brake fluid INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

Never reuse the copper washer.

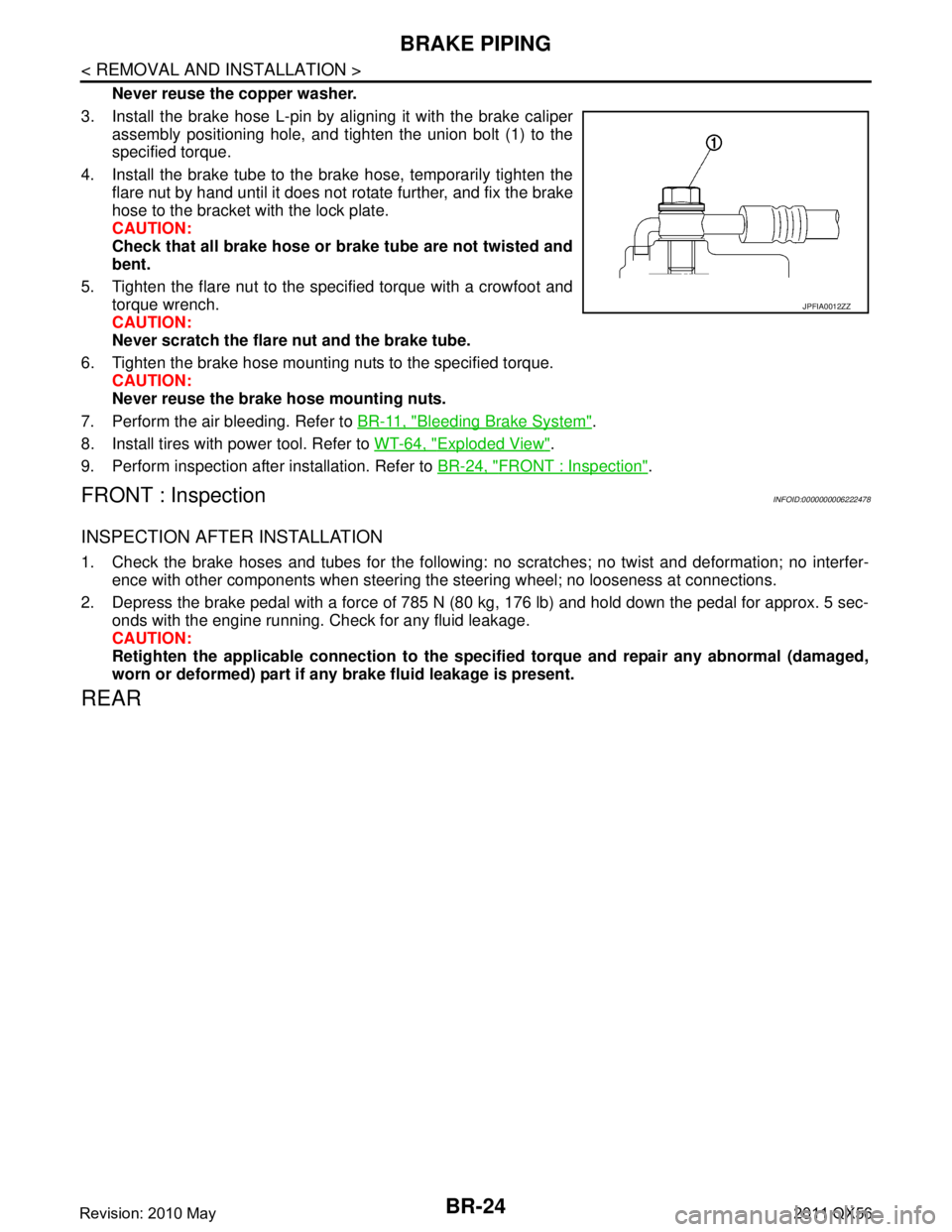

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56

Page 496 of 5598

BR-26

< REMOVAL AND INSTALLATION >

BRAKE PIPING

REAR : Removal and Installation

INFOID:0000000006222481

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose. CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

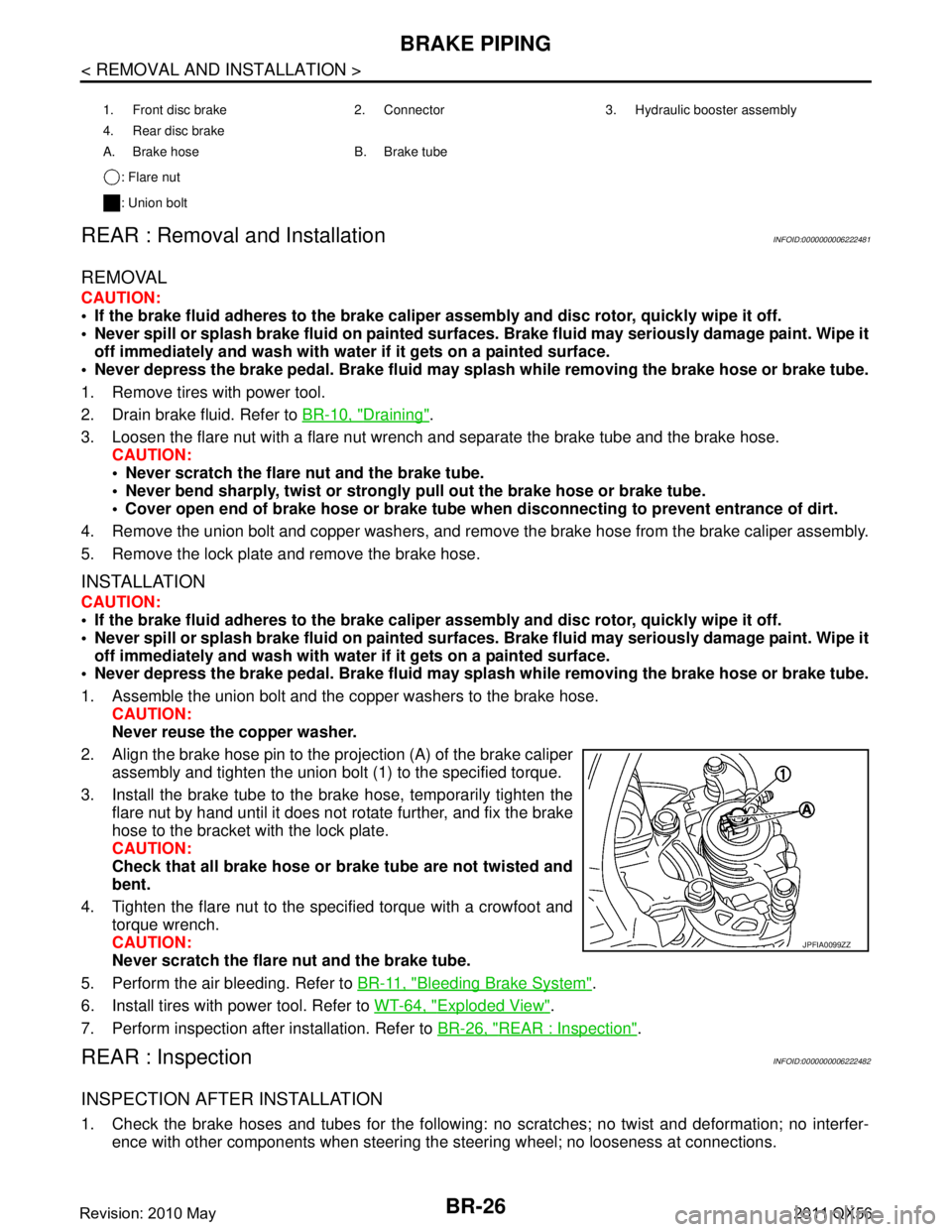

2. Align the brake hose pin to the projection (A) of the brake caliper

assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

7. Perform inspection after installation. Refer to BR-26, "

REAR : Inspection".

REAR : InspectionINFOID:0000000006222482

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0099ZZ

Revision: 2010 May2011 QX56

Page 497 of 5598

BRAKE PIPINGBR-27

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connect ion to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

Revision: 2010 May2011 QX56

Page 499 of 5598

HYDRAULIC BOOSTER ASSEMBLYBR-29

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Removal and InstallationINFOID:0000000006222484

REMOVAL

1. Turn the ignition switch OFF. CAUTION:

Never turn the ignition switch ON before th e completion of the installation procedure.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Depress the brake pedal 20 times or more to release the pressure from the accumulator. CAUTION:

Always perform this step before re moving the hydraulic booster assembly.

4. Disconnect hydraulic booster assembly harness connector.

5. Separate the brake tube from hydraulic booste r assembly with a flare nut wrench. Refer to BR-22,

"FRONT : Exploded View".

6. Remove brake tube from clip.

1. Reservoir cap 2. Lab el 3. Reservoir tank

4. Pin 5. Motor/accumulator assembly 6. Brake tube

7. Brake hose assembly 8. Grommet 9. Harness band

10. Collar 11. Bushing 12. Pin mount

13. Grommet 14. Bracket 15. Cap

16. Bushing 17. Bracket 18. ABS actuator and electric unit (con- trol unit)

19. Gasket 20. Spacer

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0748GB

Revision: 2010 May2011 QX56

Page 501 of 5598

HYDRAULIC BOOSTER ASSEMBLYBR-31

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Remove the reservoir tank mounting pin with a pin punch (com- mercial service tool).

3. Remove bolt and remove the reservoir tank and grommets from the ABS actuator and electric unit (control unit).

CAUTION:

Never drop the removed parts. The parts must not be

reused if they are dropped.

4. Slide the clamp and remove brake hose assembly.

5. Remove the brake tube with a flare nut wrench. CAUTION:

Never scratch the flare nut and the brake tube.

6. Remove the cap with a suitable tool (A).

7. Remove grommets and screws ( ) and remove motor/accumu- lator assembly harness.

8. Cut harness band. CAUTION:

Never damage the harness.

9. Remove motor/accumulator assembly from ABS actuator and electric unit (control unit).

10. Remove bushings and collars from motor/accumulator assem- bly.

11. Remove brackets and bushing fr om ABS actuator and electric

unit (control unit).

12. Remove pin mount.

13. After replacing motor/accumulator assembly, always follow the accumulator disposal procedure to discard the motor/accumulator assembly. Refer to BR-33, "

Disposal".

ASSEMBLY

Note the following, and assembly in the reverse order of disassembly.

Never use mineral oils such as kerosene or gasoline and rubber grease during the cleaning and assembly

process.

Never drop the removed parts when installing. The parts must not be reused if they are dropped.

Never allow foreign matter (e.g. dust) and oils ot her than brake fluid to enter the reservoir tank.

For non reusable parts, refer to BR-28, "

Exploded View".

When connecting motor/accumulator assembly harness, check the order of harness colors.

Temporarily tighten the brake tube flare nut to the motor/accumula- tor assembly and ABS actuator and electric unit (control unit) by

hand. Then tighten it to the specified torque with a crowfoot and

torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

JPFIA0750ZZ

JPFIA0752ZZ

JPFIA0751ZZ

A: Black

B: Red

JPFIA0753ZZ

Revision: 2010 May2011 QX56

Page 502 of 5598

BR-32

< REMOVAL AND INSTALLATION >

HYDRAULIC BOOSTER ASSEMBLY

Apply new brake fluid to grommet of between reservoir tank and grommet and ABS actuator and electric unit

(control unit).

Inspection and AdjustmentINFOID:0000000006222486

ADJUSTMENT BEFORE INSTALLATION

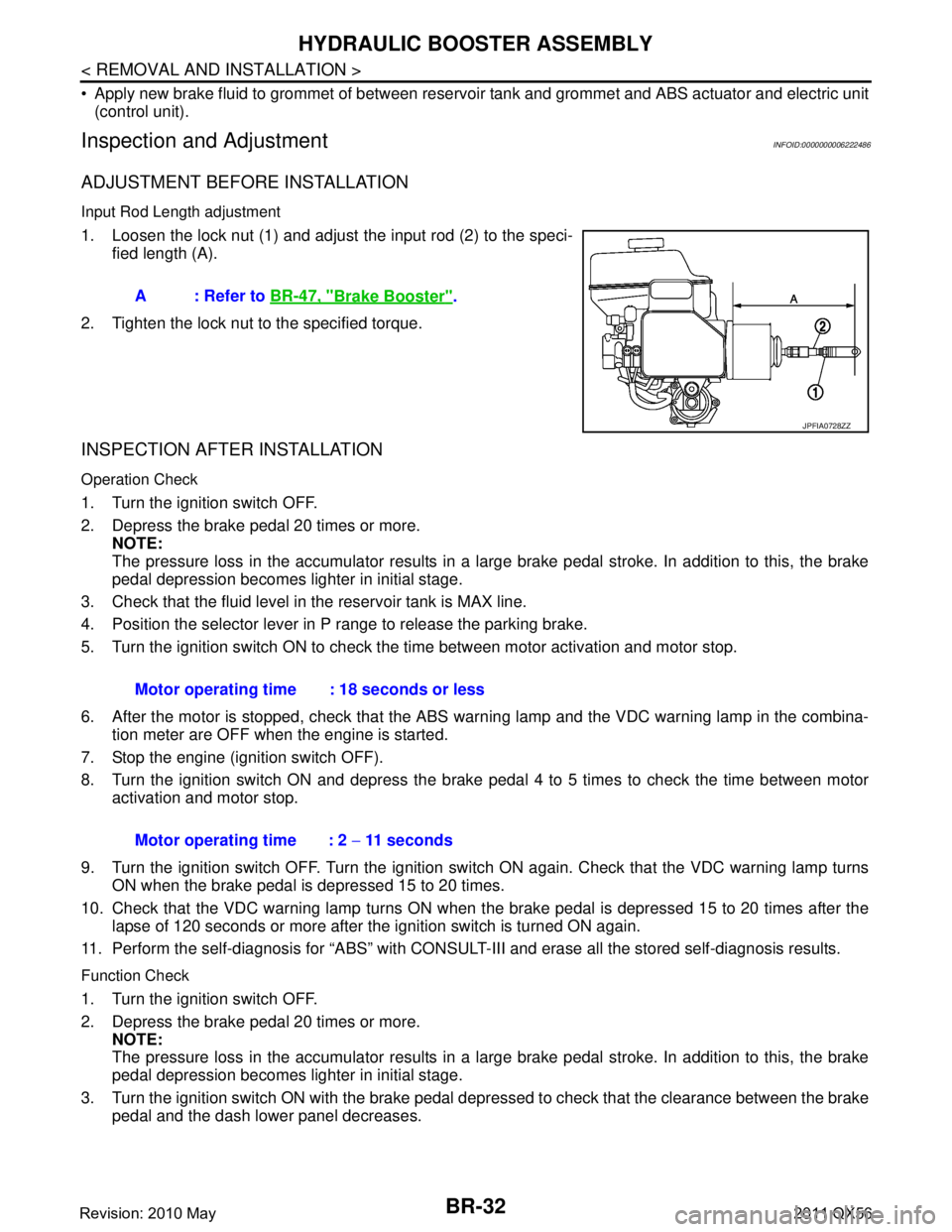

Input Rod Length adjustment

1. Loosen the lock nut (1) and adjust the input rod (2) to the speci-

fied length (A).

2. Tighten the lock nut to the specified torque.

INSPECTION AFTER INSTALLATION

Operation Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more. NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Check that the fluid level in the reservoir tank is MAX line.

4. Position the selector lever in P range to release the parking brake.

5. Turn the ignition switch ON to check the time between motor activation and motor stop.

6. After the motor is stopped, check that the ABS warn ing lamp and the VDC warning lamp in the combina-

tion meter are OFF when the engine is started.

7. Stop the engine (ignition switch OFF).

8. Turn the ignition switch ON and depress the brake pedal 4 to 5 times to check the time between motor activation and motor stop.

9. Turn the ignition switch OFF. Turn the ignition swit ch ON again. Check that the VDC warning lamp turns

ON when the brake pedal is depressed 15 to 20 times.

10. Check that the VDC warning lamp turns ON when the brake pedal is depressed 15 to 20 times after the lapse of 120 seconds or more after the ignition switch is turned ON again.

11. Perform the self-diagnosis for “ABS” with CONSULT- III and erase all the stored self-diagnosis results.

Function Check

1. Turn the ignition switch OFF.

2. Depress the brake pedal 20 times or more.

NOTE:

The pressure loss in the accumulator results in a large brake pedal stroke. In addition to this, the brake

pedal depression becomes lighter in initial stage.

3. Turn the ignition switch ON with the brake pedal depr essed to check that the clearance between the brake

pedal and the dash lower panel decreases. A : Refer to

BR-47, "

Brake Booster".

JPFIA0728ZZ

Motor operating time : 18 seconds or less

Motor operating time : 2 − 11 seconds

Revision: 2010 May2011 QX56

Page 504 of 5598

BR-34

< REMOVAL AND INSTALLATION >

FRONT DISC BRAKE

FRONT DISC BRAKE

BRAKE PAD

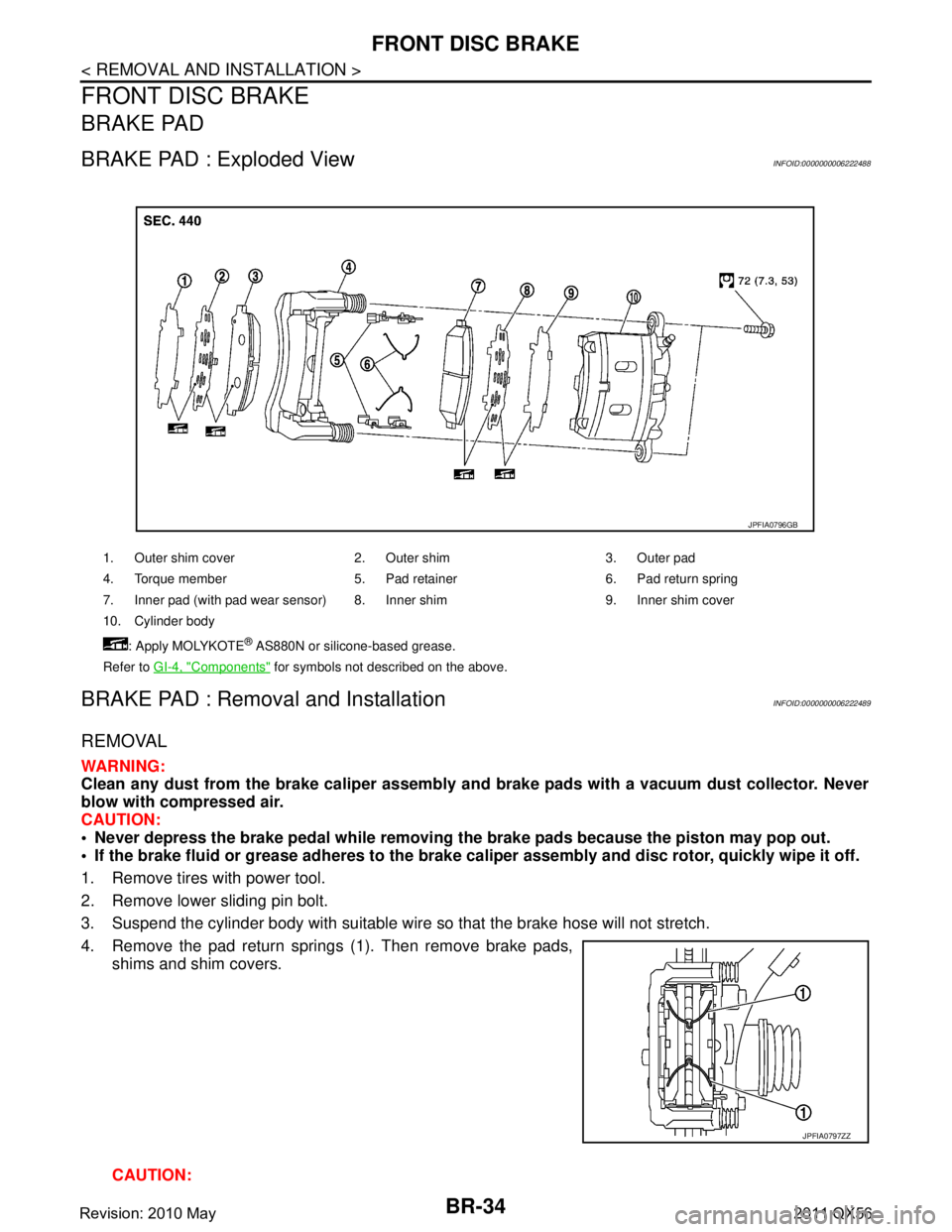

BRAKE PAD : Exploded ViewINFOID:0000000006222488

BRAKE PAD : Removal and InstallationINFOID:0000000006222489

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly and brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake calip er assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Remove lower sliding pin bolt.

3. Suspend the cylinder body with suitable wire so that the brake hose will not stretch.

4. Remove the pad return springs (1). Then remove brake pads, shims and shim covers.

CAUTION:

1. Outer shim cover 2. Outer shim 3. Outer pad

4. Torque member 5. Pad retainer 6. Pad return spring

7. Inner pad (with pad wear sensor) 8. Inner shim 9. Inner shim cover

10. Cylinder body

: Apply MOLYKOTE

® AS880N or silicone-based grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0796GB

JPFIA0797ZZ

Revision: 2010 May2011 QX56

Page 505 of 5598

FRONT DISC BRAKEBR-35

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Never deform the pad retainer when removing the pad retainers (2) from the torque member (1).

Never damage the piston boot.

Never drop the brake pads, shims and shim covers.

Remember each position of the removed brake pads.

5. Perform inspection after removal. Refer to BR-36, "

BRAKE PAD

: Inspection".

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never depress the brake pedal while removing th e brake pads because the piston may pop out.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Install the torque member if the pad retainers has been removed. CAUTION:

Securely assemble the pad retainers (1) so that it will notbe lifted up from the torque member (2).

Never deform the pad retainers.

2. Apply MOLYKOTE

® AS880N or silicone-based grease mating

faces (A and B) between the brake pad, shim and shim cover,

and install shim and shim cover to the brake pad.

CAUTION:

Always replace the shims and shim covers when replacing

the brake pad.

3. Install the brake pads to the torque member.

4. Install pad return springs (1). CAUTION:

Correctly insert the pad return spring into the pad return

spring hole on the brake pad.

5. Install cylinder body to torque member. CAUTION:

Never damage the piston boot.

When replacing brake pad with new one, check a brakefluid level in the reservoir tank because brake fluid

returns to reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool to easily press piston.

6. Install lower sliding bolt and tighter it to the specified torque.

JPFIA0118ZZ

PFIA0763J

JPFIA0798ZZ

JPFIA0797ZZ

Revision: 2010 May2011 QX56

Page 507 of 5598

FRONT DISC BRAKEBR-37

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE CALIPER ASSEMBLY : Removal and InstallationINFOID:0000000006222492

REMOVAL

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Remove tires with power tool.

2. Fix the disc rotor using wheel nuts.

3. Drain brake fluid. Refer to BR-10, "

Draining".

4. Separate brake hose from brake caliper assembly. Refer to BR-23, "

FRONT : Removal and Installation".

5. Remove torque member mounting bolts, and remove brake caliper assembly. CAUTION:

Never drop brake pad and brake caliper assembly.

6. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(AWD).

INSTALLATION

WARNING:

Clean any dust from the brake caliper assembly an d brake pads with a vacuum dust collector. Never

blow with compressed air.

CAUTION:

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid m ay splash while removing the brake hose.

If the brake fluid or grease adheres to the brake cal iper assembly and disc rotor, quickly wipe it off.

1. Torque member 2. Sliding pin boot 3. Sliding pin

4. Piston boot 5. Piston 6. Piston seal

7. Cylinder body 8. Bleeder valve 9. Cap

: Apply rubber grease.

: Apply brake fluid.

Refer to GI-4, "

Components" for symbols not described on the above.

JPFIA0800GB

Revision: 2010 May2011 QX56

Page 509 of 5598

FRONT DISC BRAKEBR-39

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

2. Apply rubber grease to piston seals (1), and install them to cali- per.

CAUTION:

Never reuse piston seals.

3. Apply rubber grease to piston boots (1). Cover the piston (2) end with piston boot, and then install cylinder side lip on piston boots

securely into a groove on cylinder body.

CAUTION:

Never reuse piston boots.

4. Apply new brake fluid to pistons (1). Push piston into cylinder body by hand and push piston boots (2) piston-side lip into the

piston groove.

CAUTION:

Press the pistons evenly and var y the pressing point to pre-

vent cylinder inner wall from being rubbed.

5. Apply rubber grease to sliding pin boots, and install sliding pin boots to torque member.

6. Apply rubber grease to sliding pin, and install the cylinder body.

7. Install sliding pin bolts and tighten it to the specified torque. Refer to BR-34, "

BRAKE PAD : Exploded View".

BRAKE CALIPER ASSEMBLY : InspectionINFOID:0000000006222494

INSPECTION AFTER DISASSEMBLY

Check the following items and replace if necessary.

Cylinder Body

Check the cylinder inner wall for rust, wear, cracks or damage.

CAUTION:

Always clean with new brake fluid. Never clean wit h mineral oil such as gasoline and light oil.

Torque Member

Check the torque member for rust, wear, cracks or damage.

Pistons

Check the surface of the piston for rust, wear, cracks or damage.

CAUTION:

A piston sliding surface is plat ed. Never polish with sandpaper.

Sliding Pin and Sliding Pin Boot

Check the sliding pins and sliding pin boots for rust, wear, cracks or damage.

INSPECTION AFTER INSTALLATION

1. Check a drag of front disc brake. If any dr ag is found, follow the procedure described below.

2. Remove brake pads. Refer to BR-34, "

BRAKE PAD : Removal and Installation".

JPFIA0032ZZ

JPFIA0782ZZ

JPFIA0034ZZ

Revision: 2010 May2011 QX56