tire pressure INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2941 of 5598

FL-12

< REMOVAL AND INSTALLATION >

EVAP CANISTER

Removal and Installation

INFOID:0000000006414454

REMOVAL

1. Remove the spare tire.

2. Disconnect harness connectors and hoses.

3. Remove EVAP canister fixing bolt.

4. Remove EVAP canister.

NOTE:

The EVAP canister vent control valve and EVAP cont rol system pressure sensor can be removed without

removing the EVAP canister.

INSTALLATION

Install in the reverse order of removal.

NOTE:

Tighten EVAP canister fixing bolt to the specified torque.

Disassembly and AssemblyINFOID:0000000006414455

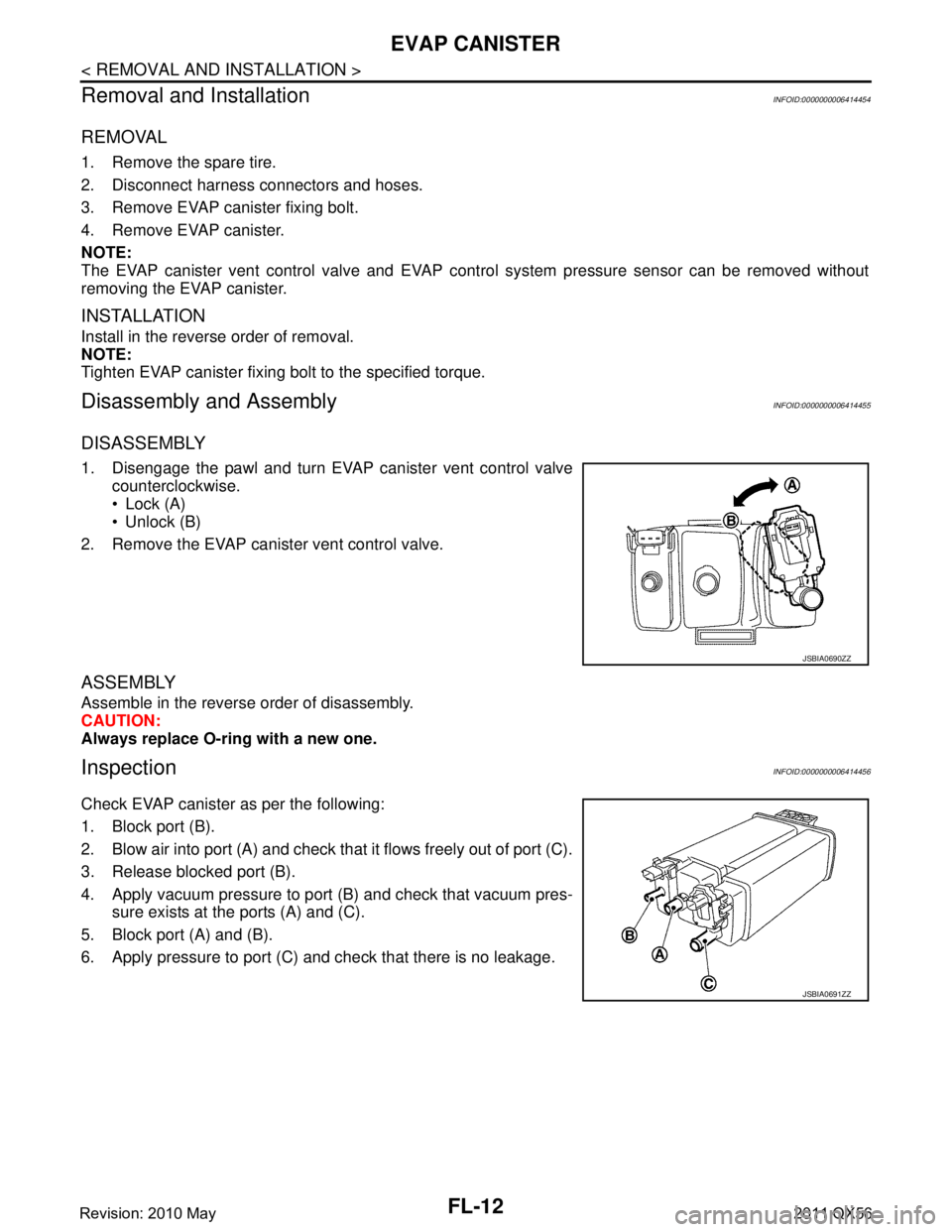

DISASSEMBLY

1. Disengage the pawl and turn EVAP canister vent control valve counterclockwise.

Lock (A)

Unlock (B)

2. Remove the EVAP canister vent control valve.

ASSEMBLY

Assemble in the reverse order of disassembly.

CAUTION:

Always replace O-ring with a new one.

InspectionINFOID:0000000006414456

Check EVAP canister as per the following:

1. Block port (B).

2. Blow air into port (A) and check that it flows freely out of port (C).

3. Release blocked port (B).

4. Apply vacuum pressure to port (B) and check that vacuum pres- sure exists at the ports (A) and (C).

5. Block port (A) and (B).

6. Apply pressure to port (C) and check that there is no leakage.

JSBIA0690ZZ

JSBIA0691ZZ

Revision: 2010 May2011 QX56

Page 2949 of 5598

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000006225640

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: Refer to WT-64, "

Inspection".

Wheel bearing axial end play: Refer to FA X - 7 , "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Lower link and upper link ball joint axial end play: Refer to FSU-15, "

Inspection" and FSU-18, "Inspection".

Shock absorber operation.

Each mounting part of axle and suspension for looseness and deformation

Lower link for cracks, deformation and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225641

CAMBER, CASTER

1. Adjust with the front/rear side adjusting bolts (1) on the lower link

(2).

2. See the following table for the amount of cam bolt scale move- ment and the variation of camber and caster.

CAUTION:

Align the adjusting bolt cutout with the stamp of lower link

bracket.

: Vehicle front

JPEIA0235ZZ

Revision: 2010 May2011 QX56

Page 2952 of 5598

FSU-10

< REMOVAL AND INSTALLATION >

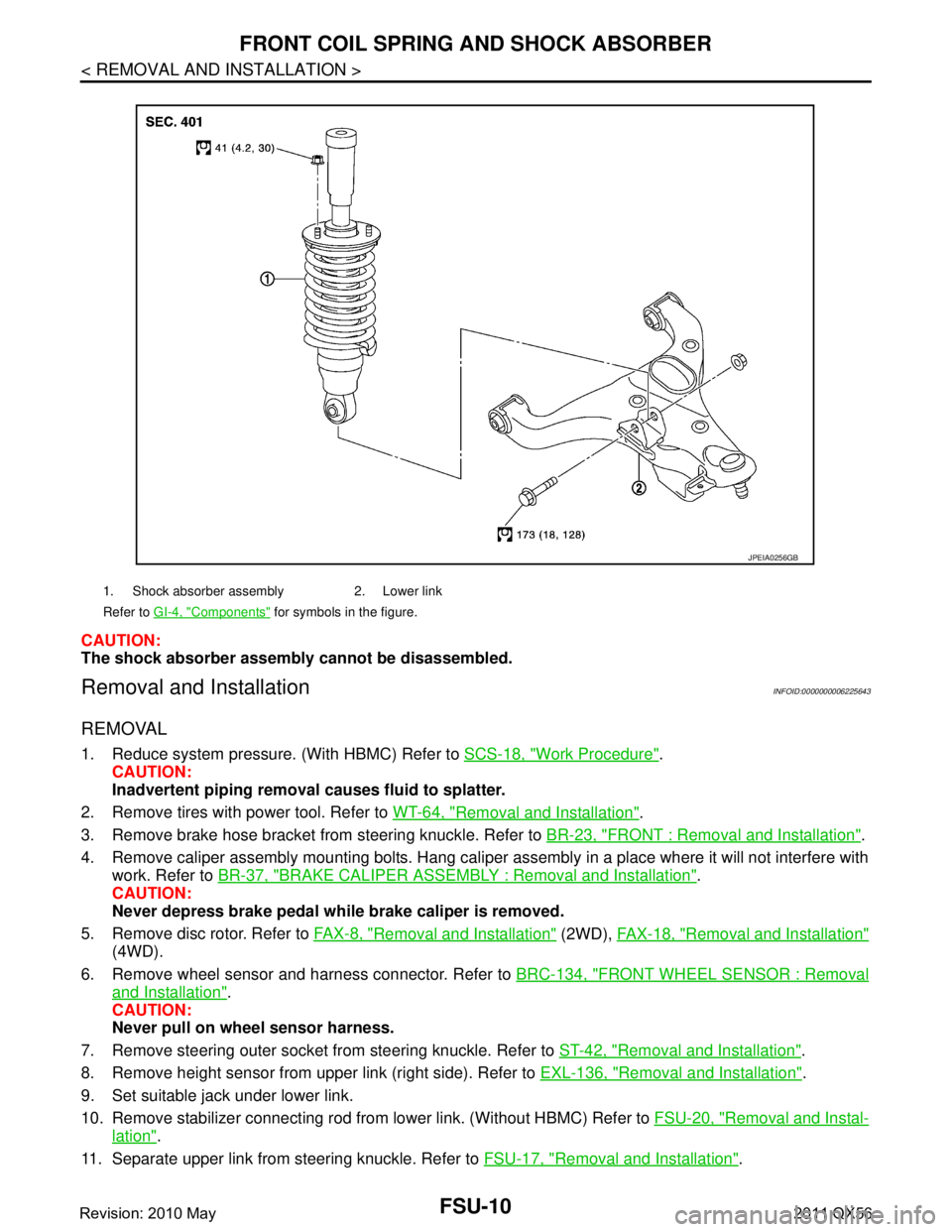

FRONT COIL SPRING AND SHOCK ABSORBER

CAUTION:

The shock absorber assembly cannot be disassembled.

Removal and InstallationINFOID:0000000006225643

REMOVAL

1. Reduce system pressure. (With HBMC) Refer to SCS-18, "Work Procedure".

CAUTION:

Inadvertent piping removal causes fluid to splatter.

2. Remove tires with power tool. Refer to WT-64, "

Removal and Installation".

3. Remove brake hose bracket from steering knuckle. Refer to BR-23, "

FRONT : Removal and Installation".

4. Remove caliper assembly mounting bolts. Hang caliper assembly in a place where it will not interfere with work. Refer to BR-37, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Never depress brake pedal while brake caliper is removed.

5. Remove disc rotor. Refer to FA X - 8 , "

Removal and Installation" (2WD), FAX-18, "Removal and Installation"

(4WD).

6. Remove wheel sensor and harness connector. Refer to BRC-134, "

FRONT WHEEL SENSOR : Removal

and Installation".

CAUTION:

Never pull on wheel sensor harness.

7. Remove steering outer socket fr om steering knuckle. Refer to ST-42, "

Removal and Installation".

8. Remove height sensor from upper link (right side). Refer to EXL-136, "

Removal and Installation".

9. Set suitable jack under lower link.

10. Remove stabilizer connecting rod from lower link. (Without HBMC) Refer to FSU-20, "

Removal and Instal-

lation".

11. Separate upper link from steering knuckle. Refer to FSU-17, "

Removal and Installation".

1. Shock absorber assembly 2. Lower link

Refer to GI-4, "

Components" for symbols in the figure.

JPEIA0256GB

Revision: 2010 May2011 QX56

Page 2981 of 5598

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

P

R

S

T

V

W

1

ABBREVIATION DESCRIPTION P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position PSP Power steering pressurePTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION RAM Random access memoryRAS Rear active steer RH Right-hand

ROM Read only memory RPM Engine speed RR Rear

ABBREVIATION DESCRIPTION SAE Society of Automoti ve Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications SRT System readiness testSST Special Service Tools

ABBREVIATION DESCRIPTION TC Turbocharger

TCM Transmission control module TCS Traction control system TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

ABBREVIATION DESCRIPTION VDC Vehicle dynamics control systemVIN Vehicle identification number

VSS Vehicle speed sensor

ABBREVIATION DESCRIPTION WOT Wide open throttle

ABBREVIATION DESCRIPTION 1

11st range first gear

Revision: 2010 May2011 QX56

Page 3443 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes INFINITI QX56 2011 Factory Owners Manual

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes](/img/42/57033/w960_57033-3442.png)

LAN

HOW TO USE THIS SECTIONLAN-23

< HOW TO USE THIS MANUAL > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

HOW TO USE THIS MANUAL

HOW TO USE THIS SECTION

CautionINFOID:0000000006220525

This section describes information peculiar to a vehicle and inspection procedures.

For trouble diagnosis procedure, refer to

LAN-18, "

Trouble Diagnosis Procedure".

Abbreviation ListINFOID:0000000006220526

Unit name abbreviations in CONSULT-III CAN diagnosis and in this section are as per the following list.

Abbreviation Unit name

4WD Transfer control unit

A-BAG Air bag diagnosis sensor unit ABS ABS actuator and electric unit (control unit)

ADP Driver seat control unit AFS AFS control unitAPA Accelerator pedal actuator AV AV control unit

BCM BCM

CGW CAN gateway DLC Data link connector

E-SUS Air levelizer control module ECM ECM

HVAC A/C auto amp. ICC ADAS control unit

IPDM-E IPDM E/R LANE Lane camera unit

LASER ICC sensor M&A Combination meter

PSB Pre-crash seat belt control unit (driver side)

PWBD Automatic back door control module

RDR-L Side radar LH

RDR-R Side radar RH STRG Steering angle sensor TCM TCM

TPMS Low tire pressure warning control unit

Revision: 2010 May2011 QX56

Page 3446 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assem INFINITI QX56 2011 Factory Owners Manual

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assem](/img/42/57033/w960_57033-3445.png)

LAN-26

< SYSTEM DESCRIPTION >[CAN]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Parts LocationINFOID:0000000006220530

1. Air bag diagnosis sensor unit 2. Lane camera unit 3. A/T assembly

4. AFS control unit 5. Transfer control unit 6. Low tire pressure warning control

unit

7. IPDM E/R 8. CAN gateway 9. ECM

10. A/C auto amp. 11. ICC sensor 12. AV control unit

13. BCM 14. ABS actuator an d electric unit (con-

trol unit) 15. Combination meter

16. Data link connector 17. Steering angle sensor 18. Accelerator pedal actuator

19. Driver seat control un it 20. Pre-crash seat be lt control unit (driv-

er side) 21. Air levelizer control module

22. ADAS control unit 23. Automatic back door control module 24. Side radar LH

25. Side radar RH

JSMIA0343ZZ

Revision: 2010 May2011 QX56

Page 3447 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine INFINITI QX56 2011 Factory Owners Manual

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine](/img/42/57033/w960_57033-3446.png)

LAN

SYSTEMLAN-27

< SYSTEM DESCRIPTION > [CAN]

C

D

E

F

G H

I

J

K L

B A

O P

N

SYSTEM

CAN COMMUNICATION SYSTEM

CAN COMMUNICATION SYSTEM : CAN

System Specification ChartINFOID:0000000006220532

Determine CAN system type from the following specification chart.

NOTE:

Refer to LAN-18, "

Trouble Diagnosis Procedure" for how to use CAN system specification chart.

Ă—: Applicable

VEHICLE EQUIPMENT IDENTIFICATION INFORMATION

NOTE:

Body type Wagon

Axle 2WD 4WD

Engine VK56VD

Transmission A/T

Brake control VDC

ICC system Ă—Ă—

CAN system type 1 2 3 4 CAN communication unit

ECM Ă—Ă—Ă—Ă—

Transfer control unit Ă—Ă—

ABS actuator and electric unit (control unit) Ă—Ă—Ă—Ă—

TCM Ă—Ă—Ă—Ă—

Air bag diagnosis sensor unit Ă—Ă—Ă—Ă—

AFS control unit Ă—Ă—

AV control unit Ă—Ă—Ă—Ă—

BCM Ă—Ă—Ă—Ă—

CAN gateway Ă—Ă—

Data link connector Ă—Ă—Ă—Ă—

A/C auto amp. Ă—Ă—Ă—Ă—

Combination meter Ă—Ă—Ă—Ă—

Steering angle sensor Ă—Ă—Ă—Ă—

Low tire pressure warning control unit Ă—Ă—Ă—Ă—

IPDM E/R Ă—Ă—Ă—Ă—

Driver seat control unit Ă—Ă—Ă—Ă—

Pre-crash seat belt control unit (driver side) Ă—Ă—

Air levelizer control module Ă—Ă—Ă—Ă—

ADAS control unit Ă—Ă—

Automatic back door control module Ă—Ă—Ă—Ă—

ITS communication unit

ADAS control unit Ă—Ă—

Side radar RH Ă—Ă—

Side radar LH Ă—Ă—

Lane camera unit Ă—Ă—

Accelerator pedal actuator Ă—Ă—

ICC sensor Ă—Ă—

Revision: 2010 May2011 QX56

Page 3452 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T

INFINITI QX56 2011 Factory Owners Manual

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T](/img/42/57033/w960_57033-3451.png)

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T

A/C compresso r feedback

signal RRT

Detention switch signal R T R

Engine restart control sig-

nal RT

Front wiper stop position

signal RT

High beam status signal R T

Hood switch signal R T

Low beam status signal R R T

Push-button ignition switch

status signal RT

Starter control relay signal R T

Steering lock unit status

signal RT

CK SUSP indi cator lamp

signal RT

Brake fluid pressure control

signal R

T

BSW warning lamp signal R T

IBA OFF indicator lamp sig-

nal RT

IBA operation signal RT

ICC operation signal R T

ICC warning lamp signal R T

Lane departure warning

lamp signal RT

LDP ON indicator lamp sig-

nal RT

Target yaw moment signal R T

Signal name

ECM

4WD

ABS

TCM

A-BAG

AFSAV

BCM

CGW

HVAC

M&A

STRG

TPMS

IPDM-E ADP

PSB

E-SUS ICC

PWBD

Revision: 2010 May2011 QX56

Page 3478 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LA INFINITI QX56 2011 Factory Owners Manual

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LA](/img/42/57033/w960_57033-3477.png)

LAN-58

< DTC/CIRCUIT DIAGNOSIS >[CAN]

MALFUNCTION AREA CHART

SHORT CIRCUIT

ITS Communication CircuitINFOID:0000000006220538

MAIN LINE

BRANCH LINE

Malfunction area Reference

ECM branch line circuit LAN-68, "

Diagnosis Procedure"

Transfer control unit branch line circuitLAN-69, "Diagnosis Procedure"

ABS actuator and electric unit (control unit) branch line circuit LAN-70, "Diagnosis Procedure"

TCM branch line circuit LAN-71, "Diagnosis Procedure"

Air bag diagnosis sensor unit branch line circuitLAN-72, "Diagnosis Procedure"

AFS control unit branch line circuitLAN-73, "Diagnosis Procedure"

AV control unit branch line circuitLAN-74, "Diagnosis Procedure"

BCM branch line circuitLAN-75, "Diagnosis Procedure"

CAN gateway branch line circuit (CAN communication circuit 1)LAN-76, "Diagnosis Procedure"

CAN gateway branch line circuit (CAN communication circuit 2)LAN-77, "Diagnosis Procedure"

Data link connector branch line circuitLAN-78, "Diagnosis Procedure"

A/C auto amp. branch line circuitLAN-79, "Diagnosis Procedure"

Combination meter branch line circuitLAN-80, "Diagnosis Procedure"

Steering angle sensor branch line circuitLAN-81, "Diagnosis Procedure"

Low tire pressure warning control unit branch line circuitLAN-82, "Diagnosis Procedure"

IPDM E/R branch line circuitLAN-83, "Diagnosis Procedure"

Driver seat control unit branch line circuitLAN-84, "Diagnosis Procedure"

Pre-crash seat belt control unit (driver side) branch line circuitLAN-85, "Diagnosis Procedure"

Air levelizer control module branch line circuitLAN-86, "Diagnosis Procedure"

ADAS control unit branch line circuitLAN-87, "Diagnosis Procedure"

Automatic back door control module branch line circuitLAN-88, "Diagnosis Procedure"

Malfunction area Reference

CAN communication circuit (Without ICC system) LAN-94, "

Diagnosis Procedure"

CAN communication circuit 1 (With ICC system)LAN-96, "Diagnosis Procedure"

CAN communication circuit 2 (With ICC system)LAN-98, "Diagnosis Procedure"

Malfunction area Reference

Main line between side radar RH and side radar LH LAN-64, "

Diagnosis Procedure"

Main line between side radar LH and lane camera unitLAN-65, "Diagnosis Procedure"

Main line between lane camera unit and accelerator pedal actu-

atorLAN-67, "Diagnosis Procedure"

Malfunction area Reference

Side radar RH branch line circuit LAN-89, "

Diagnosis Procedure"

Side radar LH branch line circuitLAN-90, "Diagnosis Procedure"

Lane camera unit branch line circuitLAN-91, "Diagnosis Procedure"

Accelerator pedal actuator branch line circuitLAN-92, "Diagnosis Procedure"

ICC sensor branch line circuitLAN-93, "Diagnosis Procedure"

Revision: 2010 May2011 QX56

Page 3502 of 5598

![INFINITI QX56 2011 Factory Owners Manual

LAN-82

< DTC/CIRCUIT DIAGNOSIS >[CAN]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220558

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the INFINITI QX56 2011 Factory Owners Manual

LAN-82

< DTC/CIRCUIT DIAGNOSIS >[CAN]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220558

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the](/img/42/57033/w960_57033-3501.png)

LAN-82

< DTC/CIRCUIT DIAGNOSIS >[CAN]

TPMS BRANCH LINE CIRCUIT

TPMS BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000006220558

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the low tire pressure warning control unit for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of low tire pressure warning control unit.

2. Check the resistance between the low tire pressu re warning control unit harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the low tire pressure warning control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the lo w tire pressure warning control unit. Refer to WT-51,

"Diagnosis Procedure".

Is the inspection result normal?

YES (Present error)>>Replace the low tire pressure warning control unit. Refer to WT-65, "Removal and

Installation".

YES (Past error)>>Error was detected in the low tire pressure warning control unit branch line.

NO >> Repair the power supply and the ground circuit.

Low tire pressure warning control unit harness connector Resistance (Ω)

Connector No. Terminal No.

M96 2 1 Approx. 54 – 66

Revision: 2010 May2011 QX56