air filter INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3126 of 5598

![INFINITI QX56 2011 Factory User Guide

HAC-20

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

1. Intake door 2. In-cabin microfilter 3. Blower motor

4. Evaporator 5. Air mix door (Driver side/Passenger

side)6. Heater core

7. Fo INFINITI QX56 2011 Factory User Guide

HAC-20

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

1. Intake door 2. In-cabin microfilter 3. Blower motor

4. Evaporator 5. Air mix door (Driver side/Passenger

side)6. Heater core

7. Fo](/img/42/57033/w960_57033-3125.png)

HAC-20

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

1. Intake door 2. In-cabin microfilter 3. Blower motor

4. Evaporator 5. Air mix door (Driver side/Passenger

side)6. Heater core

7. Foot door 8. Ventilator door 9. Upper ventilator door

10. Defroster door Fresh air intake Recirculation air

Center ventilator Side ventilator Upper ventilator

Foot Rear foot Defroster

JMIIA0727ZZ

Switch/Dial position Door position

Ventilator door Foot

doorDefroster

door Intake

door Upper

ventilator door Air mix

door

(Driver side) Air mix

door

(Passen- ger

side)

AUTO switch AUTO — AUTO

MODE switch VENT H E N —

B/L I F N —

FOOT J G O — D/F J G O B —

DEF switch J EPBK —

FRE switch

*—B—

REC switch

*—A—

Upper ventila- tor switch ON — L – M —

OFF — K —

Revision: 2010 May2011 QX56

Page 3134 of 5598

![INFINITI QX56 2011 Factory User Guide

HAC-28

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

ACCS (ADVANCED CLIMATE CONT ROL SYSTEM) : System Diagram

INFOID:0000000006275875

ACCS (ADVANCED CLIMATE CONTROL SYSTEM) : System Desc INFINITI QX56 2011 Factory User Guide

HAC-28

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

ACCS (ADVANCED CLIMATE CONT ROL SYSTEM) : System Diagram

INFOID:0000000006275875

ACCS (ADVANCED CLIMATE CONTROL SYSTEM) : System Desc](/img/42/57033/w960_57033-3133.png)

HAC-28

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

SYSTEM

ACCS (ADVANCED CLIMATE CONT ROL SYSTEM) : System Diagram

INFOID:0000000006275875

ACCS (ADVANCED CLIMATE CONTROL SYSTEM) : System DescriptionINFOID:0000000006275876

ACCS (advanced climate control system) controls pass enger room air. It maintains the cleanliness of the

passenger room air using an in-cabin microfilter and a combination of each of the following functions.

- HAC-28, "

ACCS (ADVANCED CLIMATE CONT ROL SYSTEM) : Automatic Intake Control (Exhaust Gas /

Outside Odor Detecting Mechanism)"

-HAC-29, "ACCS (ADVANCED CLIMATE CONTROL SYSTEM) : Plasmacluster Control"

NOTE:

Plasmacluster

™ ion technology developed by Sharp Corporation is installed in this item.

Plasmacluster

™ is a trademark of Sharp Corporation.

Various operations of ACCS (advanced climate contro l system) are transmitted from preset switch to AV

control unit via communication line and from AV contro l unit to A/C auto amp. via CAN communication. A/C

auto amp. sends each indication information to AV c ontrol unit via CAN communication. AV control unit dis-

plays each indication information that is received.

ACCS (ADVANCED CLIMATE CONTROL SYSTE M) : Automatic Intake Control (Ex-

haust Gas / Outside Odor Detecting Mechanism)

INFOID:0000000006275877

DESCRIPTION

In addition to air inlet automatic control of front automatic air conditioning system, A/C auto amp. controls

automatically air inlet according to signal from ex haust gas / outside odor detecting sensor, so that unpleasant

outside odor does not enter in passenger room.

OPERATION DESCRIPTION

When pressing auto intake switch while front blower motor is operated and DEF switch is OFF, auto intake switch indicator lamp and intake switch indicator lamp turn ON. Air inlet is fixed to recirculation for approxi-

mately 5 minutes, and then is switched to automatic intake control (exhaust gas / outside odor detecting

mechanism).

Air inlet switches to recirculation when exhaust gas or outside odor is detected while automatic intake control

(exhaust gas / outside odor detecting mechanism) is operated. After that, air inlet switches to fresh air intake

when exhaust gas or outside odor becomes not detectable.

NOTE:

JMIIA0819GB

Revision: 2010 May2011 QX56

Page 3660 of 5598

ENGINE OILLU-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

PERIODIC MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000006289616

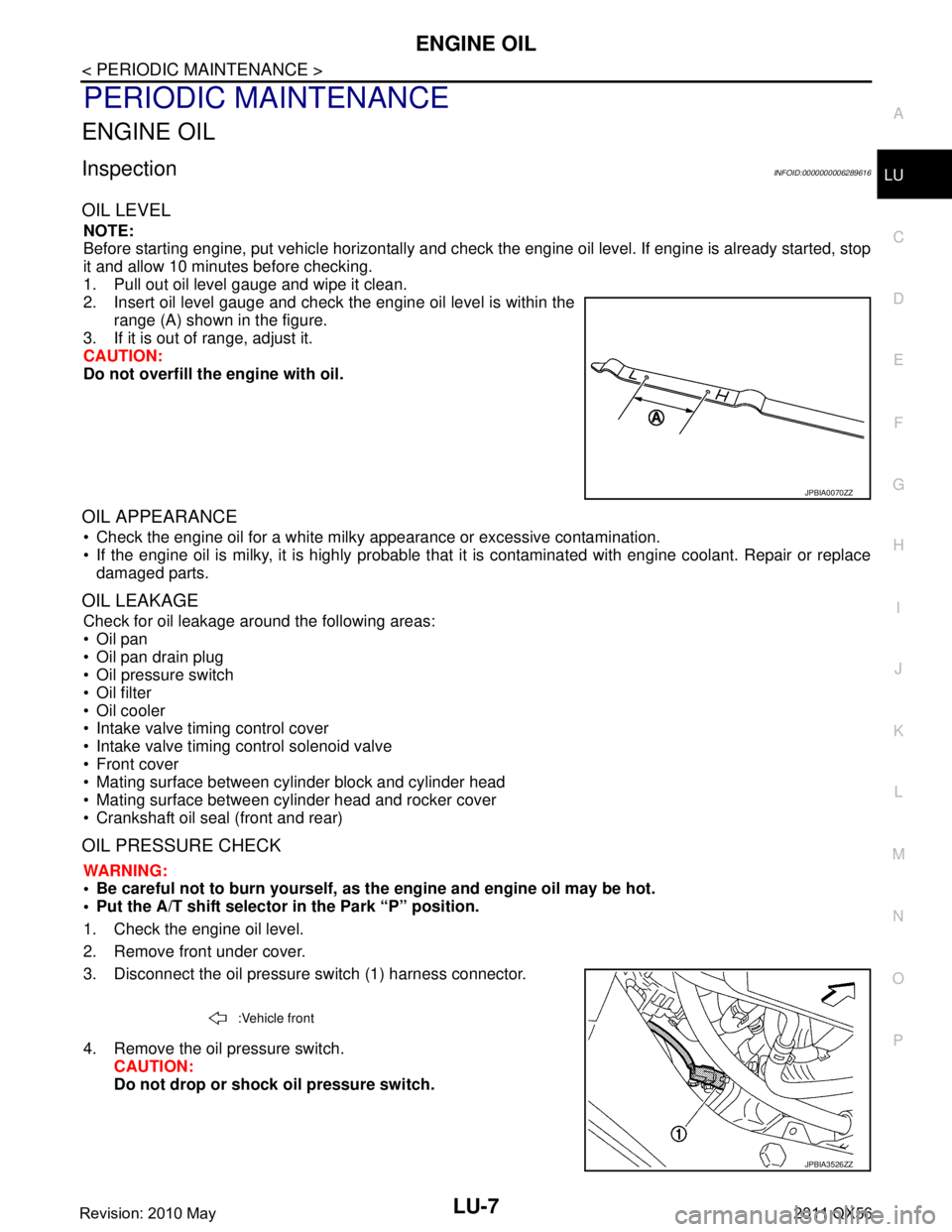

OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check

the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check the engine oil level is within the range (A) shown in the figure.

3. If it is out of range, adjust it.

CAUTION:

Do not overfill the engine with oil.

OIL APPEARANCE

Check the engine oil for a white milky appearance or excessive contamination.

If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair or replace

damaged parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

Oil pan

Oil pan drain plug

Oil pressure switch

Oil filter

Oil cooler

Intake valve timing control cover

Intake valve timing control solenoid valve

Front cover

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yourself, as th e engine and engine oil may be hot.

Put the A/T shift selector in the Park “P” position.

1. Check the engine oil level.

2. Remove front under cover.

3. Disconnect the oil pressure switch (1) harness connector.

4. Remove the oil pressure switch. CAUTION:

Do not drop or shock oil pressure switch.

JPBIA0070ZZ

:Vehicle front

JPBIA3526ZZ

Revision: 2010 May2011 QX56

Page 3665 of 5598

LU-12

< REMOVAL AND INSTALLATION >

OIL COOLER

CAUTION:

Perform this step when engine is cold.

4. Remove oil filter. Refer to LU-9, "

Removal and Installation".

5. Remove connector bolt, and remove oil cooler.

INSTALLATION

Installation is in the reverse order of removal, paying attention to the following:

Confirm that no foreign objects are adhering to the sealing surfaces of the oil cooler and oil pan.

InspectionINFOID:0000000006289623

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing compressed air through engine coolant

inlet. If necessary, replace oil cooler assembly.

Relief Valve

Inspect relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove

the valve by prying it out using a suitable tool. Install a new valve in place by tapping it in.

INSPECTION AFTER INSTALLATION

1. Check engine oil and engine coolant levels and add engine oil and engine coolant. Refer to LU-7, "Inspec-

tion" and CO-8, "Inspection".

2. Start the engine, and check for l eaks of engine oil or engine coolant.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and engine coolant level again. Refer to LU-7, "

Inspection" and CO-8, "Inspec-

tion"

Revision: 2010 May2011 QX56

Page 3671 of 5598

MA-1

MAINTENANCE

C

DE

F

G H

I

J

K L

M B

MA

SECTION MA

N

O A

CONTENTS

MAINTENANCE

PREPARATION .............

...............................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE ..........................4

GENERAL MAINTENANCE ........................... .....4

Explanation of General Maintenance .................. ......4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance .................. ......6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants .......................................... ....10

Engine Oil Recommendation ..................................10

Anti-Freeze Coolant Mixture Ratio ..........................11

ENGINE MAINTENANCE ...................................12

DRIVE BELTS ....................................................... ....12

DRIVE BELTS : Exploded View ..............................12

DRIVE BELTS : Checking .......................................12

DRIVE BELTS : Tension Adjustment .....................12

ENGINE COOLANT ............................................... ....12

ENGINE COOLANT : Inspection .............................12

ENGINE COOLANT : Draining ................................13

ENGINE COOLANT : Refilling ................................13

ENGINE COOLANT : Flushing ...............................15

RESERVOIR TANK CAP ..........................................15

RESERVOIR TANK CAP : Inspection ................. ....15

RADIATOR ............................................................ ....16

RADIATOR : Inspection ..........................................16

FUEL LINES .......................................................... ....16

FUEL LINES : Inspection ........................................17

AIR CLEANER FILTER ......................................... ....17

AIR CLEANER FILTER : Removal and Installation

....

17

ENGINE OIL ........................................................... ....17

ENGINE OIL : Draining ............................................17

ENGINE OIL : Refilling ............................................17

OIL FILTER ............................................................ ....18

OIL FILTER : Removal and Installation ...................18

SPARK PLUG ........................................................ ....18

SPARK PLUG : Removal and Installation ...............19

SPARK PLUG : Inspection ......................................19

EVAP VAPOR LINES ............................................ ....20

EVAP VAPOR LINES : Inspection ...........................20

CHASSIS MAINTENANCE ...............................21

EXHAUST SYSTEM . ..................................................21

EXHAUST SYSTEM : Inspec tion ............................21

A/T FLUID .............................................................. ....21

A/T FLUID : Inspection ............................................21

TRANSFER FLUID ................................................ ....21

TRANSFER FLUID : Inspection ..............................21

TRANSFER FLUID : Draining .................................21

TRANSFER FLUID : Refilling ..................................22

FRONT PROPELLER SHAFT: 2F P15 ................. ....22

FRONT PROPELLER SHAFT: 2F P15 : Inspec-

tion ...........................................................................

22

REAR PROPELLER SHAFT: 2F P26 .................... ....23

REAR PROPELLER SHAFT: 2F P26 : Inspection ....23

REAR PROPELLER SHAFT: 2S1410 ................... ....23

REAR PROPELLER SHAFT: 2S1410 : Inspection ....23

FRONT DIFFERENTIAL GEAR OIL: R180A ........ ....24

FRONT DIFFERENTIAL GEAR OIL: R180A : In-

spection ...................................................................

24

Revision: 2010 May2011 QX56

Page 3676 of 5598

MA-6

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

Introduction of Periodic MaintenanceINFOID:0000000006287729

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is mainly operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1INFOID:0000000006287730

EMISSION CONTROL SYSTEM

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. [ ]: At the mileage intervals only

Schedule 1Follow Periodic Maintenance Schedule 1 if the driving habits frequently include

one or more of the following driving conditions:

Repeated short trips of less than 5 miles (8 km).

Repeated short trips of less than 10 miles (16 km) with outside temperatures

remaining below freezing.

Operating in hot weather in stop-and-go “rush hour” traffic.

Extensive idling and/or low speed driving for long distances, such as police, taxi

or door-to-door delivery use.

Driving in dusty conditions.

Driving on rough, muddy, or salt spread roads.

Towing a trailer, using a camper or a car-top carrier. Emission Control Sys-

tem Maintenance

MA-6Chassis and Body

Maintenance

Schedule 2 Follow Periodic Maintenance Schedule 2 if none of driving conditions shown in

Schedule 1 apply to the driving habits. Emission Control Sys-

tem Maintenance

MA-8

Chassis and Body

Maintenance

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 3.75

(6)3 7.50

(12) 6 11 . 2 5

(18) 9 15

(24) 12 18.75

(30)15 22.5

(36) 18 26.25

(42)21 30

(48) 24

Drive belts NOTE (1) MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Fuel filter NOTE (3) —

Engine coolant* NOTE (4) MA-13

Engine oil R R R R R R R RMA-17

Engine oil filter (Use genuine

NISSAN engine oil filter or

equivalent.)R R RRRRR R

MA-18

Spark plugs (Iridium-tipped

type)Replace every 105,000 miles (168,000 km).

MA-19

Intake & exhaust valve clear-

ance*NOTE (5)

EM-12

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title

Perform at number of miles,

kilometers or months, which-

ever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Drive belts NOTE (1) I* MA-12

Air cleaner filter NOTE (2) [R]MA-17

EVAP vapor linesI*MA-20

Fuel lines I*MA-17

Revision: 2010 May2011 QX56

Page 3678 of 5598

MA-8

< PERIODIC MAINTENANCE >

PERIODIC MAINTENANCE

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) fluid /oil at every

30,000 miles (48,000 km) or 24 months.

(2) Automatic transmission fluid is maintenance-free.

(3) Refer to “Tire rotation” unde r the “General maintenance” heading earlier in this section.

Schedule 2INFOID:0000000006287731

EMISSION CONTROL SYSTEM

Abbreviations: R = Replace. I = Inspec t. Correct or replace if necessary. [ ]: At the mileage intervals only

Exhaust system I I I I MA-21

In-cabin microfilter R RVTL-17

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or - Con- tent Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000)

Months 3.75

(6)

3 7.50

(12)

6 11 . 2 5

(18)

9 15

(24)

12 18.75

(30)

15 22.5

(36)

18 26.25

(42)

21 30

(48)

24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Reference

Section - Page

or - Content Title

Perform at number of miles,

kilometers or months,

whichever comes first. Miles x 1,000

(km x 1,000) Months 33.75

(54)27 37.5

(60) 30 41.25

(66)33 45

(72) 36 48.75

(78)39 52.5

(84) 42 56.25

(90)45 60

(96) 48

Brake lines & cables I I MA-28

Brake fluid R RMA-28

Brake pads & rotors I I I IMA-30

BR-16

BR-18

BR-16

BR-18

Transfer fluid & differential

gear oil

NOTE (1) I I MA-21MA-24

MA-25

Automatic transmission flu-

id

NOTE (2)

—

Steering gear & linkage,

axle & suspension parts IIII

MA-31

MA-32

Tire rotation NOTE (3) MA-4WT-63

Drive shaft boots and pro-

peller shaft (4WD models)IIII MA-33MA-22

MA-23

MA-23

Exhaust system I I I I

MA-21

In-cabin microfilter R RVTL-17

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title

Perform at number of miles, kilo-

meters or months, whichever

comes first. Miles x 1,000

(km x 1,000)

Months 7.5

(12)

6 15

(24)

12 22.5

(36)

18 30

(48)

24 37.5

(60)

30 45

(72)

36 52.5

(84)

42 60

(96)

48

Drive belts NOTE (1) I* MA-12

Air cleaner filter [R] [R]MA-17

EVAP vapor lines I* I*MA-20

Fuel lines I* I*MA-17

Fuel filter NOTE (2) —

Engine coolant* NOTE (3) MA-13

Revision: 2010 May2011 QX56

Page 3687 of 5598

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

FUEL LINES : InspectionINFOID:0000000006394850

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leakage, cracks, damage, loose connections, chafing or

deterioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

AIR CLEANER FILTER : Removal and InstallationINFOID:0000000006394838

REMOVAL

NOTE:

The viscous paper type filter does not need cleaning between replacement intervals.

Replace the air filter as necessary for periodic maintenance. Refer to MA-6, "

Introduction of Periodic Mainte-

nance".

1. Unhook clips, and lift air cleaner case (upper).

2. Remove air cleaner filter from air cleaner case.

INSTALLATION

Install is the reverse order of removal.

ENGINE OIL

ENGINE OIL : DrainingINFOID:0000000006394841

WARNING:

Be careful not to burn yourself, as th e engine and engine oil may be hot.

Prolonged and repeated contact with used engine oil may cau se skin cancer; try to avoid direct skin

contact with used oil. If skin contact is made, w ash thoroughly with soap or hand cleaner as soon as

possible.

1. Warm up the engine, and check for any oil leaks.

2. Stop the engine and wait for at least 10 minutes.

3. Remove drain plug and oil filler cap to drain the old oil.

ENGINE OIL : RefillingINFOID:0000000006394842

1. Install drain plug with new washer. CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-10, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

A : Engine

B : Fuel line

C : Fuel tank

JPBIA0129ZZ

Tightening torque : Refer to EM-54, "Exploded View".

Engine oil capacity : Refer to LU-17, "

Periodical Maintenance Specification".

Revision: 2010 May2011 QX56

Page 4398 of 5598

![INFINITI QX56 2011 Factory User Guide

SCS-38

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

Completely engage hooks on frame when installing accumulator

assembly.

ACCUMULATOR : InspectionINFOID:0000000006256026 INFINITI QX56 2011 Factory User Guide

SCS-38

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

Completely engage hooks on frame when installing accumulator

assembly.

ACCUMULATOR : InspectionINFOID:0000000006256026](/img/42/57033/w960_57033-4397.png)

SCS-38

< REMOVAL AND INSTALLATION >[HBMC]

HYDRAULIC BODY-MOTION CONTROL SYSTEM

Completely engage hooks on frame when installing accumulator

assembly.

ACCUMULATOR : InspectionINFOID:0000000006256026

INSPECTION AFTER REMOVAL

O-ring must be free of scratches and damage.

Pipe and tube must be free of scratches and damage.

INSPECTION AFTER INSTALLATION

Check oil leakage, twists, deformation, cont act with other parts, and loose connections.

ADJUSTMENT AFTER INSTALLATION

Perform air bleeding. Refer to SCS-18, "Work Procedure".

ACCUMULATOR : DisposalINFOID:0000000006256027

CAUTION:

Always wear safety goggles.

Always wear safety gloves.

Be careful since pressure is higher when temperature is high.

Be careful since metal shavings or oi l may be blown away by compressed gas.

Discard drained oil in accordance with local laws and regulations.

WORK PROCEDURE

1. Remove both tanks using an oil filter wrench.

2. Secure tank using a vise.

3. Drill a hole as shown in the figure ( �z) using an electric drill.

Drain gas and oil.

NOTE:

Gas is colorless, odorless, and harmless.

Use an electric drill with a drill bit of approximately 4 mm (0.16 in).

Drilling a hole is easier when electric drill speed is slow.

PPMU, MIDDLE TUBE AS SEMBLY, PPMU PIPE

JSEIA0202ZZ

JSEIA0182ZZ

Revision: 2010 May2011 QX56

Page 4403 of 5598

![INFINITI QX56 2011 Factory User Guide

HYDRAULIC BODY-MOTION CONTROL SYSTEMSCS-43

< REMOVAL AND INSTALLATION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE : InspectionINFOID:0000000006256030

INSPECTION A INFINITI QX56 2011 Factory User Guide

HYDRAULIC BODY-MOTION CONTROL SYSTEMSCS-43

< REMOVAL AND INSTALLATION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE : InspectionINFOID:0000000006256030

INSPECTION A](/img/42/57033/w960_57033-4402.png)

HYDRAULIC BODY-MOTION CONTROL SYSTEMSCS-43

< REMOVAL AND INSTALLATION > [HBMC]

C

D

F

G H

I

J

K L

M A

B

SCS

N

O P

PPMU, MIDDLE TUBE ASSEMBLY, PPMU PIPE : InspectionINFOID:0000000006256030

INSPECTION AFTER REMOVAL

O-ring must be free of scratches and damage.

Pipe and tube must be free of scratches and damage.

INSPECTION AFTER INSTALLATION

Check oil leakage, twists, deformation, contact with other parts, and loose connections.

ADJUSTMENT AFTER INSTALLATION

Perform air bleeding. Refer to SCS-18, "Work Procedure".

PPMU, MIDDLE TUBE ASSEMBLY , PPMU PIPE : DisposalINFOID:0000000006256031

CAUTION:

Always wear safety goggles.

Always wear safety gloves.

Be careful since pressure is higher when temperature is high.

Be careful since metal shavings or oi l may be blown away by compressed gas.

Discard drained oil in accordance wi th local laws and regulations.

WORK PROCEDURE

1. Remove both tanks using an oil filter wrench.

2. Secure tank using a vise.

3. Drill a hole as shown in the figure ( �z) using an electric drill.

Drain gas and oil.

NOTE:

Gas is colorless, odorless, and harmless.

Use an electric drill with a drill bit of approximately 4 mm (0.16

in).

Drilling a hole is easier when electric drill speed is slow.

REAR TUBE ASSEMBLY

JSEIA0182ZZ

Revision: 2010 May2011 QX56