belt INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5037 of 5598

ST-50

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

Note the following, and install in the reverse order of removal.

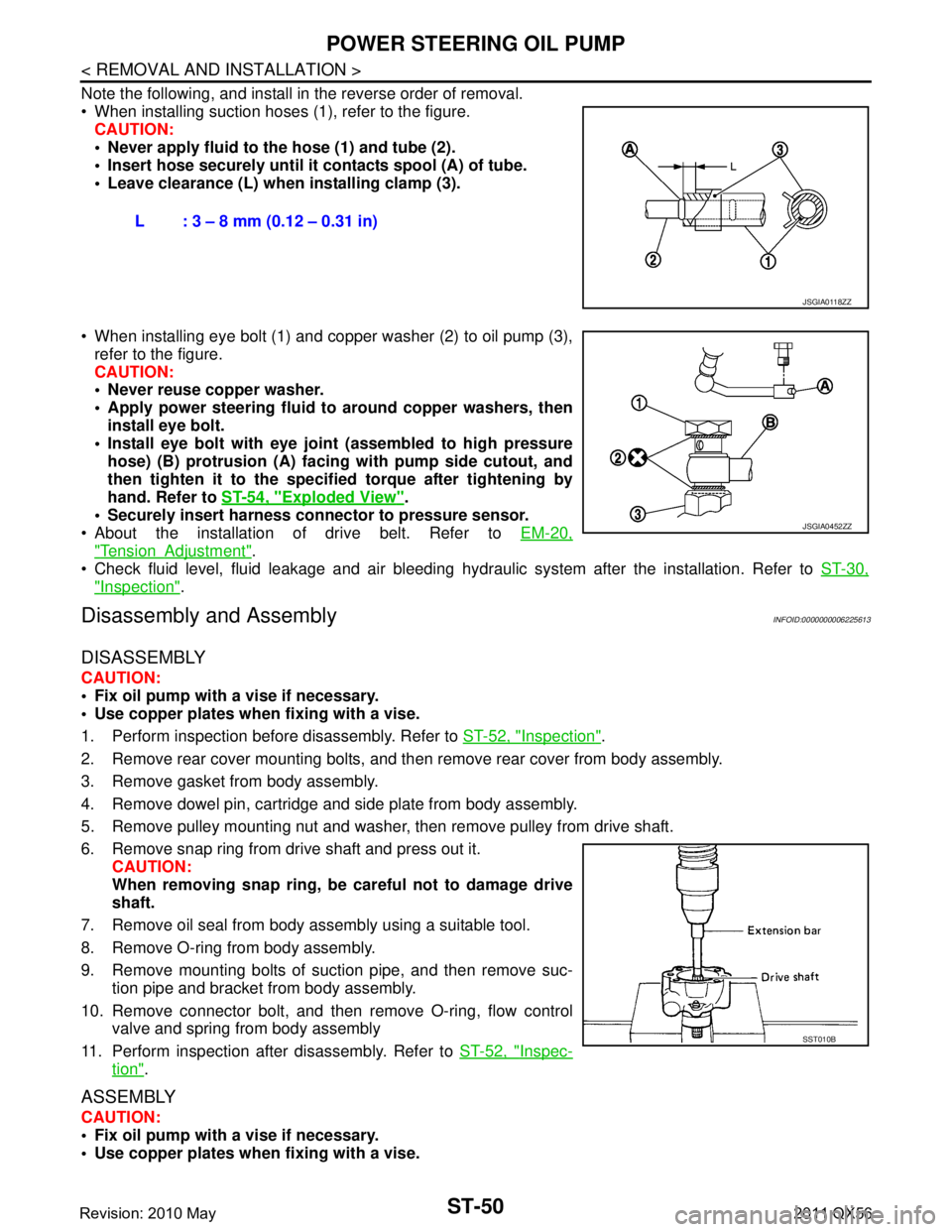

When installing suction hoses (1), refer to the figure.CAUTION:

Never apply fluid to the hose (1) and tube (2).

Insert hose securely until it contacts spool (A) of tube.

Leave clearance (L) when installing clamp (3).

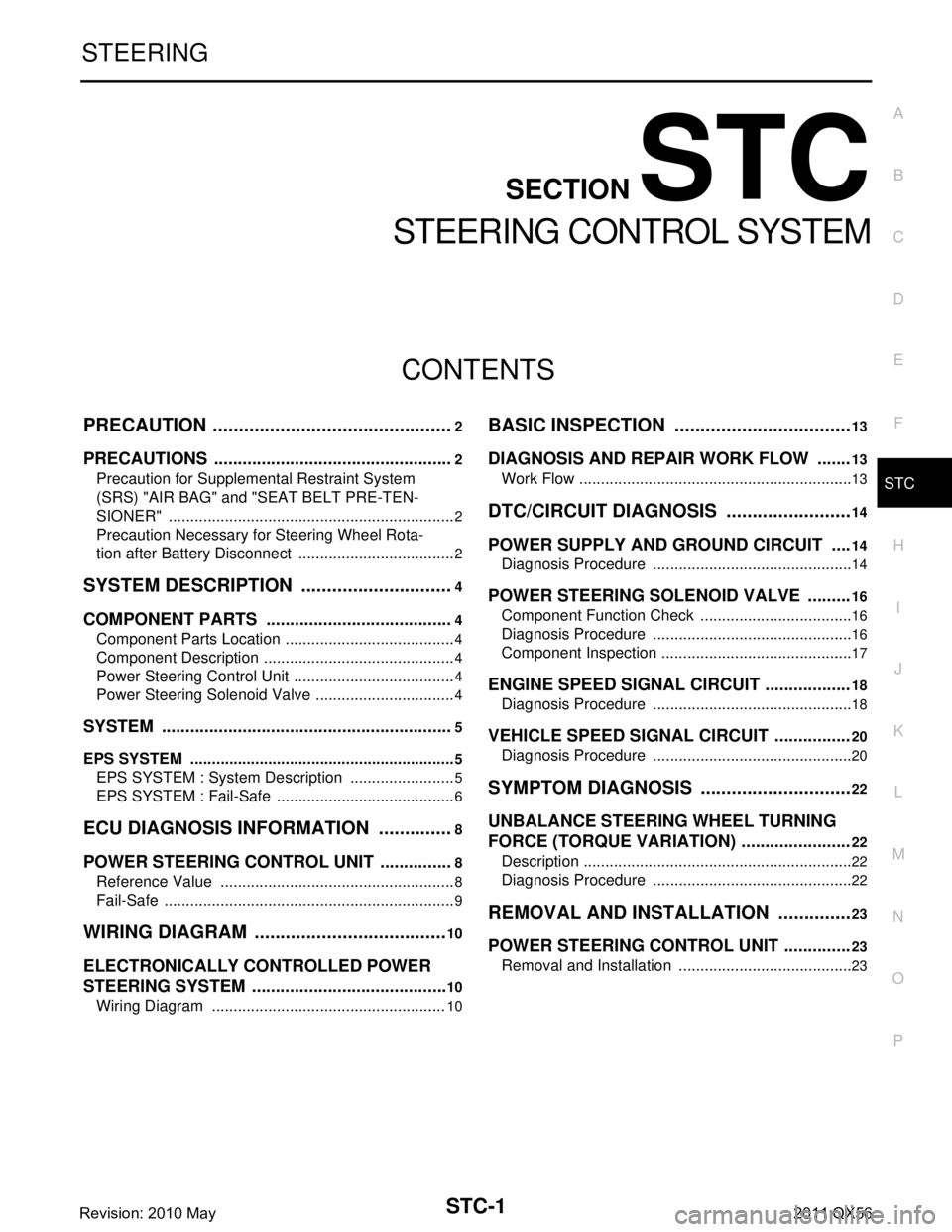

When installing eye bolt (1) and copper washer (2) to oil pump (3), refer to the figure.

CAUTION:

Never reuse copper washer.

Apply power steering fluid to around copper washers, then

install eye bolt.

Install eye bolt with eye join t (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specifi ed torque after tightening by

hand. Refer to ST-54, "

Exploded View".

Securely insert harness connector to pressure sensor.

About the installation of drive belt. Refer to EM-20,

"TensionAdjustment".

Check fluid level, fluid leakage and air bleeding hydr aulic system after the installation. Refer to ST-30,

"Inspection".

Disassembly and AssemblyINFOID:0000000006225613

DISASSEMBLY

CAUTION:

Fix oil pump with a vise if necessary.

Use copper plates when fixing with a vise.

1. Perform inspection before disassembly. Refer to ST-52, "

Inspection".

2. Remove rear cover mounting bolts, and then remove rear cover from body assembly.

3. Remove gasket from body assembly.

4. Remove dowel pin, cartridge and side plate from body assembly.

5. Remove pulley mounting nut and washer, then remove pulley from drive shaft.

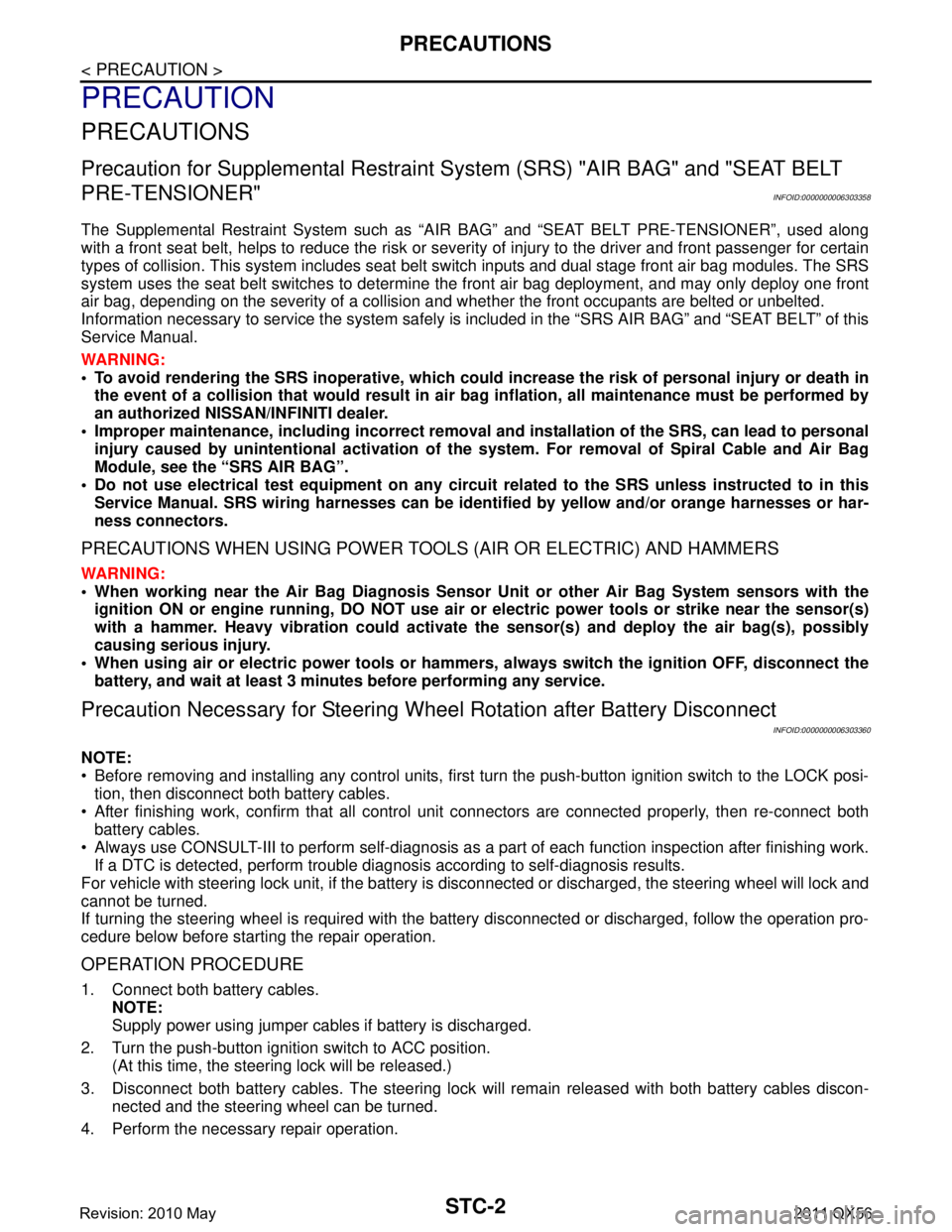

6. Remove snap ring from drive shaft and press out it. CAUTION:

When removing snap ring, be careful not to damage drive

shaft.

7. Remove oil seal from body assembly using a suitable tool.

8. Remove O-ring from body assembly.

9. Remove mounting bolts of suction pipe, and then remove suc- tion pipe and bracket from body assembly.

10. Remove connector bolt, and then remove O-ring, flow control

valve and spring from body assembly

11. Perform inspection after disassembly. Refer to ST-52, "

Inspec-

tion".

ASSEMBLY

CAUTION:

Fix oil pump with a vise if necessary.

Use copper plates when fixing with a vise.L : 3 – 8 mm (0.12 – 0.31 in)

JSGIA0118ZZ

JSGIA0452ZZ

SST010B

Revision: 2010 May2011 QX56

Page 5039 of 5598

ST-52

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

6. Install rotor to body assembly.CAUTION:

When installing rotor, turn mark face on rotor to body

assembly.

7. Install vane to rotor so that arc of vane faces cam ring side.

8. Check if drive shaft assembly turns smoothly.

9. Install gasket to body assembly. CAUTION:

Never reuse gasket.

10. Install rear cover to body assembly, and then tighten mounting bolts to the specified torque.

11. Install pulley and washer to drive shaft, and then tighten lock nut at the specified torque.

12. Apply recommended fluid to O-ring. Install flow control valve spring, flow control valve and O-ring to body assembly, and then

tighten connector bolt to the specified torque.

CAUTION:

Never reuse O-ring.

13. Apply recommended fluid to O-ring, and then install O-ring to body assembly. CAUTION:

Never reuse O-ring.

14. Install suction pipe and bracket to body assembly.

15. Perform inspection after assembly. Refer to ST-52, "

Inspection".

InspectionINFOID:0000000006225614

INSPECTION BEFORE DISASSEMBLY

Disassemble oil pump only when the following malfunctions occur.

If oil leakage is found on oil pump.

Oil pump pulley is damaged or deformed.

Performance of oil pump is low.

INSPECTION AFTER DISASSEMBLY

Body Assembly and Rear Cover Inspection

Check body assembly and rear cover for internal damage. Replace oil pump assembly if necessary.

Cartridge Assembly Inspection

Check cam ring, rotor and vane for damage. Replace oil pump assembly if necessary.

Side Plate Inspection

Check side plate for damage. Replace oil pump assembly if necessary.

Flow Control Valve Inspection

Check flow control valve and spring for damage. Replace oil pump assembly if necessary.

INSPECTION AFTER ASSEMBLY

Relief Oil Pressure

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

SGIA0989E

SST843A

Revision: 2010 May2011 QX56

Page 5040 of 5598

![INFINITI QX56 2011 Factory Service Manual

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV4810 INFINITI QX56 2011 Factory Service Manual

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV4810](/img/42/57033/w960_57033-5039.png)

POWER STEERING OIL PUMPST-53

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

1. Connect the oil pressure gauge [SST: KV48103500 (J-26357)] and the oil pressure gauge adapter [SST: KV48102500 (J-

33914)] between oil pump discharge connector and high-pres-

sure hose. Bleed air from the hydraulic circuit while opening

valve fully. Refer to ST-30, "

Inspection".

2. Start engine. Run engine until oil temperature reaches 50 to 80°C (122 to 176 °F).

CAUTION:

Leave the valve of the oil pressure gauge fully open while

starting and running engine. If engine is started with the

valve closed, the hydraulic pressure in oil pump goes up

to the relief pressure along with unusual increase of oil

temperature.

Be sure to keep hose clear of belts and other parts when engine is started.

3. Fully close the oil pressure gauge valve with engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump if the relief oil pressure is outside the standard. Refer to ST-50, "

Disassembly and Assembly".

5. Disconnect the oil pressure gauge from hydraulic circuit.

6. When installing eye bolt (1) and copper washer (2) to oil pump (3), refer to the figure.

CAUTION:

Never reuse copper washers.

Apply power steering fluid to around copper washer, theninstall eye bolt.

Install eye bolt with eye join t (assembled to high pressure

hose) (B) protrusion (A) facing with pump side cutout, and

then tighten it to the specifi ed torque after tightening by

hand. Refer to ST-54, "

Exploded View".

Securely insert harness connector to pressure sensor.

7. Check fluid level, fluid leakage and air bleeding hydraulic sys- tem after the installation. Refer to ST-30, "

Inspection".

Relief oil pressure : Refer to

ST-58, "

Relief Oil Pres-

sure".

SGIA1225E

JSGIA0452ZZ

Revision: 2010 May2011 QX56

Page 5046 of 5598

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

Component Description .............................................4

Power Steering Control Unit ......................................4

Power Steering Solenoid Valve .................................4

SYSTEM ..............................................................5

EPS SYSTEM ........................................ ......................5

EPS SYSTEM : System De scription .........................5

EPS SYSTEM : Fail-Safe ..........................................6

ECU DIAGNOSIS INFO RMATION ...............8

POWER STEERING CONTROL UNIT ........... .....8

Reference Value ................................................. ......8

Fail-Safe ....................................................................9

WIRING DIAGRAM ......................................10

ELECTRONICALLY CONTROLLED POWER

STEERING SYSTEM ...................................... ....

10

Wiring Diagram ................................................... ....10

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORK FLOW .......13

Work Flow ............................................................ ....13

DTC/CIRCUIT DIAGNOSIS .........................14

POWER SUPPLY AND GROUND CIRCUIT ....14

Diagnosis Procedure ........................................... ....14

POWER STEERING SOLENOID VALVE .........16

Component Function Check ....................................16

Diagnosis Procedure ...............................................16

Component Inspection .............................................17

ENGINE SPEED SIGNAL CIRCUIT ..................18

Diagnosis Procedure ........................................... ....18

VEHICLE SPEED SIGNAL CIRCUIT ................20

Diagnosis Procedure ...............................................20

SYMPTOM DIAGNOSIS ..............................22

UNBALANCE STEERING WHEEL TURNING

FORCE (TORQUE VARIATION) .......................

22

Description ........................................................... ....22

Diagnosis Procedure ...............................................22

REMOVAL AND INSTALLATION ...............23

POWER STEERING CONTROL UNIT ..............23

Removal and Installation ..................................... ....23

Revision: 2010 May2011 QX56

Page 5047 of 5598

STC-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006303358

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006303360

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5058 of 5598

DIAGNOSIS AND REPAIR WORK FLOWSTC-13

< BASIC INSPECTION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORK FLOW

Work FlowINFOID:0000000006256124

DETAILED FLOW

1.COLLECT THE INFORMATION FROM THE CUSTOMER

It is also important to clarify customer complaints before inspection. First of all, reproduce symptoms and

understand them fully. Ask customer about his/her complaints carefully. In some cases, it is necessary to

check symptoms by driving vehicle with customer.

CAUTION:

Customers are not professional. It is danger ous to make an easy guess like “maybe the customer

means that...,” or “maybe the cu stomer mentions this symptom”.

>> GO TO 2.

2.CHECK THE STATUS

1. Power steering fluid leakage and check the power steering fluid level. Refer to ST-30, "

Inspection".

2. Check the drive belt tension. Refer to EM-20, "

Checking".

3. Check the power steering gear for damages, cracks and fluid leakage. Refer to ST-46, "

Inspection".

4. Check the relief oil pressure. Refer to ST-52, "

Inspection".

>> GO TO 3.

3.DIAGNOSIS CHART BY SYMPTOM

Perform the diagnosis by symptom. Refer to STC-22, "

Diagnosis Procedure".

>> GO TO 4.

4.FINAL CHECK

Check the input/output standard values for the power steering control unit.

Are the power steering control unit input/output values within standard ranges respectively?

YES >> INSPECTION END

NO >> GO TO 2.

Revision: 2010 May2011 QX56

Page 5069 of 5598

STR-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION STR

A

STR

N

O P

CONTENTS

STARTING SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tools .......................................... ......4

Commercial Service Tools ........................................4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Component Description ............................................5

SYSTEM ..............................................................6

System Diagram .................................................. ......6

System Description ...................................................6

WIRING DIAGRAM .......................................7

STARTING SYSTEM ...................................... .....7

Wiring Diagram ................................................... ......7

BASIC INSPECTION ...................................11

DIAGNOSIS AND REPAIR WORKFLOW ........11

Work Flow ............................................................ ....11

DTC/CIRCUIT DIAGNOSIS .........................14

B TERMINAL CIRCUIT .....................................14

Diagnosis Procedure ........................................... ....14

S CONNECTOR CIRCUIT .................................15

Diagnosis Procedure ...............................................15

SYMPTOM DIAGNOSIS ..............................16

STARTING SYSTEM .........................................16

Symptom Table ................................................... ....16

REMOVAL AND INSTALLATION ...............17

STARTER MOTOR ...........................................17

Exploded View ..................................................... ....17

Removal and Installation .........................................18

Inspection ................................................................18

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .............................................

20

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

20

Starter Motor .......................................................

Revision: 2010 May2011 QX56

Page 5070 of 5598

STR-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006275515

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006275516

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5089 of 5598

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

7AT: RE7R01B

PRECAUTION ................ ...............................

6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

General Precautions .................................................6

Service Notice or Precaution .....................................7

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ..........................................9

SYSTEM DESCRIPTION .............................10

COMPONENT PARTS ................................... ....10

A/T CONTROL SYSTEM ...........................................10

A/T CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

10

A/T CONTROL SYSTEM : Component Descrip-

tion ...................................................................... ....

11

A/T CONTROL SYSTEM : TCM .............................12

A/T CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

12

A/T CONTROL SYSTEM : Input Speed Sensor .....12

A/T CONTROL SYSTEM : Output Speed Sensor ....12

A/T CONTROL SYSTEM : A/ T Fluid Temperature

Sensor ................................................................. ....

12

A/T CONTROL SYSTEM : Input Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Front Brake Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Direct Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : High and Low Reverse

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Low Brake Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Anti-interlock Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : 2346 Brake Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Line Pressure Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Accelerator Pedal Po-

sition Sensor ........................................................ ....

13

A/T CONTROL SYSTEM : Manual Mode Switch ....13

A/T CONTROL SYSTEM : To w Mode Switch .........14

A/T CONTROL SYSTEM : A/T CHECK Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Tow Mode Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Selector Lever Position

Indicator ............................................................... ....

14

A/T SHIFT LOCK SYSTEM ................................... ....14

A/T SHIFT LOCK SYSTEM : Component Parts

Location ...................................................................

15

A/T SHIFT LOCK SYSTEM : Component Descrip-

tion ...........................................................................

15

STRUCTURE AND OPERATION .....................16

TRANSMISSION .................................................... ....16

TRANSMISSION : Cross-Sectional View ................16

TRANSMISSION : System Diagram ........................18

TRANSMISSION : System Description ...................18

TRANSMISSION : Component Description .............41

FLUID COOLER & FLUID WARMER SYSTEM .... ....41

FLUID COOLER & FLUID WARMER SYSTEM :

System Description ..................................................

41

SYSTEM ............................................................44

A/T CONTROL SYSTEM ....................................... ....44

Revision: 2010 May2011 QX56

Page 5094 of 5598

![INFINITI QX56 2011 Factory Service Manual

TM-6

< PRECAUTION >[7AT: RE7R01B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006226734

The Supplemen INFINITI QX56 2011 Factory Service Manual

TM-6

< PRECAUTION >[7AT: RE7R01B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006226734

The Supplemen](/img/42/57033/w960_57033-5093.png)

TM-6

< PRECAUTION >[7AT: RE7R01B]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint S

ystem (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006226734

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

General PrecautionsINFOID:0000000006226735

Turn ignition switch OFF an d disconnect the battery cable

from the negative terminal before connecting or disconnect-

ing the A/T assembly connector. Because battery voltage is

applied to TCM even if igniti on switch is turned OFF.

Perform “DTC (Diagnostic Trouble Code) CONFIRMATION

PROCEDURE” after performing each TROUBLE DIAGNOSIS.

If the repair is completed DTC should not be displayed in the

“DTC CONFIRMATION PROCEDURE”.

Always use the specified brand of ATF. Refer to MA-10, "

Fluids

and Lubricants".

Use lint-free paper not cloth rags during work.

Dispose of the waste oil using the methods prescribed by law, ordi-

nance, etc. after replacing the ATF.

Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

SEF289H

SEF217U

Revision: 2010 May2011 QX56