stop start INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4725 of 5598

![INFINITI QX56 2011 Factory Service Manual

SEC-118

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26F9 CRANKING REQUEST CIRCUIT

B26F9 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226276

DTC DETECTION LOGIC

NOTE:

DTC B26F9 can INFINITI QX56 2011 Factory Service Manual

SEC-118

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26F9 CRANKING REQUEST CIRCUIT

B26F9 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226276

DTC DETECTION LOGIC

NOTE:

DTC B26F9 can](/img/42/57033/w960_57033-4724.png)

SEC-118

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26F9 CRANKING REQUEST CIRCUIT

B26F9 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226276

DTC DETECTION LOGIC

NOTE:

DTC B26F9 can be detected even though the rela

ted circuit is not used in this vehicle.

If DTC B26F9 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to BCS-70, "

DTC Logic".

If DTC B26F9 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION

1. Start engine and wait 2 seconds or more at idle speed.

2. Drive vehicle for 2 seconds or more.

3. Check DTC in “Self Diagnostic Result ” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-118, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226277

1.CHECK CRANKING REQUEST SIGNAL

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector and ground under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK CRANKING REQUEST SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Disconnect ECM connector.

4. Check continuity between BCM harness connector and ECM harness connector.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B26F9 CRANK REQ CIR SHORT BCM detects that the status of the following

signals does not match.

Cranking request signal from ECM

Starter control relay control signal from

ECM (CAN) Harness or connectors

(Can communication line is open or

shorted.)

Harness or connectors (Cranking request signal circuit is open

or shorted.)

ECM

BCM

(+)

(–) Condition Voltage (V)

(Approx.)

BCM

Connector Terminal

M69 64 Ground Ignition switch ON Engine: Stopped

Selector lever position: P

0

Engine: Stopped

Selector lever position: Other than P 12

Engine running 12

Revision: 2010 May2011 QX56

Page 4727 of 5598

![INFINITI QX56 2011 Factory Service Manual

SEC-120

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26FA CRANKING REQUEST CIRCUIT

B26FA CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226278

DTC DETECTION LOGIC

NOTE:

DTC B26FA can INFINITI QX56 2011 Factory Service Manual

SEC-120

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26FA CRANKING REQUEST CIRCUIT

B26FA CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226278

DTC DETECTION LOGIC

NOTE:

DTC B26FA can](/img/42/57033/w960_57033-4726.png)

SEC-120

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B26FA CRANKING REQUEST CIRCUIT

B26FA CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226278

DTC DETECTION LOGIC

NOTE:

DTC B26FA can be detected even though the related circuit is not used in this vehicle.

If DTC B26FA is displayed with DTC U1000, first

perform the trouble diagnosis for DTC U1000. Refer to

BCS-70, "

DTC Logic".

If DTC B26FA is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010. Refer to

BCS-71, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION

1. Start engine and wait 2 seconds or more at idle speed.

2. Drive vehicle for 2 seconds or more.

3. Check DTC in “Self Diagnostic Result ” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-120, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226279

1.CHECK CRANKING REQUEST SIGNAL

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector and ground under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK CRANKING REQUEST SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Disconnect ECM connector.

4. Check continuity between BCM harness connector and ECM harness connector.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B26FA CRANK REQ CIR OPEN BCM detects that the status of the following

signals does not match.

Cranking request signal from ECM

Starter control relay

control signal from

ECM (CAN) Harness or connectors

(Can communication line is open or

shorted.)

Harness or connectors (Cranking request signal circuit is open

or shorted.)

BCM

ECM

(+)

(–) Condition Voltage (V)

(Approx.)

BCM

Connector Terminal

M69 64 Ground Ignition switch ON Engine: Stopped

Selector lever position: P

0

Engine: Stopped

Selector lever position: Other than P 12

Engine running 12

Revision: 2010 May2011 QX56

Page 4730 of 5598

![INFINITI QX56 2011 Factory Service Manual

B209F CRANKING REQUEST CIRCUITSEC-123

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B209F CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226282

DTC DET INFINITI QX56 2011 Factory Service Manual

B209F CRANKING REQUEST CIRCUITSEC-123

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B209F CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226282

DTC DET](/img/42/57033/w960_57033-4729.png)

B209F CRANKING REQUEST CIRCUITSEC-123

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B209F CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226282

DTC DETECTION LOGIC

NOTE:

DTC B209F can be detected even though the rela ted circuit is not used in this vehicle.

If DTC B209F is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

PCS-28, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait 1 second or more at idle speed.

2. Drive vehicle for 1 second or more.

3. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-123, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226283

1.CHECK CRANKING REQUEST SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R harness connector and ground under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK CRANKING REQUEST SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Disconnect ECM connector.

4. Check continuity between IPDM E/R harness connector and ECM harness connector.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B209F CRANK REQ CIR OPEN When the following items do not match, a

malfunction is detected.

Cranking request signal from ECM

Starter contro

l relay control signal from

ECM (CAN) Harness or connectors

(CAN communication line is open or

shorted.)

Harness or connectors

(Cranking request signal circuit is open

or shorted.)

IPDM E/R

ECM

(+)

(–) Condition Voltage (V)

(Approx.)

IPDM E/R

Connector Terminal

E13 23 Ground Ignition switch ON Engine: Stopped

Selector lever position: P

0

Engine: Stopped

Selector lever position: Other than P 12

Engine running 12

Revision: 2010 May2011 QX56

Page 4732 of 5598

![INFINITI QX56 2011 Factory Service Manual

B20A0 CRANKING REQUEST CIRCUITSEC-125

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B20A0 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226284

DTC DET INFINITI QX56 2011 Factory Service Manual

B20A0 CRANKING REQUEST CIRCUITSEC-125

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B20A0 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226284

DTC DET](/img/42/57033/w960_57033-4731.png)

B20A0 CRANKING REQUEST CIRCUITSEC-125

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

B20A0 CRANKING REQUEST CIRCUIT

DTC LogicINFOID:0000000006226284

DTC DETECTION LOGIC

NOTE:

DTC B20A0 can be detected although the related circuit is not used in this vehicle.

If DTC B20A0 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

PCS-28, "

DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and wait 1 second or more at idle speed.

2. Drive vehicle for 1 second or more.

3. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected?

YES >> Refer to SEC-125, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226285

1.CHECK CRANKING REQUEST SIGNAL

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R harness connector and ground under the following conditions.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK CRANKING REQUEST SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Disconnect ECM connector.

4. Check continuity between IPDM E/R harness connector and ECM harness connector.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B20A0 CRANK REQ CIR SHORT When the following items do not match, a

malfunction is detected.

Cranking request signal from ECM

Starter control relay

control signal from

ECM (CAN) Harness or connectors

(CAN communication line is open or

shorted.)

Harness or connectors

(Cranking request signal circuit is open or

shorted.)

IPDM E/R

ECM

(+)

(–) Condition Voltage (V)

(Approx.)

IPDM E/R

Connector Terminal

E13 23 Ground Ignition switch ON Engine: Stopped

Selector lever position: P

0

Engine: Stopped

Selector lever position: Other than P 12

Engine running 12

Revision: 2010 May2011 QX56

Page 5017 of 5598

ST-30

< PERIODIC MAINTENANCE >

POWER STEERING FLUID

PERIODIC MAINTENANCE

POWER STEERING FLUID

InspectionINFOID:0000000006225597

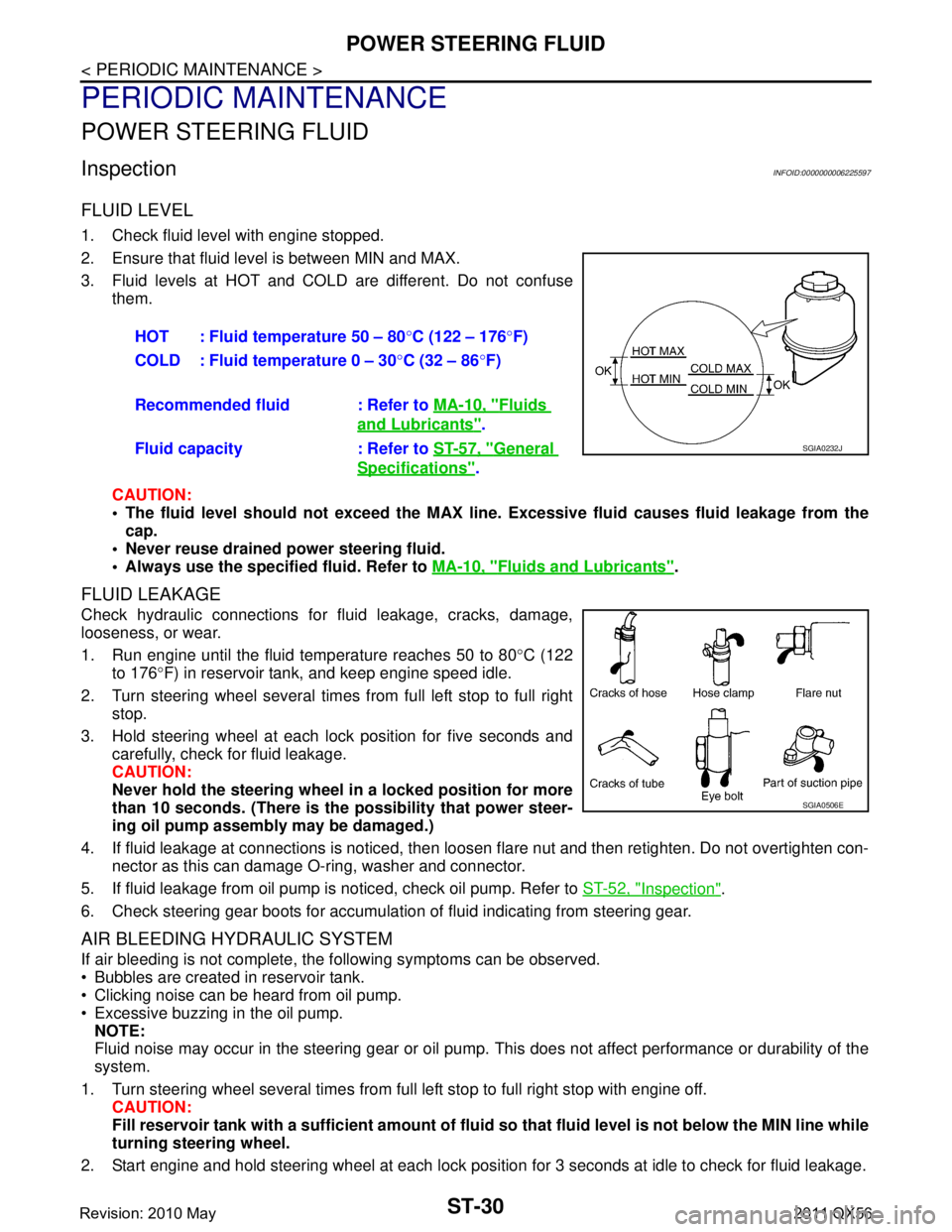

FLUID LEVEL

1. Check fluid level with engine stopped.

2. Ensure that fluid level is between MIN and MAX.

3. Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive flui d causes fluid leakage from the

cap.

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

FLUID LEAKAGE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80 °C (122

to 176 °F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right stop.

3. Hold steering wheel at each lock position for five seconds and carefully, check for fluid leakage.

CAUTION:

Never hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that power steer-

ing oil pump assembly may be damaged.)

4. If fluid leakage at connections is noticed, then loos en flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-52, "

Inspection".

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

AIR BLEEDING HYDRAULIC SYSTEM

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump. NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of the

system.

1. Turn steering wheel several times from full left stop to full right stop with engine off. CAUTION:

Fill reservoir tank with a sufficien t amount of fluid so that fluid level is not below the MIN line while

turning steering wheel.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

HOT : Fluid temperature 50 – 80

°C (122 – 176 °F)

COLD : Fluid temperature 0 – 30 °C (32 – 86 °F)

Recommended fluid : Refer to MA-10, "

Fluids

and Lubricants".

Fluid capacity : Refer to ST-57, "

General

Specifications".

SGIA0232J

SGIA0506E

Revision: 2010 May2011 QX56

Page 5086 of 5598

STR-18

< REMOVAL AND INSTALLATION >

STARTER MOTOR

Type: M001T30671

Removal and InstallationINFOID:0000000006275528

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-164, "Removal and Installation".

2. Remove engine cover. Refer to EM-25, "

Removal and Installation".

3. Remove intake manifold. Refer to EM-30, "

Removal and Installation".

4. Remove “B” terminal nut, and then “B” terminal harness.

5. Remove harness clip of “S ” connector from heater pipe.

6. Disconnect “S” connector.

7. Remove starter motor mounting bolts.

8. Remove starter motor upward from the vehicle.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Be careful to tighten “B” terminal nut carefully.

InspectionINFOID:0000000006275534

INSPECTION AFTER DISASSEMBLY

JPBIA2426GB

1. Magnetic switch assembly 2. Adjusting plate 3. “B” terminal extension

4. Gear case assembly 5. Stopper ring 6. Stopper

7. Pinion assembly 8. Internal gear 9. Yoke assembly

10. Armature assembly 11. Brush holder assembly 12. Metal RR

13. Rear cover 14. Through bolt 15. Packing

16. Ball 17. Planetary gear 18. Gear shaft

19. Dust cover kit 20. Shift lever

: High-temperature grease point

Refer to GI-4, "

Components" for symbols not described on the above.

Revision: 2010 May2011 QX56

Page 5088 of 5598

STR-20

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

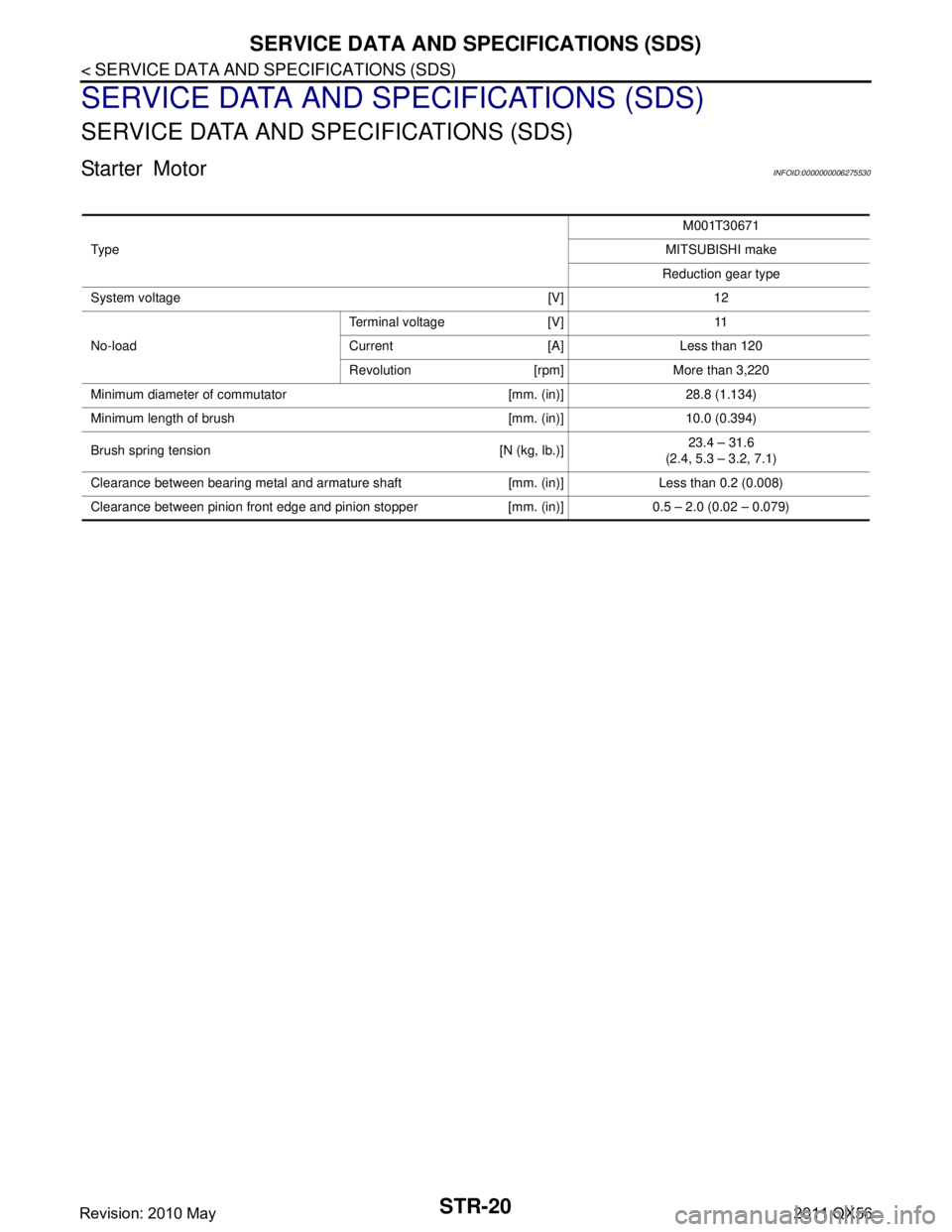

Starter MotorINFOID:0000000006275530

Ty p eM001T30671

MITSUBISHI make

Reduction gear type

System voltage [V] 12

No-load Terminal voltage [V] 11

Current [A] Less than 120

Revolution [rpm] More than 3,220

Minimum diameter of commutator [mm. (in)] 28.8 (1.134)

Minimum length of brush [mm. (in)] 10.0 (0.394)

Brush spring tension [N (kg, lb.)] 23.4 – 31.6

(2.4, 5.3 – 3.2, 7.1)

Clearance between bearing metal and armature shaft [mm. (in)] Less than 0.2 (0.008)

Clearance between pinion front edge and pinion stopper [mm. (in)] 0.5 – 2.0 (0.02 – 0.079)

Revision: 2010 May2011 QX56

Page 5099 of 5598

![INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2

INFINITI QX56 2011 Factory Service Manual

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2](/img/42/57033/w960_57033-5098.png)

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2

A/T fluid temperature sensor

Transmission range switch

Direct clutch solenoid valve

High and low reverse clutch solenoid valve

Input clutch solenoid valve

Front brake solenoid valve

Low brake solenoid valve

Anti-interlock solenoid valve

2346 brake solenoid valve

Line pressure solenoid valve

Torque converter clutch solenoid valve

A/T CONTROL SYSTEM : Component DescriptionINFOID:0000000006226739

Name Function

TCM TM-12, "

A/T CONTROL SYSTEM : TCM"

Transmission range switchTM-12, "A/T CONTROL SYSTEM : Transmission Range Switch"

Output speed sensor TM-12, "A/T CONTROL SYSTEM : Output Speed Sensor"

Input speed sensor 1

TM-12, "A/T CONTROL SYSTEM : Input Speed Sensor"Input speed sensor 2

A/T fluid temperature sensorTM-12, "

A/T CONTROL SYSTEM : A/T Fluid Temperature Sensor"

Input clutch solenoid valve TM-12, "A/T CONTROL SYSTEM : Input Clutch Solenoid Valve"

Front brake solenoid valve TM-12, "A/T CONTROL SYSTEM : Front Brake Solenoid Valve"

Direct clutch solenoid valveTM-12, "A/T CONTROL SYSTEM : Direct Clutch Solenoid Valve"

High and low reverse clutch solenoid valveTM-13, "A/T CONTROL SYSTEM : High and Low Reverse Clutch Solenoid Valve"

Low brake solenoid valve TM-13, "A/T CONTROL SYSTEM : Low Brake Solenoid Valve"

Anti-interlock solenoid valve TM-13, "A/T CONTROL SYSTEM : Anti-interlock Solenoid Valve"

2346 brake solenoid valve TM-13, "A/T CONTROL SYSTEM : 2346 Brake Solenoid Valve"

Torque converter clutch solenoid valveTM-13, "A/T CONTROL SYSTEM : Torque Converter Clutch Solenoid Valve"

Line pressure solenoid valve TM-13, "A/T CONTROL SYSTEM : Line Pressure Solenoid Valve"

Accelerator pedal position sensor TM-13, "A/T CONTROL SYSTEM : Accelerator Pedal Position Sensor"

Manual mode switch TM-13, "A/T CONTROL SYSTEM : Manual Mode Switch"

Tow mode switch TM-14, "A/T CONTROL SYSTEM : Tow Mode Switch"

A/T CHECK indicator lampTM-14, "A/T CONTROL SYSTEM : A/T CHECK Indicator Lamp"

Tow mode indicator lamp* TM-14, "A/T CONTROL SYSTEM : Tow Mode Indicator Lamp"

Selector lever position indicator TM-14, "A/T CONTROL SYSTEM : Selector Lever Position Indicator"

Stop lamp switch BRC-15, "Stop Lamp Switch"

Yaw rate/side G sensorBRC-15, "Yaw Rate/Side/Decel G sensor"

Starter relay STR-6, "System Description"

ECMEC-35, "ENGINE CONTROL SYSTEM : System Description"

BCM BCS-6, "BODY CONTROL SYSTEM : System Description"

Combination meter MWI-9, "METER SYSTEM : System Description"

ABS actuator and electric unit (control unit) BRC-16, "System Description"

Revision: 2010 May2011 QX56

Page 5132 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-44

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

SYSTEM

SYSTEM

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : System DiagramINFOID:0000000006226767

A/T CONTROL SYSTEM : System DescriptionINFOID:0000000006226768

I INFINITI QX56 2011 Factory Service Manual

TM-44

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

SYSTEM

SYSTEM

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : System DiagramINFOID:0000000006226767

A/T CONTROL SYSTEM : System DescriptionINFOID:0000000006226768

I](/img/42/57033/w960_57033-5131.png)

TM-44

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

SYSTEM

SYSTEM

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : System DiagramINFOID:0000000006226767

A/T CONTROL SYSTEM : System DescriptionINFOID:0000000006226768

INPUT/OUTPUT SIGNAL CHART

SYSTEM DESCRIPTION

The A/T senses vehicle operating conditions through vari

ous sensors or signals. It always controls the opti-

mum shift position and reduces shifting and lock-up shocks.

Receive input signals transmitted from various switches and sensors.

Determine required line pressure, shifting point, lock-up operation, etc.

JSDIA1853GB

Sensor (or signal)

⇒TCM function

⇒Actuator

Transmission range switch

Accelerator pedal position signal

Closed throttle position signal

Wide open throttle position signal

Engine speed signal

A/T fluid temperature sensor

Output speed sensor

Vehicle speed signal

Manual mode switch signal

Stop lamp switch signal

Input speed sensor 1, 2

Yaw rate/side/decel G sensor

Tow mode switch signal Line pressure control (

TM-48

)

Shift change control ( TM-50

)

Shift pattern control ( TM-54

)

Lock-up control ( TM-56

)

Fail-safe control ( TM-45

)

Self-diagnosis ( TM-61

)

CONSULT-III communication line ( TM-61

)

CAN communication line ( TM-103

)Input clutch solenoid valve

Direct clutch solenoid valve

Front brake solenoid valve

High and low reverse clutch solenoid valve

Low brake solenoid valve

Torque converter clutch solenoid valve

Line pressure solenoid valve

Anti-interlock solenoid valve

2346 brake solenoid valve

A/T CHECK indicator lamp

Tow mode indicator lamp

Shift position indicator

Back-up lamp relay

Starter relay

Revision: 2010 May2011 QX56

Page 5133 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMTM-45

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Transmit required output signals to the respective solenoids.

A/T CONTROL SYSTEM : Fail-SafeINFOID:0000000006226769 INFINITI QX56 2011 Factory Service Manual

SYSTEMTM-45

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Transmit required output signals to the respective solenoids.

A/T CONTROL SYSTEM : Fail-SafeINFOID:0000000006226769](/img/42/57033/w960_57033-5132.png)

SYSTEMTM-45

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Transmit required output signals to the respective solenoids.

A/T CONTROL SYSTEM : Fail-SafeINFOID:0000000006226769

TCM has the electrical fail-safe mode. The mode is divi ded into a maximum of 3 phases (1st fail-safe, 2nd fail-

safe and final fail-safe) and functions so that the operat ion can be continued even if the signal circuit of the

main electronically controlled input/output parts is damaged.

Even if the electronic circuit is normal, the fail-safe mode may start under special conditions (such as when the

brake pedal is depressed suddenly from a hard wheel spin st atus to stop the rotation of wheels). In this case,

turn the ignition switch OFF and back to ON after 5 seconds to resume the normal shift pattern.

Consequently, the customer's vehicle may already return to the normal condition. Refer to TM-88, "

Diagnosis

Flow".

FAIL-SAFE FUNCTION

1st Fail-SafeThe mode that the vehicle can stop safely, to prompt the driver to stop if the malfunction occurs and to shift to

2nd fail-safe early. It shifts to 2nd fail-safe or final fail-safe after the vehicle stopped.

2nd Fail-Safe The mode that the vehicle shifts to final fail-safe without changing the behavior, by identifying the malfunction-

ing parts in the condition that the driving force required for the driving is secured.

Final Fail-Safe Selects the shifting pattern that the malfunctioning parts identified at 1st fail-safe and 2nd fail-safe are not

used, and then secure the driving force that is required for the driving.

The mode that the shifting performance does not decrease by normal shift control.

DTC Veh ic le

condition Vehicle behavior for 1st fail-safe Vehicle behavior for 2nd fail-safe Vehicle behavior for final fail-safe

P0615 — Starter is disabled — Starter is disabled

P0705 — Fixed in the “D” position (The

shifting can be performed)

30 km/h (19MPH) or less

Lock-up is prohibited

The shifting between the gears of 3 - 4 - 5 - 6 - 7 can be per-

formed

Manual mode is prohibited

Shift position indicator is switched OFF

Starter relay is switched OFF (starter is disabled)

Back-up lamp is OFF

Large shift shock — Fixed in the “D” position (The

shifting can be performed)

30 km/h (19 MPH) or less

Lock-up is prohibited

The shifting between the gears of 3 - 4 - 5 - 6 - 7 can be per-

formed

Manual mode is prohibited

Shift position indicator is switched OFF

Starter relay is switched OFF (starter is disabled)

Back-up lamp is OFF

Large shift shock

P0710 Between

the gears of 1 - 2 - 3 The shifting between the gears

of 1 - 2 - 3 can be performed

Manual mode is prohibited —

The shifting between the gears

of 1 - 2 - 3 can be performed

Manual mode is prohibited

Between

the gears of 4 - 5 - 6 - 7 Fix the gear while driving

Manual mode is prohibited

—

P0717 Between

the gears of

1 - 2 - 3 The shifting between the gears

of 1 - 2 - 3 can be performed

Manual mode is prohibited —

The shifting between the gears

of 1 - 2 - 3 can be performed

Manual mode is prohibited

Between

the gears of 4 - 5 - 6 - 7 Fix the gear while driving

Manual mode is prohibited

—

Revision: 2010 May2011 QX56