service INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2942 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

FL-13

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

FL

NP

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel TankINFOID:0000000006289690

Standard and Limit

Fuel tank capacity

Approx. 98.4 (26 US gal)

Fuel recommendation Refer to GI-31, "

Fuel"

Revision: 2010 May2011 QX56

Page 2943 of 5598

FSU-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION FSU

A

B

FSU

N

O PCONTENTS

FRONT SUSPENSION

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

Precaution for Procedure without Cowl Top Cover ......3

Precautions for Suspension ......................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

Commercial Service Tools ........................................4

SYMPTOM DIAGNOSIS ...............................5

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

5

NVH Troubleshooting Chart ................................ ......5

PERIODIC MAINTENANCE ..........................6

FRONT SUSPENSION ASSEMBLY .............. .....6

Inspection ............................................................ ......6

WHEEL ALIGNMENT ..........................................7

Inspection ............................................................ ......7

Adjustment ................................................................7

REMOVAL AND INSTALLATION ................9

FRONT COIL SPRING AND SHOCK AB-

SORBER ............................................................

9

Exploded View ..................................................... .....9

Removal and Installation .........................................10

Disassembly and Assembly .....................................11

Inspection and Adjustment ......................................12

Disposal ...................................................................13

LOWER LINK ....................................................14

Exploded View .........................................................14

Removal and Installation .........................................14

Inspection ................................................................15

UPPER LINK ......................... ............................17

Exploded View ..................................................... ....17

Removal and Installation .........................................17

Inspection ................................................................18

FRONT STABILIZER ........................................20

Exploded View .........................................................20

Removal and Installation .........................................20

Inspection ................................................................20

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

21

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

21

Wheel Alignment ................................................. ....21

Ball Joint ..................................................................21

Wheel Height ...........................................................21

Revision: 2010 May2011 QX56

Page 2944 of 5598

FSU-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006271944

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006271945

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 2946 of 5598

FSU-4

< PREPARATION >

PREPARATION

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000006225636

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsINFOID:0000000006225637

Tool number

(Kent-Moore No.)

Tool name Description

ST35652000

( − )

Shock absorber attachment Disassembling and assembling shock

absorber

ST3127S000

(J-25765-A)

Preload gauge Measuring rotating torque of ball joint

ZZA0807D

ZZA0806D

Tool name

Description

Power tool Loosening bolts and nuts

Spring compressor Removing and installing coil spring

PBIC0190E

S-NT717

Revision: 2010 May2011 QX56

Page 2949 of 5598

WHEEL ALIGNMENTFSU-7

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

WHEEL ALIGNMENT

InspectionINFOID:0000000006225640

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

PRELIMINARY CHECK

Check the following:

Tires for improper air pressure and wear

Road wheels for runout: Refer to WT-64, "

Inspection".

Wheel bearing axial end play: Refer to FA X - 7 , "

Inspection" (2WD), FAX-16, "Inspection" (4WD).

Lower link and upper link ball joint axial end play: Refer to FSU-15, "

Inspection" and FSU-18, "Inspection".

Shock absorber operation.

Each mounting part of axle and suspension for looseness and deformation

Lower link for cracks, deformation and other damage

Vehicle height (posture)

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

- This type of alignment is recomm ended for any NISSAN/INFINITI vehicle.

- The four-wheel “thrust” process helps ensure that t he vehicle is properly aligned and the steering wheel is

centered.

- The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

- The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

- Your alignment equipment should be regularly ca librated in order to give correct information.

- Check with the manufacturer of your specific equi pment for their recommended Service/Calibration Sched-

ule.

ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specificati ons listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Never use these indicators.

- The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

- This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Never use this “Rolling Compensation” method.

- Use the “Jacking Compensation Method”. After installi ng the alignment targets or head units, raise the vehi-

cle and rotate the wheels 1/2 turn both ways.

- See Instructions in the alignment machine you're using for more information on this.

AdjustmentINFOID:0000000006225641

CAMBER, CASTER

1. Adjust with the front/rear side adjusting bolts (1) on the lower link

(2).

2. See the following table for the amount of cam bolt scale move- ment and the variation of camber and caster.

CAUTION:

Align the adjusting bolt cutout with the stamp of lower link

bracket.

: Vehicle front

JPEIA0235ZZ

Revision: 2010 May2011 QX56

Page 2953 of 5598

FRONT COIL SPRING AND SHOCK ABSORBERFSU-11

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

12. Separate drive shaft from steering knuckle. (4WD) Refer to FAX-22, "Removal and Installation".

13. Remove front tube assembly A and front tube asse mbly B from shock absorber. (With HBMC) Refer to

SCS-32, "

FRONT TUBE ASSEMBLY : Removal and Installation".

14. Remove shock absorber.

15. Perform inspection after removal. (With HBMC) Refer to FSU-12, "

Inspection and Adjustment".

INSTALLATION

Note the following, and install in the reverse order of removal.

Never tap on the ball joint cap of the stabilizer connecting rod with a hammer or a similar item when inserting

the stabilizer connecting rod into the lower link. (Without HBMC)

Perform final tightening of bolts and nuts at the shock absorber lower side (rubber bushing), under unladen

conditions with tires on level ground.

Perform inspection after installation. Refer to FSU-12, "

Inspection and Adjustment".

Perform adjustment after installation. (With HBMC) Refer to FSU-12, "

Inspection and Adjustment".

After replacing the shock absorber, always follow the disposal procedure to discard the shock absorber.

Refer to FSU-13, "

Disposal".

Disassembly and AssemblyINFOID:0000000006273960

CAUTION:

The shock absorber assembly can not be disassembled. (With HBMC)

DISASSEMBLY (WITHOUT HBMC)

CAUTION:

Never damage shock absorber piston rod wh en removing components from shock absorber.

1. Install shock absorber attachment [SST: ST35652000 ( −)]

(A) to shock absorber and secure it in a vise.

CAUTION:

When installing the shock ab sorber attachment to shock

absorber, wrap a shop cloth around shock absorber to pro-

tect it from damage.

2. Using a spring compressor (commercial service tool) (A), com- press coil spring between rubber seat and shock absorber until

coil spring with a spring compressor is free.

CAUTION:

Be sure a spring compresso r is securely attached coil

spring. Compress coil spring

3. Check coil spring with a spring compressor between rubber seat and shock absorber is free. And then remove piston rod lock nut

while securing the piston rod tip so that piston rod does not turn.

4. Remove washer, bushings, shock absorber mounting bracket, tube, rubber seat, bound bumper cover, dust cover from shock

absorber.

5. After removing coil spring with a spring compressor, then gradually release a spring compressor. CAUTION:

Loosen while making sure coil spri ng attachment position does not move.

6. Remove the shock absorber at tachment from shock absorber.

7. Perform inspection after disassembly. Refer to FSU-12, "

Inspection and Adjustment".

ASSEMBLY (WITHOUT HBMC)

1. Install shock absorber attachment [SST: ST35652000 ( −)] to shock absorber and secure it in a vise.

CAUTION:

JPEIA0006ZZ

JPEIA0168ZZ

Revision: 2010 May2011 QX56

Page 2954 of 5598

FSU-12

< REMOVAL AND INSTALLATION >

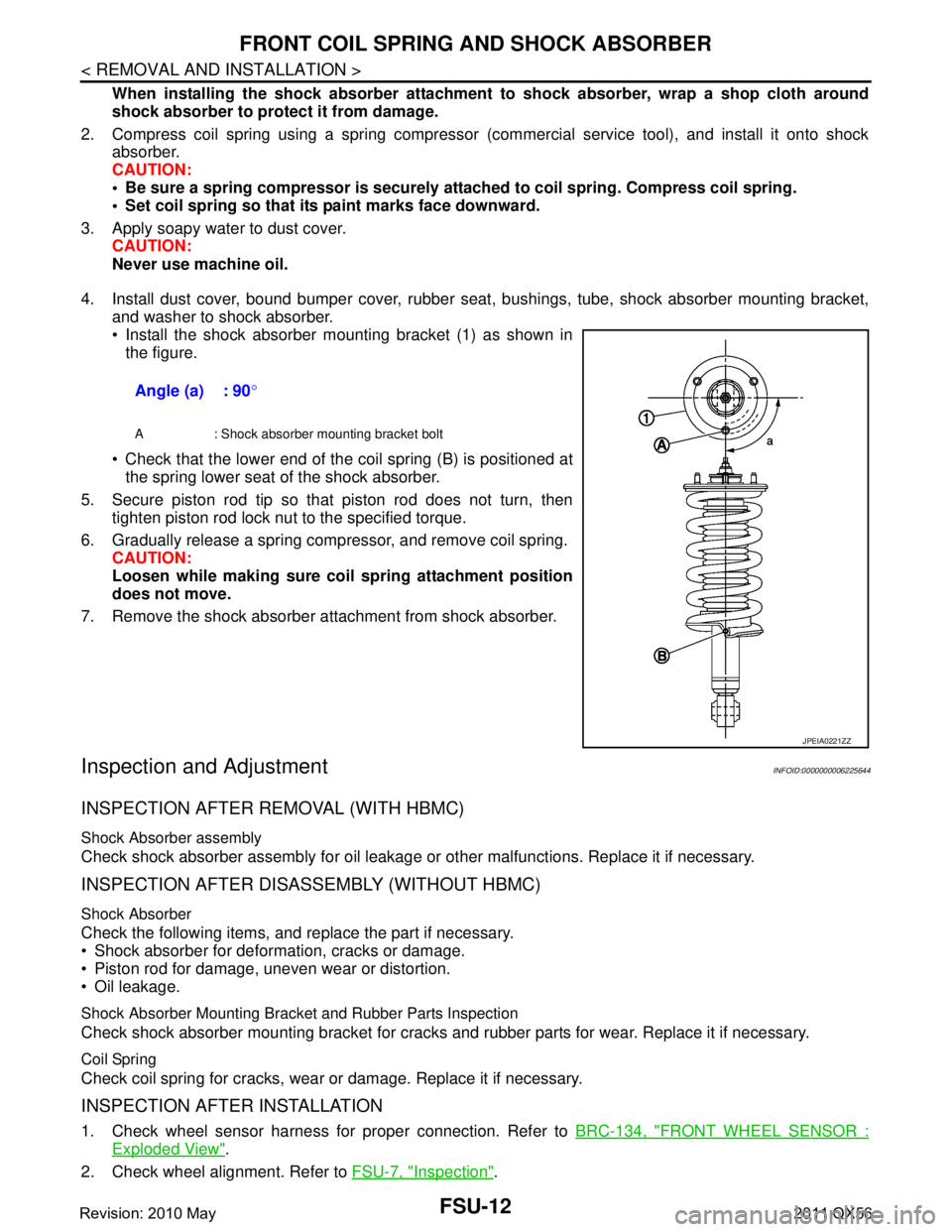

FRONT COIL SPRING AND SHOCK ABSORBER

When installing the shock absorber attachment to shock absorber, wrap a shop cloth around

shock absorber to protect it from damage.

2. Compress coil spring using a spring compressor (commercial service tool), and install it onto shock absorber.

CAUTION:

Be sure a spring compressor is securely attach ed to coil spring. Compress coil spring.

Set coil spring so that its paint marks face downward.

3. Apply soapy water to dust cover. CAUTION:

Never use machine oil.

4. Install dust cover, bound bumper cover, rubber seat , bushings, tube, shock absorber mounting bracket,

and washer to shock absorber.

Install the shock absorber mounting bracket (1) as shown in the figure.

Check that the lower end of the coil spring (B) is positioned at the spring lower seat of the shock absorber.

5. Secure piston rod tip so that piston rod does not turn, then tighten piston rod lock nut to the specified torque.

6. Gradually release a spring compressor, and remove coil spring. CAUTION:

Loosen while making sure co il spring attachment position

does not move.

7. Remove the shock absorber attachment from shock absorber.

Inspection and AdjustmentINFOID:0000000006225644

INSPECTION AFTER REMOVAL (WITH HBMC)

Shock Absorber assembly

Check shock absorber assembly for oil leakage or other malfunctions. Replace it if necessary.

INSPECTION AFTER DISASSEMBLY (WITHOUT HBMC)

Shock Absorber

Check the following items, and replace the part if necessary.

Shock absorber for deformation, cracks or damage.

Piston rod for damage, uneven wear or distortion.

Oil leakage.

Shock Absorber Mounting Bracket and Rubber Parts Inspection

Check shock absorber mounting bracket for cracks and rubber parts for wear. Replace it if necessary.

Coil Spring

Check coil spring for cracks, wear or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-134, "FRONT WHEEL SENSOR :

Exploded View".

2. Check wheel alignment. Refer to FSU-7, "

Inspection".

Angle (a) : 90

°

A : Shock absorber mounting bracket bolt

JPEIA0221ZZ

Revision: 2010 May2011 QX56

Page 2963 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

FSU-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D F

G H

I

J

K L

M A

B

FSU

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

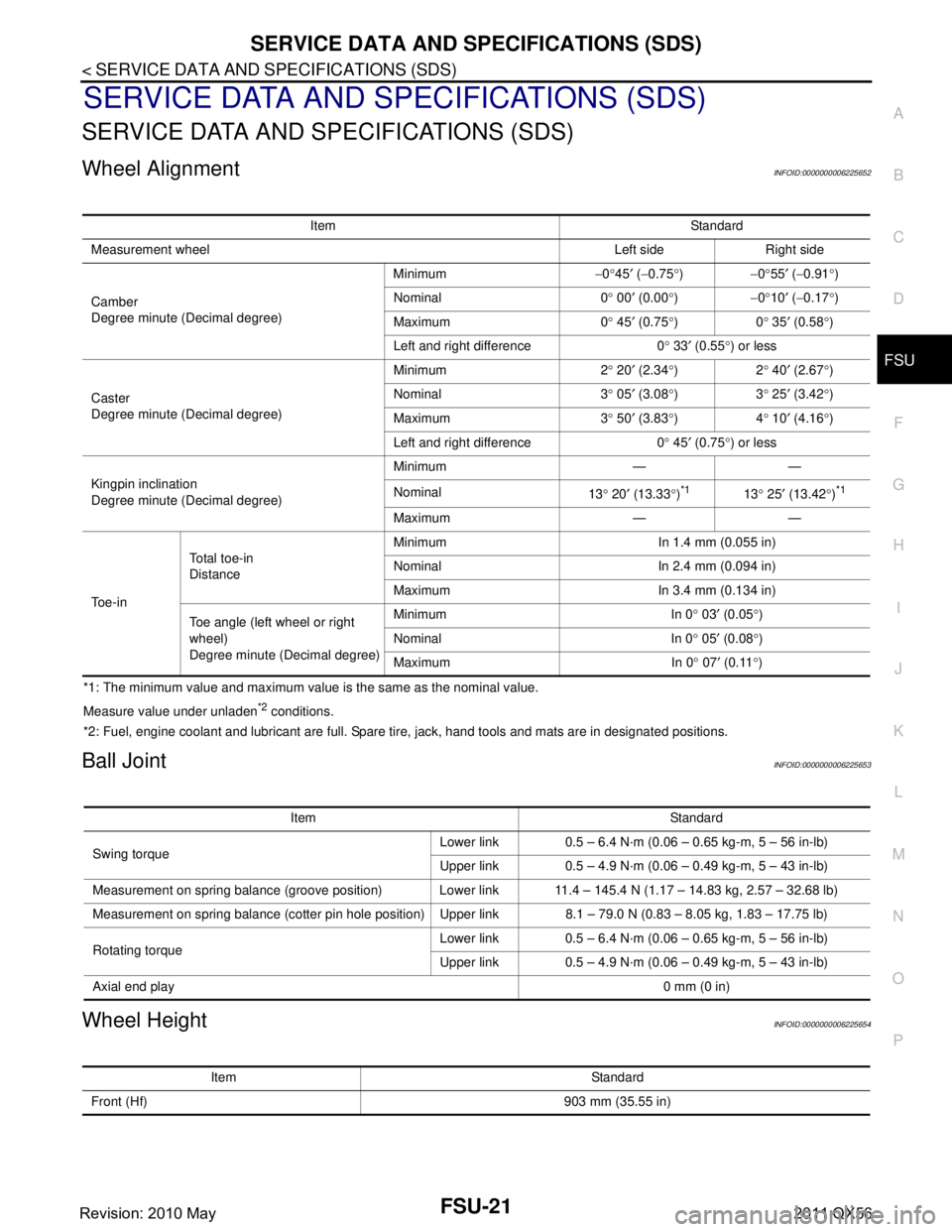

Wheel AlignmentINFOID:0000000006225652

*1: The minimum value and maximum value is the same as the nominal value.

Measure value under unladen

*2 conditions.

*2: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

Ball JointINFOID:0000000006225653

Wheel HeightINFOID:0000000006225654

Item Standard

Measurement wheel Left side Right side

Camber

Degree minute (Decimal degree) Minimum

−0 °45 ′ ( −0.75 °) −0°55 ′ ( −0.91 °)

Nominal 0 ° 00 ′ (0.00 °) −0°10 ′ ( −0.17 °)

Maximum 0 ° 45 ′ (0.75 °)0 ° 35 ′ (0.58 °)

Left and right difference 0 ° 33 ′ (0.55 °) or less

Caster

Degree minute (Decimal degree) Minimum 2

° 20 ′ (2.34 °)2 ° 40 ′ (2.67 °)

Nominal 3 ° 05 ′ (3.08 °)3 ° 25 ′ (3.42 °)

Maximum 3 ° 50 ′ (3.83 °)4 ° 10 ′ (4.16

° )

Left and right difference 0 ° 45 ′ (0.75 °) or less

Kingpin inclination

Degree minute (Decimal degree) Minimum — —

Nominal

13° 20 ′ (13.33 °)

*113 ° 25 ′ (13.42 °)*1

Maximum — —

To e - i n To t a l t o e - i n

Distance

Minimum In 1.4 mm (0.055 in)

Nominal In 2.4 mm (0.094 in)

Maximum In 3.4 mm (0.134 in)

Toe angle (left wheel or right

wheel)

Degree minute (Decimal degree) Minimum In 0

° 03 ′ (0.05 °)

Nominal In 0 ° 05 ′ (0.08 °)

Maximum In 0 ° 07 ′ (0.11 °)

Item Standard

Swing torque Lower link 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Upper link 0.5 – 4.9 N·m (0.06 – 0.49 kg-m, 5 – 43 in-lb)

Measurement on spring balance (groove position) Lower link 11.4 – 145.4 N (1.17 – 14.83 kg, 2.57 – 32.68 lb)

Measurement on spring balance (cotter pin hole position) Upper link 8.1 – 79.0 N (0.83 – 8.05 kg, 1.83 – 17.75 lb)

Rotating torque Lower link 0.5 – 6.4 N·m (0.06 – 0.65 kg-m, 5 – 56 in-lb)

Upper link 0.5 – 4.9 N·m (0.06 – 0.49 kg-m, 5 – 43 in-lb)

Axial end play 0 mm (0 in)

Item Standard

Front (Hf) 903 mm (35.55 in)

Revision: 2010 May2011 QX56

Page 2964 of 5598

FSU-22

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.Rear (Hr) 890 mm (35.04 in)

Item Standard

SFA746B

Revision: 2010 May2011 QX56

Page 2965 of 5598

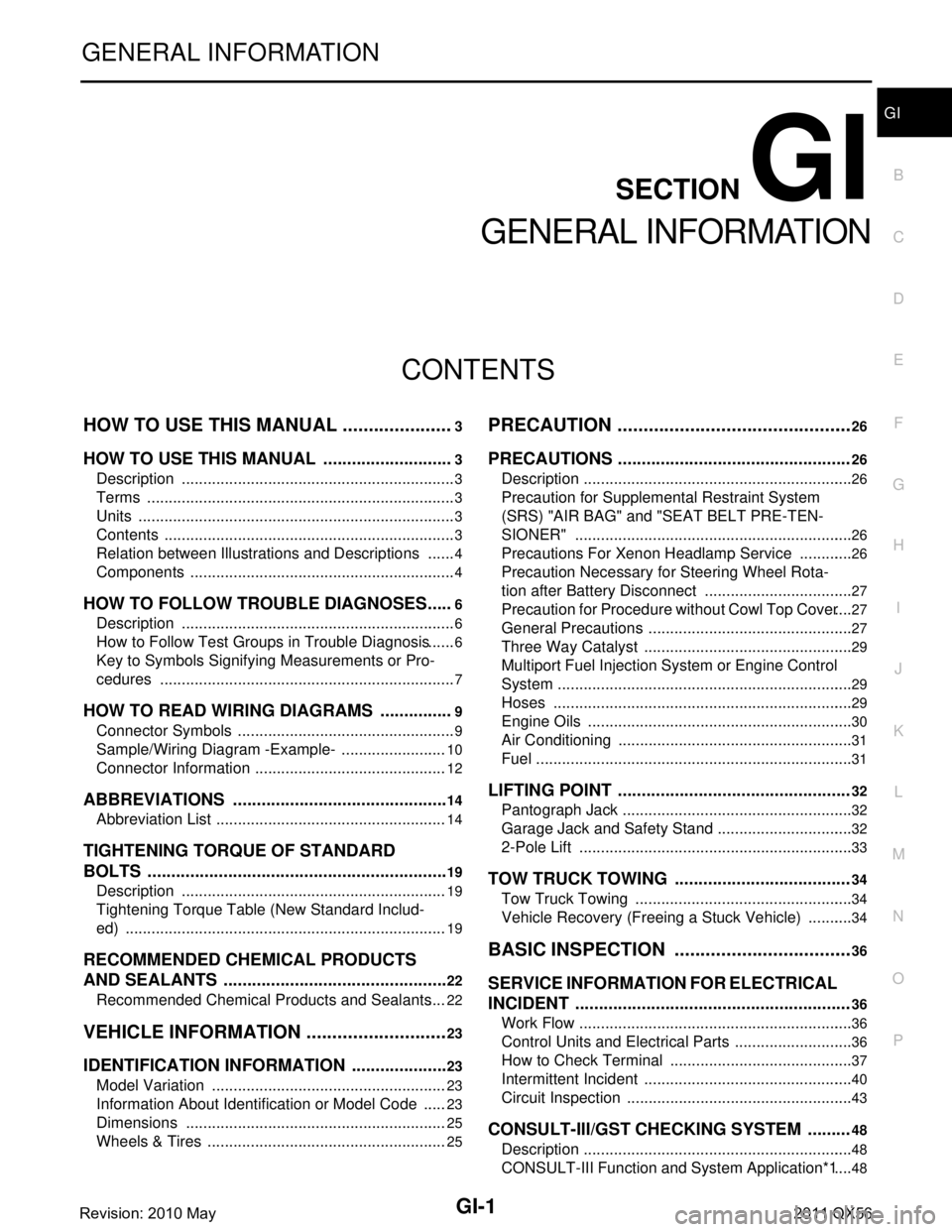

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector Symbols ............................................. ......9

Sample/Wiring Diagram -Example- .........................10

Connector Information .............................................12

ABBREVIATIONS .......................................... ....14

Abbreviation List .................................................. ....14

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

19

Description .......................................................... ....19

Tightening Torque Table (New Standard Includ-

ed) ...........................................................................

19

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

22

Recommended Chemical Products and Sealants ....22

VEHICLE INFORMATION ............................23

IDENTIFICATION INFORMATION ................. ....23

Model Variation ................................................... ....23

Information About Identification or Model Code ......23

Dimensions .............................................................25

Wheels & Tires ........................................................25

PRECAUTION ..............................................26

PRECAUTIONS .................................................26

Description ........................................................... ....26

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

26

Precautions For Xenon Headlamp Service .............26

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect ...................................

27

Precaution for Procedure without Cowl Top Cover ....27

General Precautions ................................................27

Three Way Catalyst .................................................29

Multiport Fuel Injection System or Engine Control

System .....................................................................

29

Hoses ......................................................................29

Engine Oils ..............................................................30

Air Conditioning .......................................................31

Fuel ..........................................................................31

LIFTING POINT .................................................32

Pantograph Jack ......................................................32

Garage Jack and Safety Stand ................................32

2-Pole Lift ................................................................33

TOW TRUCK TOWING .....................................34

Tow Truck Towing ...................................................34

Vehicle Recovery (Freeing a Stuck Vehicle) ...........34

BASIC INSPECTION ...................................36

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

36

Work Flow ............................................................ ....36

Control Units and Electrical Parts ............................36

How to Check Terminal ...........................................37

Intermittent Incident .................................................40

Circuit Inspection .....................................................43

CONSULT-III/GST CHECKING SYSTEM .........48

Description ...............................................................48

CONSULT-III Function and System Application*1 ....48

Revision: 2010 May2011 QX56