TPMS INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3577 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTO INFINITI QX56 2011 Factory Owners Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTO](/img/42/57033/w960_57033-3576.png)

LAN

TPMS BRANCH LINE CIRCUITLAN-157

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 2)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256300

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the low ti re pressure warning control unit for damage, bend and

loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressure warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3609 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTO INFINITI QX56 2011 Factory Owners Manual

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTO](/img/42/57033/w960_57033-3608.png)

LAN

TPMS BRANCH LINE CIRCUITLAN-189

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 3)]

C

D

E

F

G H

I

J

K L

B A

O P

N

TPMS BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256347

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the low ti re pressure warning control unit for damage, bend and

loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressure warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3636 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-216

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256387

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

INFINITI QX56 2011 Factory Owners Manual

LAN-216

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256387

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/42/57033/w960_57033-3635.png)

LAN-216

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 4)]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006256387

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the low tire pressure warning control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressu re warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56

Page 3674 of 5598

MA-4

< PERIODIC MAINTENANCE >

GENERAL MAINTENANCE

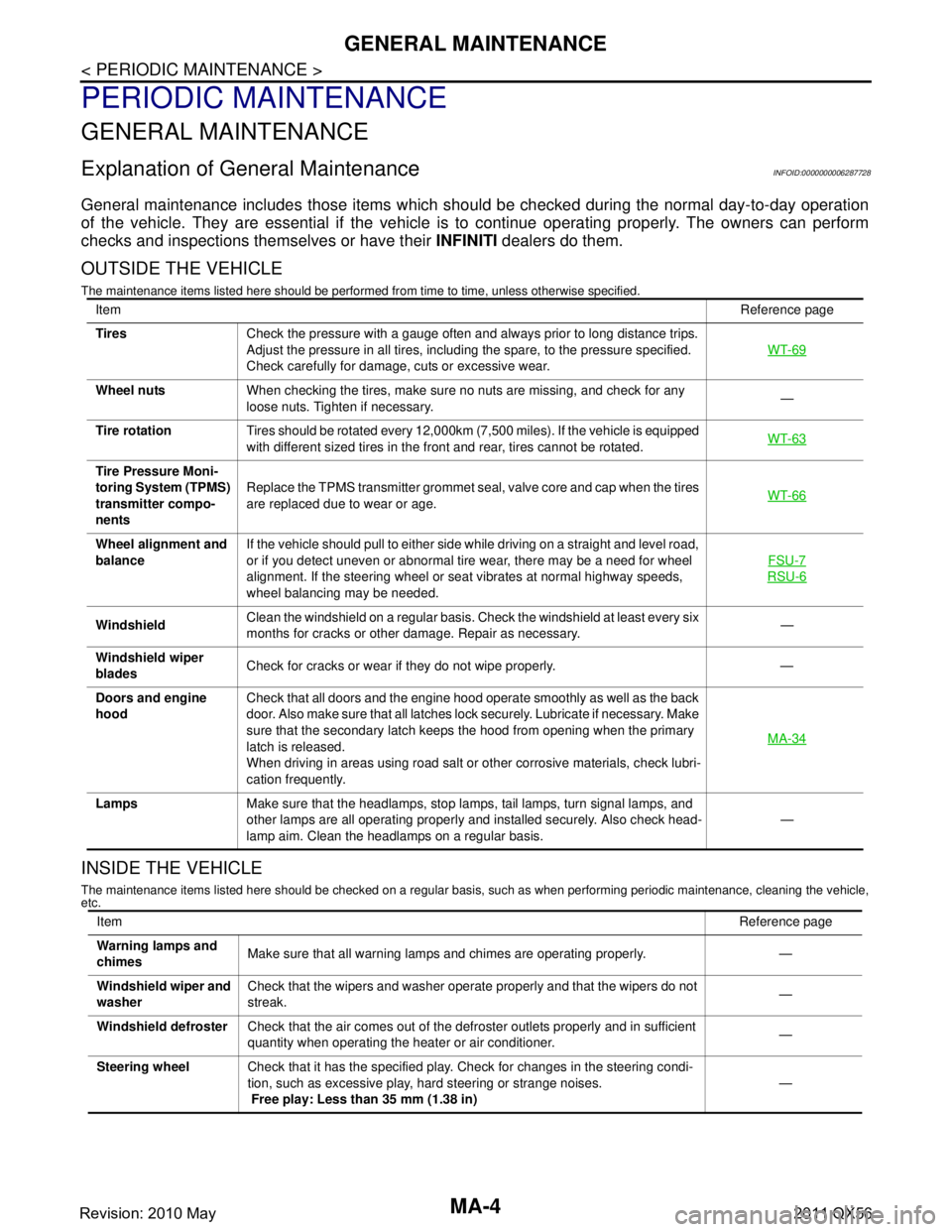

PERIODIC MAINTENANCE

GENERAL MAINTENANCE

Explanation of General MaintenanceINFOID:0000000006287728

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed fr om time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the pressure specified.

Check carefully for damage, cuts or excessive wear. WT-69

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary. —

Tire rotation Tires should be rotated every 12,000km (7,500 miles). If the vehicle is equipped

with different sized tires in the front and rear, tires cannot be rotated. WT-63

Tire Pressure Moni-

toring System (TPMS)

transmitter compo-

nentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-66

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

RSU-6

Windshield

Clean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary. —

Windshield wiper

blades Check for cracks or wear if they do not wipe properly. —

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the back

door. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently. MA-34

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head-

lamp aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly. —

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner. —

Steering wheel Check that it has the specified play. Check for changes in the steering condi-

tion, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Revision: 2010 May2011 QX56

Page 5451 of 5598

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for TPMS ...................4

Service Notice or Precautions for Road Wheel .........4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

Commercial Service Tools ........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................7

Low Tire Pressure Warning Control Unit ...................7

Transmitter ................................................................7

Tire Pressure Receiver .............................................8

Low Tire Pressure Warning Lamp .............................8

SYSTEM ..............................................................9

System Description ............................................. ......9

Tire Inflation Indicator Function ...............................10

DIAGNOSIS SYSTEM (LOW TIRE PRES-

SURE WARNING CONTROL UNIT) ..................

12

CONSULT-III Function ........................................ ....12

ECU DIAGNOSIS INFORMATION ..............14

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ..................................................... ....

14

Reference Value ................................................. ....14

DTC Inspection Priority Chart .................................17

DTC Index ...............................................................18

WIRING DIAGRAM ......................................19

TIRE PRESSURE MONITORING SYSTEM ......19

Wiring Diagram .................................................... ....19

BASIC INSPECTION ...................................25

DIAGNOSIS AND REPAIR WORK FLOW .......25

Work Flow ............................................................ ....25

ADDITIONAL SERVICE WHEN REPLACING

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ........................................................

27

Description ...............................................................27

Work Procedure .......................................................27

TRANSMITTER WAKE UP OPERATION .........28

Description ...............................................................28

Work Procedure .......................................................28

ID REGISTRATION ...........................................29

Description ...............................................................29

Work Procedure .......................................................29

DTC/CIRCUIT DIAGNOSIS .........................31

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

31

DTC Logic ............................................................ ....31

Diagnosis Procedure ...............................................31

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

33

DTC Logic ............................................................ ....33

Diagnosis Procedure ...............................................33

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

37

DTC Logic ............................................................ ....37

Diagnosis Procedure ...............................................37

C1728 RECEIVER ID ........................................39

Revision: 2010 May2011 QX56

Page 5452 of 5598

WT-2

DTC Logic ...............................................................39

Diagnosis Procedure ..............................................39

C1729 VEHICLE SPEED SIGNAL ....................41

DTC Logic ............................................................ ...41

Diagnosis Procedure ..............................................41

C1750, C1751, C1752, C1753 RECEIVER ........42

DTC Logic ............................................................ ...42

Diagnosis Procedure ..............................................42

C1754 LOW TIRE PRESSURE WARNING

CONTROL UNIT ................................................

45

DTC Logic ............................................................ ...45

Diagnosis Procedure ..............................................45

C1755, C1756, C1757, C1758 POOR RE-

CEIVING CONDITIONS .....................................

47

DTC Logic ............................................................ ...47

Diagnosis Procedure ..............................................47

U1000 CAN COMM CIRCUIT ............................49

Description ........................................................... ...49

DTC Logic ...............................................................49

Diagnosis Procedure ..............................................49

U1010 CONTROL UNIT (CAN) .........................50

Description ........................................................... ...50

DTC Logic ...............................................................50

Diagnosis Procedure ..............................................50

POWER SUPPLY AND GROUND CIRCUIT .....51

Diagnosis Procedure ........................................... ...51

LOW TIRE PRESSURE WARNING LAMP .......52

Component Function Check ................................ ...52

Diagnosis Procedure ..............................................52

SYMPTOM DIAGNOSIS .............................53

TPMS SYMPTOMS ......................................... ...53

Symptom Table ................................................... ...53

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN ON .......................................

56

Description ........................................................... ...56

Diagnosis Procedure ..............................................56

LOW TIRE PRESSURE WARNING LAMP

DOES NOT TURN OFF .....................................

57

Description ........................................................... ...57

Diagnosis Procedure ..............................................57

LOW TIRE PRESSURE WARNING LAMP

BLINKS ..............................................................

58

Description ........................................................... ...58

Diagnosis Procedure ............................................ ...58

TIRE INFLATION INDICATOR DOES NOT

ACTIVATE .........................................................

59

Description ........................................................... ...59

Diagnosis Procedure ...............................................59

ID REGISTRATION CANNOT BE COMPLET-

ED ......................................................................

60

Description ........................................................... ...60

Diagnosis Procedure ..............................................60

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

61

NVH Troubleshooting Chart ................................. ...61

PERIODIC MAINTENANCE .......................62

ROAD WHEEL ................................................ ...62

Adjustment ........................................................... ...62

Tire Rotation ...........................................................63

REMOVAL AND INSTALLATION ..............64

ROAD WHEEL TIRE ASSEMBLY ................. ...64

Exploded View ..................................................... ...64

Removal and Installation .........................................64

Inspection ................................................................64

LOW TIRE PRESSURE WARNING CON-

TROL UNIT ........................................................

65

Exploded View ..................................................... ...65

Removal and Installation .........................................65

TRANSMITTER .................................................66

Exploded View ..................................................... ...66

Removal and Installation .........................................66

TIRE PRESSURE RECEIVER ...........................68

Exploded View ..................................................... ...68

FRONT TIRE PRESSURE RECEIVER .................. ...68

FRONT TIRE PRESSURE RECEIVER : Removal

and Installation ........................................................

68

REAR TIRE PRESSURE RECEIVER .......................68

REAR TIRE PRESSURE RECEIVER : Removal

and Installation ..................................................... ...

68

SERVICE DATA AND SPECIFICATIONS

(SDS) .......... ................................................

69

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ...

69

Road Wheel ......................................................... ...69

Tire Air Pressure .....................................................69

Revision: 2010 May2011 QX56

Page 5454 of 5598

WT-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for TPMSINFOID:0000000006225485

Low tire pressure warning lamp blinks for 1min, then turns ON when occurring any malfunction except low tire pressure. Erase the self-diagnosis memories for low tire pressure warning control unit, or register the ID

to turn low tire pressure warning lamp OFF. For ID registration, refer to WT-29, "

Work Procedure".

ID registration is required when replacing or rotating wheel s, replacing transmitter or low tire pressure warn-

ing control unit. Refer to WT-29, "

Work Procedure".

Replace grommet seal, valve core and cap of transmitter in TPMS, when replacing each tire by reaching the

wear limit. Refer to WT-66, "

Exploded View".

For tire inflation indicator function, refer to the following.

- When inflating the tires, park the vehicle in the safe area and ensure the safety of the working area.

- Read and understand the tire inflation indicator function prior to use.

- Inflate the tires one at a time.

- If there is no response for approximately 15 seconds or mo re after inflating the tires, cancel the use of the

tire inflation indicator function or move the vehicle approximately 1 m (3.2 ft) backward or forward to try

again. The air filler pressure may be weak or out of service area.

- Despite the high-precision TPMS pressure sensor, an i ndicated value may differ from that of the pressure

gauge.

- Air pressure is measured rather high due to the rise in tire air temperature after driving.

- If TPMS is malfunctioning, the tire inflation indicator is unusable.

Service Notice or Precautions for Road WheelINFOID:0000000006225486

Genuine NISSAN aluminum wheel is designed for each type of vehicle. Use it on the specified vehicle only.

Use Genuine NISSAN parts for the wheel nuts.

Always use them after adjusting the wheel balance. For the balance weights, use Genuine NISSAN alumi-

num wheel weights.

Use caution when handling the aluminum wheels, because they can be easily scratched. When removing

dirt, do not use any abrasives, a wire brush, or other it ems that may scratch the coating. Use a neutral deter-

gent if a detergent is needed.

After driving on roads scattered with anti-ici ng salts, wash off the wheels completely.

When installing road wheels onto the vehicle, always wipe of f any dirt or foreign substances to prevent them

from being trapped between the contact surfaces of wheel.

Never apply oil to nut and bolt threads.

Revision: 2010 May2011 QX56

Page 5457 of 5598

COMPONENT PARTSWT-7

< SYSTEM DESCRIPTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

Component DescriptionINFOID:0000000006225489

*: Mainly used for the tire inflation function.

Low Tire Pressure Warning Control UnitINFOID:0000000006225490

After the low tire pressure warning control unit (1) receives the tire pressure signal from the tire pressure receiver, it controls the oper-

ation of the low tire pressure warning lamp, hazard warning lamp,

and horn.

NOTE:

The hazard warning lamp and the horn are used for the tire infla-

tion indicator function.

Performs self-diagnosis of the Tire Pressure Monitoring System

(TPMS).

Controls tire inflation indicator function.

TransmitterINFOID:0000000006225491

The transmitter (1) is installed at the position of the air valve on the

road wheel (2). It measures the ti re pressure and transmits the tire

pressure information by radio waves.

Component parts Reference/Function

Transmitter WT-7, "

Transmitter"

Tire pressure receiverWT-8, "Tire Pressure Receiver"

Low tire pressure warning control unit WT-7, "Low Tire Pressure Warning Control Unit"

Low tire pressure warning lamp WT-8, "Low Tire Pressure Warning Lamp"

AV control unit AV- 1 0 , "Component Description"

BCMBCS-6, "BODY CONTROL SYSTEM : System Description"

ABS actuator and electric unit (control unit)BRC-16, "System Description"

TCM*TM-10, "A/T CONTROL SYSTEM : Component Parts Location"

JPEIC0071ZZ

: Outside

JPEIC0013ZZ

Revision: 2010 May2011 QX56

Page 5459 of 5598

SYSTEMWT-9

< SYSTEM DESCRIPTION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

SYSTEM

System DescriptionINFOID:0000000006225494

During driving, the TPMS (Tire Pressure Monitoring System) receives the signal transmitted from transmitter

installed in each wheel. The low tire pressure warning control unit has pressure judgment and trouble diag-

nosis functions. When the low tire pressure warning control unit detects low inflation pressure or another

unusual symptom, the low tire pressure warning lamps in the combination meter comes on.

If the tire pressure is less than the specified value, t he low tire pressure warning lamp illuminates that the tire

pressure is less than the specified value.

Activates the TPMS (Tire Pressure Monitoring Sy stem) when the vehicle speed is 40 km/h (25 MPH) or

more.

The tire pressure information for each wheel is displayed on the vehicle information display.

Added tire inflation indicator function to TPMS (Tire Pressure Monitoring System). Refer to WT-10, "

Tire

Inflation Indicator Function".

SYSTEM DIAGRAM

INPUT/OUTPUT SIGNAL

The signal transmission/reception between units via a comm unication line is mainly as listed in the following

table.

JPEIC0084GB

Component parts Signal item

Low tire pressure warning control

unit Transmits the following signals via CAN communication to BCM.

Low tire pressure

warning lamp signal

Hazard request signal

Horn request signal*

Transmits the following signals via CAN communication to the AV control unit.

Low tire pressure warning lamp signal

Tire pressure data signal

BCM Transmits the following signal via CAN communication to the combination meter, based on sig-

nals from low tire pressure warning control unit.

Low tire pressure

warning lamp signal

Transmits the following signal via CAN communication to the IPDM E/R, based on signals from

low tire pressure wa rning control unit.

Horn request signal*

Receives the following signal via CAN communication from low tire pressure warning control

unit.

Hazard request signal

AV control unit Receives the following signals via CAN communication from low tire pressure warning control

unit.

Low tire pressure

warning lamp signal

Tire pressure data signal

Revision: 2010 May2011 QX56

Page 5462 of 5598

WT-12

< SYSTEM DESCRIPTION >

DIAGNOSIS SYSTEM (LOW TIRE PRESSURE WARNING CONTROL UNIT)

DIAGNOSIS SYSTEM (LOW TIRE PRESSURE WARNING CONTROL

UNIT)

CONSULT-III FunctionINFOID:0000000006225496

APPLICATION ITEMS

CONSULT-III performs the following functions in combinat ion of data reception, instruction, and transmission

via communication lines from low tire pressure warning control unit.

*: The following diagnosis information is erased by erasing.

DTC

ECU IDENTIFICATION

Part number of low tire pressure warning control unit is displayed.

SELF DIAGNOSIS RESULTS

Refer to WT-18, "DTC Index".

DATA MONITOR

ACTIVE TEST

NOTE:

After completing the work below, perform an active test.

1. Check ID registration state and perform self-diagnosis.

2. Erase the self-diagnosis result history.

Mode FUNCTION DESCRIPTION

ECU IDENTIFICATION Displays the part number of low tire pressure warning control unit.

SELF-DIAGNOSIS RESULTS Self-diagnosis result can be quickly read.

*

DATA MONITOR Input and output data of low tire pressure warning control unit can be read.

ACTIVE TESTSends command to the low tire pressure warning control unit to change output signals and check

operation of output system.

WORK SUPPORT Components can be quickly and accurately adjusted.

Monitor item (Unit) Remarks

VHCL SPEED SE

[(km/h) or (MPH)] Vehicle speed is displayed.

AIR PRESS FL

[(kPa), (kg/cm

2) or (Psi)] Air pressure of front LH tires is displayed.

AIR PRESS FR

[(kPa), (kg/cm

2) or (Psi)] Air pressure of front RH tires is displayed.

AIR PRESS RR

[(kPa), (kg/cm

2) or (Psi)] Air pressure of rear

RH tires is displayed.

AIR PRESS RL

[(kPa), (kg/cm

2) or (Psi)] Air pressure of rear

LH tires is displayed.

ID REGST FL1 ID registration status of front LH transmitter is displayed.

ID REGST FR1 ID registration status of front RH transmitter is displayed.

ID REGST RR1 ID registration status of rear RH transmitter is displayed.

ID REGST RL1 ID registration status of rear LH transmitter is displayed.

WARNING LAMP Control status of low tire pressure warning lamp is displayed.

BUZZER Control status of buzzer in combination meter by low tire pressure warning con-

trol unit is displayed.

NOTE:

Not use in TPMS, but displayed.

Revision: 2010 May2011 QX56