tow INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4799 of 5598

SRC-6

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006219946

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

ServiceINFOID:0000000006219947

Never use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

Before servicing the SRS, turn ignition switch OF F, disconnect battery negative terminal and wait 3 minutes

or more.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt pre-

tensioner to deploy. Therefore, never work on any SR S connectors or wires until at least 3 minutes have

passed.

Diagnosis sensor unit must always be installed with their arrow marks “ ⇐” pointing towards the front of the

vehicle for proper operation. Also chec k diagnosis sensor unit for cracks, deformities or rust before installa-

tion and replace as required.

The spiral cable must be aligned with the neutral position since its rotations are limited. Never turn steering

wheel and column after removal of steering gear.

Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad side facing upward and seat mounted front side air bag module standing with the stud bolt side facing down.

Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

After air bag inflates, the front instrument panel assembly should be replaced if damaged.

Always replace instrument panel pad following front passenger air bag deployment.

Never solder the harness when making repairs. Check that harness is not pinched and that there is no con-

tact with other components.

Never allow harness to come in contact with oil, grease, waste oil, or water.

Never insert foreign materials, such as a screwdriver , into the harness connector. (This is to prevent acci-

dental activation caused by static electricity.)

Always use CONSULT-III or SRS air bag warning lamp to perform the circuit diagnosis. (Never use an elec- tric tester such as a circuit tester.)

Never enter in the deployment area of the pop-up roll bar. Never put an object in the deployment area of the

pop-up roll bar. (This is to prevent injury in case of an unintentional deployment.)

Revision: 2010 May2011 QX56

Page 4991 of 5598

ST-4

< PRECAUTION >

PRECAUTIONS

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Service Notice or Precautions for Steering SystemINFOID:0000000006225573

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehicle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

- Before disassembly, thoroughly clean the outside of the unit.

- Disassembly should be done in a clean work area. It is im portant to prevent the internal parts from becoming

contaminated by dirt or other foreign matter.

- For easier and proper assembly, place disassembled parts in order on a parts rack.

- Use nylon cloth or paper towels to clean the parts; co mmon shop rags can leave lint that might interfere with

their operation.

- Never reuse non-reusable parts.

- Before assembling, apply the specified grease to the directed parts.

Revision: 2010 May2011 QX56

Page 5038 of 5598

POWER STEERING OIL PUMPST-51

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Apply recommended grease to oil seal lips (1). Apply recom- mended fluid to around oil seal. Install oil seal to body assembly,

using a drift.

CAUTION:

Never reuse oil seal.

2. Apply recommended fluid to drive shaft, and press drive shaft into body assembly, then install snap ring.

CAUTION:

Never reuse snap ring.

3. Apply recommended fluid to O-ring, and then install O-ring into body assembly.

CAUTION:

Never reuse O-ring.

4. Install side plate to body assembly.

5. Install dowel pin (1) into dowel pin hole (A), and then install cam ring (2) pointing it's D

1 side toward the body assembly (3) side

as shown in the figure.

When installing cam ring, turn carved face with a letter E (B) of

it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing th e incorrect direction, it may

cause oil pump operation malfunction.

SGIA1150E

SGIA0422E

JSGIA0110ZZ

Revision: 2010 May2011 QX56

Page 5089 of 5598

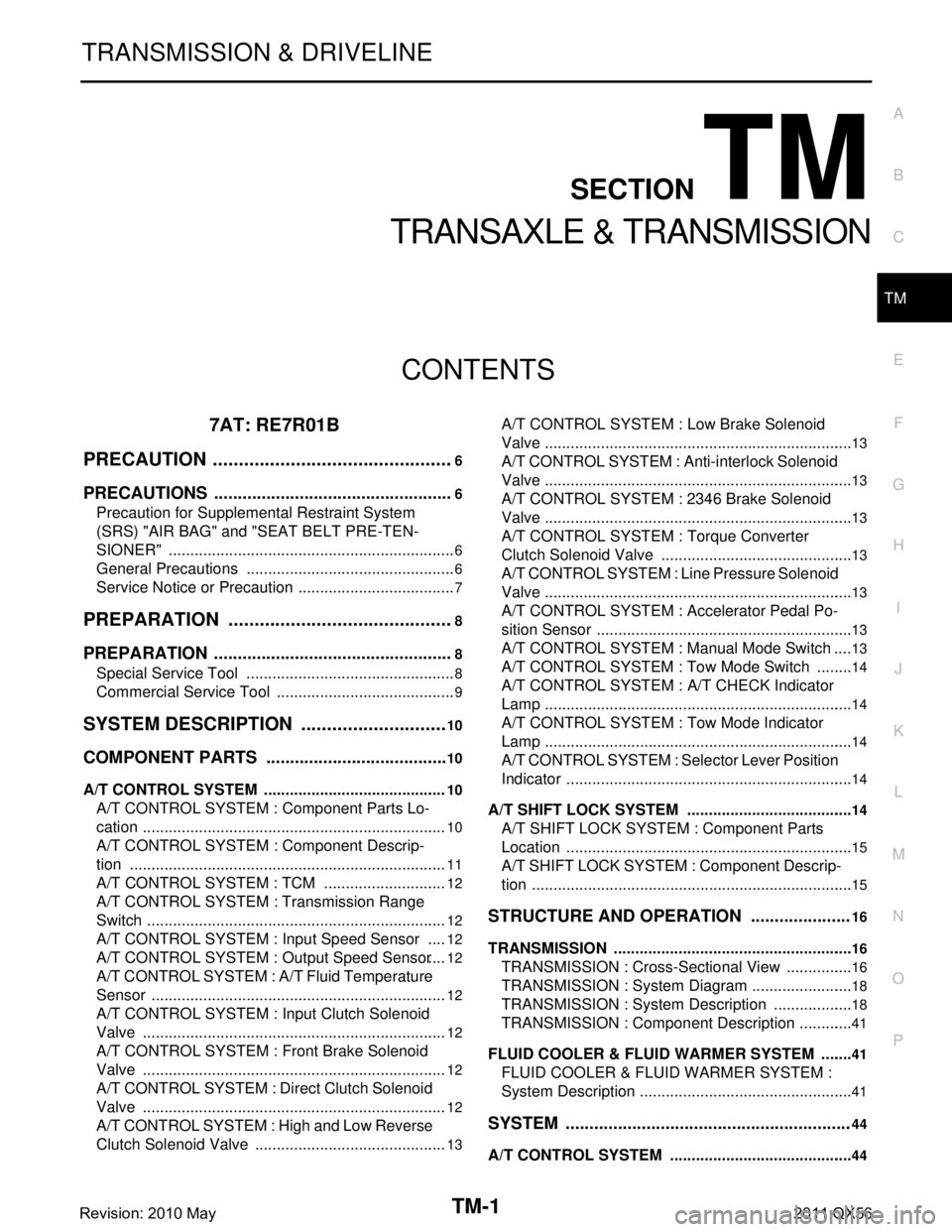

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

7AT: RE7R01B

PRECAUTION ................ ...............................

6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

General Precautions .................................................6

Service Notice or Precaution .....................................7

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ..........................................9

SYSTEM DESCRIPTION .............................10

COMPONENT PARTS ................................... ....10

A/T CONTROL SYSTEM ...........................................10

A/T CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

10

A/T CONTROL SYSTEM : Component Descrip-

tion ...................................................................... ....

11

A/T CONTROL SYSTEM : TCM .............................12

A/T CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

12

A/T CONTROL SYSTEM : Input Speed Sensor .....12

A/T CONTROL SYSTEM : Output Speed Sensor ....12

A/T CONTROL SYSTEM : A/ T Fluid Temperature

Sensor ................................................................. ....

12

A/T CONTROL SYSTEM : Input Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Front Brake Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Direct Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : High and Low Reverse

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Low Brake Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Anti-interlock Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : 2346 Brake Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Line Pressure Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Accelerator Pedal Po-

sition Sensor ........................................................ ....

13

A/T CONTROL SYSTEM : Manual Mode Switch ....13

A/T CONTROL SYSTEM : To w Mode Switch .........14

A/T CONTROL SYSTEM : A/T CHECK Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Tow Mode Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Selector Lever Position

Indicator ............................................................... ....

14

A/T SHIFT LOCK SYSTEM ................................... ....14

A/T SHIFT LOCK SYSTEM : Component Parts

Location ...................................................................

15

A/T SHIFT LOCK SYSTEM : Component Descrip-

tion ...........................................................................

15

STRUCTURE AND OPERATION .....................16

TRANSMISSION .................................................... ....16

TRANSMISSION : Cross-Sectional View ................16

TRANSMISSION : System Diagram ........................18

TRANSMISSION : System Description ...................18

TRANSMISSION : Component Description .............41

FLUID COOLER & FLUID WARMER SYSTEM .... ....41

FLUID COOLER & FLUID WARMER SYSTEM :

System Description ..................................................

41

SYSTEM ............................................................44

A/T CONTROL SYSTEM ....................................... ....44

Revision: 2010 May2011 QX56

Page 5091 of 5598

TM-3

CEF

G H

I

J

K L

M A

B

TM

N

O P

Description ..........................................................

..

114

DTC Logic .............................................................114

Diagnosis Procedure .............................................115

P0730 INCORRECT GEAR RATIO ..................116

Description .......................................................... ..116

DTC Logic .............................................................116

Diagnosis Procedure .............................................116

P0731 1GR INCORRECT RATIO .....................118

Description .......................................................... ..118

DTC Logic .............................................................118

Diagnosis Procedure .............................................119

P0732 2GR INCORRECT RATIO .....................120

Description .......................................................... ..120

DTC Logic .............................................................120

Diagnosis Procedure .............................................121

P0733 3GR INCORRECT RATIO .....................122

Description .......................................................... ..122

DTC Logic .............................................................122

Diagnosis Procedure .............................................123

P0734 4GR INCORRECT RATIO .....................124

Description .......................................................... ..124

DTC Logic .............................................................124

Diagnosis Procedure .............................................125

P0735 5GR INCORRECT RATIO .....................126

Description .......................................................... ..126

DTC Logic .............................................................126

Diagnosis Procedure .............................................127

P0740 TORQUE CONVERTER ........................128

DTC Logic ........................................................... ..128

Diagnosis Procedure .............................................128

P0744 TORQUE CONVERTER ........................129

Description .......................................................... ..129

DTC Logic .............................................................129

Diagnosis Procedure .............................................129

P0745 PRESSURE CONTROL SOLENOID A ..131

DTC Logic ........................................................... ..131

Diagnosis Procedure .............................................131

P0750 SHIFT SOLENOID A .............................132

DTC Logic ........................................................... ..132

Diagnosis Procedure .............................................132

P0775 PRESSURE CONTROL SOLENOID B ..133

DTC Logic ........................................................... ..133

Diagnosis Procedure .............................................133

P0780 SHIFT ....................................................134

Description .......................................................... ..134

DTC Logic .............................................................134

Diagnosis Procedure .............................................134

P0795 PRESSURE CONTROL SOLENOID C ..136

DTC Logic ........................................................... ..136

Diagnosis Procedure ........................................... ..136

P1705 TP SENSOR .........................................137

DTC Logic ..............................................................137

Diagnosis Procedure .............................................137

P1721 VEHICLE SPEED SIGNAL ..................138

Description .............................................................138

DTC Logic ..............................................................138

Diagnosis Procedure .............................................139

P1730 INTERLOCK ........................................140

Description .............................................................140

DTC Logic ..............................................................140

Judgment of Interlock ............................................140

Diagnosis Procedure .............................................141

P1734 7GR INCORRECT RATIO ...................142

Description .............................................................142

DTC Logic ..............................................................142

Diagnosis Procedure .............................................143

P1815 M-MODE SWITCH ...............................144

DTC Logic ..............................................................144

Diagnosis Procedure .............................................144

Component Inspection (Manual Mode Switch) ......146

P2713 PRESSURE CONTROL SOLENOID D .147

DTC Logic ............................................................ ..147

Diagnosis Procedure .............................................147

P2722 PRESSURE CONTROL SOLENOID E .148

DTC Logic ..............................................................148

Diagnosis Procedure .............................................148

P2731 PRESSURE CONTROL SOLENOID F .149

DTC Logic ..............................................................149

Diagnosis Procedure .............................................149

P2807 PRESSURE CONTROL SOLENOID G .150

DTC Logic ............................................................ ..150

Diagnosis Procedure .............................................150

MAIN POWER SUPPLY AND GROUND CIR-

CUIT ................................................................

151

Diagnosis Procedure .............................................151

TOW MODE SYSTEM .....................................153

Component Function Check ..................................153

Diagnosis Procedure .............................................153

Component Inspection ...........................................155

SHIFT POSITION INDICATOR CIRCUIT ........156

Description .............................................................156

Component Function Check ..................................156

Diagnosis Procedure .............................................156

SHIFT LOCK SYSTEM ...................................157

Component Function Check ..................................157

Diagnosis Procedure .............................................157

Component Inspection (Stop Lamp Switch) ..........159

Component Inspection (Park Position Switch) ......159

Revision: 2010 May2011 QX56

Page 5092 of 5598

TM-4

Component Inspection (Shift Lock Solenoid) ........159

SELECTOR LEVER POSITION INDICATOR ..161

Component Function Check ................................ ..161

Diagnosis Procedure .............................................161

Component Inspection (Selector Lever Position

Indicator) ................................................................

163

SYMPTOM DIAGNOSIS ............................165

SYSTEM SYMPTOM ...................................... .165

Symptom Table ................................................... ..165

PERIODIC MAINTENANCE ..................... ..175

A/T FLUID ....................................................... .175

Inspection ............................................................ ..175

REMOVAL AND INSTALLATION ..............176

A/T SHIFT SELECTOR ................................... .176

Exploded View ..................................................... ..176

Removal and Installation .......................................176

Inspection and Adjustment ....................................177

CONTROL CABLE ..........................................178

Exploded View ..................................................... ..178

Removal and Installation .......................................178

Inspection and Adjustment ....................................179

SELECTOR LEVER POSITION INDICATOR ..180

Removal and Installation ..................................... ..180

TOW MODE SWITCH ......................................181

Removal and Installation ..................................... ..181

CONTROL VALVE & TCM ..............................182

Exploded View ..................................................... ..182

Removal and Installation .......................................182

Inspection and Adjustment ....................................186

PARKING COMPONENTS ..............................187

2WD ........................................................................ ..187

2WD : Exploded View ............................................187

2WD : Removal and Installation ............................187

2WD : Inspection ...................................................190

REAR OIL SEAL ..............................................192

2WD ........................................................................ ..192

2WD : Exploded View ............................................192

2WD : Removal and Installation ............................192

2WD : Inspection ...................................................193

4WD ........................................................................ ..193

4WD : Exploded View ............................................193

4WD : Removal and Installation ............................193

4WD : Inspection and Adjustment .........................194

OUTPUT SPEED SENSOR .............................195

2WD ........................................................................ ..195

2WD : Exploded View ...........................................195

2WD : Removal and Installation ............................195

2WD : Inspection and Adjustment .........................198

AIR BREATHER HOSE ....................................199

2WD ........................................................................ .199

2WD : Exploded View ...........................................199

2WD : Removal and Installation ............................199

4WD ........................................................................ .200

4WD : Exploded View ...........................................200

4WD : Removal and Installation ............................200

FLUID COOLER SYSTEM ...............................202

Exploded View ..................................................... .202

Removal and Installation .......................................202

Inspection and Adjustment ....................................204

UNIT REMOVAL AND INSTALLATION ...205

TRANSMISSION ASSEMBLY ..........................205

2WD ........................................................................ .205

2WD : Exploded View ...........................................205

2WD : Removal and Installation ............................205

2WD : Inspection and Adjustment .........................207

4WD ........................................................................ .207

4WD : Exploded View ...........................................208

4WD : Removal and Installation ............................208

4WD : Inspection and Adjustment .........................210

UNIT DISASSEMBLY AND ASSEMBLY ..211

TRANSMISSION ASSEMBLY ..........................211

Exploded View ..................................................... .211

Oil Channel ...........................................................222

Location of Needle Bearings and Bearing Races .222

Location of Snap Rings .........................................225

Disassembly ..........................................................226

Assembly ..............................................................243

Inspection ..............................................................267

OIL PUMP, 2346 BRAKE, FRONT BRAKE

PISTON .............................................................

270

Exploded View ..................................................... .270

Disassembly ..........................................................270

Assembly ..............................................................274

Inspection and Adjustment ....................................277

UNDER DRIVE CARRIER, FRONT BRAKE

HUB ..................................................................

279

Exploded View ..................................................... .279

Disassembly ..........................................................279

Assembly ..............................................................280

Inspection ..............................................................280

FRONT CARRIER, INPUT CLUTCH, REAR

INTERNAL GEAR .............................................

282

Exploded View ..................................................... .282

Disassembly ..........................................................283

Revision: 2010 May2011 QX56

Page 5095 of 5598

![INFINITI QX56 2011 Factory Repair Manual

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop r INFINITI QX56 2011 Factory Repair Manual

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop r](/img/42/57033/w960_57033-5094.png)

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

Place disassembled parts in order for easier and proper assembly.

All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

Gaskets, seals and O-rings should be repl aced any time the A/T is disassembled.

It is very important to perform func tional tests whenever they are indicated.

The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Never use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

When the A/T drain plug is removed, only some of the ATF is drained. Old ATF will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing” when changing ATF. Refer to TM-94, "

Changing".

Occasionally, the parking gear may be locked with the to rque insufficiently released, when stopping the vehi-

cle by shifting the selector lever from “D” or “R” to “P” position with the brake pedal depressed.

In this case, the shock with a thud caused by the abrupt release of torque may occur when shifting the selec-

tor lever from “P” posit ion to other positions.

However, this symptom is not a malfunction which results in the damage of parts.

Service Notice or PrecautionINFOID:0000000006274263

ATF COOLER SERVICE

If ATF contains frictional material (clutches, bands, etc. ), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiat or or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to TM-97,

"Cleaning". For radiator replacement, refer to CO-13, "Exploded View".

Revision: 2010 May2011 QX56

Page 5098 of 5598

![INFINITI QX56 2011 Factory Repair Manual

TM-10

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : Co

mponent Parts LocationINFOID:0000000006226738

1. Yaw rate/side INFINITI QX56 2011 Factory Repair Manual

TM-10

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : Co

mponent Parts LocationINFOID:0000000006226738

1. Yaw rate/side](/img/42/57033/w960_57033-5097.png)

TM-10

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

SYSTEM DESCRIPTION

COMPONENT PARTS

A/T CONTROL SYSTEM

A/T CONTROL SYSTEM : Co

mponent Parts LocationINFOID:0000000006226738

1. Yaw rate/side/decel G sensor

Refer to BRC-10, "

Component Parts

Location". 2.

Tow mode switch

*13. IPDM E/R

Refer to PCS-4, "

Component Parts

Location".

4. ECM Refer to EC-16, "

Component Parts

Location". 5. ABS actuator and electric unit (con-

trol unit)

Refer to BRC-10, "Component Parts

Location". 6. Accelerator pedal position sensor

Refer to EC-16, "

Component Parts

Location".

7. Stop lamp switch Refer to BRC-10, "

Component Parts

Location". 8. BCM

Refer to BCS-4, "

BODY CONTROL

SYSTEM : Component Parts Loca-

tion". 9. Combination meter

Refer to MWI-6, "

METER SYSTEM :

Component Parts Location".

10. Shift position indicator (In the information display in the

combination meter) 11. A/T CHECK indicator lamp

(On the combination meter) 12. Tow mode indicator lamp

13. Selector lever position indicator 14. Manual mode switch 15. A/T assembly connector

16. Output speed sensor

*217.Control valve & TCM*3

A. Center console B. A/T shift selector assembly C. A/T assembly

*1 : Tow mode switch is integrated in to SNOW MODE/TOW MODE/VDC OFF switch assembly (2WD models) or 4WD switch

assembly (4WD models).

*2 : Output speed sensor is installed in A/T assembly.

*3 : Control valve & TCM is installed in A/T assembly.

JSDIA1773GB

Revision: 2010 May2011 QX56

Page 5099 of 5598

![INFINITI QX56 2011 Factory Repair Manual

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2

INFINITI QX56 2011 Factory Repair Manual

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2](/img/42/57033/w960_57033-5098.png)

COMPONENT PARTSTM-11

< SYSTEM DESCRIPTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

NOTE:

The following components are included in the control valve & TCM (17).

TCM

Input speed sensor 1, 2

A/T fluid temperature sensor

Transmission range switch

Direct clutch solenoid valve

High and low reverse clutch solenoid valve

Input clutch solenoid valve

Front brake solenoid valve

Low brake solenoid valve

Anti-interlock solenoid valve

2346 brake solenoid valve

Line pressure solenoid valve

Torque converter clutch solenoid valve

A/T CONTROL SYSTEM : Component DescriptionINFOID:0000000006226739

Name Function

TCM TM-12, "

A/T CONTROL SYSTEM : TCM"

Transmission range switchTM-12, "A/T CONTROL SYSTEM : Transmission Range Switch"

Output speed sensor TM-12, "A/T CONTROL SYSTEM : Output Speed Sensor"

Input speed sensor 1

TM-12, "A/T CONTROL SYSTEM : Input Speed Sensor"Input speed sensor 2

A/T fluid temperature sensorTM-12, "

A/T CONTROL SYSTEM : A/T Fluid Temperature Sensor"

Input clutch solenoid valve TM-12, "A/T CONTROL SYSTEM : Input Clutch Solenoid Valve"

Front brake solenoid valve TM-12, "A/T CONTROL SYSTEM : Front Brake Solenoid Valve"

Direct clutch solenoid valveTM-12, "A/T CONTROL SYSTEM : Direct Clutch Solenoid Valve"

High and low reverse clutch solenoid valveTM-13, "A/T CONTROL SYSTEM : High and Low Reverse Clutch Solenoid Valve"

Low brake solenoid valve TM-13, "A/T CONTROL SYSTEM : Low Brake Solenoid Valve"

Anti-interlock solenoid valve TM-13, "A/T CONTROL SYSTEM : Anti-interlock Solenoid Valve"

2346 brake solenoid valve TM-13, "A/T CONTROL SYSTEM : 2346 Brake Solenoid Valve"

Torque converter clutch solenoid valveTM-13, "A/T CONTROL SYSTEM : Torque Converter Clutch Solenoid Valve"

Line pressure solenoid valve TM-13, "A/T CONTROL SYSTEM : Line Pressure Solenoid Valve"

Accelerator pedal position sensor TM-13, "A/T CONTROL SYSTEM : Accelerator Pedal Position Sensor"

Manual mode switch TM-13, "A/T CONTROL SYSTEM : Manual Mode Switch"

Tow mode switch TM-14, "A/T CONTROL SYSTEM : Tow Mode Switch"

A/T CHECK indicator lampTM-14, "A/T CONTROL SYSTEM : A/T CHECK Indicator Lamp"

Tow mode indicator lamp* TM-14, "A/T CONTROL SYSTEM : Tow Mode Indicator Lamp"

Selector lever position indicator TM-14, "A/T CONTROL SYSTEM : Selector Lever Position Indicator"

Stop lamp switch BRC-15, "Stop Lamp Switch"

Yaw rate/side G sensorBRC-15, "Yaw Rate/Side/Decel G sensor"

Starter relay STR-6, "System Description"

ECMEC-35, "ENGINE CONTROL SYSTEM : System Description"

BCM BCS-6, "BODY CONTROL SYSTEM : System Description"

Combination meter MWI-9, "METER SYSTEM : System Description"

ABS actuator and electric unit (control unit) BRC-16, "System Description"

Revision: 2010 May2011 QX56

Page 5102 of 5598

![INFINITI QX56 2011 Factory Repair Manual

TM-14

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

A/T CONTROL SYSTEM : Tow Mode Switch

INFOID:0000000006226756

Tow mode switch is integrated in to

Tow mode switch is integrated in to SN INFINITI QX56 2011 Factory Repair Manual

TM-14

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

A/T CONTROL SYSTEM : Tow Mode Switch

INFOID:0000000006226756

Tow mode switch is integrated in to

Tow mode switch is integrated in to SN](/img/42/57033/w960_57033-5101.png)

TM-14

< SYSTEM DESCRIPTION >[7AT: RE7R01B]

COMPONENT PARTS

A/T CONTROL SYSTEM : Tow Mode Switch

INFOID:0000000006226756

Tow mode switch is integrated in to

Tow mode switch is integrated in to SNOW MODE /TOW MODE/VDC OFF switch assembly (2WD models)

or 4WD switch assembly (4WD models).

When tow mode switch is pressed while tow mode indicator lamp on combination meter is OFF, the tow mode turns ON and tow mode indicator lamp turns ON.

When tow mode switch is pressed while tow mode indicator lamp on combination meter is ON, the tow mode

turns OFF and tow mode indicator lamp turns OFF.

A/T CONTROL SYSTEM : A/ T CHECK Indicator LampINFOID:0000000006226757

A/T CHECK INDICATOR LAMP

Turns ON when ignition switch turns ON and turns OFF when the system is normal, for bulb check purposes.

A/T CONTROL SYSTEM : Tow Mode Indicator LampINFOID:0000000006226758

TOW MODE INDICATOR LAMP

Turns ON when tow mode is switched to operational status (ON) by tow mode switch.

A/T CONTROL SYSTEM : Selector Lever Position IndicatorINFOID:0000000006226759

Indicates selector lever position.

A/T SHIFT LOCK SYSTEM

Condition (status) A/T CHECK indicator lamp

Ignition switch OFF OFF

For approx. 2 seconds after the ignition switch is turned ON ON

Approx. 2 seconds after ignition switch is turned ON OFF

A/T is malfunctioning OFF

Condition (status) Tow mode indicator lamp

Ignition switch OFF OFF

When ignition switch turns ON OFF

Press tow mode switch while tow mode indicator lamp is OFF. ON

Press tow mode switch while tow mode indicator lamp is ON. OFF

Revision: 2010 May2011 QX56