tow INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1254 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation INFINITI QX56 2011 Factory Owners Manual

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation](/img/42/57033/w960_57033-1253.png)

DAS

HANDLING PRECAUTIONDAS-289

< SYSTEM DESCRIPTION > [LDW & LDP]

C

D

E

F

G H

I

J

K L

M B

N P A

- When driving without normal tire conditions (for example, tire wear, low tire pressure, installation of spare tire, tire chains, non-standard wheels).

- When the vehicle is equipped with non-origi nal brake parts or suspension parts.

- When towing a trailer or other vehicle.

Excessive noise will interfere with the warning chime sound, and the chime may not be heard.

The functions of the LDP system (warning and brake control assist) may or may not operate properly under

the following conditions:

- On roads where there are multiple parallel lane marker s; lane markers that are faded or not painted clearly;

yellow painted lane markers; non-standard lane markers or lane markers covered with water, dirt or snow,

etc.

- On roads where discontinued lane markers are still detectable.

- On roads where there are sharp curves.

- On roads where there are sharply contrasting objects, such as shadows, snow, water, wheel ruts, seams or

lines remaining after road repairs (The LDP syste m could detect these items as lane markers.).

- On roads where the traveling lane merges or separates.

- When the vehicle's traveling direction does not align with the lane marker.

- When traveling close to other vehicle in front of the vehicle, which obstructs the lane camera unit detection

range.

- When rain, snow or dirt adheres to the windshield in front of the lane camera unit.

- When the headlights are not bright due to dirt on the lens or if the aiming is not adjusted properly.

- When strong light enters the lane camera unit (For example, the light directly shines on the front of the vehi-

cle at sunrise or sunset.)

- When a sudden change in brightness occurs (For exampl e, when the vehicle enters or exits a tunnel or

under a bridge.)

While the LDP system is operating, driver may hear a sound of brake operation. This is normal and indicates

that the LDP system is operating properly.

Revision: 2010 May2011 QX56

Page 1382 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side rada INFINITI QX56 2011 Factory Owners Manual

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side rada](/img/42/57033/w960_57033-1381.png)

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side radar for BSW system is located inside the rear bumper.

Always keep the rear bumper near the side radar clean.

Do not attach a sticker (including transparent material), install an accessory or paintwork near the side radar.

Do not strike or damage the areas around the side radar.

Do not strike, damage, and scratch the side radar, especially the vent seal (gray circular) area, under repair.

PRECAUTIONS FOR BLIND SPOT WARNING

The BSW system is not a replacement for proper driving procedure and are not designed to prevent contact

with vehicles or objects. When changing lanes, always us e the side and rear mirrors and turn and look in the

direction driver will move to ensure it is safe to change lanes. Never rely solely on the BSW system.

The BSW system may not provide a warning for v ehicles that pass through the detection zone quickly.

Do not use the BSW system when towing a trai ler because the system may not function properly.

Excessive noise (e.g. audio system volume, open vehicle window) will interfere with the chime sound, and it may not be heard.

The side radar may not be able to detect and activate BSW when certain objects are present such as:

- Pedestrians, bicycles, animals.

- Several types of vehicles such as motorcycles.

- Oncoming vehicles.

- Vehicles remaining in the detection z one when driver accelerate from a stop.

- A vehicle merging into an adjacent lane at a speed approximately the same as vehicle.

- A vehicle approaching rapidly from behind.

- A vehicle which vehicle overtakes rapidly.

Severe weather or road spray conditions may reduce t he ability of the side radar to detect other vehicles.

The side radar detection zone is designed based on a standard lane width. When driving in a wider lane, the

side radar may not detect vehicles in an adjacent lane. When driving in a narrow lane, the side radar may

detect vehicles driving two lanes away.

The side radar are designed to ignore most stationary objects, however objects such as guardrails, walls,

foliage and parked vehicles may occasionally be det ected. This is a normal operating condition.

Revision: 2010 May2011 QX56

Page 1487 of 5598

![INFINITI QX56 2011 Factory Owners Manual

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacem INFINITI QX56 2011 Factory Owners Manual

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacem](/img/42/57033/w960_57033-1486.png)

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacement for proper dr

iving procedure and are not designed to prevent contact

with vehicles or objects. When changing lanes, always us e the side and rear mirrors and turn and look in the

direction driver will move to ensure it is safe to change lanes. Never rely solely on the BSW system.

The BSW system may not provide a warning for vehi cles that pass through the detection zone quickly.

Do not use the BSW system when towing a traile r because the system may not function properly.

Excessive noise (e.g. audio system volume, open vehi cle window) will interfere with the chime sound, and it

may not be heard.

The side radar may not be able to detect and activate BSW when certain objects are present such as:

- Pedestrians, bicycles, animals.

- Several types of vehicles such as motorcycles.

- Oncoming vehicles.

- Vehicles remaining in the detection z one when driver accelerate from a stop.

- A vehicle merging into an adjacent lane at a speed approximately the same as vehicle.

- A vehicle approaching rapidly from behind.

- A vehicle which vehicle overtakes rapidly.

Severe weather or road spray conditions may reduce t he ability of the side radar to detect other vehicles.

The side radar detection zone is designed based on a standard lane width. When driving in a wider lane, the

side radar may not detect vehicles in an adjacent l ane. When driving in a narrow lane, the side radar may

detect vehicles driving two lanes away.

The side radar are designed to ignore most stationary objects, however objects such as guardrails, walls,

foliage and parked vehicles may occasionally be detected. This is a normal operating condition.

Revision: 2010 May2011 QX56

Page 1774 of 5598

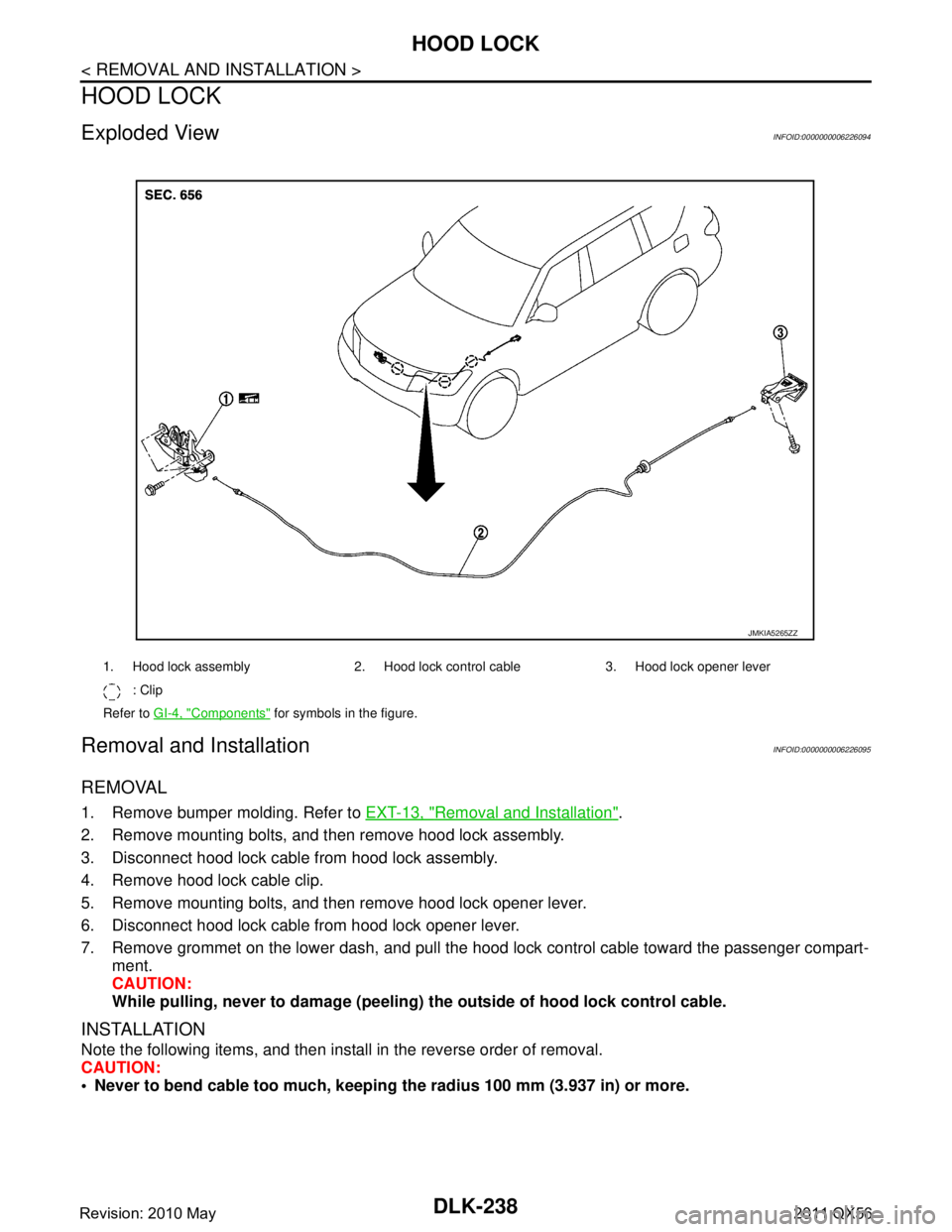

DLK-238

< REMOVAL AND INSTALLATION >

HOOD LOCK

HOOD LOCK

Exploded ViewINFOID:0000000006226094

Removal and InstallationINFOID:0000000006226095

REMOVAL

1. Remove bumper molding. Refer to EXT-13, "Removal and Installation".

2. Remove mounting bolts, and then remove hood lock assembly.

3. Disconnect hood lock cable from hood lock assembly.

4. Remove hood lock cable clip.

5. Remove mounting bolts, and then remove hood lock opener lever.

6. Disconnect hood lock cable from hood lock opener lever.

7. Remove grommet on the lower dash, and pull the hood lock control cable toward the passenger compart- ment.

CAUTION:

While pulling, never to da mage (peeling) the outside of hood lock control cable.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Never to bend cable too much, keeping the radius 100 mm (3.937 in) or more.

1. Hood lock assembly 2. Hood lock control cable 3. Hood lock opener lever

: Clip

Refer to GI-4, "

Components" for symbols in the figure.

JMKIA5265ZZ

Revision: 2010 May2011 QX56

Page 1778 of 5598

DLK-242

< REMOVAL AND INSTALLATION >

FRONT DOOR LOCK

7. While pulling outside handle, remove door key cylinder assem-bly (driver side) or outside handle escutcheon (passenger side).

8. While pulling outside handle (1), slide toward rear of vehicle to remove outside handle.

9. Remove front gasket and rear gasket.

10. Slide toward rear of vehicle to remove outside handle bracket.

11. Disconnect door lock cable from outside handle bracket.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

When installing key rod, rotate key rod holder until a click is felt.

Check door lock cable is properly engaged with outside handle bracket.

After installation, check door op en/close, lock/unlock operation.

JMKIA0560ZZ

JMKIA0524ZZ

JMKIA2652ZZ

Revision: 2010 May2011 QX56

Page 1780 of 5598

DLK-244

< REMOVAL AND INSTALLATION >

REAR DOOR LOCK

INSIDE HANDLE : Removal and Installation

INFOID:0000000006226103

REMOVAL

1. Remove rear door finisher. Refer to INT-16, "Removal and Installation".

2. Remove inside handle escutcheon. Refer to INT-16, "

Exploded View"

3. Remove inside handle mounting screws, and then remove inside handle.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check door lock cables are properly engaged with inside handle.

After installation, check door open/close, lock/unlock operation.

OUTSIDE HANDLE

OUTSIDE HANDLE : Removal and InstallationINFOID:0000000006226104

REMOVAL

1. Fully close rear door glass.

2. Remove rear door finisher. Refer to INT-16, "

Removal and Installation".

3. Remove sealing screen. NOTE:

Cat the buty-tape so that some parts of the buty-t ape do not remain on the sealing screen, if the sealing

screen is reused.

4. Remove door side grommet, and loosen TORX bolt from grom- met hole.

5. While pulling outside handle, remove outside handle escutch- eon.

6. While pulling outside handle (1), slide toward rear of vehicle to remove outside handle.

: TORX bolt

JMKIA0025ZZ

JMKIA5342ZZ

JMKIA0524ZZ

Revision: 2010 May2011 QX56

Page 1781 of 5598

REAR DOOR LOCKDLK-245

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

7. Remove front gasket and rear gasket.

8. Slide toward rear of vehicle to remove outside handle bracket.

9. Disconnect door lock cable from outside handle bracket.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

Check door lock cable is properly engaged with outside handle bracket.

After installation, check door op en/close, lock/unlock operation.

JMKIA2652ZZ

Revision: 2010 May2011 QX56

Page 1783 of 5598

BACK DOOR LOCKDLK-247

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

3. Remove clips and TORX screws of touch sensor.

4. Pull harness of touch sensor out of back door and remove touch sensor.

INSTALLATION

Note the following item, and then install in the reverse order of removal.

CAUTION:

Check back door open/close operation after installation.

BACK DOOR SUPPORT ROD

BACK DOOR SUPPORT ROD : Removal and InstallationINFOID:0000000006226108

REMOVAL

1. Remove cap of back door finisher side (LH). Refer to INT-39, "Exploded View".

2. Remove stud ball (1) of back door support rod (3) from back door assembly (2).

3. Remove automatic back door control module. Refer to DLK-262, "

Removal and Installation".

NOTE:

When replacing back door support rod, replace stud ba ll and automatic back door control module as a set,

since back door support rod is engaged and connected to stud ball and automatic back door control mod-

ule.

INSTALLATION

Note the following items, and then install in the reverse order of removal.

CAUTION:

When reusing stud ball, always a pply locking sealant before installing stud ball to back door.

Check back door open/close opera tion after installation.

EMERGENCY LEVER

EMERGENCY LEVER : Unlock proceduresINFOID:0000000006226109

UNLOCK PROCEDURES

NOTE:

If back door lock cannot be unlocked due to a malfuncti on or battery discharge, follow the procedures to

unlock back door.

1. Remove the emergency handle mask. Refer to INT-39, "

Exploded View".

2. From inside the vehicle, rotate emergency lever toward lower direction and unlock.

JMKIA5442ZZ

JMKIA5264ZZ

Revision: 2010 May2011 QX56

Page 1788 of 5598

DLK-252

< REMOVAL AND INSTALLATION >

CAB MOUNTING INSULATOR

Drain brake fluid from brake line. Refer to BR-10, "Draining".

Release fuel pressure. Refer to EC-153, "

Work Procedure".

Disconnect both battery cables. Refer to PG-164, "

Removal and Installation".

Drain engine coolant from radiator. Refer to CO-8, "

Draining".

Discharge refrigerant from A/C circuit. Refer to HA-20, "

Recycle Refrigerant".

Drain power steering fluid from reservoir tank.

4. Remove parts relating to connection of body assembly and frame assembly. Tire and wheel: Refer to WT-64, "

Removal and Installation" (with TPMS).

Front fender protector (LH and RH): Refer to EXT-23, "

FENDER PROTECTOR : Removal and Installa-

tion".

Front bumper: Refer to EXT-13, "

Removal and Installation".

Radiator core support upper: Refer to DLK-220, "

Removal and Installation".

Fan shroud: Refer to CO-16, "

Removal and Installation".

Battery and battery case: Refer to PG-164, "

Removal and Installation".

Air cleaner case (upper and lower): Refer to EM-27, "

Removal and Installation".

Engine cover: Refer to EM-25, "

Removal and Installation".

Rear wheel house protector (LH and RH): EXT-24, "

REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

Rear bumper: Refer to EXT-17, "

Removal and Installation".

Fuel filler tube: Remove to FL-8, "

Exploded View".

Spare tire

Towing hook bracket.

5. Separate parts relating to connection of body assembly and frame assembly. Vehicle front

Disconnect ICC sensor connector. (models with ICC) Refer to CCS-176, "

Removal and Installation".

Remove radiator upper hose and radiator lower hose from radiator assembly. Refer to CO-13,

"Exploded View".

Remove A/T fluid cooler hose B and A/T fluid cooler hose E from A/T fluid cooler tubes. Refer to TM-

202, "Exploded View".

Remove power steering return hose from oil cooler, and then power steering return hose clamp bolt from frame assembly. Refer to ST-54, "

Exploded View".

Remove power steering suction hose from reservoir tank. Refer to ST-54, "

Exploded View".

CAUTION:

Never spill power steering fluid in engine room.

Remove A/C low-presser flexible hose from A/C low-presser pipe. Refer to HA-35, "

LOW-PRESSURE

FLEXIBLE HOSE : Removal and Installation".

Remove A/C hi-presser flexible hose from condenser. Refer to HA-34, "

HIGH-PRESSURE FLEXIBLE

HOSE : Removal and Installation".

Remove all engine Control Harness connectors, har ness clips and others that are connected to the

body assembly side of the engine room. (engine room LH and RH side). Refer to PG-148, "

Engine Con-

trol Harness".

NOTE:

Separate harness connectors from ECM (engine control module). Refer to EC-10, "

General Precau-

tions".

CAUTION:

When pulling out harnesses, never damage harnesses or connectors.

After temporarily securing connectors, cover th em with vinyl or similar material to protect

against adhesion of foreign materials.

Disconnect engine room harness connectors and remo ve harness clips from engine assembly (engine

RH side). Refer to PG-146, "

Engine Room Harness".

Remove heater hoses from front water outlet tube (engine room RH side). Refer to HA-33, "

Exploded

View".

Disconnect front wheel sensor connectors (LH and RH). Refer to BRC-134, "

FRONT WHEEL SENSOR

: Exploded View".

Disconnect fuel feed tube and EVAP hos e (front wheel well LH side).

Remove steering lower shaft from steering gear side assembly. Refer to ST-37, "

Removal and Installa-

tion"

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and

steering gear assembly.

Revision: 2010 May2011 QX56

Page 1809 of 5598

![INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push INFINITI QX56 2011 Factory Owners Manual

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push](/img/42/57033/w960_57033-1808.png)

PRECAUTIONSDLN-7

< PRECAUTION > [TRANSFER: ATX90A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Service Notice or Precautions for TransferINFOID:0000000006222211

CAUTION:

Use Genuine NISSAN Transfer Fluid. Refer to MA-10, "

Fluids and Lubricants".

Never reuse transfer fluid, once it has been drained.

Check the fluid level or repl ace the fluid only with the vehicle parked on level ground.

During removal or installati on, keep inside of transfer clear of dust or dirt.

Replace all tires at the same time. Always use tir es of the proper size and the same brand and pat-

tern. Fitting improper size and unusually worn tires applies excessive force to vehicle mechanism

and can cause longitudinal vibration.

Disassembly should be done in a clean work area, it is preferable to work in dustproof area.

Before proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the

internal parts from becoming contamin ated by dirt or other foreign matter.

All parts should be carefully cl eaned with a general purpose, non-flammable solvent before inspec-

tion or reassembly.

Check for the correct installation status prior to removal or disassembly. If matching marks are

required, be certain they do not interfere wit h the function of the parts when applied.

Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace

them with a new ones if necessary.

Gaskets, seals and O-rings should be replaced any time the transfer is disassembled.

In principle, tighten bolts or nu ts gradually in several steps workin g diagonally from inside to out-

side. If tightening sequence is specified, use it.

Observe the specified torque when assembling.

Clean and flush the parts su fficiently and blow-dry them.

Be careful not to damage sliding surfaces and mating surfaces.

Clean inner parts with lint-free cloth or towels . Do not use cotton work gloves and rags to prevent

adhering fibers.

Revision: 2010 May2011 QX56