air filter INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4461 of 5598

SE-2

SECOND HEATED SEAT SYSTEM : System De-

scription ..................................................................

16

CLIMATE CONTROLLED SEAT SYSTEM ........... ...17

CLIMATE CONTROLLED SEAT SYSTEM : Sys-

tem Diagram ........................................................ ...

17

CLIMATE CONTROLLED SEAT SYSTEM : Sys-

tem Description .................................................... ...

17

CLIMATE CONTROLLED SEAT SYSTEM : Fail-

safe .........................................................................

17

ECU DIAGNOSIS INFORMATION ..............20

CLIMATE CONTROLLED SEAT CONTROL

UNIT ................................................................ ...

20

Reference Value .................................................. ...20

Fail-safe ..................................................................21

WIRING DIAGRAM .....................................24

POWER SEAT CONTROL SYSTEM (PAS-

SENGER SIDE) ............................................... ...

24

Wiring Diagram .................................................... ...24

LUMBAR SUPPORT SYSTEM ..........................28

Wiring Diagram .................................................... ...28

SECOND SEAT POWER UNLOCK SYSTEM ...33

Wiring Diagram .......................................................33

THIRD SEAT SEATBACK POWER FOLDING

SYSTEM .......................................................... ...

39

Wiring Diagram .................................................... ...39

FRONT HEATED SEAT SYSTEM .....................45

Wiring Diagram .................................................... ...45

SECOND HEATED SEAT SYSTEM ..................50

Wiring Diagram .................................................... ...50

CLIMATE CONTROLLED SEAT SYSTEM .......55

Wiring Diagram .................................................... ...55

BASIC INSPECTION ...................................66

DIAGNOSIS AND REPAIR WORK FLOW ..... ...66

Work Flow ............................................................ ...66

DTC/CIRCUIT DIAGNOSIS ...................... ...67

POWER SUPPLY AND GROUND CIRCUIT .. ...67

CLIMATE CONTROLLED SEAT CONTROL UNIT ...67

CLIMATE CONTROLLED SEAT CONTROL UNIT

: Diagnosis Procedure ............................................

67

CLIMATE CONTROLLED SEAT CONTROL UNIT

: Component Inspection ..........................................

70

CLIMATE CONTROLLED SEAT SWITCH ........72

Component Function Check .............................. ...72

Diagnosis Procedure ..............................................72

Component Inspection ............................................74

SEATBACK THERMAL ELECTRIC UNIT ........75

Component Function Check ............................... ...75

Diagnosis Procedure ...............................................75

SEATBACK THERMAL ELECTRIC UNIT

SENSOR ............................................................

77

Component Function Check ............................... ...77

Diagnosis Procedure ...............................................77

Component Inspection ............................................78

SEAT CUSHION THERMAL ELECTRIC UNIT ...79

Component Function Check ............................... ...79

Diagnosis Procedure ...............................................79

SEAT CUSHION THERMAL ELECTRIC UNIT

SENSOR ............................................................

81

Component Function Check ............................... ...81

Diagnosis Procedure ...............................................81

Component Inspection ............................................82

CLIMATE CONTROLLED SEATBACK

BLOWER MOTOR .............................................

83

Component Function Check ............................... ...83

Diagnosis Procedure ...............................................83

CLIMATE CONTROLLED SEAT CUSHION

BLOWER MOTOR .............................................

86

Component Function Check ............................... ...86

Diagnosis Procedure ...............................................86

CLIMATE CONTROLLED SEAT SWITCH IN-

DICATOR ...........................................................

89

Component Function Check ............................... ...89

Diagnosis Procedure ...............................................89

CLIMATE CONTROLLED SEAT BLOWER

FILTER ...............................................................

91

SEATBACK BLOWER MOTOR ............................. ...91

SEATBACK BLOWER MOTOR : Diagnosis Pro-

cedure .....................................................................

91

SEAT CUSHION BLOWER MOTOR ..................... ...91

SEAT CUSHION BLOWER MOTOR : Diagnosis

Procedure ...............................................................

91

SYMPTOM DIAGNOSIS ............................92

CLIMATE CONTROLLED SEAT DOES NOT

OPERATE. ...................................................... ...

92

Diagnosis Procedure ............................................ ...92

TEMPERATURE ADJUSTMENT IS IMPOSSI-

BLE ....................................................................

94

SEATBACK ............................................................ ...94

SEATBACK : Diagnosis Procedure ........................94

SEAT CUSHION ..................................................... ...94

SEAT CUSHION : Diagnosis Procedure .................94

Revision: 2010 May2011 QX56

Page 4553 of 5598

SE-94

< SYMPTOM DIAGNOSIS >

TEMPERATURE ADJUSTMENT IS IMPOSSIBLE

TEMPERATURE ADJUSTMENT IS IMPOSSIBLE

SEATBACK

SEATBACK : Diagnosis ProcedureINFOID:0000000006217413

1.CHECK CLIMATE CONTROLLED SEATBACK BLOWER FILTER

Check climate controlled seatback blower filter.

Refer to SE-91, "

SEATBACK BLOWER MOTOR : Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK CLIMATE CONTROLLED SEAT SWITCH

Check climate controlled seat switch.

Refer to SE-72, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK SEATBACK THERMAL ELECTRIC UNIT SENSOR

Check seatback thermal electric unit sensor.

Refer to SE-81, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK SEATBACK THERMAL ELECTRIC UNIT

Check seatback thermal electric unit.

Refer to SE-75, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CHECK CLIMATE CONTROLLED SEATBACK BLOWER MOTOR

Check climate controlled seatback blower motor.

Refer to SE-83, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Repair or replace the malfunctioning parts.

6.CONFIRM THE OPERATION

Confirm the operation again.

Is the inspection result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

SEAT CUSHION

SEAT CUSHION : Diagnosis ProcedureINFOID:0000000006217414

1.CHECK CLIMATE CONTROLLED SEAT CUSHION BLOWER FILTER

Check climate controlled seat cushion blower filter.

Refer to SE-91, "

SEAT CUSHION BLOWER MOTOR : Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

Revision: 2010 May2011 QX56

Page 4569 of 5598

SE-110

< REMOVAL AND INSTALLATION >

FRONT SEAT

16. Seat cushion trim 17. Seat cushion pad 18. Seat control unit

19. Seat cushion front finisher 20. Front inner slide cover 21. Front outer slide cover

22. Seat cushion climate controlled seat duct finisher 23. Seat cushion thermal electric unit 24. Seat cushion climate controlled seat

hook (front)

25. Seat cushion climate controlled seat duct 26. Seat cushion climate controlled seat

blower filter 27. Climate controlled seat cushion

blower motor

28. Seat cushion climate controlled seat harness 29. Seat cushion climate controlled seat

hook (rear) 30. Seat cushion climate controlled seat

bracket

31. Climate controlled seat control unit 32. Seat cushion outer finisher 33. Seat slide and lifter switch knob

34. Seat reclining switch knob 35. Seat control switch 36. Lumber support switch

37. Seat control switch cover 38. Seat cushion outer finisher inside (rear)39. Seat cushion outer finisher inside

(front)

40. Seat harness 41. Rear outer slide cover 42. Seat cushion lower outer finisher

43. Side air bag module 44. Seatback board 45. Headrest display harness and upper tube

46. Headrest display harness 47. Clip 48. Seatback climate controlled seat duct

49. Climate controlled seatback blower motor 50. Climate controlled seatback blower

motor bracket 51. Seatback climate controlled seat

blower filter

52. Seatback thermal electric unit 53. Seatback thermal electric unit brack- et54. Seatback climate controlled seat

duct finisher

55. Seat cushion lower inner finisher 56. Rear inner slide cover 57. Headrest display harness lower tube

58. Lumber support unit assembly 59. Seat frame assembly

: Pawl

: Metal clip

Refer to GI-4, "

Components" for symbols in the figure.

Revision: 2010 May2011 QX56

Page 4802 of 5598

COMPONENT PARTSSRC-9

< SYSTEM DESCRIPTION >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

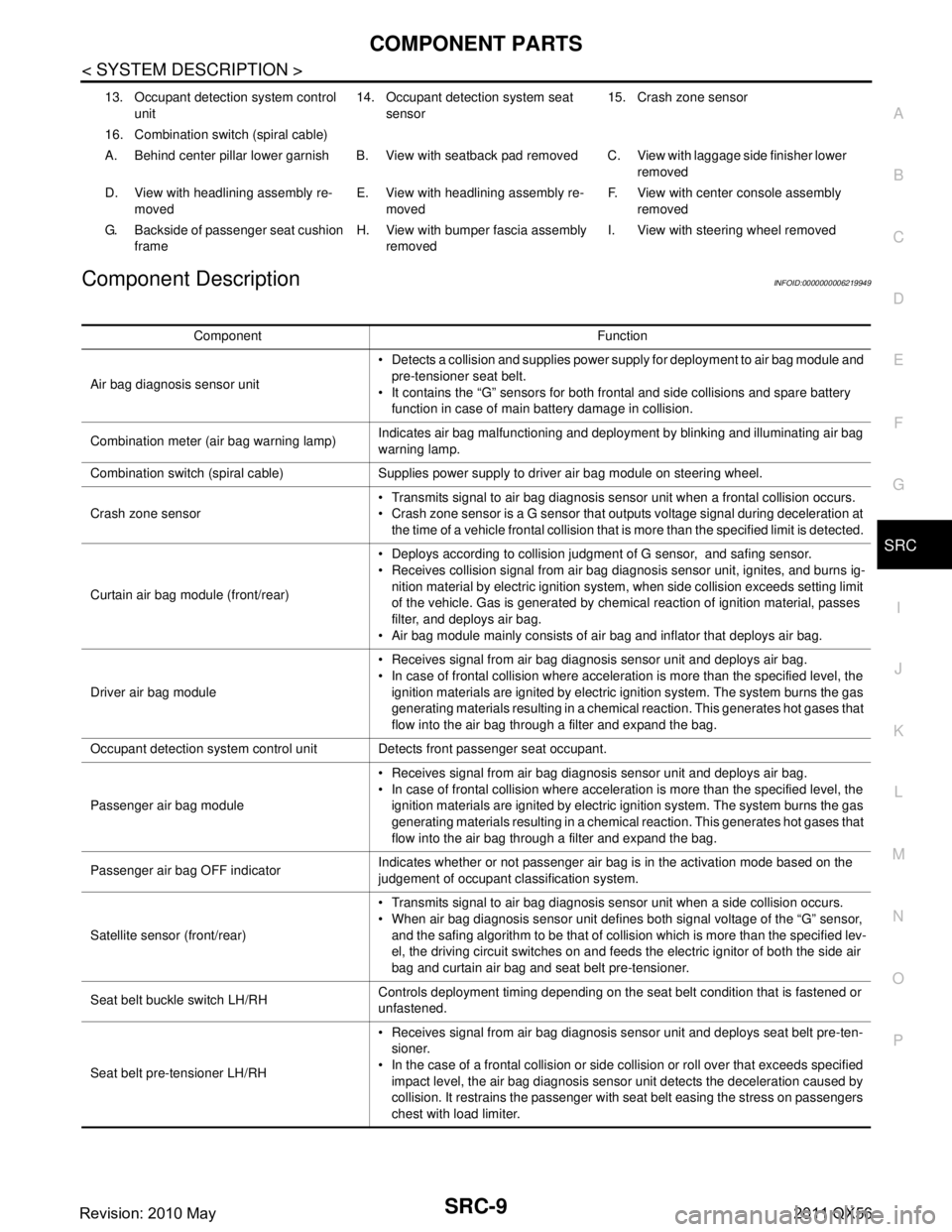

Component DescriptionINFOID:0000000006219949

13. Occupant detection system control unit 14. Occupant detection system seat

sensor 15. Crash zone sensor

16. Combination switch (spiral cable)

A. Behind center pillar lower garnish B. View with seatback pad removed C. View with laggage side finisher lower removed

D. View with headlining assembly re- moved E. View with headlining assembly re-

moved F. View with center console assembly

removed

G. Backside of passenger seat cushion frame H. View with bumper fascia assembly

removed I. View with steering wheel removed

Component Function

Air bag diagnosis sensor unit Detects a collision and supplies power supply for deployment to air bag module and

pre-tensioner seat belt.

It contains the “G” sensors for both frontal and side collisions and spare battery function in case of main battery damage in collision.

Combination meter (air bag warning lamp) Indicates air bag malfunctioning and deployment by blinking and illuminating air bag

warning lamp.

Combination switch (spiral cable) Supplies power supply to driver air bag module on steering wheel.

Crash zone sensor Transmits signal to air bag diagnosis sensor unit when a frontal collision occurs.

Crash zone sensor is a G sensor that outputs voltage signal during deceleration at

the time of a vehicle frontal collision that is more than the specified limit is detected.

Curtain air bag module (front/rear) Deploys according to collision judgment of G sensor, and safing sensor.

Receives collision signal from air bag diagnosis sensor unit, ignites, and burns ig-

nition material by electric ignition system, when side collision exceeds setting limit

of the vehicle. Gas is generated by chemical reaction of ignition material, passes

filter, and deploys air bag.

Air bag module mainly consists of air bag and inflator that deploys air bag.

Driver air bag module Receives signal from air bag diagnosis sensor unit and deploys air bag.

In case of frontal collision where acceleration is more than the specified level, the

ignition materials are ignited by electric ignition system. The system burns the gas

generating materials resulting in a chemical reaction. This generates hot gases that

flow into the air bag through a filter and expand the bag.

Occupant detection system control unit Detects front passenger seat occupant.

Passenger air bag module Receives signal from air bag diagnosis sensor unit and deploys air bag.

In case of frontal collision where acceleration is more than the specified level, the

ignition materials are ignited by electric ignition system. The system burns the gas

generating materials resulting in a chemical reaction. This generates hot gases that

flow into the air bag through a filter and expand the bag.

Passenger air bag OFF indicator Indicates whether or not passenger air bag is in the activation mode based on the

judgement of occupant classification system.

Satellite sensor (front/rear) Transmits signal to air bag diagnosis sensor unit when a side collision occurs.

When air bag diagnosis sensor unit defines both signal voltage of the “G” sensor,

and the safing algorithm to be that of collision which is more than the specified lev-

el, the driving circuit switches on and feeds the electric ignitor of both the side air

bag and curtain air bag and seat belt pre-tensioner.

Seat belt buckle switch LH/RH Controls deployment timing depending on the seat belt condition that is fastened or

unfastened.

Seat belt pre-tensioner LH/RH Receives signal from air bag diagnosis sensor unit and deploys seat belt pre-ten-

sioner.

In the case of a frontal collision or side collision or roll over that exceeds specified impact level, the air bag diagnosis sensor unit detects the deceleration caused by

collision. It restrains the passenger with seat belt easing the stress on passengers

chest with load limiter.

Revision: 2010 May2011 QX56

Page 4803 of 5598

SRC-10

< SYSTEM DESCRIPTION >

COMPONENT PARTS

Side air bag module LH/RH Receives signal from air bag diagnosis sensor unit and deploys air bag.

In case of side collision where acceleration is more than the specified level, the ig-

nition materials are ignited by electric ignition system. The system burns the gas

generating materials resulting in a chemical reaction. This generates hot gases that

flow into the air bag through a filter and expand the bag.

Lap pre-tensioner LH/RH Receives signal from air bag diagnosis sensor unit and deploys lap pre-tensioner.

In the case of a frontal collision or side collision or roll over that exceeds specified

impact level, the air bag diagnosis sensor unit detects the deceleration caused by

collision. It restrains the passenger with seat belt easing the stress on passengers

chest with load limiter.

Lap pre-tensioner upgrades passenger restrain function by reducing movement of lumber during a frontal collision or side collision or roll over.

Component Function

Revision: 2010 May2011 QX56

Page 4805 of 5598

SRC-12

< SYSTEM DESCRIPTION >

SYSTEM

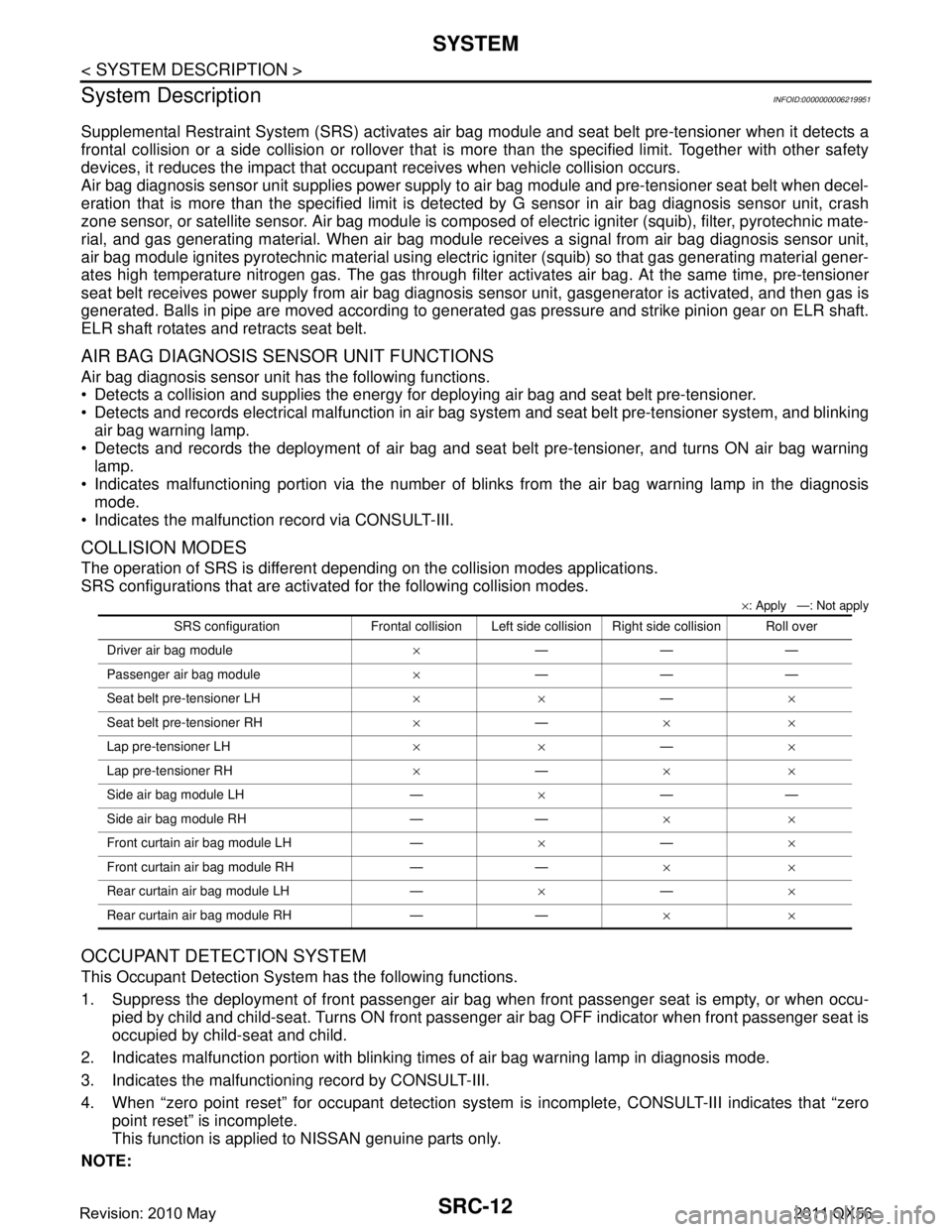

System Description

INFOID:0000000006219951

Supplemental Restraint System (SRS ) activates air bag module and seat belt pre-tensioner when it detects a

frontal collision or a side collision or rollover that is more than the specified limit. Together with other safety

devices, it reduces the impact that occup ant receives when vehicle collision occurs.

Air bag diagnosis sensor unit supplies power supply to air bag module and pre-tensioner seat belt when decel-

eration that is more than the specified limit is detec ted by G sensor in air bag diagnosis sensor unit, crash

zone sensor, or satellite sensor. Air bag module is composed of electric igniter (squib), filter, pyrotechnic mate-

rial, and gas generating material. When air bag module re ceives a signal from air bag diagnosis sensor unit,

air bag module ignites pyrotechnic material using electric igniter (squib) so that gas generating material gener-

ates high temperature nitrogen gas. The gas through filter activates air bag. At the same time, pre-tensioner

seat belt receives power supply from air bag diagnosis sensor unit, gasgenerator is activated, and then gas is

generated. Balls in pipe are moved according to generated gas pressure and strike pinion gear on ELR shaft.

ELR shaft rotates and retracts seat belt.

AIR BAG DIAGNOSIS SENSOR UNIT FUNCTIONS

Air bag diagnosis sensor unit has the following functions.

Detects a collision and supplies the energy for deploying air bag and seat belt pre-tensioner.

Detects and records electrical malfunction in air bag system and seat belt pre-tensioner system, and blinking

air bag warning lamp.

Detects and records the deployment of air bag and s eat belt pre-tensioner, and turns ON air bag warning

lamp.

Indicates malfunctioning portion via the number of blin ks from the air bag warning lamp in the diagnosis

mode.

Indicates the malfunction record via CONSULT-III.

COLLISION MODES

The operation of SRS is different depending on the collision modes applications.

SRS configurations that are activa ted for the following collision modes.

×: Apply —: Not apply

OCCUPANT DETECTION SYSTEM

This Occupant Detection System has the following functions.

1. Suppress the deployment of front passenger air bag w hen front passenger seat is empty, or when occu-

pied by child and child-seat. Turns ON front passenger air bag OFF indicator when front passenger seat is

occupied by child-seat and child.

2. Indicates malfunction portion with blinking times of air bag warning lamp in diagnosis mode.

3. Indicates the malfunctioning record by CONSULT-III.

4. When “zero point reset” for occupant detection system is incomplete, CONSULT-III indicates that “zero

point reset” is incomplete.

This function is applied to NISSAN genuine parts only.

NOTE:

SRS configuration Frontal collision Left side collision Right side collision Roll over

Driver air bag module ×———

Passenger air bag module ×———

Seat belt pre-tensioner LH ××—×

Seat belt pre-tensioner RH ×— ××

Lap pre-tensioner LH ××—×

Lap pre-tensioner RH ×— ××

Side air bag module LH — ×——

Side air bag module RH — — ××

Front curtain air bag module LH — ×— ×

Front curtain air bag module RH — — ××

Rear curtain air bag module LH — ×— ×

Rear curtain air bag module RH — — ××

Revision: 2010 May2011 QX56

Page 5186 of 5598

![INFINITI QX56 2011 Factory Owners Manual

TM-98

< BASIC INSPECTION >[7AT: RE7R01B]

A/T FLUID COOLER

DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte

rior may lead to inaccurate debris identification.

1. Position INFINITI QX56 2011 Factory Owners Manual

TM-98

< BASIC INSPECTION >[7AT: RE7R01B]

A/T FLUID COOLER

DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte

rior may lead to inaccurate debris identification.

1. Position](/img/42/57033/w960_57033-5185.png)

TM-98

< BASIC INSPECTION >[7AT: RE7R01B]

A/T FLUID COOLER

DIAGNOSIS PROCEDURE

NOTE:

Insufficient cleaning of the cooler inlet hose exte

rior may lead to inaccurate debris identification.

1. Position an oil pan under the A/T inlet and outlet cooler hoses.

2. Clean the exterior and tip of the cooler inlet hose.

3. Insert the extension adapter hose of a can of Transmission

Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

Wear safety glasses and rubber gloves when spraying the Transmission Cooler Cleaner.

Spray Transmission Cooler Cleaner only with adequate

ventilation.

Avoid contact with eyes and skin.

Never breath vapors or spray mist.

4. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until ATF flows out of the cooler inlet hose for 5 seconds.

5. Tie a common white, basket-type coffee filter to the end of the cooler inlet hose.

6. Insert the tip of an air gun into the end of the cooler outlet hose.

7. Wrap a shop rag around the air gun tip and end of cooler outlet hose.

8. Blow compressed air regulated to 5 to 9 kg/cm

2 (71 to 128 psi)

through the cooler outlet hose to force any remaining ATF into

the coffee filter.

9. Remove the coffee filter from the end of the cooler inlet hose.

10. Perform “INSPECTION PROCEDURE”.

INSPECTION PROCEDURE

1. Inspect the coffee filter for debris.

a. If small metal debris less than 1 mm (0.040 in) in size or metal powder is found in the coffee filter, this is normal. If normal

debris is found, the A/T fluid cooler/radiator can be re-used and

the procedure is ended.

JPDIA0712GB

JPDIA0714GB

JPDIA0715GB

SCIA2967E

Revision: 2010 May2011 QX56

Page 5403 of 5598

IN-CABIN MICROFILTERVTL-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

IN-CABIN MICROFILTER

Exploded ViewINFOID:0000000006276313

Refer to VTL-14, "Exploded View".

Removal and InstallationINFOID:0000000006276314

REMOVAL

1. Remove glove box assembly. Refer to IP-14, "Removal and Installation".

2. Remove filter cover, and then remove air conditioner filter.

CAUTION:

If the filter is deformed/damaged when removing , replace it with a new one. Deformed/damaged filter

may deteriorate the dust collecting performance.

INSTALLATION

Note the following item, and install in the reverse order of removal.

CAUTION:

When installing, handle the filter with ext reme care to avoid deforming/damaging.

ReplacementINFOID:0000000006276315

Replace in-cabin microfilter.

Refer to MA-6, "

Schedule 1" and MA-8, "Schedule 2".

Affix a caution label inside the glove box when replacing filter.

Revision: 2010 May2011 QX56