service INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2701 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-139

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

OPISTON PIN

Unit: mm (in)

CONNECTING ROD

Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT

End gap

Top 0.23 - 0.28 (0.0091 - 0.0110) 0.50 (0.0197)

2nd 0.50 - 0.65 (0.0197 - 0.0256) 0.84 (0.0331)

Oil (rail ring) 0.20 - 0.60 (0.0079 - 0.0236) 0.95 (0.0374)

Items Standard Limit

Piston pin outer diameter 21.989 - 21.995 (0.8657 - 0.8659) —

Piston to piston pin oil clearance 0.002 - 0.006 (0.0001 - 0.0002) —

Connecting rod bushing oil clearance 0.005 - 0.017 (0.0002 - 0.0007) 0.030 (0.0012)

Items Standard Limit

Center distance 154.45 - 154.55 (6.08 - 6.08) —

Bend [per 100 (3.94)] — 0.15 (0.0059)

Torsion [per 100 (3.94)] — 0.30 (0.0118)

Connecting rod bushing inner diameter* 22.000 - 22.006 (0.8661 - 0.8664) —

Connecting rod big end diameter (Without bearing) Grade No. A 57.000 - 57.001 (2.2441 - 2.2441)

Grade No. B 57.001 - 57.002 (2.2441 - 2.2442)

Grade No. C 57.002 - 57.003 (2.2442 - 2.2442)

Grade No. D 57.003 - 57.004 (2.2442 - 2.2442)

Grade No. E 57.004 - 57.005 (2.2442 - 2.2443)

Grade No. F 57.005 - 57.006 (2.2443 - 2.2443)

Grade No. G 57.006 - 57.007 (2.2443 - 2.2444)

Grade No. H 57.007 - 57.008 (2.2444 - 2.2444)

Grade No. J 57.008 - 57.009 (2.2444 - 2.2444)

Grade No. K 57.009 - 57.010 (2.2444 - 2.2445)

Grade No. L 57.010 - 57.011 (2.2445 - 2.2445)

Grade No. M 57.011 - 57.012 (2.2445 - 2.2446)

Grade No. N 57.012 - 57.013 (2.2446 - 2.2446)

Side clearance 0.20 - 0.40 (0.0079 - 0.0158) 0.40 (0.0157)

Revision: 2010 May2011 QX56

Page 2702 of 5598

EM-140

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

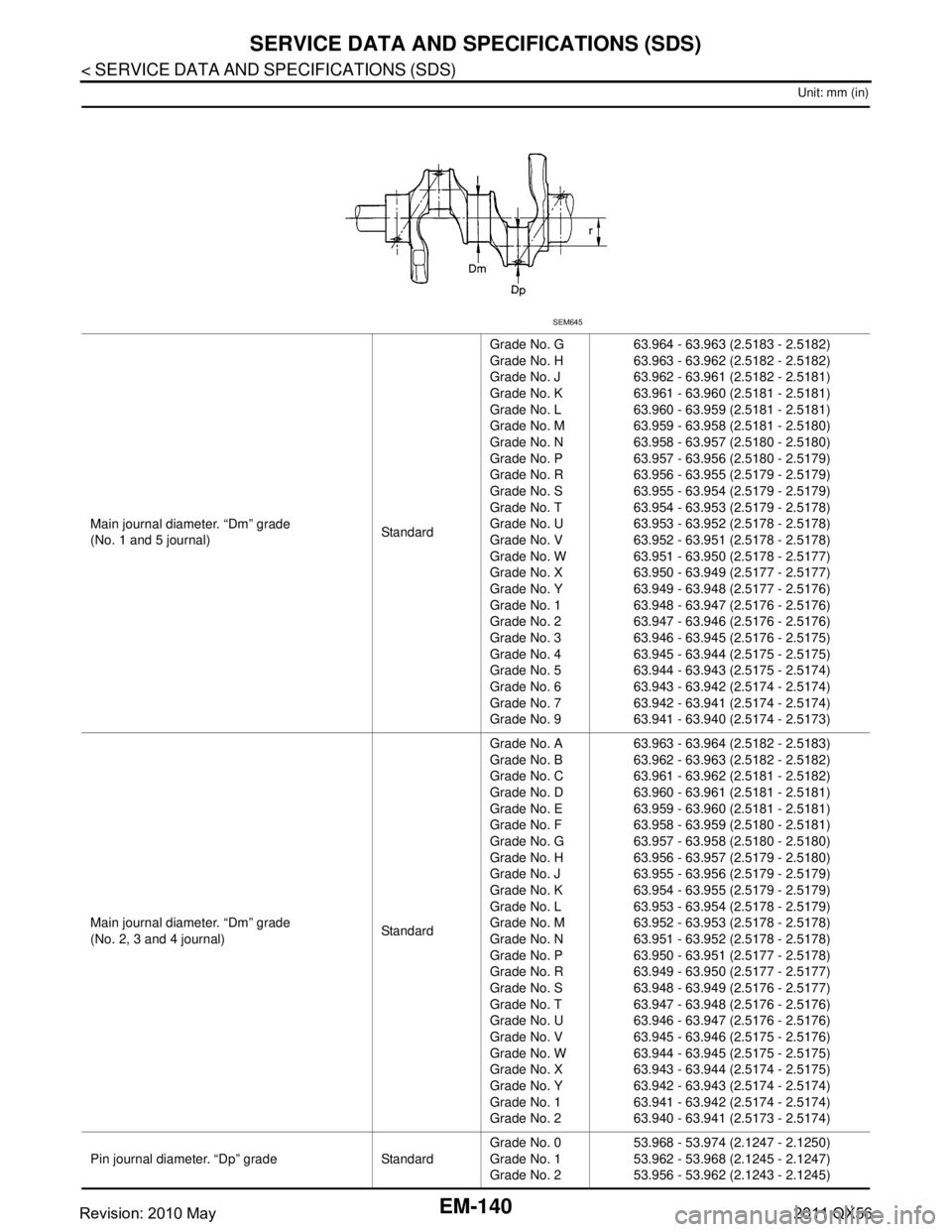

Main journal diameter. “Dm” grade

(No. 1 and 5 journal)StandardGrade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2

Grade No. 3

Grade No. 4

Grade No. 5

Grade No. 6

Grade No. 7

Grade No. 9 63.964 - 63.963 (2.5183 - 2.5182)

63.963 - 63.962 (2.5182 - 2.5182)

63.962 - 63.961 (2.5182 - 2.5181)

63.961 - 63.960 (2.5181 - 2.5181)

63.960 - 63.959 (2.5181 - 2.5181)

63.959 - 63.958 (2.5181 - 2.5180)

63.958 - 63.957 (2.5180 - 2.5180)

63.957 - 63.956 (2.5180 - 2.5179)

63.956 - 63.955 (2.5179 - 2.5179)

63.955 - 63.954 (2.5179 - 2.5179)

63.954 - 63.953 (2.5179 - 2.5178)

63.953 - 63.952 (2.5178 - 2.5178)

63.952 - 63.951 (2.5178 - 2.5178)

63.951 - 63.950 (2.5178 - 2.5177)

63.950 - 63.949 (2.5177 - 2.5177)

63.949 - 63.948 (2.5177 - 2.5176)

63.948 - 63.947 (2.5176 - 2.5176)

63.947 - 63.946 (2.5176 - 2.5176)

63.946 - 63.945 (2.5176 - 2.5175)

63.945 - 63.944 (2.5175 - 2.5175)

63.944 - 63.943 (2.5175 - 2.5174)

63.943 - 63.942 (2.5174 - 2.5174)

63.942 - 63.941 (2.5174 - 2.5174)

63.941 - 63.940 (2.5174 - 2.5173)

Main journal diameter. “Dm” grade

(No. 2, 3 and 4 journal) StandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2 63.963 - 63.964 (2.5182 - 2.5183)

63.962 - 63.963 (2.5182 - 2.5182)

63.961 - 63.962 (2.5181 - 2.5182)

63.960 - 63.961 (2.5181 - 2.5181)

63.959 - 63.960 (2.5181 - 2.5181)

63.958 - 63.959 (2.5180 - 2.5181)

63.957 - 63.958 (2.5180 - 2.5180)

63.956 - 63.957 (2.5179 - 2.5180)

63.955 - 63.956 (2.5179 - 2.5179)

63.954 - 63.955 (2.5179 - 2.5179)

63.953 - 63.954 (2.5178 - 2.5179)

63.952 - 63.953 (2.5178 - 2.5178)

63.951 - 63.952 (2.5178 - 2.5178)

63.950 - 63.951 (2.5177 - 2.5178)

63.949 - 63.950 (2.5177 - 2.5177)

63.948 - 63.949 (2.5176 - 2.5177)

63.947 - 63.948 (2.5176 - 2.5176)

63.946 - 63.947 (2.5176 - 2.5176)

63.945 - 63.946 (2.5175 - 2.5176)

63.944 - 63.945 (2.5175 - 2.5175)

63.943 - 63.944 (2.5174 - 2.5175)

63.942 - 63.943 (2.5174 - 2.5174)

63.941 - 63.942 (2.5174 - 2.5174)

63.940 - 63.941 (2.5173 - 2.5174)

Pin journal diameter. “Dp” grade Standard Grade No. 0

Grade No. 1

Grade No. 253.968 - 53.974 (2.1247 - 2.1250)

53.962 - 53.968 (2.1245 - 2.1247)

53.956 - 53.962 (2.1243 - 2.1245)

SEM645

Revision: 2010 May2011 QX56

Page 2703 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-141

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Total indicator reading

Main BearingINFOID:0000000006289596

MAIN BEARING

UNDERSIZE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Center distance “r”

45.96 - 46.04 (1.8095 - 1.8126)

Ta p e r Limit 0.0025 (0.0001)

Out-of-round 0.0025 (0.0001)

Crankshaft runout [TIR*] Standard Less than 0.05 (0.002)

Limit 0.10 (0.0039)

Crankshaft end play Standard 0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.012)

Grade number Thickness mm (in) Width mm (in) Identification color Remarks

0 2.483 - 2.486 (0.0978 - 0.0979)

19.9 - 20.1

(0.783 - 0.791) Black

Grade is the same

for upper and lower

bearings.

1 2.486 - 2.489 (0.0979 - 0.0980) Brown

2 2.489 - 2.492 (0.0980 - 0.0981) Green

3 2.492 - 2.495 (0.0981 - 0.0982) Yellow

4 2.495 - 2.498 (0.0982 - 0.0983) Blue

5 2.498 - 2.501 (0.0983 - 0.0985) Pink

6 2.501 - 2.504 (0.0985 - 0.0986) Purple

7 2.504 - 2.507 (0.0986 - 0.0987) White

8 2.507 - 2.510 (0.0987 - 0.0988) Red

01 UPR 2.483 - 2.486 (0.0978 - 0.0979) Black

Grade and color are

different for upper

and lower bearings.

LWR 2.486 - 2.489 (0.0979 - 0.0980) Brown

12 UPR 2.486 - 2.489 (0.0979 - 0.0980) Brown

LWR 2.489 - 2.492 (0.0980 - 0.0981) Green

23 UPR 2.489 - 2.492 (0.0980 - 0.0981) Green

LWR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

34 UPR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

LWR 2.495 - 2.498 (0.0982 - 0.0983) Blue

45 UPR 2.495 - 2.498 (0.0982 - 0.0983) Blue

LWR 2.498 - 2.501 (0.0983 - 0.0985) Pink

56 UPR 2.498 - 2.501 (0.0983 - 0.0985) Pink

LWR 2.501 - 2.504 (0.0985 - 0.0986) Purple

67 UPR 2.501 - 2.504 (0.0985 - 0.0986) Purple

LWR 2.504 - 2.507 (0.0986 - 0.0987) White

78 UPR 2.504 - 2.507 (0.0986 - 0.0987) White

LWR 2.507 - 2.510 (0.0987 - 0.0988) Red

Items Thickness Main journal diameter

0.25 (0.0098) 2.618 - 2.626 (0.1031 - 0.1034) Grind so that bearing clearance is the specified value.

Revision: 2010 May2011 QX56

Page 2704 of 5598

EM-142

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

*: Actual clearance

Connecting Rod BearingINFOID:0000000006289597

CONNECTING ROD BEARING

UNDERSIZE

Unit: mm (in)

CONNECTING ROD BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearanceItems Standard Limit

Main bearing oil clearance No.1 and 5 0.001 - 0.011 (0.00004 - 0.00043)*

0.065 (0.0026)

No.2, 3 and 4 0.007 - 0.017 (0.0003 - 0.0007)*

Grade number Thickness mm (in) Width mm (in) Identification color (mark)

1 1.500 - 1.503 (0.0591 - 0.0592)

18.1 - 18.3

(0.713 - 0.720) Black

2 1.503 - 1.506 (0.0592 - 0.0593) Brown

3 1.506 - 1.509 (0.0593 - 0.0594) Green

4 1.509 - 1.512 (0.0594 - 0.0595) Yellow

Items Thickness Pin journal diameter

0.25 (0.0098) 1.627 - 1.635 (0.0641 - 0.0644) Grind so that bearing clearance is the specified value.

Items Standard Limit

Connecting rod bearing oil clearance 0.020 - 0.039 (0.0008 - 0.0015)* 0.070 (0.0028)

Revision: 2010 May2011 QX56

Page 2705 of 5598

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Removal and Installation ..................................... ......2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE .........................4

EXHAUST SYSTEM ...........................................4

Inspection ............................................................ .....4

REMOVAL AND INSTALLATION ................5

EXHAUST SYSTEM ...........................................5

Exploded View ..................................................... .....5

Removal and Installation ..........................................5

Inspection .................................................................6

Revision: 2010 May2011 QX56

Page 2707 of 5598

PREPARATIONEX-3

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

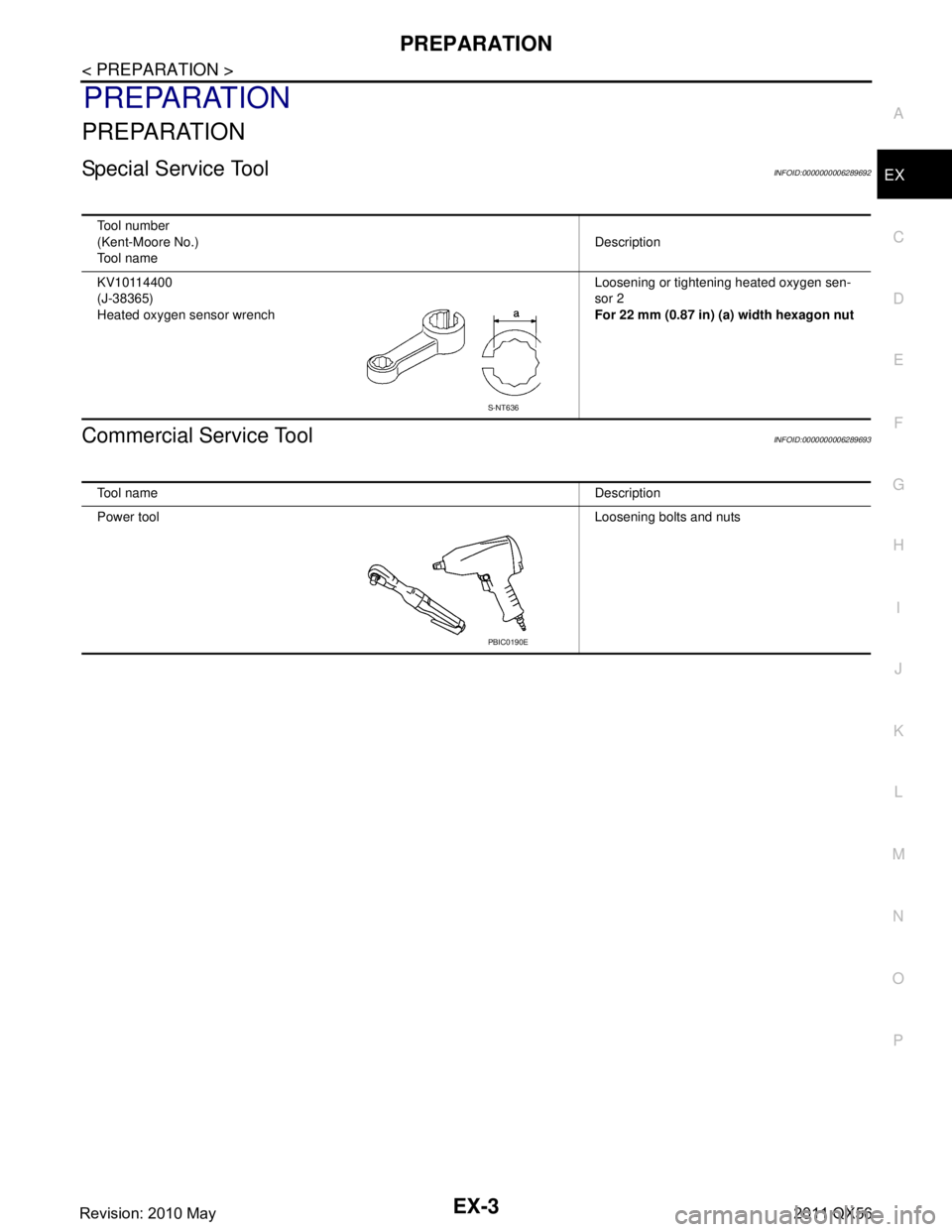

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000006289692

Commercial Service ToolINFOID:0000000006289693

Tool number

(Kent-Moore No.)

Tool name

Description

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sor 2

For 22 mm (0.87 in) (a) width hexagon nut

S-NT636

Tool name

Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: 2010 May2011 QX56

Page 2712 of 5598

EXL-2

EXTERIOR LAMP BATTERY SAVER SYSTEM :

System Description .................................................

21

DIAGNOSIS SYSTEM (BCM) ............................22

COMMON ITEM ..................................................... ...22

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) ................................................. ...

22

HEADLAMP ........................................................... ...23

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ..........................................................

23

FLASHER ............................................................... ...25

FLASHER : CONSULT-III Function (BCM -

FLASHER) ..............................................................

25

DIAGNOSIS SYSTEM (IPDM E/R) ....................27

Diagnosis Description .......................................... ...27

CONSULT-III Function (IPDM E/R) ........................29

DIAGNOSIS SYSTEM (AFS) .............................32

CONSULT-III Function (ADAPTIVE LIGHT) ........ ...32

ECU DIAGNOSIS INFORMATION ..............34

BCM, IPDM E/R .............................................. ...34

List of ECU Reference ......................................... ...34

AFS CONTROL UNIT ........................................35

Reference Value .................................................. ...35

Fail-Safe .................................................................38

DTC Inspection Priority Chart .................................39

DTC Index ..............................................................39

WIRING DIAGRAM .....................................40

EXTERIOR LIGHTING SYSTEM .................... ...40

Wiring Diagram .................................................... ...40

BASIC INSPECTION ...................................59

DIAGNOSIS AND REPAIR WORKFLOW ...... ...59

Work Flow ............................................................ ...59

INSPECTION AND ADJUSTMENT ...................61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) .............. ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : De-

scription ..................................................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : Special

Repair Requirement ...............................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) ................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Descrip-

tion ....................................................................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Special

Repair Requirement ............................................. ...

61

LEVELIZER ADJUSTMENT ......................................61

LEVELIZER ADJUSTMENT : Description ..............61

LEVELIZER ADJUSTMENT : Special Repair Re-

quirement ............................................................. ...

61

DTC/CIRCUIT DIAGNOSIS ........................63

B2503, B2504 SWIVEL ACTUATOR ............. ...63

DTC Logic ............................................................ ...63

Diagnosis Procedure ...............................................64

Component Inspection ............................................67

B2513 HEIGHT SENSOR UNUSUAL [FR] .......68

DTC Logic ............................................................ ...68

Diagnosis Procedure ...............................................68

B2514 HEIGHT SENSOR UNUSUAL [RR] .......71

DTC Logic ............................................................ ...71

Diagnosis Procedure ...............................................71

B2516 SHIFT SIGNAL [P, R] ............................74

DTC Logic ............................................................ ...74

Diagnosis Procedure ...............................................74

B2517 VEHICLE SPEED SIGNAL ....................75

DTC Logic ............................................................ ...75

Diagnosis Procedure ...............................................75

B2519 LEVELIZER CALIBRATION ..................76

DTC Logic ............................................................ ...76

Diagnosis Procedure ...............................................76

B2521 ECU CIRCUIT ........................................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ...............................................77

C0126 STEERING ANGLE SENSOR SIGNAL ...80

DTC Logic ............................................................ ...80

Diagnosis Procedure ...............................................80

C0428 STEERING ANGLE SENSOR CALI-

BRATION ...........................................................

81

DTC Logic ............................................................ ...81

Diagnosis Procedure ...............................................81

U1000 CAN COMM CIRCUIT ............................82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

U1010 CONTROL UNIT (CAN) .........................83

DTC Logic ............................................................ ...83

Diagnosis Procedure ...............................................83

POWER SUPPLY AND GROUND CIRCUIT .....84

AFS CONTROL UNIT ............................................. ...84

AFS CONTROL UNIT : Diagnosis Procedure .........84

Revision: 2010 May2011 QX56

Page 2714 of 5598

EXL-4

HAZARD SWITCH ...........................................133

Exploded View ..................................................... ..133

AFS SWITCH ...................................................134

Exploded View ..................................................... ..134

Removal and Installation .......................................134

AFS CONTROL UNIT ......................................135

Exploded View ..................................................... ..135

Removal and Installation .......................................135

HEIGHT SENSOR ............................................136

Exploded View ..................................................... ..136

Removal and Installation .......................................136

REAR COMBINATION LAMP .........................138

Exploded View ..................................................... ..138

Removal and Installation .......................................138

HIGH-MOUNTED STOP LAMP .......................140

Exploded View ..................................................... .140

Removal and Installation .......................................140

BACK-UP LAMP ............................................ ..141

Exploded View ..................................................... .141

Removal and Installation .......................................141

Replacement .........................................................142

LICENSE PLATE LAMP ...................................143

Exploded View ..................................................... .143

Removal and Installation .......................................143

Replacement .........................................................143

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

145

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

145

Bulb Specifications ............................................... .145

Revision: 2010 May2011 QX56

Page 2715 of 5598

![INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO INFINITI QX56 2011 Factory Service Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/42/57033/w960_57033-2714.png)

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006450052

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 2733 of 5598

![INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)EXL-23

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP

HEADLAMP : CONSULT-III Func tion (BCM - HEAD LAMP)INFOID:0000000006213911

WORK SUPPORT

CONS INFINITI QX56 2011 Factory Service Manual

DIAGNOSIS SYSTEM (BCM)EXL-23

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP

HEADLAMP : CONSULT-III Func tion (BCM - HEAD LAMP)INFOID:0000000006213911

WORK SUPPORT

CONS](/img/42/57033/w960_57033-2732.png)

DIAGNOSIS SYSTEM (BCM)EXL-23

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP

HEADLAMP : CONSULT-III Func tion (BCM - HEAD LAMP)INFOID:0000000006213911

WORK SUPPORT

CONSULT screen item Indication/Unit Description

Vehicle Speed km/h Vehicle speed of the moment a particular DTC is detected

Odo/Trip Meter km Total mileage (Odometer value) of the moment a particular DTC is detected

Vehicle Condition SLEEP>LOCK

Power position status of

the moment a particular

DTC is detected While turning BCM status from low power consumption mode to

normal mode (Power supply position is “LOCK”)

SLEEP>OFF While turning BCM status from low power consumption mode to

normal mode (Power supply position is “OFF”.)

LOCK>ACC While turning power supply position from “LOCK” to “ACC”

ACC>ON While turning power supply position from “ACC” to “IGN”

RUN>ACC While turning power supply position

from “RUN” to “ACC” (Vehicle

is stopping and selector lever is except P position.)

CRANK>RUN While turning power su

pply position from “CRANKING” to “RUN”

(From cranking up the engine to run it)

RUN>URGENT While turning power su

pply position from “RUN“ to “ACC” (Emer-

gency stop operation)

ACC>OFF While turning power supply position from “ACC” to “OFF”

OFF>LOCK While turning power supply position from “OFF” to “LOCK”

OFF>ACC While turning power supply position from “OFF” to “ACC”

ON>CRANK While turning po wer supply position from “IGN” to “CRANKING”

OFF>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “OFF”.) to low power consumption mode

LOCK>SLEEP While turning BCM status from normal mode (Power supply posi-

tion is “LOCK”.) to low power consumption mode

LOCK Power supply position is “LOCK” (Ignition switch OFF with steer-

ing is locked.)

OFF Power supply position

is “OFF” (Ignition switch OFF with steering

is unlocked.)

ACC Power supply position is “ACC” (Ignition switch ACC)

ON Power supply position is “IGN” (Ignition switch ON with engine

stopped)

ENGINE RUN Power supply posi

tion is “RUN” (Ignition switch ON with engine

running)

CRANKING Power supply position is “CRANKING” (At engine cranking)

IGN Counter 0 - 39 The number of times that ignition switch is turned ON after DTC is detected

The number is 0 when a malfunction is detected now.

The number increases like 1

→ 2 → 3...38 → 39 after returning to the normal condition

whenever ignition switch OFF → ON.

The number is fixed to 39 until the self-diagnosis results are erased if it is over 39.

Service item Setting item Setting

CUSTOM A/LIGHT SETTING MODE 1*

1Normal

MODE 2 More sensitive setting than normal setting (Turns ON earlier than normal opera-

tion)

MODE 3 More sensitive setting than MODE 2 (Turns ON earlier than MODE 2)

MODE 4 Less sensitive setting than normal setting (Turns ON later than normal operation)

Revision: 2010 May2011 QX56