radio INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 359 of 5598

AV

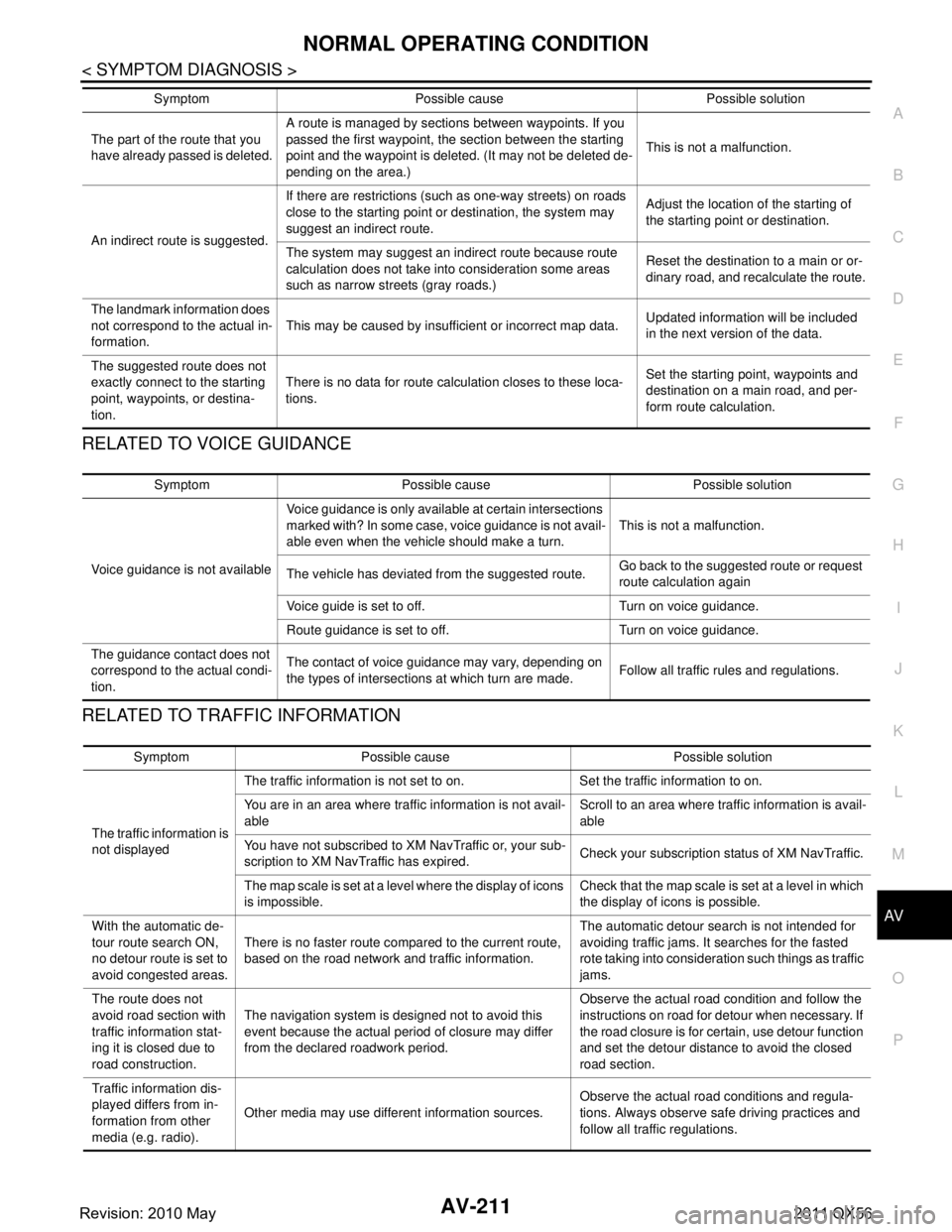

NORMAL OPERATING CONDITIONAV-211

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

K L

M B A

O P

RELATED TO VOICE GUIDANCE

RELATED TO TRAFFIC INFORMATION

The part of the route that you

have already passed is deleted. A route is managed by sections between waypoints. If you

passed the first waypoint, the section between the starting

point and the waypoint is deleted. (It may not be deleted de-

pending on the area.)

This is not a malfunction.

An indirect route is suggested. If there are restrictions (such as one-way streets) on roads

close to the starting point or destination, the system may

suggest an indirect route.

Adjust the location of the starting of

the starting point or destination.

The system may suggest an indirect route because route

calculation does not take into consideration some areas

such as narrow stre ets (gray roads.) Reset the destination to a main or or-

dinary road, and recalculate the route.

The landmark information does

not correspond to the actual in-

formation. This may be caused by insufficient or incorrect map data.

Updated information will be included

in the next version of the data.

The suggested route does not

exactly connect to the starting

point, waypoints, or destina-

tion. There is no data for route calculation closes to these loca-

tions.

Set the starting point, waypoints and

destination on a main road, and per-

form route calculation.

Symptom Possible cause Possible solution

Symptom Possible cause Possible solution

Voice guidance is not available Voice guidance is only available at certain intersections

marked with? In some case, voice guidance is not avail-

able even when the vehicle should make a turn.

This is not a malfunction.

The vehicle has deviated from the suggested route. Go back to the suggested route or request

route calculation again

Voice guide is set to off. Turn on voice guidance.

Route guidance is set to off. Turn on voice guidance.

The guidance contact does not

correspond to the actual condi-

tion. The contact of voice guidance may vary, depending on

the types of intersections at which turn are made.

Follow all traffic rules and regulations.

Symptom Possible cause Possible solution

The traffic information is

not displayed The traffic information is not set to on. Set the traffic information to on.

You are in an area where traffic information is not avail-

able

Scroll to an area where traffic information is avail-

able

You have not subscribed to XM NavTraffic or, your sub-

scription to XM NavTraffic has expired. Check your subscription status of XM NavTraffic.

The map scale is set at a level where the display of icons

is impossible. Check that the map scale is set at a level in which

the display of icons is possible.

With the automatic de-

tour route search ON,

no detour route is set to

avoid congested areas. There is no faster route compared to the current route,

based on the road network and traffic information. The automatic detour search is not intended for

avoiding traffic jams. It searches for the fasted

rote taking into consideration such things as traffic

jams.

The route does not

avoid road section with

traffic information stat-

ing it is closed due to

road construction. The navigation system is designed not to avoid this

event because the actual period of closure may differ

from the declared roadwork period. Observe the actual road condition and follow the

instructions on road for detour when necessary. If

the road closure is for certain, use detour function

and set the detour distance to avoid the closed

road section.

Traffic information dis-

played differs from in-

formation from other

media (e.g. radio). Other media may use different information sources.

Observe the actual road conditions and regula-

tions. Always observe safe driving practices and

follow all traffic regulations.

Revision: 2010 May2011 QX56

Page 373 of 5598

AV

SATELLITE RADIO ANTENNAAV-225

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M B A

O P

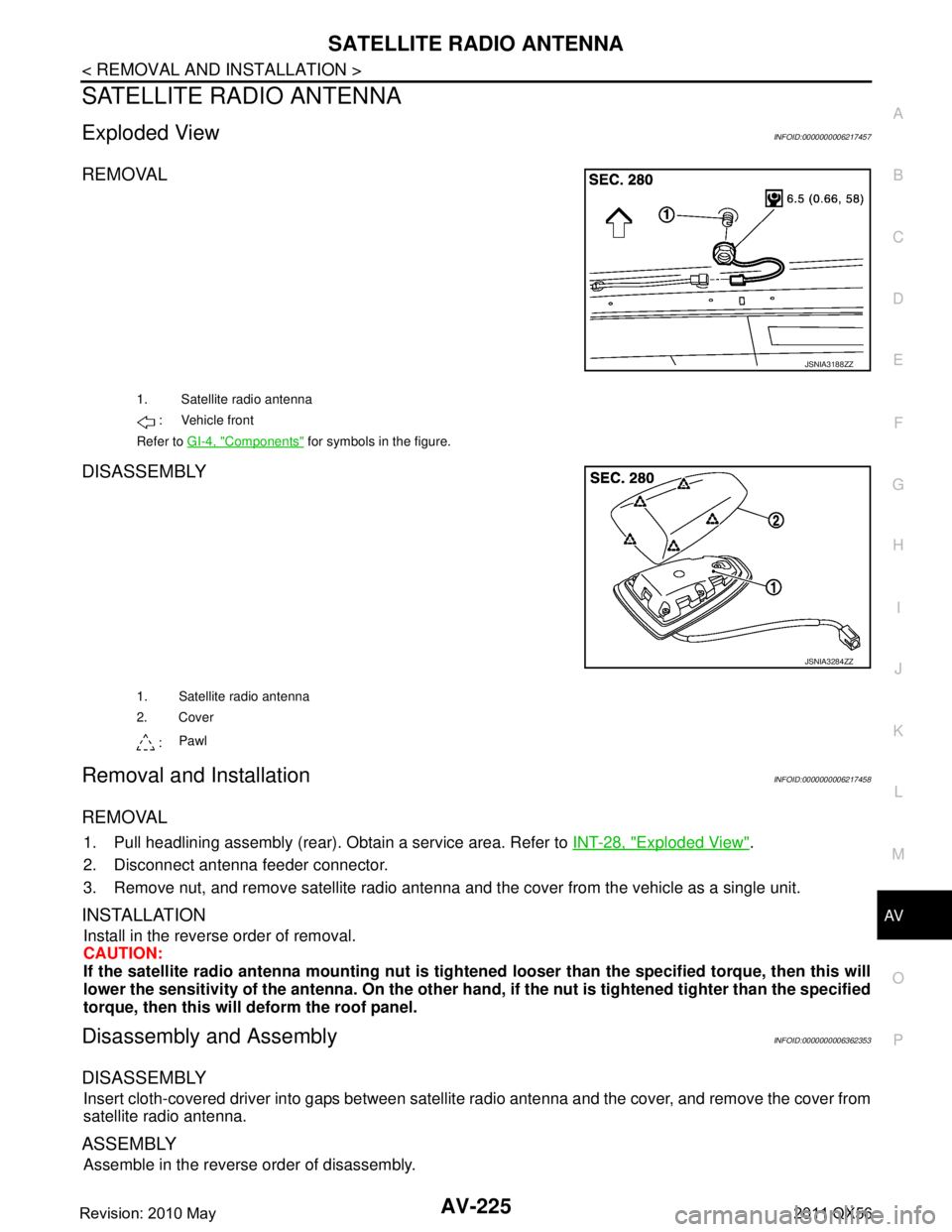

SATELLITE RADIO ANTENNA

Exploded ViewINFOID:0000000006217457

REMOVAL

DISASSEMBLY

Removal and InstallationINFOID:0000000006217458

REMOVAL

1. Pull headlining assembly (rear). Obtain a service area. Refer to INT-28, "Exploded View".

2. Disconnect antenna feeder connector.

3. Remove nut, and remove satellite radio antenna and the cover from the vehicle as a single unit.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

If the satellite radio ante nna mounting nut is tightened looser than the specified torque, then this will

lower the sensitivity of the antenna. On the other hand, if the nut is tightened tighter than the specified

torque, then this will deform the roof panel.

Disassembly and AssemblyINFOID:0000000006362353

DISASSEMBLY

Insert cloth-covered driver into gaps between satel lite radio antenna and the cover, and remove the cover from

satellite radio antenna.

ASSEMBLY

Assemble in the reverse order of disassembly.

JSNIA3188ZZ

1. Satellite radio antenna

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JSNIA3284ZZ

1. Satellite radio antenna

2. Cover

: Pawl

Revision: 2010 May2011 QX56

Page 524 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negativ](/img/42/57033/w960_57033-523.png)

PRECAUTIONSBRC-7

< PRECAUTION > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

and tires installed on the vehicle are the specified si ze and parts. Brake performance and controllability may

be negatively affected when other parts than the specified are installed.

Brake stopping distance may become longer and steering stability may be negatively affected, when tires in

different size and combination or other parts than the specified are used.

When a radio (including wiring), antenna and antenna lead line are located near ABS actuator and electric

unit (control unit), a malfunction or improper operation ma y occur for the control of VDC function, TCS func-

tion, ABS function, EBD function, hill start assist func tion or brake limited slip differential (BLSD) function.

When the following items are replaced by other parts than genuine parts or modified, ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, and the control may not operate normally for VDC

function, TCS function, ABS function, EB D function, hill start assist function or brake limited slip differential

(BLSD) function.

- Suspension component parts (shock absorber, spring, bushing and others)

- Tire and wheel (other than the specified size)

- Brake component parts (brake pad, disc rotor, brake caliper and others)

- Engine component parts (ECM, muffler and others)

- Body reinforcement component parts (rollover bar, tower bar and others)

When suspension, tire and brake component parts are excessively worn or deteriorated and the vehicle is

driven, ABS warning lamp, brake warning lamp and VDC warning lamp may tu\

rn ON, and the control may

not operate normally for VDC function, TCS function, ABS function, EBD function, hill start assist function or

brake limited slip differential (BLSD) function.

ABS warning lamp, brake warning lamp and VDC warning lamp may turn ON, when only front wheel or rear wheel is rotated using a free roller. This is not a ma lfunction, because it is caused by wheel speed difference

between wheel that is rotated and wheel that is not rota ted. In this case, perform self-diagnosis, check self-

diagnosis results, and erase memory.

When power supply voltage is not normal, ABS warning lamp, brake warning lamp and VDC warning lamp

turn ON. ABS actuator and electric unit (control unit) st ops control for VDC function, TCS function, ABS func-

tion, EBD function, hill start assist function or brake limited slip differential (BLSD) function. Ordinary brake

operates. After power supply returns to normal, ABS warning lamp, brake warning lamp and VDC warning

lamp turn OFF. The control becomes operative for VD C function, TCS function, ABS function, EBD function,

hill start assist function or brake li mited slip differential (BLSD) function.

VDC warning lamp may turn ON and VDC function or TCS function may not normally operate, when driving

on a special road the is extremely slanted (bank in a circ uit course). This is not a malfunction if the status

returns to normal for VDC function or TCS function after the engine is started again. In this case, perform

self-diagnosis, check self-diagnosis results, and erase memory.

A malfunction in yaw rate/side/decel G sensor syste m may be detected when the vehicle sharply turns dur-

ing a spin turn, acceleration turn or drift driving while VDC function or TCS function are OFF (VDC OFF

switch is pressed and VDC OFF indicator lamp is in ON st atus). This is not a malfunction if the status returns

to normal for VDC function or TCS function after the engine is started again. In this case, perform self-diag-

nosis, check self-diagnosis results, and erase memory

Precaution for Harness RepairINFOID:0000000006222558

Solder the repair part, and wrap it with tape. [Twisted wire fray must be 110 mm (4.33 in) or less.]

SKIB8766E

Revision: 2010 May2011 QX56

Page 648 of 5598

![INFINITI QX56 2011 Factory Owners Manual

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

BRC-131

< SYMPTOM DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

DescriptionINFOID:000000000 INFINITI QX56 2011 Factory Owners Manual

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

BRC-131

< SYMPTOM DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

DescriptionINFOID:000000000](/img/42/57033/w960_57033-647.png)

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

BRC-131

< SYMPTOM DIAGNOSIS > [WITH VDC]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

BRAKE PEDAL VIBRATION OR OPERATION SOUND OCCURS

DescriptionINFOID:0000000006222665

Brake pedal vibrates and motor sound from ABS actuat or and electric unit (control unit) occurs, when the

engine starts.

Brake pedal vibrates during braking.

CAUTION:

Vibration may be felt during brake pedal is lightly de pressed (just placing a foot on it) in the following

conditions. This is normal.

When shifting gears

When driving on slippery road

During cornering at high speed

When passing over bumps or grooves [Approx. 50 mm (1.97 in) or more]

When pulling away just after starting engine [at approx. 10 km/h (6.2 MPH) or higher]

Diagnosis ProcedureINFOID:0000000006222666

1.CHECK SYMPTON 1

Depress the brake pedal 10 times or more with the engine stopped and decrease the accumulator pressure to

check that there are pedal vibrations when the engine is started.

Do vibrations occur?

YES >> GO TO 2.

NO >> Check brake pedal. Refer to BR-21, "

Inspection and Adjustment".

2.CHECK SYMPTON 2

Depress the brake pedal 10 times or more with the engine stopped and decrease the accumulator pressure to

check that motor noise from ABS actuator and electr ic unit (control unit) occurs when the engine starts.

Does the operation sound occur?

YES >> GO TO 3.

NO >> Perform self-diagnosis for “ABS” with CONSULT-III.

3.CHECK SYMPTON 3

Check symptoms when electrical component (headlamps, etc.) switches are operated.

Does the symptom occur?

YES >> Check that radio (including wiring), antenna and antenna lead-in wires are not located near ABS actuator and electric unit (control unit). Move them if they are located near ABS actuator and elec-

tric unit (control unit).

NO >> Normal

Revision: 2010 May2011 QX56

Page 1573 of 5598

SYSTEM (INTEGRATED HOMELINK TRANSMITTER)DLK-37

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

SYSTEM (INTEGRATED HO MELINK TRANSMITTER)

System DescriptionINFOID:0000000006256146

Item Function

Integrated homelink transmitter A maximum of 3 radio signals can be stored and transmitted to operate the garage door, etc.

Revision: 2010 May2011 QX56

Page 2037 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

con INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

con](/img/42/57033/w960_57033-2036.png)

PRECAUTIONSEC-13

< PRECAUTION > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

When installing C.B. ham radio or a mobile phone, be sure to

observe the following as it may adversely affect electronic

control systems depending on installation location.

- Keep the antenna as far as possi ble from the electronic con-

trol units.

- Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Never let them run parallel for a long distance.

- Adjust the antenna and feeder line so that the standing-wave

ratio can be kept smaller.

- Be sure to ground the radio to vehicle body.

SEF708Y

Revision: 2010 May2011 QX56

Page 2992 of 5598

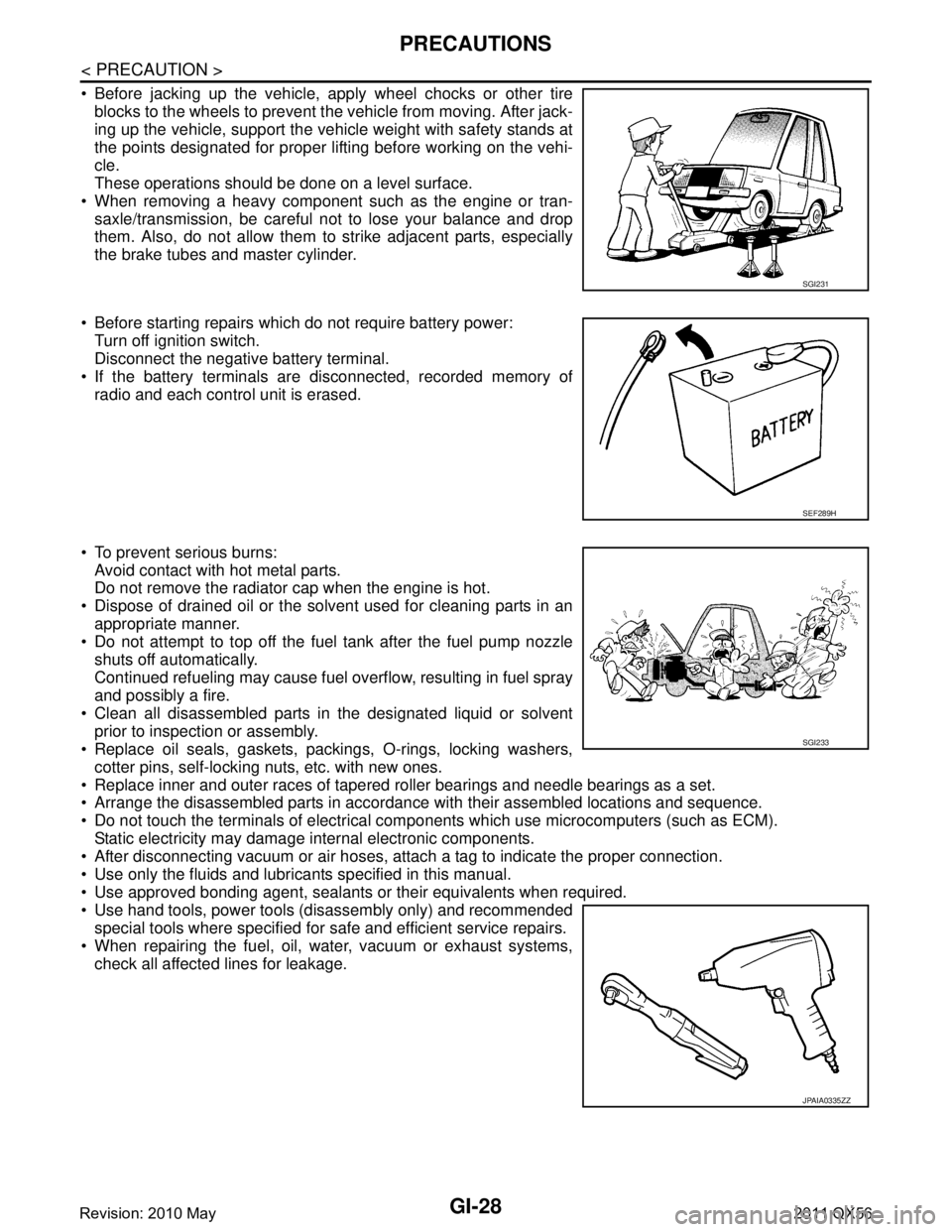

GI-28

< PRECAUTION >

PRECAUTIONS

Before jacking up the vehicle, apply wheel chocks or other tireblocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or tran- saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

Before starting repairs which do not require battery power: Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leakage.

SGI231

SEF289H

SGI233

JPAIA0335ZZ

Revision: 2010 May2011 QX56

Page 3000 of 5598

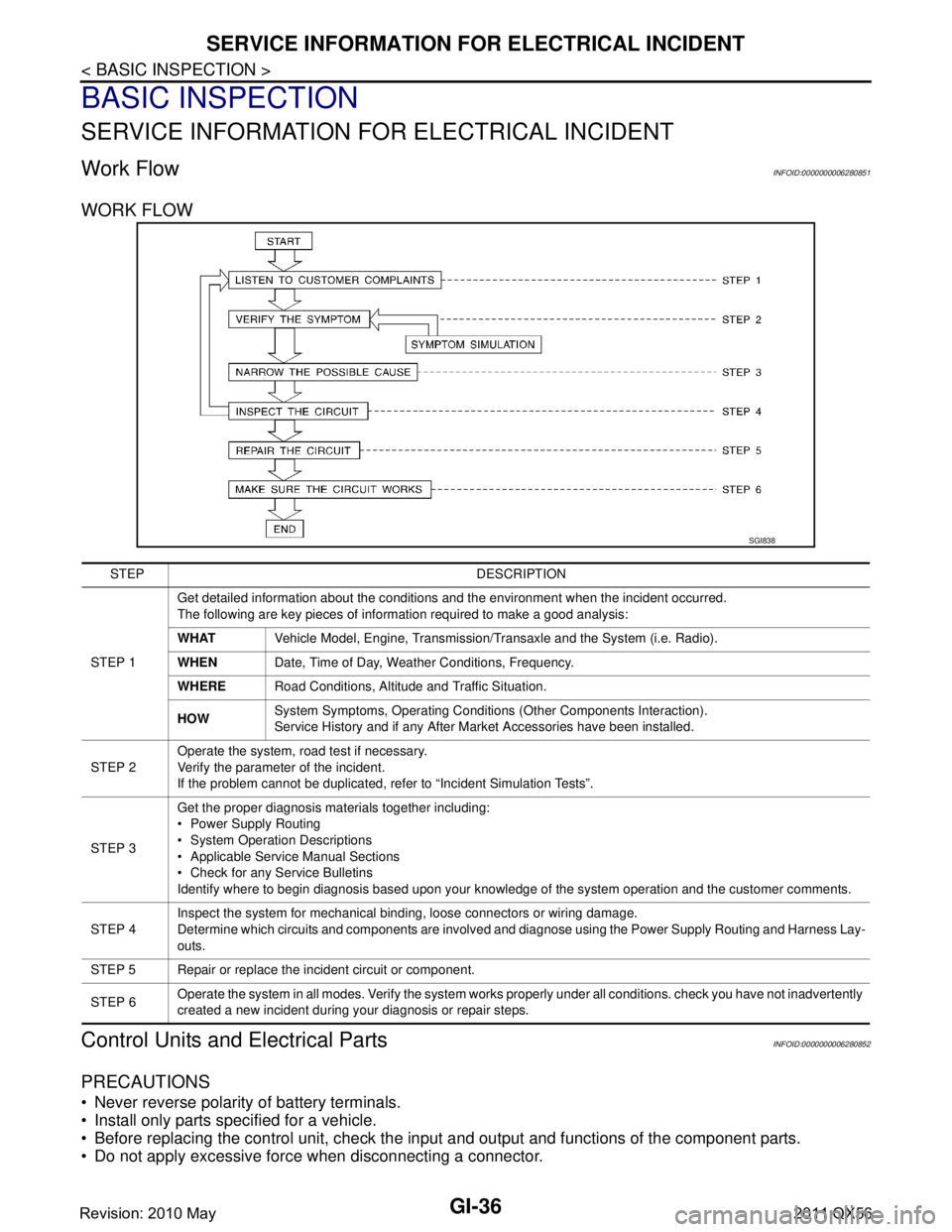

GI-36

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

BASIC INSPECTION

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

Work FlowINFOID:0000000006280851

WORK FLOW

Control Units and Electrical PartsINFOID:0000000006280852

PRECAUTIONS

Never reverse polarity of battery terminals.

Install only parts specified for a vehicle.

Before replacing the control unit, check the i nput and output and functions of the component parts.

Do not apply excessive force when disconnecting a connector.

SGI838

STEP DESCRIPTION

STEP 1 Get detailed information about the conditions and the environment when the incident occurred.

The following are key pieces of information required to make a good analysis:

WHAT

Vehicle Model, Engine, Transmission/Transaxle and the System (i.e. Radio).

WHEN Date, Time of Day, Weather Conditions, Frequency.

WHERE Road Conditions, Altitude and Traffic Situation.

HOW System Symptoms, Operating Conditions

(Other Components Interaction).

Service History and if any After Market Accessories have been installed.

STEP 2 Operate the system, road test if necessary.

Verify the parameter of the incident.

If the problem cannot be duplicated, refer to “Incident Simulation Tests”.

STEP 3 Get the proper diagnosis materials together including:

Power Supply Routing

System Operation Descriptions

Applicable Service Manual Sections

Check for any Service Bulletins

Identify where to begin diagnosis based upon your knowledge of the system operation and the customer comments.

STEP 4 Inspect the system for mechanical binding, loose connectors or wiring damage.

Determine which circuits and components are involved and diagnose using the Power Supply Routing and Harness Lay-

outs.

STEP 5 Repair or replace the incident circuit or component.

STEP 6 Operate the system in all modes. Verify the system works properly under all conditions. check you have not inadvertently

created a new incident during your diagnosis or repair steps.

Revision: 2010 May2011 QX56

Page 3006 of 5598

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

An unclamped or loose harness can cause wiring to be pinched by seat components (such as slide guides)

during vehicle vibration. If the wiring runs under s eating areas, inspect wire routing for possible damage or

pinching.

HEAT SENSITIVE

The customer's concern may occur during hot weather or after car has sat for a short time. In such cases you will want to check for a

heat sensitive condition.

To determine if an electrical component is heat sensitive, heat the component with a heat gun or equivalent.

CAUTION:

Never heat components above 60 °C (140 °F).

If incident occurs while heating the unit, either replace or properly insulate the component.

FREEZING

The customer may indicate the incident goes away after the carwarms up (winter time). The cause could be related to water freez-

ing somewhere in the wiring/electrical system.

There are two methods to check for this. The first is to arrange for the owner to leave his car overnight. Check it will get cold enough

to demonstrate his complaint. Leave the car parked outside over-

night. In the morning, do a quick and thorough diagnosis of those

electrical components which could be affected.

The second method is to put the suspect component into a freezer long enough for any water to freeze. Reinstall the part into the car

and check for the reoccurrence of the incident. If it occurs, repair or

replace the component.

WATER INTRUSION

The incident may occur only during high humidity or in rainy/snowy

weather. In such cases the incident could be caused by water intru-

sion on an electrical part. This can be simulated by soaking the car

or running it through a car wash.

CAUTION:

Never spray water directly on any electrical components.

ELECTRICAL LOAD

The incident may be electrical load sensitive. Perform diagnosis with

all accessories (including A/C, rear window defogger, radio, fog

lamps) turned on.

COLD OR HOT START UP

On some occasions an electrical incident may occur only when the car is started cold, or it may occur when

the car is restarted hot shortly after being turned off. In these cases you may have to keep the car overnight to

make a proper diagnosis.

JPAIA0733GB

SGI843

SGI844

SGI845

Revision: 2010 May2011 QX56

Page 4192 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PWO

NORMAL OPERATING CONDITIONPWO-33

< SYMPTOM DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006257122

Because of modified sine wave INFINITI QX56 2011 Factory Owners Manual

PWO

NORMAL OPERATING CONDITIONPWO-33

< SYMPTOM DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006257122

Because of modified sine wave](/img/42/57033/w960_57033-4191.png)

PWO

NORMAL OPERATING CONDITIONPWO-33

< SYMPTOM DIAGNOSIS > [AC 120 V OUTLET]

C

D

E

F

G H

I

J

K L

B A

O P

N

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006257122

Because of modified sine wave output, the AC 120 V out

let may not operate normally for electric appliance of

which electric power consumption is 150 W or less.

Electric appliances requiring a large amount of electr ic power consumption at startup (e.g. CRT-based TV,

power tool)

Measuring instruments for data requiring accuracy (e.g. medical equipment, measuring instrument)

Microprocessor-controlled appliances (e.g. microprocessor-controlled blanket)

Noise may be caused in radio or TV, depending on an electric appliance.

Revision: 2010 May2011 QX56