torque INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5352 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

60. Install converter housing to transmission case, and tighten con-

verter housing bolts ( ) to the specified torque.

61. INFINITI QX56 2011 Factory Service Manual

TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

60. Install converter housing to transmission case, and tighten con-

verter housing bolts ( ) to the specified torque.

61.](/img/42/57033/w960_57033-5351.png)

TM-264

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

60. Install converter housing to transmission case, and tighten con-

verter housing bolts ( ) to the specified torque.

61. Connect TCM connector (A).

62. Install joint connector (1) to the control valve & TCM. CAUTION:

Apply ATF to O-ring of joint connector.

63. Install the control valve & TCM (1) to transmission case.

CAUTION:

JPDIA1107ZZ

JSDIA1813ZZ

JSDIA1719ZZ

JSDIA1823ZZ

Revision: 2010 May2011 QX56

Page 5353 of 5598

![INFINITI QX56 2011 Factory Service Manual

TRANSMISSION ASSEMBLYTM-265

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Make sure that input speed sen sor securely installs input

speed sensor holes (A).

Ha INFINITI QX56 2011 Factory Service Manual

TRANSMISSION ASSEMBLYTM-265

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Make sure that input speed sen sor securely installs input

speed sensor holes (A).

Ha](/img/42/57033/w960_57033-5352.png)

TRANSMISSION ASSEMBLYTM-265

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Make sure that input speed sen sor securely installs input

speed sensor holes (A).

Hang down output speed sensor harness toward outside

so as not to disturb installa tion of the control valve &

TCM.

Adjust A/T assembly harness connector of the control

valve & TCM to terminal ho le of transmission case.

Assemble it so that manual valve cutout is engaged with manual plate projection.

64. Install bolts and clip (1) to the control valve & TCM. Tighten bolt (E) to the specified torque before tightening the other than bolts.

*: Reamer bolt

65. Connect output speed sensor connector (A).

66. Engage output speed sensor harness with terminal clips ( ).

JPDIA1106ZZ

SCIA5035E

: Front

Bolt symbol Length mm (in) Number of bolts A 43 (1.69) 3

B 40 (1.57) 2

C 54 (2.13) 6

D 50 (1.97) 2

E* 50 (1.97) 1

JPDIA1105ZZ

JPDIA1104ZZ

Revision: 2010 May2011 QX56

Page 5354 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-266

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

67. Pull down joint connector (1).

CAUTION:

Be careful not to damage connector.

68. Install snap ring (1) to joint connect INFINITI QX56 2011 Factory Service Manual

TM-266

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

67. Pull down joint connector (1).

CAUTION:

Be careful not to damage connector.

68. Install snap ring (1) to joint connect](/img/42/57033/w960_57033-5353.png)

TM-266

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

67. Pull down joint connector (1).

CAUTION:

Be careful not to damage connector.

68. Install snap ring (1) to joint connector (2).

69. Install magnets (1) in oil pan.

70. Install oil pan gasket to transmission case. CAUTION:

Never reuse oil pan gasket.

Install it in the direction to align hole positions.

Completely remove all moisture, oil and old gasket, etc.from oil pan gasket mounting surface.

71. Install oil pan (2) and clips (1) to transmission case. CAUTION:

Be careful not to pinch harnesses.

Completely remove all moisture, oil and old gasket, etc.from oil pan mounting surface.

72. Tighten oil pan mounting bolts to the specified torque in numeri- cal order shown in the figure after temporarily tightening them.

Tighten oil pan mounting bolts to the specified torque.

CAUTION:

Never reuse oil pan mounting bolts.

73. Install drain plug to oil pan. Tighten drain plug to the specified torque.

CAUTION:

Never reuse drain plug gasket.

JSDIA1764ZZ

JSDIA1765ZZ

JPDIA0009ZZ

: Front

: Oil pan mounting bolt

JSDIA1591ZZ

: Front

JSDIA1592GB

Revision: 2010 May2011 QX56

Page 5355 of 5598

![INFINITI QX56 2011 Factory Service Manual

TRANSMISSION ASSEMBLYTM-267

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

74. Pour ATF into torque converter. Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of INFINITI QX56 2011 Factory Service Manual

TRANSMISSION ASSEMBLYTM-267

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

74. Pour ATF into torque converter. Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of](/img/42/57033/w960_57033-5354.png)

TRANSMISSION ASSEMBLYTM-267

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

74. Pour ATF into torque converter. Approximately 2 liter (2-1/8 US qt, 1-3/4 Imp qt) of ATF is

required for a new torque converter.

When reusing old torque co nverter, add the same amount

of ATF as was drained.

75. Install torque converter while aligning notches of torque con- verter with notches of oil pump.

CAUTION:

Install torque converte r while rotating it.

76. Measure dimension “A” to make sure that torque converter is in proper position.

InspectionINFOID:0000000006226919

INSPECTION AFTER REMOVAL

Oil Pan

Check foreign materials in oil pan to help determine causes of mal-

function. If the ATF is very dark, smells burned, or contains foreign

particles, the frictional material (clutches, band) may need replace-

ment. A tacky film that will not wipe clean indicates varnish build up.

Varnish can cause valves, servo, and clutches to stick and can

inhibit pump pressure.

If frictional material is detected, perform A/T fluid cooler

cleaning. Refer to TM-97, "

Cleaning".

Torque Converter

SAT428DA

SCIA5010E

B: Scale

C : Straightedge

Dimension “A” : Refer to TM-297, "Torque Converter".

JPDIA0042ZZ

SCIA5199E

Revision: 2010 May2011 QX56

Page 5356 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-268

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

Check torque converter one-way clutch using a check tool as shown

at figure.

1. Insert a check tool into the groove of bea INFINITI QX56 2011 Factory Service Manual

TM-268

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

Check torque converter one-way clutch using a check tool as shown

at figure.

1. Insert a check tool into the groove of bea](/img/42/57033/w960_57033-5355.png)

TM-268

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

Check torque converter one-way clutch using a check tool as shown

at figure.

1. Insert a check tool into the groove of bearing support built into

one-way clutch outer race.

2. When fixing bearing support with a check tool, rotate one-way clutch spline using a screwdriver.

3. Make sure that inner race rotates clockwise only. If not, replace

torque converter assembly.

1st One-way Clutch

Check operation of 1st one-way clutch.

1. Install 1st one-way clutch (1) to front brake hub (with under drivecarrier).

2. Hold 1st one-way clutch.

3. Check front brake hub for correct locking and unlocking direc- tions. If necessary, replace 1st one-way clutch.

Under Drive Sun Gear

Check for deformation, fatigue or damage. If necessary, replace the under drive sun gear.

Mid Carrier Assembly

Check for deformation, fatigue or damage. If necessary, replace the mid carrier assembly.

Rear Carrier Assembly

Check for deformation, fatigue or damage. If necessary, replace the rear carrier assembly.

Reverse Brake Drive Plates

Check facing for burns, cracks or damage. If necessary, replace the plate.

Reverse Brake Retaining Plate, Driven Plates and Dish Plates

Check facing for burns, cracks or damage. If necessary, replace the plate.

Each Snap Ring

Check for deformation, fatigue or damage. If necessary, replace the snap ring.

Parking Actuator Support and Parking Pawl

SCIA3171E

: Unlocked

: Locked

JSDIA1713ZZ

Revision: 2010 May2011 QX56

Page 5363 of 5598

![INFINITI QX56 2011 Factory Service Manual

OIL PUMP, 2346 BRAKE, FRONT BRAKE PISTONTM-275

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

3. Using the drift, install oil pump housing oil seal to the oil pump h INFINITI QX56 2011 Factory Service Manual

OIL PUMP, 2346 BRAKE, FRONT BRAKE PISTONTM-275

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

3. Using the drift, install oil pump housing oil seal to the oil pump h](/img/42/57033/w960_57033-5362.png)

OIL PUMP, 2346 BRAKE, FRONT BRAKE PISTONTM-275

< UNIT DISASSEMBLY AND ASSEMBLY > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

3. Using the drift, install oil pump housing oil seal to the oil pump housing until it is flush.

CAUTION:

Never reuse oil seal.

Apply ATF to oil seal.

4. Install oil pump housing to oil pump cover and tighten bolts ( ) to the specified torque in numerical order shown in the figure

after temporarily tightening them.

5. Install D-ring (large) (1) and D-ring (small) (2) to 2346 brake pis- ton.

6. Install 2346 brake piston (1) to oil pump assembly.

7. Install D-ring (inner) (1) and D-ring (outer) (2) to front brake pis- ton.

SCIA5313E

JPDIA1101ZZ

JPDIA1100ZZ

JSDIA1722ZZ

JPDIA1098ZZ

Revision: 2010 May2011 QX56

Page 5384 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-296

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationIN INFINITI QX56 2011 Factory Service Manual

TM-296

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationIN](/img/42/57033/w960_57033-5383.png)

TM-296

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000006226944

*1: Refer to

MA-10, "Fluids and Lubricants".

*2: The fluid capacity is the reference value.

Vehicle Speed at Which Gear Shifting OccursINFOID:0000000006226945

NORMAL MODE

Unit: km/h (MPH)

At half throttle, the accelerator opening is 4/8 of the full opening.

TOW MODE

Applied model 2WD 4WD

Transmission model code number 1XR1E 1XR1D

Stall torque ratio 1.93 : 1

Transmission gear ratio 1st 4.887

2nd 3.170

3rd 2.027

4th 1.412

5th 1.000

6th 0.864

7th 0.775

Reverse 4.041

Recommended fluid Genuine NISSAN Matic S ATF

*1

Fluid capacity10.0 liter (10-5/8 US qt, 8-3/4 Imp qt)*2

CAUTION:

Use only Genuine NISSAN Matic S ATF. Never mix with other ATF.

Using ATF other than Genuine NISSAN Matic S ATF will cause deterioration driveability and A/T durability, and may damage

the A/T, which is not covered by the INFINITI new vehicle limited warranty.

Gear position Throttle position

Full throttle Half throttle

D

1 → D256 – 60 (35 – 37) 42 – 46 (26 – 29)

D

2 → D389 – 97 (55 – 60) 73 – 81 (45 – 50)

D

3 → D4141 – 151 (88 – 94) 112 – 122 (70 – 76)

D

4 → D5205 – 215 (127 – 134) 134 – 144 (83 – 89)

D

5 → D6250 – 260 (155 – 162) 173 – 183 (108 – 114)

D

6 → D7250 – 260 (155 – 162) 206 – 216 (128 – 134)

D

7 → D6240 – 250 (149 – 155) 161 – 171 (100 – 106)

D

6 → D5240 – 250 (149 – 155) 130 – 140 (81 – 87)

D

5 → D4180 – 190 (112 – 118) 84 – 94 (52 – 58)

D

4 → D3126 – 136 (78 – 85) 58 – 68 (36 – 42)

D

3 → D266 – 74 (41 – 46) 30 – 38 (19 – 24)

D

2 → D123 – 27 (14 – 17) 10 – 14 (6 – 9)

Revision: 2010 May2011 QX56

Page 5385 of 5598

![INFINITI QX56 2011 Factory Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-297

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Unit: km/h (MPH)

At half throttle, the accelerator opening is 4/ INFINITI QX56 2011 Factory Service Manual

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-297

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Unit: km/h (MPH)

At half throttle, the accelerator opening is 4/](/img/42/57033/w960_57033-5384.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

TM-297

< SERVICE DATA AND SPECIFICATIONS (SDS) [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Unit: km/h (MPH)

At half throttle, the accelerator opening is 4/8 of the full opening.

The vehicle speed included in the above table is a speed with the tow mode ON and a heavy load towed.

Vehicle Speed at Which Lock-up Occurs/ReleasesINFOID:0000000006226946

Vehicle speed with D5 position.

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

Stall SpeedINFOID:0000000006226947

2WD MODELS

4WD MODELS

*: Refer to DLN-18, "4WD SYSTEM : System Description".

Torque ConverterINFOID:0000000006226948

Gear position Throttle position

Full throttle Half throttle

D

1 → D257 – 61 (35 – 38) 50 – 54 (31 – 34)

D

2 → D389 – 97 (55 – 60) 76 – 84 (47 – 52)

D

3 → D4141 – 151 (88 – 94) 116 – 126 (72 – 78)

D

4 → D5205 – 215 (127 – 134) 159 – 169 (99 – 105)

D

5 → D6251 – 261 (156 – 162) 189 – 199 (117 – 124)

D

6 → D7251 – 261 (156 – 162) 215 – 225 (134 – 140)

D

7 → D6240 – 250 (149 – 155) 161 – 171 (100 – 106)

D

6 → D5240 – 250 (149 – 155) 130 – 140 (81 – 87)

D

5 → D4180 – 190 (112 – 118) 84 – 94 (52 – 58)

D

4 → D3126 – 136 (78 – 85) 58 – 68 (36 – 42)

D

3 → D266 – 74 (41 – 46) 30 – 38 (19 – 24)

D

2 → D124 – 28 (15 – 17) 10 – 14 (6 – 9)

Throttle position Vehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 50 – 58 (31 – 36) 50 – 58 (31 – 36)

Half throttle 163 – 171 (101 – 106) 163 – 171 (101 – 106)

Sta ll sp ee d 1,777 – 2,077 rpm

4WD shift switch* AUTO, 4H 4L

Stall speed 1,777 – 2,077 rpm 1,540 – 1,840 rpm

Dimension between end of converter housing and torque converter 24.0 mm (0.94 in)

Revision: 2010 May2011 QX56

Page 5513 of 5598

ROAD WHEELWT-63

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

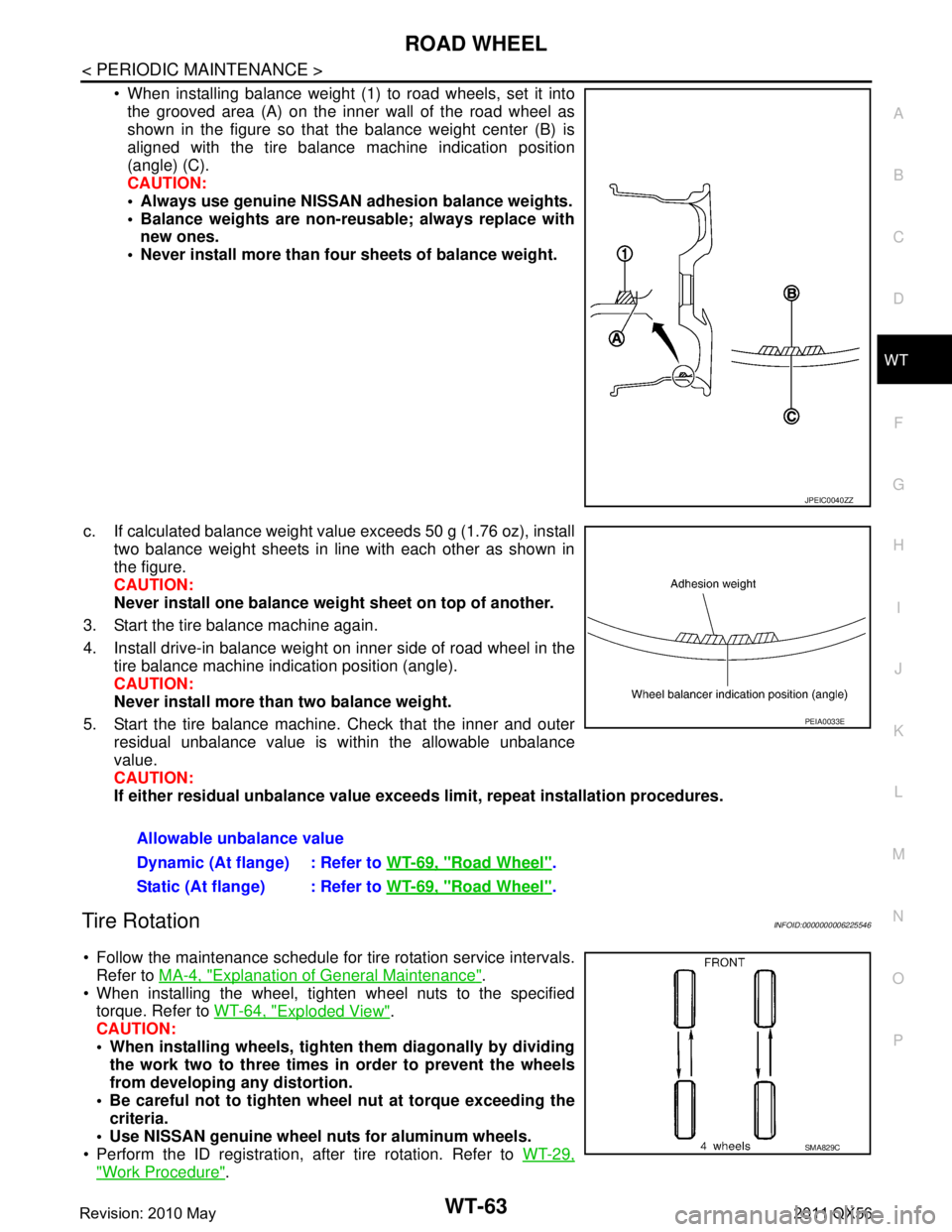

When installing balance weight (1) to road wheels, set it into the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

Always use genuine NISSAN ad hesion balance weights.

Balance weights are non-re usable; always replace with

new ones.

Never install more than four sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Never install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Never install more than two balance weight.

5. Start the tire balance machine. Check that the inner and outer residual unbalance value is within the allowable unbalance

value.

CAUTION:

If either residual unbalan ce value exceeds limit, repeat installation procedures.

Tire RotationINFOID:0000000006225546

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-4, "

Explanation of General Maintenance".

When installing the wheel, tighten wheel nuts to the specified torque. Refer to WT-64, "

Exploded View".

CAUTION:

When installing wheels, tighte n them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wh eel nut at torque exceeding the

criteria.

Use NISSAN genuine wheel nuts for aluminum wheels.

Perform the ID registration, after tire rotation. Refer to WT-29,

"Work Procedure".

JPEIC0040ZZ

Allowable unbalance value

Dynamic (At flange) : Refer to WT-69, "

Road Wheel".

Static (At flange) : Refer to WT-69, "

Road Wheel".

PEIA0033E

SMA829C

Revision: 2010 May2011 QX56