZZ

JMKIA5264ZZ

Revision: 2010 May2011 QX56

Page 1784 of 5598

DLK-248

< REMOVAL AND INSTALLATION >

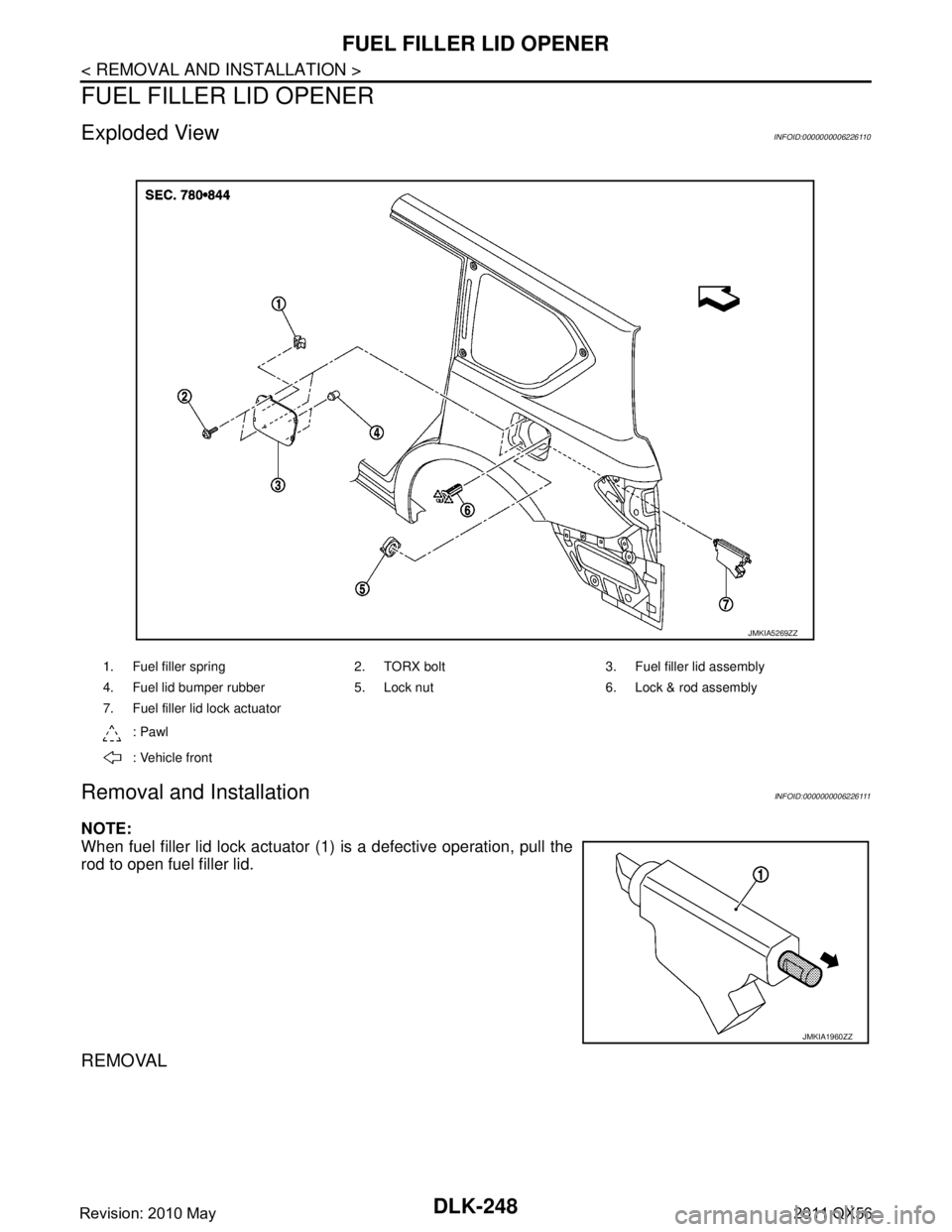

FUEL FILLER LID OPENER

FUEL FILLER LID OPENER

Exploded ViewINFOID:0000000006226110

Removal and InstallationINFOID:0000000006226111

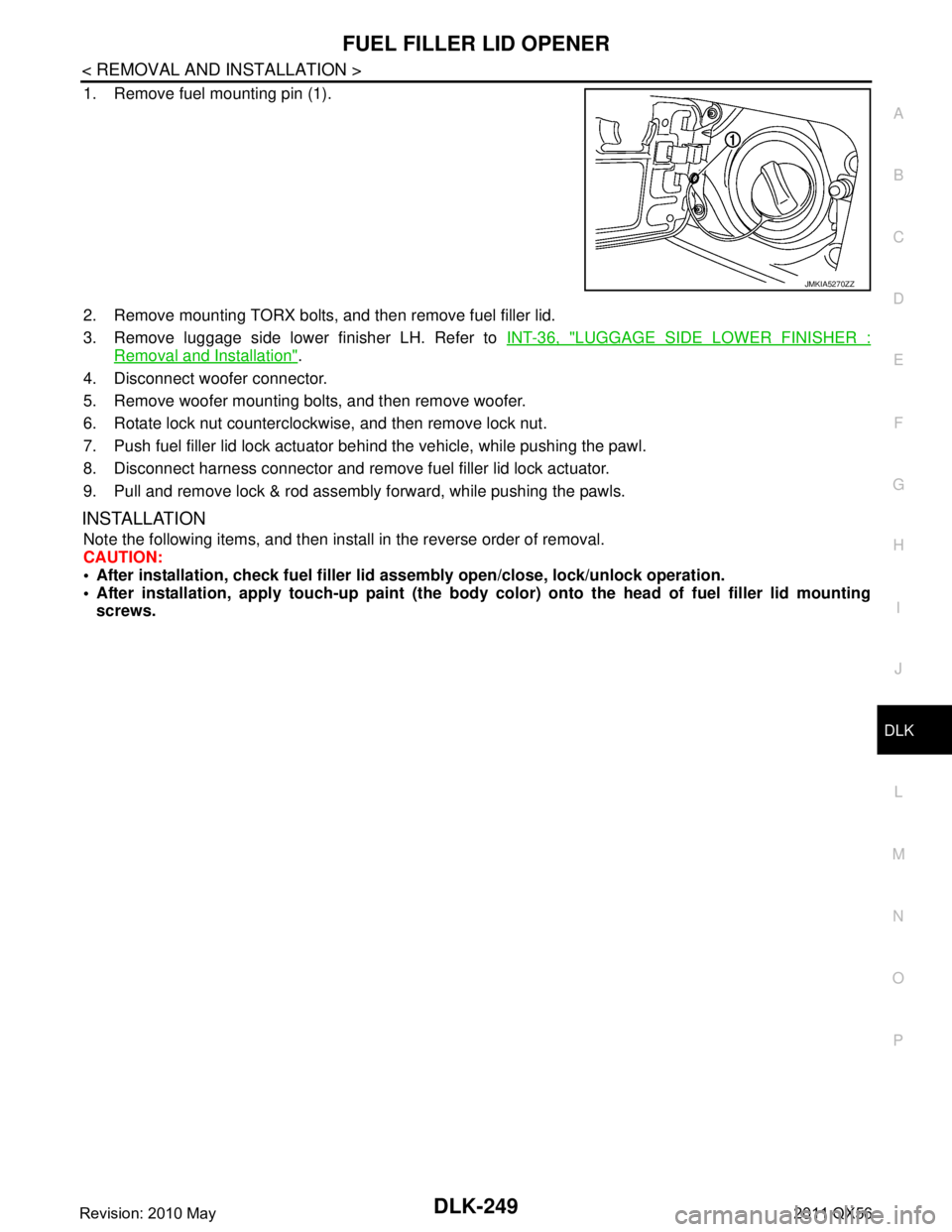

NOTE:

When fuel filler lid lock actuator (1) is a defective operation, pull the

rod to open fuel filler lid.

REMOVAL

1. Fuel filler spring 2. TORX bolt 3. Fuel filler lid assembly

4. Fuel lid bumper rubber 5. Lock nut 6. Lock & rod assembly

7. Fuel filler lid lock actuator: Pawl

: Vehicle front

JMKIA5269ZZ

JMKIA1960ZZ

Revision: 2010 May2011 QX56

Page 1785 of 5598

FUEL FILLER LID OPENERDLK-249

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

1. Remove fuel mounting pin (1).

2. Remove mounting TORX bolts, and then remove fuel filler lid.

3. Remove luggage side lower finisher LH. Refer to INT-36, "

LUGGAGE SIDE LOWER FINISHER :

Removal and Installation".

4. Disconnect woofer connector.

5. Remove woofer mounting bolts, and then remove woofer.

6. Rotate lock nut counterclockwise, and then remove lock nut.

7. Push fuel filler lid lock actuator behind the vehicle, while pushing the pawl.

8. Disconnect harness connector and remove fuel filler lid lock actuator.

9. Pull and remove lock & rod assembly forward, while pushing the pawls.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

After installation, check fuel filler li d assembly open/close, lock/unlock operation.

After installation, apply touch-up paint (the body color) onto the head of fuel filler lid mounting

screws.

JMKIA5270ZZ

Revision: 2010 May2011 QX56

Page 1786 of 5598

DLK-250

< REMOVAL AND INSTALLATION >

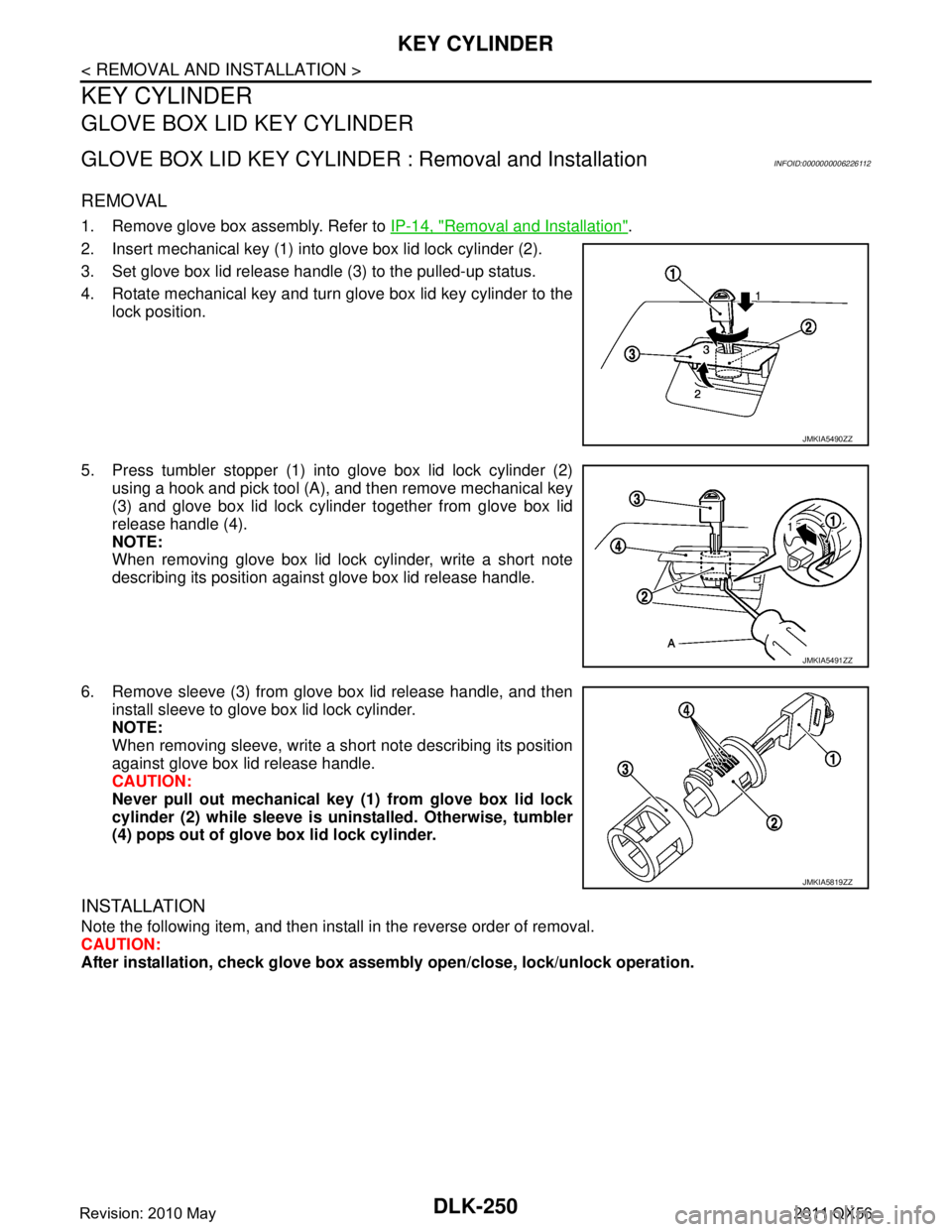

KEY CYLINDER

KEY CYLINDER

GLOVE BOX LID KEY CYLINDER

GLOVE BOX LID KEY CYLINDER : Removal and InstallationINFOID:0000000006226112

REMOVAL

1. Remove glove box assembly. Refer to IP-14, "Removal and Installation".

2. Insert mechanical key (1) into glove box lid lock cylinder (2).

3. Set glove box lid release handle (3) to the pulled-up status.

4. Rotate mechanical key and turn glove box lid key cylinder to the lock position.

5. Press tumbler stopper (1) into glove box lid lock cylinder (2) using a hook and pick tool (A), and then remove mechanical key

(3) and glove box lid lock cylinder together from glove box lid

release handle (4).

NOTE:

When removing glove box lid lock cylinder, write a short note

describing its position against glove box lid release handle.

6. Remove sleeve (3) from glove box lid release handle, and then install sleeve to glove box lid lock cylinder.

NOTE:

When removing sleeve, write a short note describing its position

against glove box lid release handle.

CAUTION:

Never pull out mechanical key (1) from glove box lid lock

cylinder (2) while sl eeve is uninstalled. Otherwise, tumbler

(4) pops out of glove box lid lock cylinder.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

After installation, check glove box assem bly open/close, lock/unlock operation.

JMKIA5490ZZ

JMKIA5491ZZ

JMKIA5819ZZ

Revision: 2010 May2011 QX56

Page 1787 of 5598

CAB MOUNTING INSULATORDLK-251

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

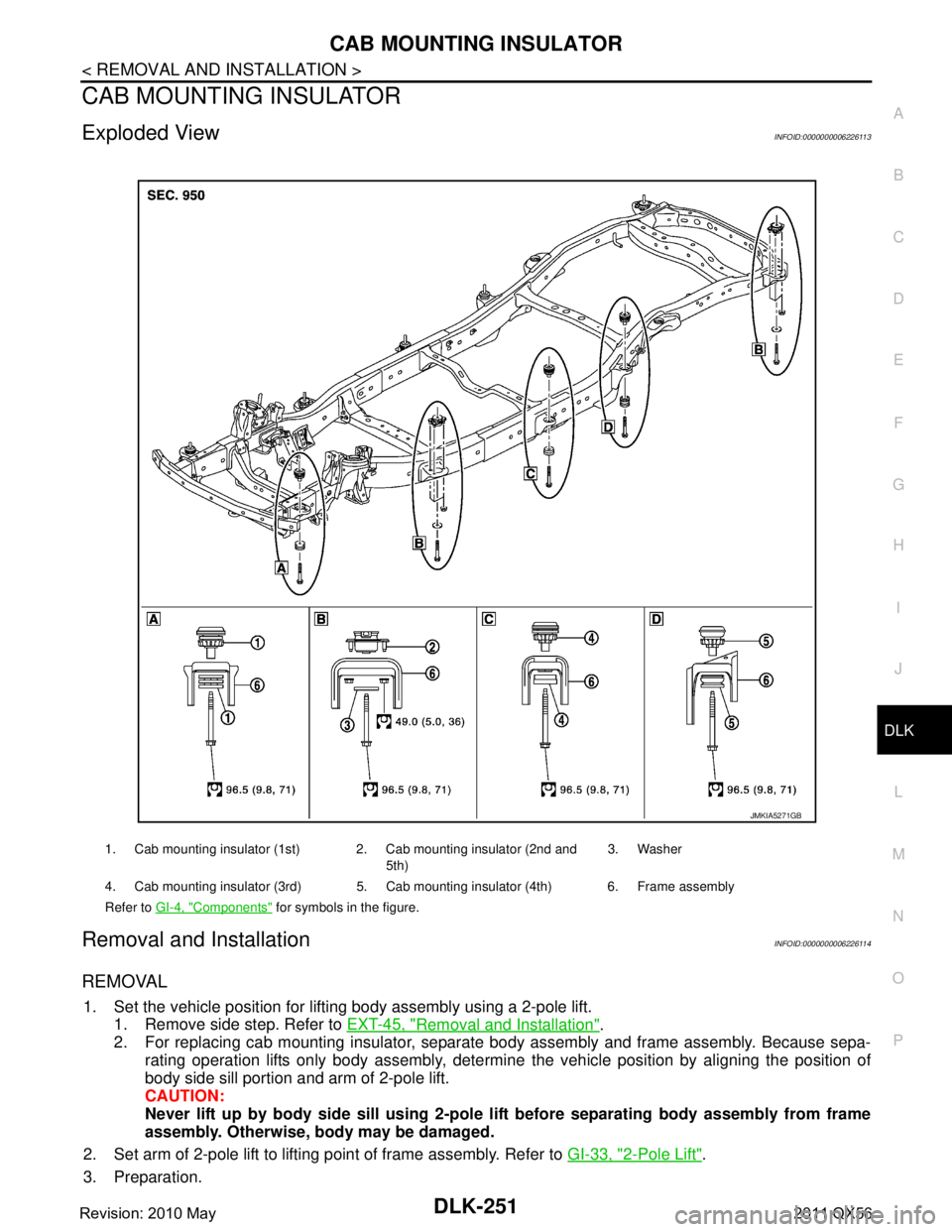

CAB MOUNTING INSULATOR

Exploded ViewINFOID:0000000006226113

Removal and InstallationINFOID:0000000006226114

REMOVAL

1. Set the vehicle position for lifting body assembly using a 2-pole lift. 1. Remove side step. Refer to EXT-45, "

Removal and Installation".

2. For replacing cab mounting insulator, separate body assembly and frame assembly. Because sepa-

rating operation lifts only body assembly, determine the vehicle position by aligning the position of

body side sill portion and arm of 2-pole lift.

CAUTION:

Never lift up by body side sill using 2-pole lift before separating body assembly from frame

assembly. Otherwise, body may be damaged.

2. Set arm of 2-pole lift to lifting point of frame assembly. Refer to GI-33, "

2-Pole Lift".

3. Preparation.

1. Cab mounting insulator (1st) 2. Cab mounting insulator (2nd and 5th)3. Washer

4. Cab mounting insulator (3rd) 5. Cab mo unting insulator (4th) 6. Frame assembly

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5271GB

Revision: 2010 May2011 QX56

Page 1788 of 5598

DLK-252

< REMOVAL AND INSTALLATION >

CAB MOUNTING INSULATOR

Drain brake fluid from brake line. Refer to BR-10, "Draining".

Release fuel pressure. Refer to EC-153, "

Work Procedure".

Disconnect both battery cables. Refer to PG-164, "

Removal and Installation".

Drain engine coolant from radiator. Refer to CO-8, "

Draining".

Discharge refrigerant from A/C circuit. Refer to HA-20, "

Recycle Refrigerant".

Drain power steering fluid from reservoir tank.

4. Remove parts relating to connection of body assembly and frame assembly. Tire and wheel: Refer to WT-64, "

Removal and Installation" (with TPMS).

Front fender protector (LH and RH): Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

Front bumper: Refer to EXT-13, "

Removal and Installation".

Radiator core support upper: Refer to DLK-220, "

Removal and Installation".

Fan shroud: Refer to CO-16, "

Removal and Installation".

Battery and battery case: Refer to PG-164, "

Removal and Installation".

Air cleaner case (upper and lower): Refer to EM-27, "

Removal and Installation".

Engine cover: Refer to EM-25, "

Removal and Installation".

Rear wheel house protector (LH and RH): EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

Rear bumper: Refer to EXT-17, "

Removal and Installation".

Fuel filler tube: Remove to FL-8, "

Exploded View".

Spare tire

Towing hook bracket.

5. Separate parts relating to connection of body assembly and frame assembly. Vehicle front

Disconnect ICC sensor connector. (models with ICC) Refer to CCS-176, "

Removal and Installation".

Remove radiator upper hose and radiator lower hose from radiator assembly. Refer to CO-13,

"Exploded View".

Remove A/T fluid cooler hose B and A/T fluid cooler hose E from A/T fluid cooler tubes. Refer to TM-

202, "Exploded View".

Remove power steering return hose from oil cooler, and then power steering return hose clamp bolt from frame assembly. Refer to ST-54, "

Exploded View".

Remove power steering suction hose from reservoir tank. Refer to ST-54, "

Exploded View".

CAUTION:

Never spill power steering fluid in engine room.

Remove A/C low-presser flexible hose from A/C low-presser pipe. Refer to HA-35, "

LOW-PRESSURE

FLEXIBLE HOSE : Removal and Installation".

Remove A/C hi-presser flexible hose from condenser. Refer to HA-34, "

HIGH-PRESSURE FLEXIBLE

HOSE : Removal and Installation".

Remove all engine Control Harness connectors, har ness clips and others that are connected to the

body assembly side of the engine room. (engine room LH and RH side). Refer to PG-148, "

Engine Con-

trol Harness".

NOTE:

Separate harness connectors from ECM (engine control module). Refer to EC-10, "

General Precau-

tions".

CAUTION:

When pulling out harnesses, never damage harnesses or connectors.

After temporarily securing connectors, cover th em with vinyl or similar material to protect

against adhesion of foreign materials.

Disconnect engine room harness connectors and remo ve harness clips from engine assembly (engine

RH side). Refer to PG-146, "

Engine Room Harness".

Remove heater hoses from front water outlet tube (engine room RH side). Refer to HA-33, "

Exploded

View".

Disconnect front wheel sensor connectors (LH and RH). Refer to BRC-134, "

FRONT WHEEL SENSOR

: Exploded View".

Disconnect fuel feed tube and EVAP hos e (front wheel well LH side).

Remove steering lower shaft from steering gear side assembly. Refer to ST-37, "

Removal and Installa-

tion"

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly.

Revision: 2010 May2011 QX56

Page 1789 of 5598

CAB MOUNTING INSULATORDLK-253

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

Remove brake tube from connector (front wheel well LH and RH side). Refer to BR-22, "FRONT :

Exploded View"

Vehicle center side

Remove A/T control cable from manual lever. Refer to TM-178, "

Removal and Installation".

Separate parking brake rear cable (LH and RH) from parking brake front cable. Refer to PB-5, "

Removal

and Installation".

Remove engine room harness connector (frame assembly RH center side). Refer to PG-146, "

Engine

Room Harness"

- Remove harness connector protector.

- Disconnect chassis harness connector from engine room harness connector.

- Remove harness bracket bolt, and then remove engi ne room harness connector from frame assembly.

Vehicle rear side

Remove EVAP hose (canister side).

Remove rear final drive breather hose from air breather tube (body side). Refer to DLN-201, "

Removal

and Installation".

Disconnect body harness connector from chassis harness connectors (frame assembly LH rear side).

Refer to PG-150, "

Body Harness"

6. Set safety stand to frame assembly. Release arm of 2-pole lift.

7. Remove cab mounting insulator bolts.

8. Set arm of 2-pole lift to body side sill portion of body.

9. Slowly lift 2-pole lift.

CAUTION:

Check that there is no inte rference with the vehicle.

Check that all connection points are disconnected.

10. Remove cab mounting insulator.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Before starting engine, check oil/fl uid levels including engine coolant and engine oil. If levels are

less than the required quantity, fill to the specified level. Refer to MA-10, "

Fluids and Lubricants".

Warm up engine thoroughly to check that there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

Revision: 2010 May2011 QX56

Page 1790 of 5598

DLK-254

< REMOVAL AND INSTALLATION >

DOOR SWITCH

DOOR SWITCH

Removal and InstallationINFOID:0000000006226115

REMOVAL

Remove the door switch mounting bolt, and then remove door switch.

INSTALLATION

Install in the reverse order of removal.

Revision: 2010 May2011 QX56