Head lamp INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4761 of 5598

![INFINITI QX56 2011 Factory Service Manual

SEC-154

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

PANIC ALARM FUNCTION DOES NOT OPERATE

PANIC ALARM FUNCTION

DOES NOT OPERATE

DescriptionINFOID:0000000006226336

NOTE:

Before performing th INFINITI QX56 2011 Factory Service Manual

SEC-154

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

PANIC ALARM FUNCTION DOES NOT OPERATE

PANIC ALARM FUNCTION

DOES NOT OPERATE

DescriptionINFOID:0000000006226336

NOTE:

Before performing th](/img/42/57033/w960_57033-4760.png)

SEC-154

< SYMPTOM DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

PANIC ALARM FUNCTION DOES NOT OPERATE

PANIC ALARM FUNCTION

DOES NOT OPERATE

DescriptionINFOID:0000000006226336

NOTE:

Before performing the diagnosis following procedure, check “Work Flow”. Refer to SEC-48, "

Work Flow".

Check that vehicle is under the condition shown in “Conditions of vehicle” before starting diagnosis, and

check each symptom.

CONDITIONS OF VEHICLE (OPERATION CONDITIONS)

Ignition switch is in OFF or LOCK position.

Intelligent Key is removed from key slot.

Diagnosis ProcedureINFOID:0000000006226337

1.CHECK REMOTE KEYL ESS ENTRY FUNCTION

Check remote keyless entry function.

Does door lock/unlock with Intelligent key button?

YES >> GO TO 2.

NO >> Go to DLK-175, "

Diagnosis Procedure".

2.CHECK VEHICLE SECURITY ALARM OPERATION

Check vehicle security alarm operation.

Does alarm (headlamps and horns) active?

YES >> GO TO 3.

NO >> Go to SEC-18, "

VEHICLE SECURITY SYSTEM : System Description".

3.CHECK “PANIC ALARM SET” SETTING IN “WORK SUPPORT”

Check “PANIC ALARM SET” setting in “WORK SUPPORT”.

Refer to SEC-22, "

INTELLIGENT KEY : CONSULT-III F unction (BCM - INTELLIGENT KEY)".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Set “PANIC ALARM SET” setting in “WORK SUPPORT”.

4.CONFIRM THE OPERATION

Confirm the operation again.

Is the result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 4771 of 5598

SR-8

< BASIC INSPECTION >

COLLISION DIAGNOSIS

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

FOR SIDE AND ROLLOVER COLLISION : When SRS is not activated in a collision

INFOID:0000000006113083

CAUTION:

Due to varying models and option levels, not all part s listed in the chart below apply to all vehicles.

WORK PROCEDURE

1. Before performing any of the following steps, ensur e that all vehicle body and structural repairs have been

completed.

2. Check the SRS components and the related parts using the following table. If the front seat back assembly is damaged, t he front seat back assembly must be replaced.

If the door finisher assembly is damaged, the door finisher assembly and door-mounted curtain air bag

module must be replaced.

3. Perform self-diagnosis using CONSULT-III and “AIR BAG” warning lamp. Refer to SRC-14, "

Description"

for details. Make sure entire SRS operates properly.

4. After the work is completed, perform self-diagnosis to check that no malfunction is detected. Refer to

SRC-14, "

Description".

SRS INSPECTION (FOR SIDE AND ROLLOVER COLLISION)

Part Inspection

Side curtain air bag module LH If the side curtain air bag LH has deployed:

REPLACE the side curtain air bag module LH.

Install with new fasteners.

Side curtain air bag module RH If the side curtain air bag RH has deployed:

REPLACE the side curtain air bag module RH.

Install with new fasteners.

Front side air bag module LH If the front side air bag LH has deployed:

REPLACE front seatback assembly LH.

Front side air bag module RH If the front side air bag RH has deployed:

REPLACE front seatback assembly RH.

Side air bag (satellite) sensor

(LH or RH) If any of the SRS components have deployed:

REPLACE the side air bag (satellite) sensor on the collision side with new fasteners.

Diagnosis sensor unit If any of the SRS components have deployed:

REPLACE the diagnosis sensor unit with new fasteners.

Seat belt pre-tensioner assem-

blies

(All applicable locations: buckle,

retractor, lap outer) If either the driver or passenger seat belt pre-tensioner* has been activated:

REPLACE all seat belt pre-tensioner assemblies with new fasteners.

*: Confirm seat belt pre-tensioner activation using CONSULT-III only.

Center inner pillar 1. Check the center inner pillar on the collision side for damage (dents, cracks, deformation, etc.).

2. If damaged

− REPAIR the center inner pillar.

Trim/headlining 1. Check for visible signs of damage (dents, cracks, deformation, etc.) of the interior trim on the

collision side.

2. If damaged − REPLACE the damaged trim parts.

Door-mounted curtain air bag

module LH If the door-mounted curtain air bag module LH has deployed:

REPLACE the door finisher LH and door-mounted curtain air bag module.

Install with new fasteners.

Door-mounted curtain air bag

module RH If the door-mounted curtain air bag module RH has deployed:

REPLACE the door finisher RH and door-mounted curtain air bag module.

Install with new fasteners.

Pop-up roll bar assemblies If the pop-up roll bar has deployed:

REPLACE pop-up roll bar assemblies and pop-up roll bar covers.

Install with new fasteners.

Revision: 2010 May2011 QX56

Page 4802 of 5598

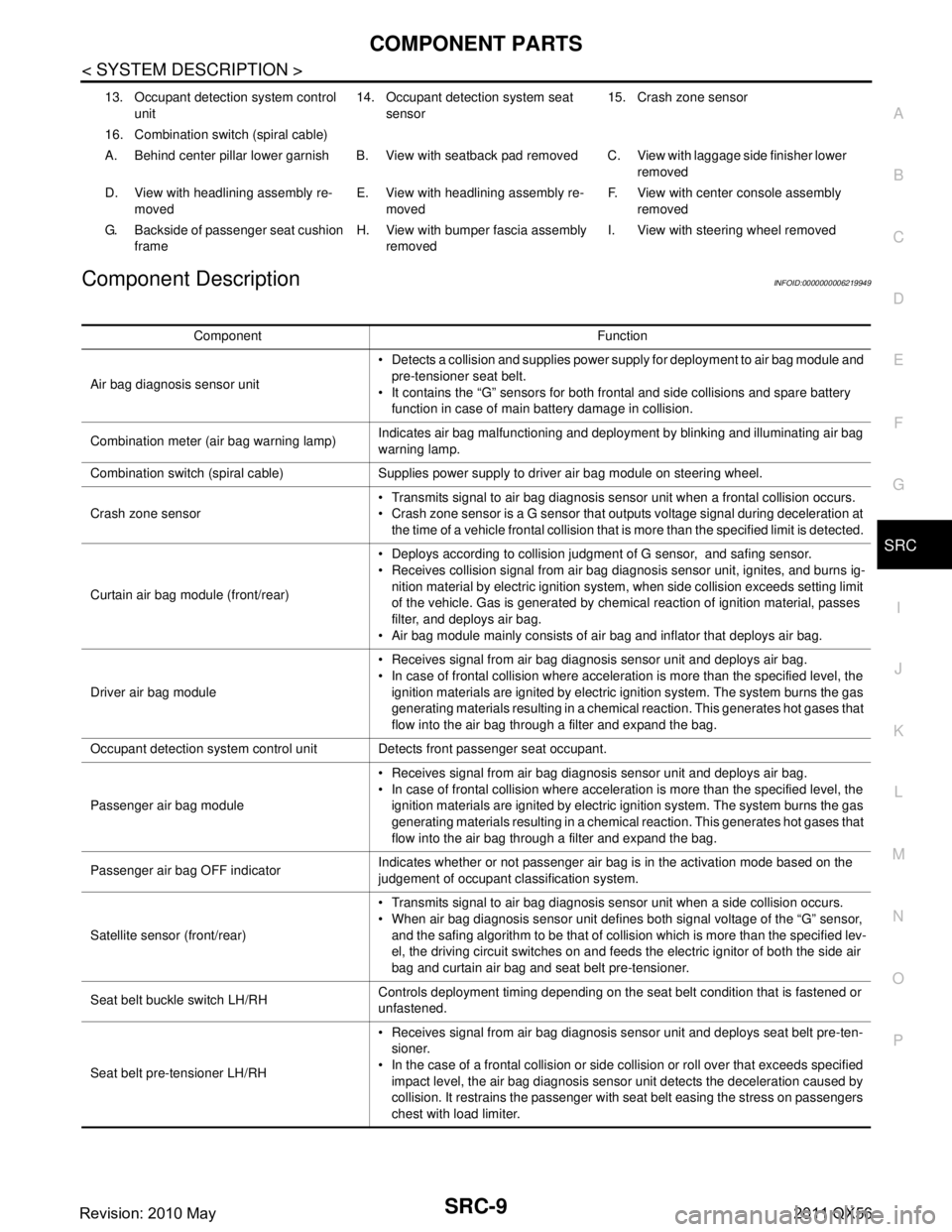

COMPONENT PARTSSRC-9

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

Component DescriptionINFOID:0000000006219949

13. Occupant detection system control unit 14. Occupant detection system seat

sensor 15. Crash zone sensor

16. Combination switch (spiral cable)

A. Behind center pillar lower garnish B. View with seatback pad removed C. View with laggage side finisher lower removed

D. View with headlining assembly re- moved E. View with headlining assembly re-

moved F. View with center console assembly

removed

G. Backside of passenger seat cushion frame H. View with bumper fascia assembly

removed I. View with steering wheel removed

Component Function

Air bag diagnosis sensor unit Detects a collision and supplies power supply for deployment to air bag module and

pre-tensioner seat belt.

It contains the “G” sensors for both frontal and side collisions and spare battery function in case of main battery damage in collision.

Combination meter (air bag warning lamp) Indicates air bag malfunctioning and deployment by blinking and illuminating air bag

warning lamp.

Combination switch (spiral cable) Supplies power supply to driver air bag module on steering wheel.

Crash zone sensor Transmits signal to air bag diagnosis sensor unit when a frontal collision occurs.

Crash zone sensor is a G sensor that outputs voltage signal during deceleration at

the time of a vehicle frontal collision that is more than the specified limit is detected.

Curtain air bag module (front/rear) Deploys according to collision judgment of G sensor, and safing sensor.

Receives collision signal from air bag diagnosis sensor unit, ignites, and burns ig-

nition material by electric ignition system, when side collision exceeds setting limit

of the vehicle. Gas is generated by chemical reaction of ignition material, passes

filter, and deploys air bag.

Air bag module mainly consists of air bag and inflator that deploys air bag.

Driver air bag module Receives signal from air bag diagnosis sensor unit and deploys air bag.

In case of frontal collision where acceleration is more than the specified level, the

ignition materials are ignited by electric ignition system. The system burns the gas

generating materials resulting in a chemical reaction. This generates hot gases that

flow into the air bag through a filter and expand the bag.

Occupant detection system control unit Detects front passenger seat occupant.

Passenger air bag module Receives signal from air bag diagnosis sensor unit and deploys air bag.

In case of frontal collision where acceleration is more than the specified level, the

ignition materials are ignited by electric ignition system. The system burns the gas

generating materials resulting in a chemical reaction. This generates hot gases that

flow into the air bag through a filter and expand the bag.

Passenger air bag OFF indicator Indicates whether or not passenger air bag is in the activation mode based on the

judgement of occupant classification system.

Satellite sensor (front/rear) Transmits signal to air bag diagnosis sensor unit when a side collision occurs.

When air bag diagnosis sensor unit defines both signal voltage of the “G” sensor,

and the safing algorithm to be that of collision which is more than the specified lev-

el, the driving circuit switches on and feeds the electric ignitor of both the side air

bag and curtain air bag and seat belt pre-tensioner.

Seat belt buckle switch LH/RH Controls deployment timing depending on the seat belt condition that is fastened or

unfastened.

Seat belt pre-tensioner LH/RH Receives signal from air bag diagnosis sensor unit and deploys seat belt pre-ten-

sioner.

In the case of a frontal collision or side collision or roll over that exceeds specified impact level, the air bag diagnosis sensor unit detects the deceleration caused by

collision. It restrains the passenger with seat belt easing the stress on passengers

chest with load limiter.

Revision: 2010 May2011 QX56

Page 5024 of 5598

STEERING SHAFTST-37

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

STEERING SHAFT

Exploded ViewINFOID:0000000006225604

Removal and InstallationINFOID:0000000006225605

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Fix the steering wheel.

3. Remove steering shaft fixing bolt and nut (lower joint side). CAUTION:

The steering shaft bellows are easily bent. N ever press the bellows too much with a tool.

4. Remove lower joint fixing bolt (steering gear side).

5. Remove lower joint from steering shaft and steering gear assembly. CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

6. Turn carpet and remove the hole cover mounting nuts.

7. Remove the upper joint fixing bolt and nut (steering shaft side).

1. Lower joint 2. Steering shaft 3. Hole cover*

4. Clamp* 5. Hole cover seal 6. Collar

7. Upper joint

*: Replace “3” and “4” as a set.

Refer to GI-4, "

Components" for symbols in the figure.

JPGIA0067GB

Revision: 2010 May2011 QX56

Page 5029 of 5598

ST-42

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

Vehicle speed sensitive type

Removal and InstallationINFOID:0000000006225608

REMOVAL

1. Set vehicle to the straight-ahead position.

2. Remove tires.

3. Remove front final drive assembly. Refer to DLN-162, "

Removal and Installation".

10. Retainer 11. O-ring 12. Low pressure piping

13. Gear-sub assembly 14. Rear cover cap 15. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPGIA0073GB

1. Outer socket 2. Boot clamp 3. Boot

4. Inner socket 5. Boot clamp 6. Gear housing assembly

7. Adjusting screw 8. Adjusting screw lock nut 9. Spring

10. Retainer 11. O-ring 12. Low pressure piping

13. Power steering solenoid valve 14. Gear-sub assembly 15. Rear cover cap

16. Cylinder tubes

: Apply power steering fluid.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

: A p p l y G e n u i n e L i q u i d G a s k e t , T h r e e B o n d 1111 B o r e q u i v a l e n t . : Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

Revision: 2010 May2011 QX56

Page 5420 of 5598

![INFINITI QX56 2011 Factory Service Manual

WCS-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY, OUTKY, LK

WN]Displays status of Intelligent Key system warning judged INFINITI QX56 2011 Factory Service Manual

WCS-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY, OUTKY, LK

WN]Displays status of Intelligent Key system warning judged](/img/42/57033/w960_57033-5419.png)

WCS-16

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY, OUTKY, LK

WN]Displays status of Intelligent Key system warning judged from meter display signal

received from BCM with CAN communication line.

ACC TARGET

[On/Off] Status of vehicle ahead detection indicator judged from meter display signal re-

ceived from ADAS control unit with CAN communication line.

ACC DISTANCE

[Off, Short, Middle, Long] Status of set distance indicator judged from meter display signal received from

ADAS control unit with

CAN communication line.

ACC OWN VHL

[On/Off] Status of own vehicle indicator judged from meter display signal received from

ADAS control unit with

CAN communication line.

ACC SET SPEED

[Off, km/h] Status of set vehicle speed indicator judged from meter display signal received

from ADAS control unit with CAN communication line.

ACC UNIT

[On/Off] Status of display unit judged from meter display signal received from ADAS con-

trol unit with CAN communication line.

SHIFT IND

[P, R, N, D, M1, M2, M3, M4, M5, M6,

M7] Status of shift position indicator judged from shift position signal and manual mode

indicator signal received from TCM with CAN communication line.

4WD IND

[AUTO, LOCK, 2W, 4Lo, HL1, HL2,

MALF] Status of 4WD indicator judged from 4WD indicator signal received from 4WD

control unit with CAN communication line.

BSW IND

[Off] This item is displayed, but cannot be monitored.

BSW W/L

[On/Off] Status of BSW warning lamp (orange) judged from BSW warning lamp signal re-

ceived from ADAS control unit with CAN communication line.

AT S MODE SW

[On/Off] Status of snow mode switch.

M RANGE SW

[On/Off] Status of manual mode switch.

NM RANGE SW

[On/Off] Status of non-manual mode switch.

AT SFT UP SW

[On/Off] Status of manual mode shift up switch.

AT SFT DWN SW

[On/Off] Status of manual mode shift down switch.

PKB SW

[On/Off] Status of parking brake switch.

BUCKLE SW

[On/Off] Status of seat belt buckle switch (driver side).

BRAKE OIL SW

[On/Off] Status of brake fluid level switch.

A/C AMP CONN

[Off] This item is displayed, but cannot be monitored.

ENTER SW

[On/Off] Status of (ENTER) switch.

SELECT SW

[On/Off] Status of (SELECT) switch.

DISTANCE

[km] Value of distance to empty calculated by combination meter.

OUTSIDE TEMP

[ ° C or °F] Ambient temperature value converted from ambient sensor signal received from

ambient sensor.

NOTE:

This may not match with the temperature value indicated on the information dis-

play. (Because the information display value is a corrected value from the ambient

sensor input value.)

Display item [Unit]

MAIN

SIGNALS Description

Revision: 2010 May2011 QX56

Page 5423 of 5598

WCS

DIAGNOSIS SYSTEM (BCM)WCS-19

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

DIAGNOSIS SYSTEM (BCM)

COMMON ITEM

COMMON ITEM : CONSULT-III Fu nction (BCM - COMMON ITEM)INFOID:0000000006419721

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the following for all sub system selection items.

×: Applicable item

*: This item is indicated, but not used.

FREEZE FRAME DATA (FFD)

The BCM records the following vehicle condition at the time a particular DTC is detected, and displays on

CONSULT-III.

Diagnosis mode Function Description

Work Support Changes the setting for each system function.

Self Diagnostic Result Displays the diagnosis results judged by BCM. Refer to BCS-57, "

DTCIndex".

CAN Diag Support Monitor Monitors the reception status of CAN communication viewed from BCM. Refer to CONSULT-III opera-

tion manual.

Data Monitor The BCM input/output signals are displayed.

Active Test The signals used to activate each device are forcibly supplied from BCM.

Ecu Identification The BCM part number is displayed.

Configuration Read and save the vehicle specification.

Write the vehicle specification when replacing BCM.

System Sub system selection item Diagnosis mode

Work Support Data Monitor Active Test

Door lock DOOR LOCK ×××

Rear window defo gger REAR DEFOGGER ××

Warning chime BUZZER ××

Interior room lamp timer INT LAMP ×××

Exterior lamp HEAD LAMP ×××

Wiper and washer WIPER ×××

Turn signal and hazard warning lamps FLASHER ×××

— AIR CONDITONER* ××

Intelligent Key system

Engine start system INTELLIGENT KEY

×××

Combination switch COMB SW ×

Body control system BCM ×

IVIS IMMU ×××

Interior room lamp battery saver BATTERY SAVER ×××

Back door TRUNK ×

Vehicle security system THEFT ALM ×××

RAP system RETAINED PWR ×

Signal buffer system SIGNAL BUFFER ××

Revision: 2010 May2011 QX56

Page 5428 of 5598

WCS-24

< ECU DIAGNOSIS INFORMATION >

COMBINATION METER

DCA INDIgnition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

CHECK SUS IND Ignition switch

ONCK SUSP indicator lamp ON On

CK SUSP indicator lamp OFF Off

LCD Ignition switch

ON

During engine start in

formation indication B&P I

Ignition switch

ACC During engine start information indication B&P N

Ignition switch

LOCK During key ID warning indication ID NG

Ignition switch

LOCK During steering lock information indication ROTAT

Ignition switch

LOCK During P position warning indication SFT P

Ignition switch

LOCK During Intelligent Key insert information in-

dication

INSRT

Ignition switch

LOCK During Intelligent Key low battery warning

indication

BATT

Ignition switch

ON During take away warning indication NO KY

Ignition switch

LOCK During key warnin

g indication OUTKY

Ignition switch

ON During ACC warning indication LK WN

ACC TARGET Ignition switch

ONDuring vehicle ahead detection indicator in-

dication

On

Other than the above Off

ACC DISTANCE Ignition switch

ONWhen following distance set to “LONG” LONG

When following distance set to “MIDDLE” MID

When following distance set to “SHORT” SHORT

Set distance indicator not displayed Off

ACC OWN VHL Ignition switch

ONDuring own vehicle indicator indication On

Other than the above Off

ACC SET SPEED Ignition switch

ONDuring set vehicle speed indicator not dis-

played

Off

During set vehicle speed indicator dis-

played Indicates the set vehicle speed

ACC UNIT Ignition switch

ONSet vehicle speed indicator unit display ON On

Set vehicle speed indicator unit display OFF Off

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 5448 of 5598

WCS-44

< SYMPTOM DIAGNOSIS >

THE LIGHT REMINDER WARNING DOES NOT SOUND

SYMPTOM DIAGNOSIS

THE LIGHT REMINDER WARNING DOES NOT SOUND

DescriptionINFOID:0000000006222532

Light reminder warning chime does not sound even though headlamp is illuminated.

Diagnosis ProcedureINFOID:0000000006222533

1.CHECK COMBINATION SWITCH (LIGHTING SWITCH) OPERATION

Check that the headlamps operate normally by operat ing the combination switch (lighting switch).

Do they operate normally?

YES >> GO TO 2.

NO >> Refer to EXL-113, "

Symptom Table".

2.CHECK DRIVER SIDE DOOR SWITCH SIGNAL CIRCUIT

Perform the check for the driver side door switch signal circuit. Refer to DLK-117, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair harness or connector.

3.CHECK DRIVER SIDE DOOR SWITCH

Perform a unit check for the driver side door switch. Refer to DLK-119, "

Component Inspection".

Is the inspection result normal?

YES >> Replace BCM. Refer to BCS-81, "Removal and Installation".

NO >> Replace driver side door switch. Refer to DLK-254, "

Removal and Installation".

Revision: 2010 May2011 QX56

Page 5520 of 5598

WW-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER & WASHER

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Component Description ............................................6

Washer Switch ..........................................................6

SYSTEM ..............................................................7

FRONT WIPER AND WASHER SYSTEM ............. ......7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Diagram ..............................................................

7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Description .........................................................

7

FRONT WIPER AND WASHER SYSTEM : Fail-

safe ...........................................................................

9

REAR WIPER AND WASHER SYSTEM ............... ....10

REAR WIPER AND WASHER SYSTEM : System

Diagram ...................................................................

10

REAR WIPER AND WASHER SYSTEM : System

Description ..............................................................

10

REAR WIPER AND WASHER SYSTEM :

Fail Safe .................................................................

12

HEADLAMP WASHER SYSTEM .......................... ....12

HEADLAMP WASHER SYSTEM : System Dia-

gram ........................................................................

13

HEADLAMP WASHER SYSTEM : System De-

scription ...................................................................

13

DIAGNOSIS SYSTEM (BCM) ............................14

COMMON ITEM ..................................................... ....14

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

14

WIPER .................................................................... ....15

WIPER : CONSULT-III Function (BCM - WIPER) ....15

DIAGNOSIS SYSTEM (IPDM E/R) ...................18

Diagnosis Description ..............................................18

CONSULT-III Function (IPDM E/R) .........................20

ECU DIAGNOSIS INFORMATION ..............23

BCM, IPDM E/R .................................................23

List of ECU Reference ......................................... ....23

WIRING DIAGRAM ......................................24

WIPER AND WASHER SYSTEM .....................24

Wiring Diagram .................................................... ....24

BASIC INSPECTION ...................................33

DIAGNOSIS AND REPAIR WORKFLOW ........33

Work Flow ............................................................ ....33

DTC/CIRCUIT DIAGNOSIS .........................35

WIPER AND WASHER FUSE ...........................35

Diagnosis Procedure ........................................... ....35

FRONT WIPER MOTOR LO CIRCUIT ..............36

Component Function Check ....................................36

Diagnosis Procedure ...............................................36

FRONT WIPER MOTOR HI CIRCUIT ...............37

Component Function Check ....................................37

Diagnosis Procedure ...............................................37

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

38

Component Function Check ....................................38

Diagnosis Procedure ...............................................38

Revision: 2010 May2011 QX56