engine coolant INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 956 of 5598

CO-14

< REMOVAL AND INSTALLATION >

RADIATOR

to release built-up pressure. Carefully remove radiator cap by turning it all the way. Note that the reser-

voir tank cap side is also under pressure.

1. Remove front under cover with power tool. Refer to EXT-25, "

Exploded View".

2. Remove engine cover. Refer to EM-25, "

Exploded View".

3. Drain engine coolant from radiator. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when the engine is cold.

Never spill engine coolant on drive belts.

4. Remove radiator hose (lower).

5. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

6. Move reservoir tank to the position without the hindrance for work.

7. Remove radiator core support cover. Refer to DLK-220, "

Exploded View".

8. Remove fan shroud (upper), refer to following.

a. Remove EVAP hose mounting bolts and move harness to aside.

b. Move air cleaner case to the position without the hindrance for work. Refer to EM-27, "

Exploded View".

NOTE:

The air cleaner case connector is not required to be disconnected.

9. Remove radiator grille. Refer to EXT-19, "

Exploded View".

10. Move condenser to the position without the hindranc e for work with the following procedures. Refer to HA-

38, "Exploded View".

Remove mounting bolts and disconnect A/C piping from radiator.

Remove air guide from radiator. Refer to EXT-12, "

Exploded View".

Remove radiator mounting bolts.

11. Remove radiator hose (upper).

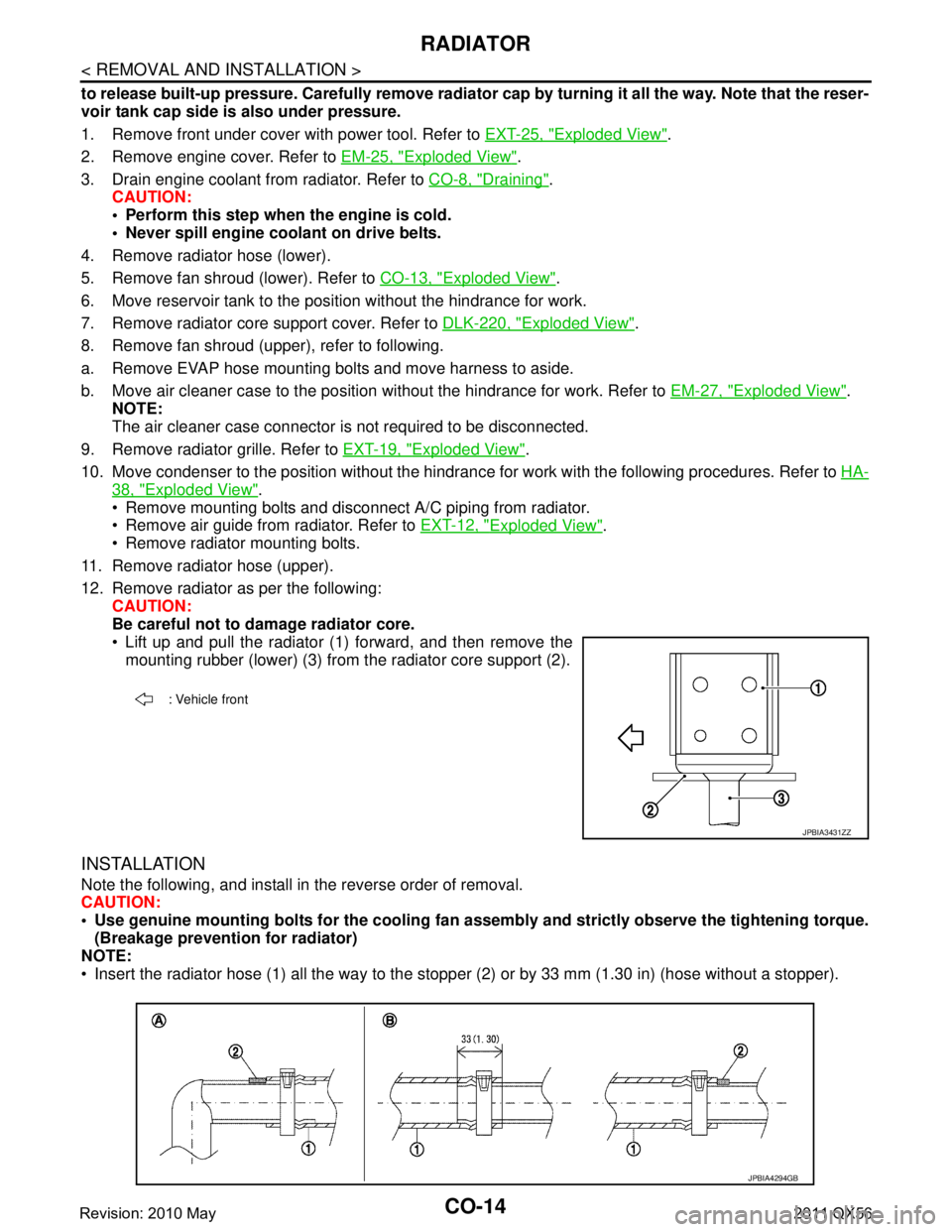

12. Remove radiator as per the following: CAUTION:

Be careful not to damage radiator core.

Lift up and pull the radiator (1) forward, and then remove themounting rubber (lower) (3) from the radiator core support (2).

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Use genuine mounting bolts for th e cooling fan assembly and strictly observe the tightening torque.

(Breakage prevention for radiator)

NOTE:

Insert the radiator hose (1) all the way to the st opper (2) or by 33 mm (1.30 in) (hose without a stopper).

: Vehicle front

JPBIA3431ZZ

JPBIA4294GB

Revision: 2010 May2011 QX56

Page 957 of 5598

RADIATORCO-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

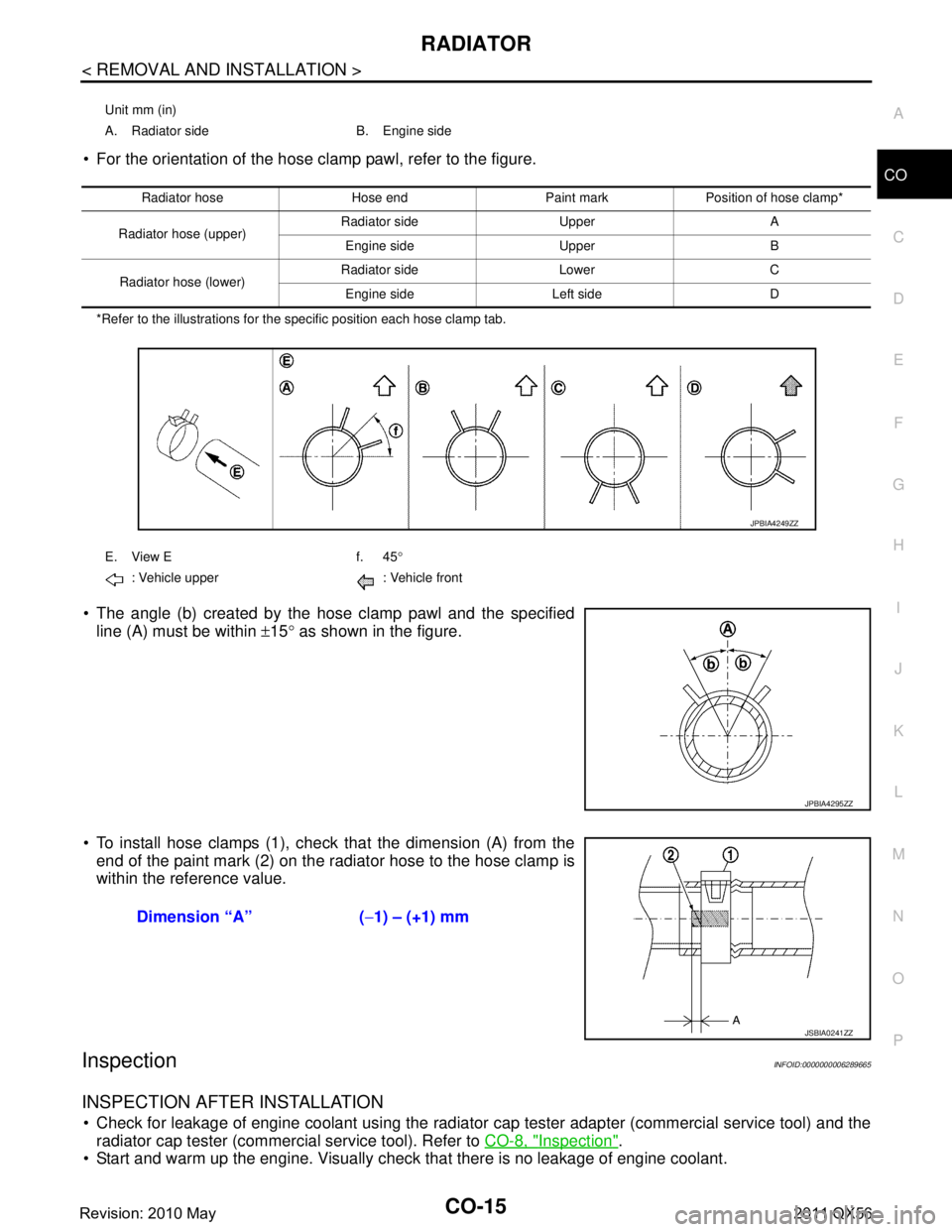

For the orientation of the hose clamp pawl, refer to the figure.

*Refer to the illustrations for the specific position each hose clamp tab.

The angle (b) created by the hose clamp pawl and the specified

line (A) must be within ±15 ° as shown in the figure.

To install hose clamps (1), check that the dimension (A) from the end of the paint mark (2) on the radiator hose to the hose clamp is

within the reference value.

InspectionINFOID:0000000006289665

INSPECTION AFTER INSTALLATION

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

Unit mm (in)

A. Radiator side B. Engine side

Radiator hose Hose end Paint mark Position of hose clamp*

Radiator hose (upper) Radiator side Upper A

Engine side Upper B

Radiator hose (lower) Radiator side Lower C

Engine side Left side D

E. View E f. 45 °

: Vehicle upper : Vehicle front

JPBIA4249ZZ

JPBIA4295ZZ

Dimension “A” ( −1) – (+1) mm

JSBIA0241ZZ

Revision: 2010 May2011 QX56

Page 959 of 5598

COOLING FANCO-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

13. Remove the fan bracket, refer to following.

Disconnect A/C compressor harness connector. Refer to HA-30, "

Exploded View".

Remove A/C compressor mounting bolt. Refer to HA-30, "

Exploded View".

Remove fan bracket mounting bolt.

INSTALLATION

Installation is in the reverse order of removal.

InspectionINFOID:0000000006289668

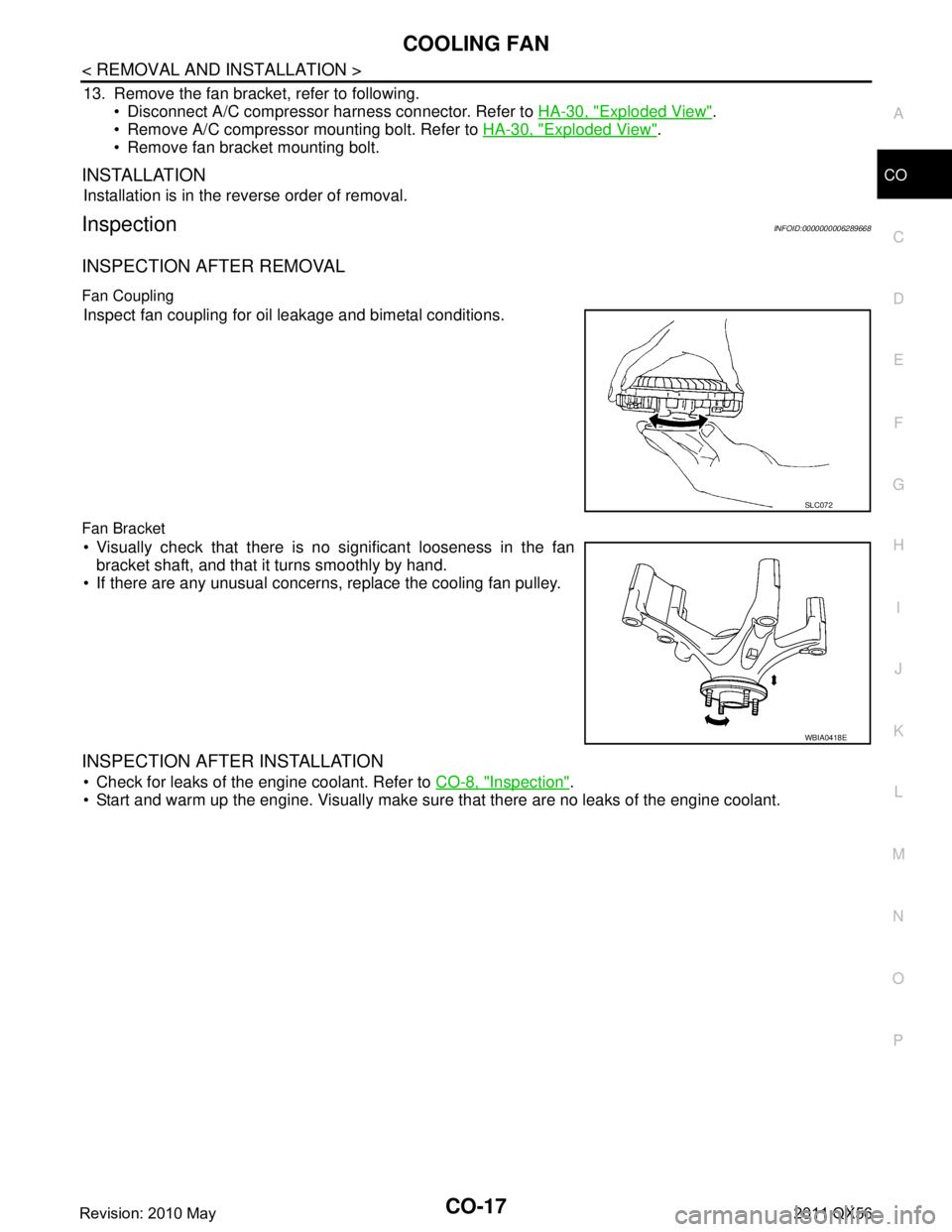

INSPECTION AFTER REMOVAL

Fan Coupling

Inspect fan coupling for oil leakage and bimetal conditions.

Fan Bracket

Visually check that there is no significant looseness in the fan bracket shaft, and that it turns smoothly by hand.

If there are any unusual concerns, replace the cooling fan pulley.

INSPECTION AFTER INSTALLATION

Check for leaks of the engine coolant. Refer to CO-8, "Inspection".

Start and warm up the engine. Visually make sure that there are no leaks of the engine coolant.

SLC072

WBIA0418E

Revision: 2010 May2011 QX56

Page 960 of 5598

CO-18

< REMOVAL AND INSTALLATION >

WATER PUMP

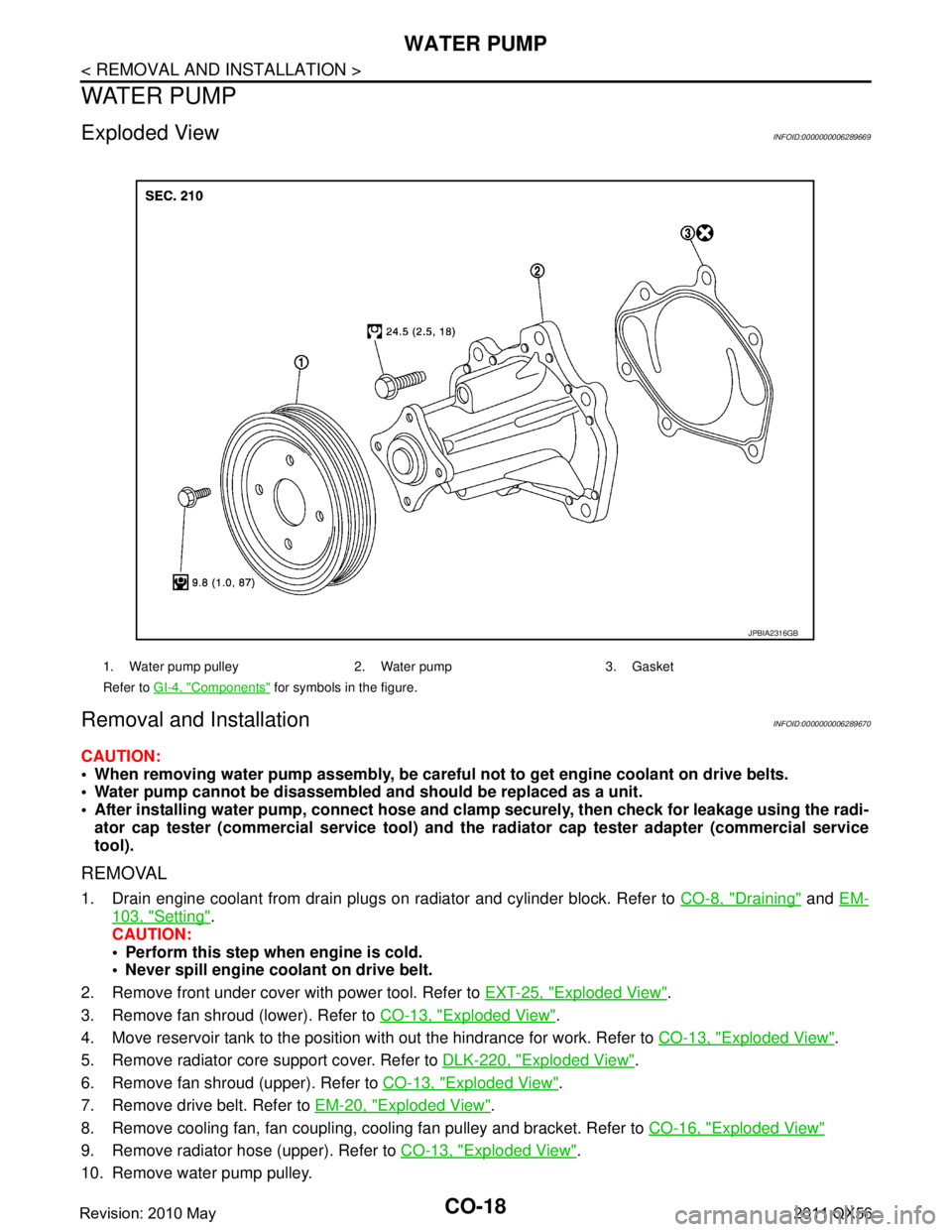

WATER PUMP

Exploded ViewINFOID:0000000006289669

Removal and InstallationINFOID:0000000006289670

CAUTION:

When removing water pump assembly, be careful not to get engine coolant on drive belts.

Water pump cannot be disassembled and should be replaced as a unit.

After installing water pump, co nnect hose and clamp securely, then check for leakage using the radi-

ator cap tester (commercial service tool) and the radiator cap tester adapter (commercial service

tool).

REMOVAL

1. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belt.

2. Remove front under cover with power tool. Refer to EXT-25, "

Exploded View".

3. Remove fan shroud (lower). Refer to CO-13, "

Exploded View".

4. Move reservoir tank to the position with out the hindrance for work. Refer to CO-13, "

Exploded View".

5. Remove radiator core support cover. Refer to DLK-220, "

Exploded View".

6. Remove fan shroud (upper). Refer to CO-13, "

Exploded View".

7. Remove drive belt. Refer to EM-20, "

Exploded View".

8. Remove cooling fan, fan coupling, cooling fan pulley and bracket. Refer to CO-16, "

Exploded View"

9. Remove radiator hose (upper). Refer to CO-13, "Exploded View".

10. Remove water pump pulley.

1. Water pump pulley 2. Water pump 3. Gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA2316GB

Revision: 2010 May2011 QX56

Page 961 of 5598

WATER PUMPCO-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

11. Remove water pump. Refer to

CO-18, "Exploded View".

Engine coolant will leak from cylinder block, so have a receptacle ready under vehicle.

CAUTION:

Handle the water pump vane so that it does not contact any other parts.

Never disassemble water pump.

INSTALLATION

Install in the reverse order of removal.

InspectionINFOID:0000000006289671

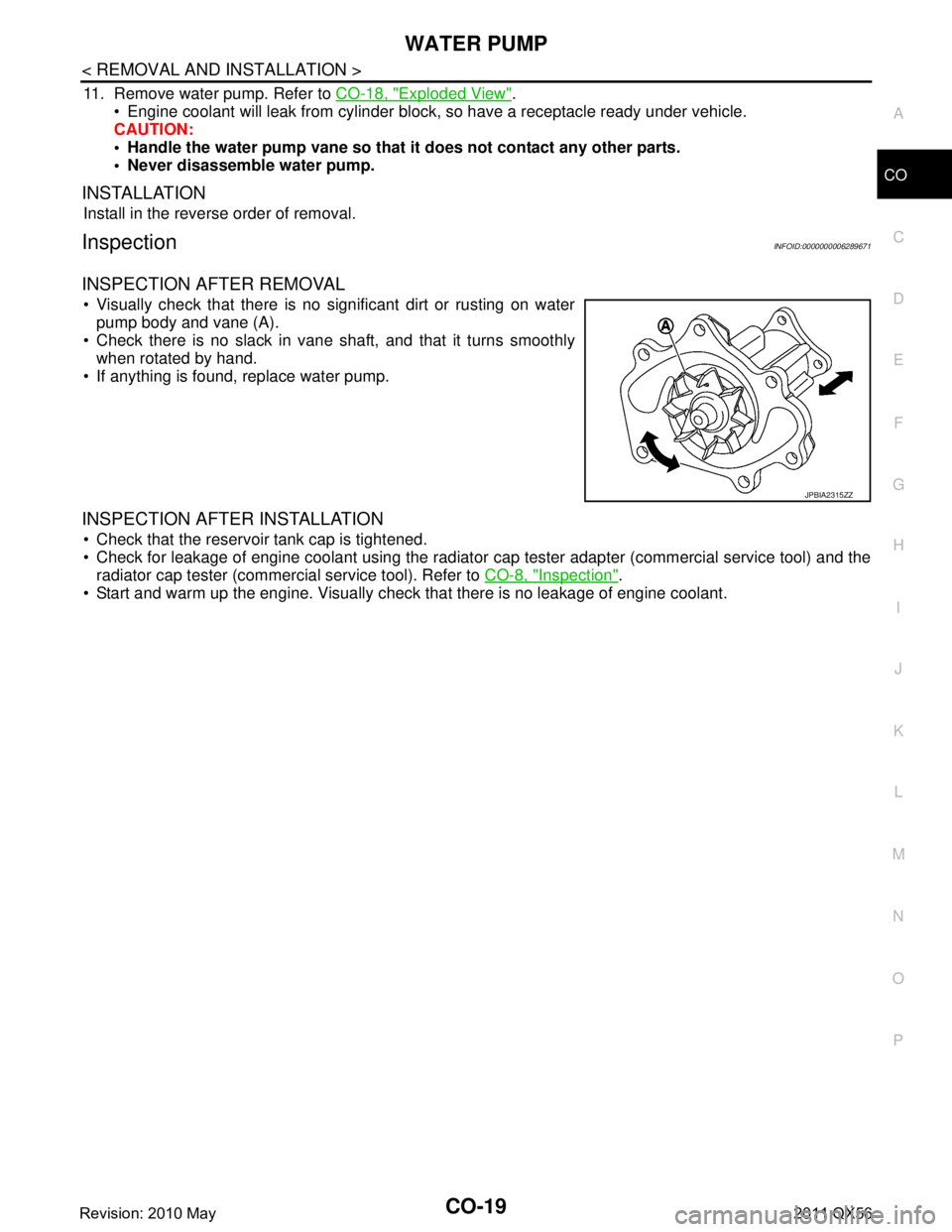

INSPECTION AFTER REMOVAL

Visually check that there is no significant dirt or rusting on water pump body and vane (A).

Check there is no slack in vane shaft, and that it turns smoothly when rotated by hand.

If anything is found, replace water pump.

INSPECTION AFTER INSTALLATION

Check that the reservoir tank cap is tightened.

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually check that there is no leakage of engine coolant.

JPBIA2315ZZ

Revision: 2010 May2011 QX56

Page 963 of 5598

WATER INLET AND THERMOSTAT ASSEMBLYCO-21

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

2. Remove front under cover with power tool. Refer to

EXT-25, "Exploded View".

3. Drain engine coolant from drain plugs on radiator and cylinder block. Refer to CO-8, "

Draining" and EM-

103, "Setting".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

4. Disconnect radiator hose (upper and lower). Refer to CO-13, "

Exploded View".

5. Remove intake manifold. Refer to EM-30, "

Exploded View".

6. Remove fuel feed tube. Refer to EM-43, "

Exploded View".

7. Remove water hose, water connector, heater pipes and heater hoses.

8. Remove thermostat housing.

9. Remove water inlet and thermostat.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to spill engine coolant over en gine room. Use rag to absorb engine coolant.

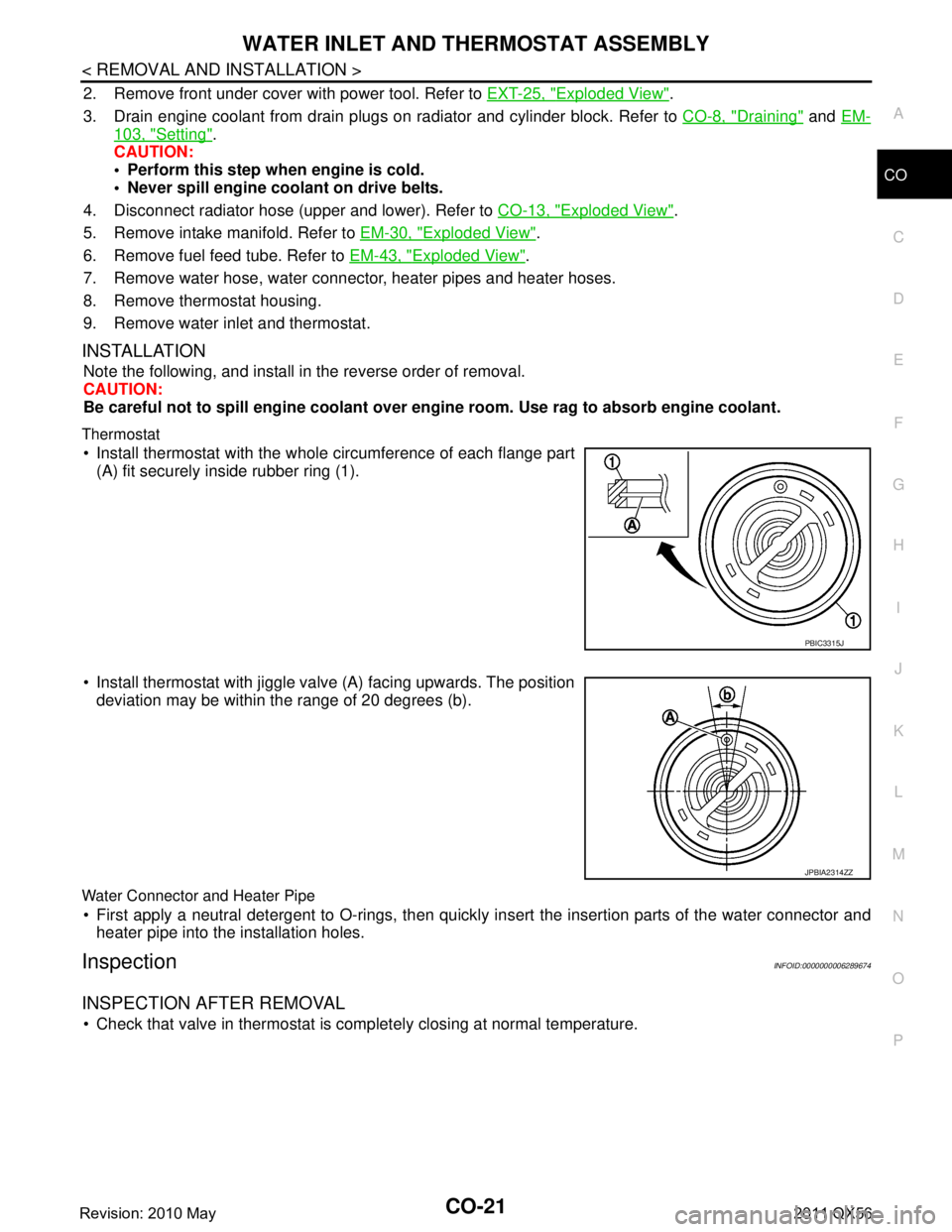

Thermostat

Install thermostat with the whole circumference of each flange part

(A) fit securely inside rubber ring (1).

Install thermostat with jiggle valve (A) facing upwards. The position deviation may be within the range of 20 degrees (b).

Water Connector and Heater Pipe

First apply a neutral detergent to O-rings, then quickly in sert the insertion parts of the water connector and

heater pipe into the installation holes.

InspectionINFOID:0000000006289674

INSPECTION AFTER REMOVAL

Check that valve in thermostat is co mpletely closing at normal temperature.

PBIC3315J

JPBIA2314ZZ

Revision: 2010 May2011 QX56

Page 964 of 5598

CO-22

< REMOVAL AND INSTALLATION >

WATER INLET AND THERMOSTAT ASSEMBLY

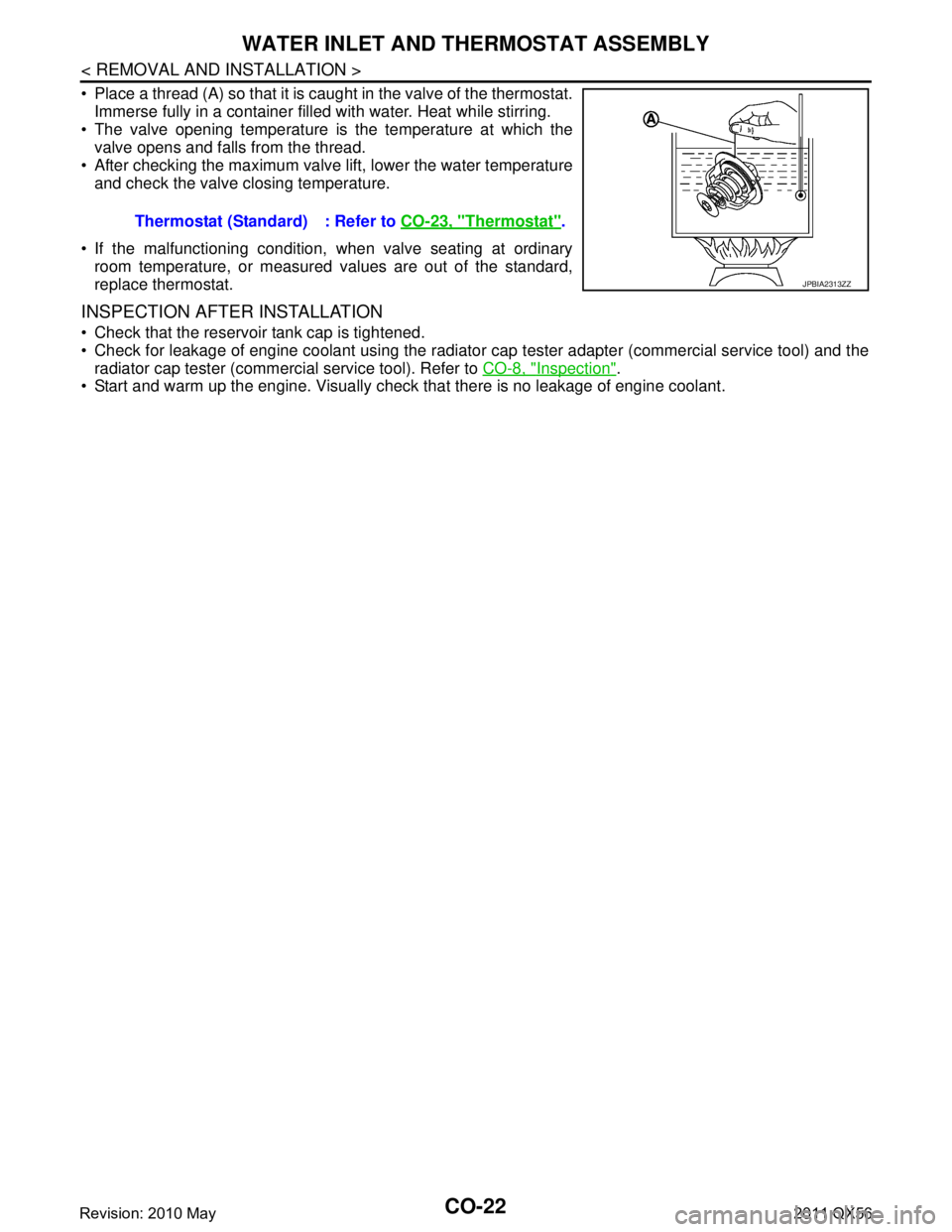

Place a thread (A) so that it is caught in the valve of the thermostat.Immerse fully in a container filled with water. Heat while stirring.

The valve opening temperature is the temperature at which the

valve opens and falls from the thread.

After checking the maximum valve lift, lower the water temperature and check the valve closing temperature.

If the malfunctioning condition, when valve seating at ordinary room temperature, or measured values are out of the standard,

replace thermostat.

INSPECTION AFTER INSTALLATION

Check that the reservoir tank cap is tightened.

Check for leakage of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-8, "

Inspection".

Start and warm up the engine. Visually chec k that there is no leakage of engine coolant.

Thermostat (Standard) : Refer to

CO-23, "

Thermostat".

JPBIA2313ZZ

Revision: 2010 May2011 QX56

Page 965 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-23

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

CO

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

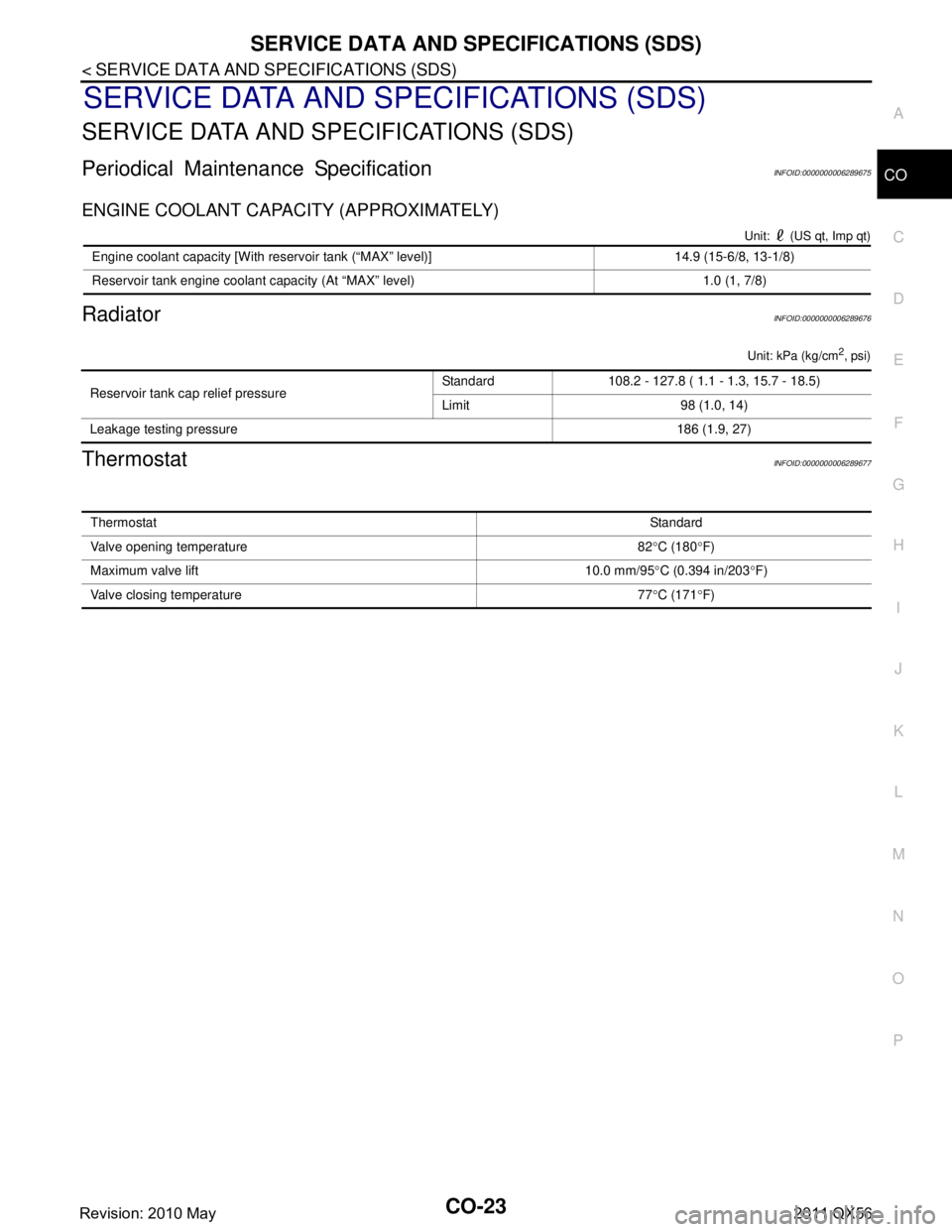

Periodical Maintenance SpecificationINFOID:0000000006289675

ENGINE COOLANT CAPACITY (APPROXIMATELY)

Unit: (US qt, Imp qt)

RadiatorINFOID:0000000006289676

Unit: kPa (kg/cm2, psi)

ThermostatINFOID:0000000006289677

Engine coolant capacity [With reservoir tank (“MAX” level)] 14.9 (15-6/8, 13-1/8)

Reservoir tank engine coolant capacity (At “MAX” level) 1.0 (1, 7/8)

Reservoir tank cap relief pressure

Standard 108.2 - 127.8 ( 1.1 - 1.3, 15.7 - 18.5)

Limit 98 (1.0, 14)

Leakage testing pressure 186 (1.9, 27)

ThermostatStandard

Valve opening temperature 82 °C (180 °F)

Maximum valve lift 10.0 mm/95 °C (0.394 in/203 °F)

Valve closing temperature 77 °C (171 °F)

Revision: 2010 May2011 QX56

Page 1305 of 5598

![INFINITI QX56 2011 Factory User Guide

DAS-340

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

CAMERA AIMING ADJUSTMENT

DescriptionINFOID:0000000006223734

Always adjust the camera aiming after removing

and installing or replacin INFINITI QX56 2011 Factory User Guide

DAS-340

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

CAMERA AIMING ADJUSTMENT

DescriptionINFOID:0000000006223734

Always adjust the camera aiming after removing

and installing or replacin](/img/42/57033/w960_57033-1304.png)

DAS-340

< BASIC INSPECTION >[LDW & LDP]

CAMERA AIMING ADJUSTMENT

CAMERA AIMING ADJUSTMENT

DescriptionINFOID:0000000006223734

Always adjust the camera aiming after removing

and installing or replacing the lane camera unit.

CAUTION:

Place the vehicle on level ground when th e camera aiming adjustment is operated.

Follow the CONSULT-III when performing the came ra aiming. (Camera aiming adjustment cannot be

operated without CONSULT-III.)

Work Procedure (Preparation)INFOID:0000000006223735

1.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis of ADAS control unit and lane camera unit.

Is any DTC detected?

Except “C1B01”>>Perform diagnosis on the detected DTC and repair or replace the applicable item. Refer to

DAS-310, "

DTC Index" (ICC/ADAS) or DAS-316, "DTC Index" (LANE CAMERA).

“C1B01” or no DTC>>GO TO 2.

2.PREPARATION BEFORE CAMERA AIMING ADJUSTMENT

1. Perform pre-inspection for diagnosis. Refer to DAS-335, "

Inspection Procedure".

2. Adjust the tire pressure to the specified pressure value.

3. Maintain no-load in vehicle.

4. Check if coolant and engine oil are filled up to correct level and fuel tank is full.

5. Shift the selector lever to “P” position and release the parking brake.

6. Clean the windshield.

7. Completely clear off the instrument panel.

>> GO TO 3.

3. PREPARATION OF AIMING ADJUSTMENT JIG

Prepare the aiming adjustment jig according to the following procedure and the figure.

1. Print out the target mark attached in this service manual. Refer to DAS-343, "

Work Procedure (Target

Mark Sample)".

2. Stick a printed target mark on the board with a scotch tape or a piece of double-sided tape.

NOTE:

Use the board that peripheral area of the ta rget is monochrome such as a white-board.

Notice that the cross of the target is horizontal and vertical.

JPOIA0011ZZ

Revision: 2010 May2011 QX56

Page 1788 of 5598

DLK-252

< REMOVAL AND INSTALLATION >

CAB MOUNTING INSULATOR

Drain brake fluid from brake line. Refer to BR-10, "Draining".

Release fuel pressure. Refer to EC-153, "

Work Procedure".

Disconnect both battery cables. Refer to PG-164, "

Removal and Installation".

Drain engine coolant from radiator. Refer to CO-8, "

Draining".

Discharge refrigerant from A/C circuit. Refer to HA-20, "

Recycle Refrigerant".

Drain power steering fluid from reservoir tank.

4. Remove parts relating to connection of body assembly and frame assembly. Tire and wheel: Refer to WT-64, "

Removal and Installation" (with TPMS).

Front fender protector (LH and RH): Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

Front bumper: Refer to EXT-13, "

Removal and Installation".

Radiator core support upper: Refer to DLK-220, "

Removal and Installation".

Fan shroud: Refer to CO-16, "

Removal and Installation".

Battery and battery case: Refer to PG-164, "

Removal and Installation".

Air cleaner case (upper and lower): Refer to EM-27, "

Removal and Installation".

Engine cover: Refer to EM-25, "

Removal and Installation".

Rear wheel house protector (LH and RH): EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

Rear bumper: Refer to EXT-17, "

Removal and Installation".

Fuel filler tube: Remove to FL-8, "

Exploded View".

Spare tire

Towing hook bracket.

5. Separate parts relating to connection of body assembly and frame assembly. Vehicle front

Disconnect ICC sensor connector. (models with ICC) Refer to CCS-176, "

Removal and Installation".

Remove radiator upper hose and radiator lower hose from radiator assembly. Refer to CO-13,

"Exploded View".

Remove A/T fluid cooler hose B and A/T fluid cooler hose E from A/T fluid cooler tubes. Refer to TM-

202, "Exploded View".

Remove power steering return hose from oil cooler, and then power steering return hose clamp bolt from frame assembly. Refer to ST-54, "

Exploded View".

Remove power steering suction hose from reservoir tank. Refer to ST-54, "

Exploded View".

CAUTION:

Never spill power steering fluid in engine room.

Remove A/C low-presser flexible hose from A/C low-presser pipe. Refer to HA-35, "

LOW-PRESSURE

FLEXIBLE HOSE : Removal and Installation".

Remove A/C hi-presser flexible hose from condenser. Refer to HA-34, "

HIGH-PRESSURE FLEXIBLE

HOSE : Removal and Installation".

Remove all engine Control Harness connectors, har ness clips and others that are connected to the

body assembly side of the engine room. (engine room LH and RH side). Refer to PG-148, "

Engine Con-

trol Harness".

NOTE:

Separate harness connectors from ECM (engine control module). Refer to EC-10, "

General Precau-

tions".

CAUTION:

When pulling out harnesses, never damage harnesses or connectors.

After temporarily securing connectors, cover th em with vinyl or similar material to protect

against adhesion of foreign materials.

Disconnect engine room harness connectors and remo ve harness clips from engine assembly (engine

RH side). Refer to PG-146, "

Engine Room Harness".

Remove heater hoses from front water outlet tube (engine room RH side). Refer to HA-33, "

Exploded

View".

Disconnect front wheel sensor connectors (LH and RH). Refer to BRC-134, "

FRONT WHEEL SENSOR

: Exploded View".

Disconnect fuel feed tube and EVAP hos e (front wheel well LH side).

Remove steering lower shaft from steering gear side assembly. Refer to ST-37, "

Removal and Installa-

tion"

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly.

Revision: 2010 May2011 QX56