Head lamp INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3379 of 5598

INT-30

< REMOVAL AND INSTALLATION >

HEADLINING

6. Disconnect harness connectors. Lane camera unit harness connector (1) (if equipped).

Inside mirror harness connector (2).

Light & rain sensor harness connector / rain sensor harness

connector (3).

7. Remove assist grips Insert a small flat-bladed screwdriver (A) into the gap between

assist grip cap (1), and then remove assist grip cap.

Remove assist grip mounting bolts, and then remove assist grips (2).

8. Insert a remover tool (A) between luggage room lamp (1) and roof garnish to disengage the fixing metal clips, and then discon-

nect luggage room lamp harness connector.

CAUTION:

Apply protective tape (B) to the roof garnish to protect from

damage.

9. Insert a remover tool (A) between roof garnish (1) and body panel to disengage the fixing clips and pawls, and then remove

roof garnish.

10. Remove front pillar garnish (LH and RH). Refer to INT-19, "

FRONT PILLAR GARNISH : Removal and

Installation".

11. Remove front kicking plate inner (LH and RH) and rear kicking plate inner (LH and RH). Refer to INT-20,

"KICKING PLATE INNER : Removal and Installation".

12. Remove dash side finisher (LH and RH). Refer to INT-18, "

DASH SIDE FINISHER : Removal and Installa-

tion".

13. Remove center pillar lower garnish (LH and RH). Refer to INT-22, "

CENTER PILLAR LOWER GARNISH :

Removal and Installation".

JMJIA4054ZZ

JMJIA4063ZZ

: Metal clip

JMLIA1059ZZ

: Clip

: Pawl

JMJIA4066ZZ

Revision: 2010 May2011 QX56

Page 3380 of 5598

HEADLININGINT-31

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

14. Remove luggage side lower finisher (LH and RH). Refer to INT-36, "LUGGAGE SIDE LOWER FINISHER

: Removal and Installation".

15. Remove front body side welt (LH and RH) and rear body side welt (LH and RH). Refer to INT-20, "

BODY

SIDE WELT : Removal and Installation".

16. Remove center pillar upper garnish (LH and RH). Refer to INT-22, "

CENTER PILLAR UPPER GARNISH :

Removal and Installation".

17. Remove rear pillar finisher (LH and RH). Refer to INT-37, "

REAR PILLAR FINISHER : Removal and

Installation".

18. Remove back pillar garnish (LH and RH). Refer to INT-37, "

BACK PILLAR GARNISH : Removal and

Installation".

19. Remove luggage side upper finisher (LH and RH). Refer to INT-38, "

LUGGAGE SIDE UPPER FINISHER

: Removal and Installation".

20. Insert a remover tool between map lamp assembly (1) and headlining assembly to disengage the fixing metal clips, and

then remove map lamp assembly.

21. Peel off dual lock fastener between headlining assembly and roof panel.

22. Remove headlining clips located at the rear side

23. Remove headlining assembly (1) through the back door.

CAUTION:

When removing, 2 workers are required.

Never bend headlini ng when removing.

Be careful not to scratch or damage any part of the body while taking out the headlining.

24. Remove the following parts after removing headlining assembly.

: Metal clip

JMJIA4062ZZ

JMJIA4068ZZ

Revision: 2010 May2011 QX56

Page 3381 of 5598

INT-32

< REMOVAL AND INSTALLATION >

HEADLINING

Personal lamp assembly. Refer to INL-77, "Removal and Installation".

Rear ventilator grille assembly. Refer to VTL-13, "

REAR VENTILATOR GRILLE : Removal and Installa-

tion".

Headlining harness.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Be careful not to bend h eadlining when installing.

First install metal clips of map lamp assembly and cl ips of the rear end of headlining for positioning.

Revision: 2010 May2011 QX56

Page 3433 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati INFINITI QX56 2011 Factory Service Manual

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communicati](/img/42/57033/w960_57033-3432.png)

LAN

TROUBLE DIAGNOSISLAN-13

< SYSTEM DESCRIPTION > [CAN FUNDAMENTAL]

C

D

E

F

G H

I

J

K L

B A

O P

N

NOTE:

When data link connector branch line is open, transmi

ssion and reception of CAN communication signals

are not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

The model (all units on CAN communication system are Diag on CAN) cannot perform CAN diagnosis with

CONSULT-III if the following error occurs. The error is judged by the symptom.

Example: Main Line Between Data Link Connector and ABS Actuator and Electr ic Unit (Control Unit) Open Circuit

Unit name Major symptom

ECM

Normal operation.

BCM

EPS control unit

Combination meter

ABS actuator and electric

unit (control unit)

TCM

IPDM E/R

Error Difference of symptom

Data link connector branch line open circuit Normal operation.

CAN-H, CAN-L harness short-circuit Most of the units which are connected to the CAN communication

system enter fail-safe mode or are deactivated.

SKIB8740E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter The shift position indicator and OD OFF indicator turn OFF.

The speedometer is inoperative.

The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3434 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract INFINITI QX56 2011 Factory Service Manual

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extract](/img/42/57033/w960_57033-3433.png)

LAN-14

< SYSTEM DESCRIPTION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: CAN-H, CAN-L Harness Short Circuit

CAN Diagnosis with CONSULT-IIIINFOID:0000000006220519

CAN diagnosis on CONSULT-III extracts the root

cause by receiving the following information.

Response to the system call

Control unit diagnosis information

Self-diagnosis

CAN diagnostic support monitor

SKIB8741E

Unit name Major symptom

ECM Engine torque limiting is affected, and shift harshness increases.

Engine speed drops.

BCM Reverse warning chime does not sound.

The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

The room lamp does not turn ON.

The engine does not start (if an error or malfunction occurs while turning the igni- tion switch OFF.)

The steering lock does not release (if an error or malfunction occurs while turning the ignition switch OFF.)

EPS control unit The steeri ng effort increases.

Combination meter The tachometer and the speedometer do not move.

Warning lamps turn ON.

Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R When the ignition switch is ON,

The headlamps (Lo) turn ON.

The cooling fan continues to rotate.

Revision: 2010 May2011 QX56

Page 3450 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

P range signal T R R

R range signal T R R

Shift position signal R R T R R R R R

Tow mode indicator lamp

signalTR

Pre-roll over signal T R

Pre-tensioner oper INFINITI QX56 2011 Factory Service Manual

LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

P range signal T R R

R range signal T R R

Shift position signal R R T R R R R R

Tow mode indicator lamp

signalTR

Pre-roll over signal T R

Pre-tensioner oper](/img/42/57033/w960_57033-3449.png)

LAN-30

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

P range signal T R R

R range signal T R R

Shift position signal R R T R R R R R

Tow mode indicator lamp

signalTR

Pre-roll over signal T R

Pre-tensioner operation

signal TR

AFS OFF indicator lamp

signal TR

A/C switch operation signal T R

Rear window defogger

switch signal TR

System selection signal T R

System setting signal TR R

RT

RT

Automatic back door re-

quest signal TR

Back door lock status signal T R

Buzzer output signal TR

RT

Buzzer request signal TR

RT

Dimmer signal T R R

Door switch signal T R R R R

Door unlock signal T R

Front fog light request sig-

nal TR

Front wiper request signal T R R

Handle position signal T R

Headlamp washer request

signal TR

High beam request signal T R R

Horn reminder signal T R

Ignition switch ON signal TRRR

RT

Ignition switch signal T R

Interlock/PNP switch signal TR

RT

Key ID signal T R

Key switch signal T R

Key warning lamp signal T R

Low beam request signal T R Signal name

ECM

4WD

ABS

TCM

A-BAG

AFSAV

BCM

CGW

HVAC

M&A

STRG

TPMS

IPDM-E ADP

PSB

E-SUS ICC

PWBD

Revision: 2010 May2011 QX56

Page 3674 of 5598

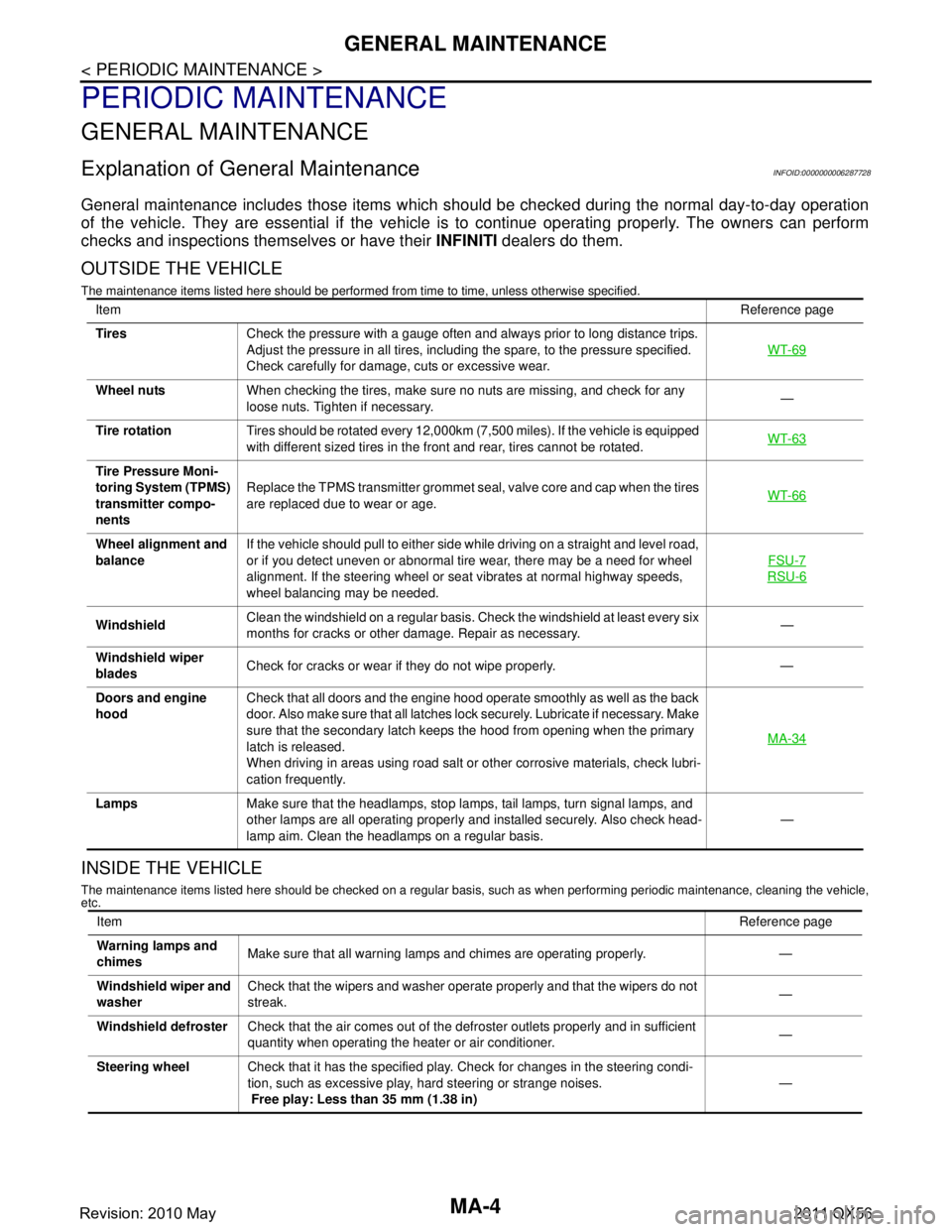

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56

Page 3775 of 5598

![INFINITI QX56 2011 Factory Service Manual

MWI-32

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

AIR PRES W/L

[On/Off]Status of low tire pressure warning lamp judged from low tire pressure warning

lamp signal received from BCM w INFINITI QX56 2011 Factory Service Manual

MWI-32

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

AIR PRES W/L

[On/Off]Status of low tire pressure warning lamp judged from low tire pressure warning

lamp signal received from BCM w](/img/42/57033/w960_57033-3774.png)

MWI-32

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (COMBINATION METER)

AIR PRES W/L

[On/Off]Status of low tire pressure warning lamp judged from low tire pressure warning

lamp signal received from BCM with CAN communication line.

KEY G/Y W/L

[On/Off] Status of KEY warning lamp

(Green/Yellow) detected from KEY warning lamp sig-

nal is received from BCM via CAN communication.

KEY KNOB W/L

[Off] This item is displayed, but cannot be monitored.

AFS OFF IND

[On/Off] Status of AFS OFF indicator lamp judged from AFS OFF indicator lamp signal re-

ceived from AFS control unit with CAN communication line.

DDS

* W/L

[Off] This item is displayed, but cannot be monitored.

LANE W/L

[On/Off] Status of lane departure warning lamp judged from lane departure warning lamp

signal received from ADAS control unit with CAN communication line.

LDP IND

[On/Off] Status of LDP ON indicator lamp judged from LDP ON indicator lamp signal re-

ceived from ADAS control unit with CAN communication line.

AT P W / L

[On/Off] Status of ATP warning lamp judged from ATP warning lamp signal received from

4WD control unit with CAN communication line.

DCA IND

[Off] This item is displayed, but cannot be monitored.

CHECK SUS IND

[On/Off] Status of CK SUSP indicator lamp judged from CK SUSP indicator lamp signal re-

ceived from E-SUS control unit with CAN communication line.

LCD

[B&P N, B&P I, ID NG, ROTAT, SFT

P, INSRT, BATT, NO KY, OUTKY, LK

WN] Displays status of Intelligent Key system warning judged from meter display signal

received from BCM with CAN communication line.

ACC TARGET

[On/Off] Status of vehicle ahead detection indicator judged from meter display signal re-

ceived from ADAS control unit with CAN communication line.

ACC DISTANCE

[Off, Short, Middle, Long] Status of set distance indicator judged from meter display signal received from

ADAS control unit with

CAN communication line.

ACC OWN VHL

[On/Off] Status of own vehicle indicator judged from meter display signal received from

ADAS control unit with

CAN communication line.

ACC SET SPEED

[Off, km/h] Status of set vehicle speed indicator judged from meter display signal received

from ADAS control unit with CAN communication line.

ACC UNIT

[On/Off] Status of display unit judged from meter display signal received from ADAS con-

trol unit with CAN communication line.

SHIFT IND

[P, R, N, D, M1, M2, M3, M4, M5, M6,

M7] Status of shift position indicator judged from shift position signal and manual mode

indicator signal received from TCM with CAN communication line.

4WD IND

[AUTO, LOCK, 2W, 4Lo, HL1, HL2,

MALF] Status of 4WD indicator judged from 4WD indicator signal received from 4WD

control unit with CAN communication line.

BSW IND

[Off] This item is displayed, but cannot be monitored.

BSW W/L

[On/Off] Status of BSW warning lamp (orange) judged from BSW warning lamp signal re-

ceived from ADAS control unit with CAN communication line.

AT S MODE SW

[On/Off] Status of snow mode switch.

M RANGE SW

[On/Off] Status of manual mode switch.

NM RANGE SW

[On/Off] Status of non-manual mode switch.

AT SFT UP SW

[On/Off] Status of manual mode shift up switch.

Display item [Unit]

MAIN

SIGNALS Description

Revision: 2010 May2011 QX56

Page 3780 of 5598

MWI

COMBINATION METERMWI-37

< ECU DIAGNOSIS INFORMATION >

C

DE

F

G H

I

J

K L

M B A

O P

DCA IND Ignition switch

ONNOTE:

This item is displayed, but cannot be moni-

tored.

Off

CHECK SUS IND Ignition switch

ONCK SUSP indicator lamp ON On

CK SUSP indicator lamp OFF Off

LCD Ignition switch

ON

During engine start in

formation indication B&P I

Ignition switch

ACC During engine start in

formation indication B&P N

Ignition switch

LOCK During key ID warning indication ID NG

Ignition switch

LOCK During steering lock information indication ROTAT

Ignition switch

LOCK During P position warning indication SFT P

Ignition switch

LOCK During Intelligent Key insert information in-

dication

INSRT

Ignition switch

LOCK During Intelligent Key low battery warning

indication

BATT

Ignition switch

ON During take away warning indication NO KY

Ignition switch

LOCK During key warning indication OUTKY

Ignition switch

ON During ACC warning indication LK WN

ACC TARGET Ignition switch

ONDuring vehicle ahead detection indicator in-

dication

On

Other than the above Off

ACC DISTANCE Ignition switch

ONWhen following distance set to “LONG” LONG

When following distance set to “MIDDLE” MID

When following distance set to “SHORT” SHORT

Set distance indicator not displayed Off

ACC OWN VHL Ignition switch

ONDuring own vehicle indicator indication On

Other than the above Off

ACC SET SPEED Ignition switch

ONDuring set vehicle speed indicator not dis-

played

Off

During set vehicle speed indicator dis-

played Indicates the set vehicle speed

ACC UNIT Ignition switch

ONSet vehicle speed indicator unit display ON On

Set vehicle speed indicator unit display OFF Off

Monitor Item Condition Value/Status

Revision: 2010 May2011 QX56

Page 3847 of 5598

![INFINITI QX56 2011 Factory Service Manual

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM a INFINITI QX56 2011 Factory Service Manual

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM a](/img/42/57033/w960_57033-3846.png)

PCS-6

< SYSTEM DESCRIPTION >[IPDM E/R]

SYSTEM

NOTE:

BCM controls the starter relay.

RELAY CONTROL SYSTEM : Fail-SafeINFOID:0000000006220163

CAN COMMUNICATION CONTROL

When CAN communication with ECM and BCM is impossible,

IPDM E/R performs fail-safe control. After CAN

communication recovers normally, it also returns to normal control.

If No CAN Communication Is Available With ECM

If No CAN Communication Is Available With BCM

Control relay Input/output Transmi t unit Control part Reference page

Headlamp low relay

Headlamp high relay Low beam request signal

High beam request signal

BCM (CAN)

Headlamp (LO)

Headlamp (HI) EXL-10

Front fog lamp relay Front fog light request signal BCM (CAN) Front fog lamp

EXL-20

Tail lamp relay Position light request signal BCM (CAN) Parking lamp

License plate

lamp

Tail lamp

Side marker lamp EXL-18

Illuminations

INL-6

Front wiper relay

Front wiper high relayFront wiper request signal BCM (CAN)

Front wiper motorWW-7Front wiper stop position sig-

nal Front wiper motor

Rear window defogger

relay Rear window defogger control

signal

BCM (CAN)

Rear window defog-

ger

DEF-6

Horn relay

Theft warning horn

relay Theft warning horn request

signal

Horn reminder signal BCM (CAN)

Horn (high)

Horn (low) SEC-17

Starter relayNOTE

Starter control relayStarter control rela

y signal BCM (CAN)

Starter motorSEC-10

,

SEC-10Steering lock unit condition

signal Steering lock unit

Starter relay control signal TCM

Steering lock relay Steering lock relay signal BCM (CAN)

Steering lock unitSEC-10

Steering lock unit condition

signal Steering lock unit

A/T shift selector (detention

switch) signal A/T shift selector

(detention switch)

A/C relay A/C compressor request sig-

nal ECM (CAN)

A/C compressor

(Magnet clutch) HAC-17

Headlamp washer relay

Headlamp washer request

signal BCM (CAN)Headlamp washer

pump WW-13

Ignition relay

Ignition relay-2

Ignition relay-3Ignition switch ON signal BCM (CAN)

Each control unit,

sensor, actuator and

relay (ignition power

supply)PCS-29Vehicle speed signal

Combination meter

(CAN)

Push-button ignition switch

signal Push-button ignition

switch

Control part Fail-safe operation

Cooling fan Transmits the pulse duty signal (PWM signal) 100% when the ignition switch is turned ON.

Transmits the pulse duty signal (PWM signal) 0% when the ignition switch is turned OFF.

A/C compressor A/C relay OFF

Alternator Transmits the power generation command signal (PWM signal) 0%

Revision: 2010 May2011 QX56