belt INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4946 of 5598

B1183 LAP PRE-TENSIONER LHSRC-153

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

B1183 LAP PRE-TENSIONER LH

DTC LogicINFOID:0000000006220102

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter diagnosis mode if no malfunction is detected in user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-149, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220103

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace wiring harness.

3.REPLACE LAP PRE-TENSIONER LH

1. Replace lap pre-tensioner LH. Refer to SB-6, "

SEAT BELT RETRACTOR : Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-149, "

DTC Logic".

Is DTC detected?

YES >> GO TO 4.

NO >> INSPECTION END

4.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-26, "

Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-149, "

DTC Logic".

Is DTC detected?

YES >> GO TO 1.

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B1183 PRE-TEN2 FRONT LH [VB-SHORT] Lap pre-tensioner LH circuit is shorted

to some power supply circuit Harness or connectors

(Lap pre-tensioner circuit is shorted.)

Malfunction in lap pre-tensioner LH

Malfunction in air bag diagnosis sensor unit

Revision: 2010 May2011 QX56

Page 4947 of 5598

SRC-154

< DTC/CIRCUIT DIAGNOSIS >

B1184 LAP PRE-TENSIONER LH

B1184 LAP PRE-TENSIONER LH

DTC LogicINFOID:0000000006220104

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter diagnosis mode if no malfunction is detected in user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-150, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220105

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace wiring harness.

3.REPLACE LAP PRE-TENSIONER LH

1. Replace lap pre-tensioner LH. Refer to SB-6, "

SEAT BELT RETRACTOR : Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-150, "

DTC Logic".

Is DTC detected?

YES >> GO TO 4.

NO >> INSPECTION END

4.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-26, "

Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-150, "

DTC Logic".

Is DTC detected?

YES >> GO TO 1.

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B1184 PRE-TEN2 FRONT LH [GND-SHORT] Lap pre-tensioner LH circuit is shorted to

ground Harness or connectors

(Lap pre-tensioner circuit is shorted.)

Malfunction in lap pre-tensioner LH

Malfunction in air bag diagnosis sensor unit

Revision: 2010 May2011 QX56

Page 4948 of 5598

B1185 LAP PRE-TENSIONER LHSRC-155

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G

I

J

K L

M A

B

SRC

N

O P

B1185 LAP PRE-TENSIONER LH

DTC LogicINFOID:0000000006220106

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter diagnosis mode if no malfunction is detected in user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-151, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220107

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal and wait at least 3

minutes. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace harness connector.

2.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace wiring harness.

3.REPLACE LAP PRE-TENSIONER LH

1. Replace lap pre-tensioner LH. Refer to SB-6, "

SEAT BELT RETRACTOR : Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-151, "

DTC Logic".

Is DTC detected?

YES >> GO TO 4.

NO >> INSPECTION END

4.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-26, "

Removal and Installation".

2. Perform DTC confirmation procedure. Refer to SRC-151, "

DTC Logic".

Is DTC detected?

YES >> GO TO 1.

NO >> INSPECTION END

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B1185 PRE-TEN2 FRONT LH [SHORT] Lap pre-tensioner LH circuit are shorted

to each other Harness or connectors

(Lap pre-tensioner circuit is shorted.)

Malfunction in lap pre-tensioner LH

Malfunction in air bag diagnosis sensor unit

Revision: 2010 May2011 QX56

Page 4967 of 5598

SRC-174

< DTC/CIRCUIT DIAGNOSIS >

B1209 FRONTAL COLLISION DETECTION

B1209 FRONTAL COLLISION DETECTION

DescriptionINFOID:0000000006220128

The air bags and seat belt pre-tensioners for driver and passenger are activated by the air bag diagnosis sen-

sor unit signal transmitted at the time of the frontal collision.

DTC LogicINFOID:0000000006220129

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter the diagnosis mode if no malfunction is detected in the user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-174, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220130

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait at least 3

minutes or more. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.PERFORM COLLISION DIAGNOSIS

Perform collision diagnosis.Refer to SR-5, "

FOR FRONTAL COLLISION : When SRS is activated in a colli-

sion" or SR-6, "FOR FRONTAL COLLISION : When SRS is not activated in a collision".

Is collision diagnosis complete?

YES >> GO TO 2.

NO >> INSPECTION END

2.FINAL INSPECTION

Perform “AIR BAG” Self Diagnostic Result.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Perform diagnosis of applicable DTC.Refer to SRC-22, "

DTCIndex".

DTCDisplay contents of

CONSULT-III DTC detecting condition Possible cause

B1209 FRONTAL COLLI-

SION DETECTION Seat belt pre-tensioner, driver side air bag and passen-

ger air bag are deployed

—

Revision: 2010 May2011 QX56

Page 4969 of 5598

SRC-176

< DTC/CIRCUIT DIAGNOSIS >

B1211 ROLLOVER DETECTION

B1211 ROLLOVER DETECTION

DescriptionINFOID:0000000006220134

The seat belt pre-tensioner, door-mounted curtain air bag and pop-up roll bar are activated by the air bag diag-

nosis sensor unit signal at the time of rollover.

DTC LogicINFOID:0000000006220135

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “AIR BAG” Self Diagnostic Result.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp status. Refer to SRC-14, "

On Board Diagnosis Function".

NOTE:

SRS does not enter the diagnosis mode if no malfunction is detected in the user mode.

Is malfunctioning part detected?

YES >> Refer to SRC-176, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006220136

WARNING:

Before servicing, turn ignition sw itch OFF, disconnect battery negative terminal, and wait at least 3

minutes or more. (To discharge backup capacitor.)

Never use unspecified tester or other measuring device.

1.PERFORM COLLISION DIAGNOSIS

Perform collision diagnosis.Refer to SR-7, "

FOR SIDE AND ROLLOVER COLLISI ON : When SRS is activated

in a collision" or SR-8, "FOR SIDE AND ROLLOVER COLLISION : When SRS is not activated in a collision".

Iscollision diagnosis complete?

YES >> GO TO 2.

NO >> INSPECTION END

2.FINAL INSPECTION

Perform “AIR BAG” Self Diagnostic Result.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Peform diagnosis of applicable DTC.Refer to SRC-22, "

DTCIndex".

DTCDisplay contents of

CONSULT-III DTC detecting condition Possible cause

B1211 ROLLOVER DETECTION Seat belt pre-tensioner and curtain air bag module are

deployed because of rollover detection —

Revision: 2010 May2011 QX56

Page 4986 of 5598

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

SRC-193

< SYMPTOM DIAGNOSIS >

C

D E

F

G

I

J

K L

M A

B

SRC

N

O P

SYMPTOM DIAGNOSIS

SRS AIR BAG WARNING LAMP DOES NOT TURN OFF

Diagnosis ProcedureINFOID:0000000006220157

1.CHECK AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Check the deployment of air bag m odule and seat belt pre-tensioner.

Is air bag module deployed?

YES >> Replace the malfunctioning parts.

NO >> GO TO 2.

2.CHECK AIR BAG FUSE

Check 10 A fuse [No.2, located in fuse block (J/B)].

Is the inspection result normal?

YES >> GO TO 3.

NO >> Replace the fuse.

3.CHECK HARNESS CONNECTOR

Check the harness connector.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace harness connectors.

4.CHECK WIRING HARNESS

Check the wiring harness externals.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace wiring harness.

5.REPLACE AIR BAG DIAGNOSIS SENSOR UNIT

1. Replace air bag diagnosis sensor unit. Refer to SR-26, "

Removal and Installation".

2. Check air bag warning lamp operation.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 6.

6.REPLACE COMBINATION METER

1. Replace combination meter. Refer to MWI-85, "

Removal and Installation".

2. Check air bag warning lamp operation.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 4988 of 5598

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Service Notice or Precautions for Steering System

......

4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tools .......................................... ......5

Commercial Service Tools ........................................6

SYSTEM DESCRIPTION ..............................7

COMPONENT PARTS ................................... .....7

Component Parts Location (Heated Steering

Wheel) ................................................................. ......

7

Component Description (Heated Steering Wheel) ......7

Heated Steering Wheel .............................................7

Heated Steering Wheel Switch .................................8

Heated Steering Wheel Relay ...................................8

SYSTEM ..............................................................9

System Description (Heated Steering Wheel) ..... ......9

WIRING DIAGRAM ......................................10

HEATED STEERING WHEEL ........................ ....10

Wiring Diagram ................................................... ....10

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORK FLOW .... ....13

WorkFlow (Heated Steering Wheel) .................... ....13

STEERING WHEEL ............................................14

Inspection ............................................................ ....14

DTC/CIRCUIT DIAGNOSIS .........................16

HEATED STEERING WHEEL SYSTEM ...........16

Component Function Check ................................ ....16

Diagnosis Procedure ...............................................16

Component Inspection (Heated Steering Wheel) ....18

Component Inspection (Heated Steering Wheel

Relay) ......................................................................

19

HEATED STEERING WHEEL SWITCH INDI-

CATOR LAMP ...................................................

20

Component Function Check ....................................20

Diagnosis Procedure ...............................................20

Component Inspection (Heated Steering Wheel

Relay) ......................................................................

22

SYMPTOM DIAGNOSIS ..............................23

HEATED STEERING WHEEL SYSTEM DOES

NOT ACTIVATE ................................................

23

Description ........................................................... ....23

Diagnosis Procedure ...............................................23

HEATED STEERING WHEEL SWITCH INDI-

CATOR LAMP DOES NOT TURN ON ..............

26

Description ...............................................................26

Diagnosis Procedure ...............................................26

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

29

NVH Troubleshooting Chart ....................................29

PERIODIC MAINTENANCE ........................30

POWER STEERING FLUID ..............................30

Inspection ............................................................ ....30

STEERING WHEEL ..........................................32

Inspection ................................................................32

REMOVAL AND INSTALLATION ...............33

Revision: 2010 May2011 QX56

Page 4990 of 5598

PRECAUTIONSST-3

< PRECAUTION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006272045

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation after Battery Disconnect

INFOID:0000000006272046

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the batte ry disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wil l remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 5016 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGST-29

< SYMPTOM DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

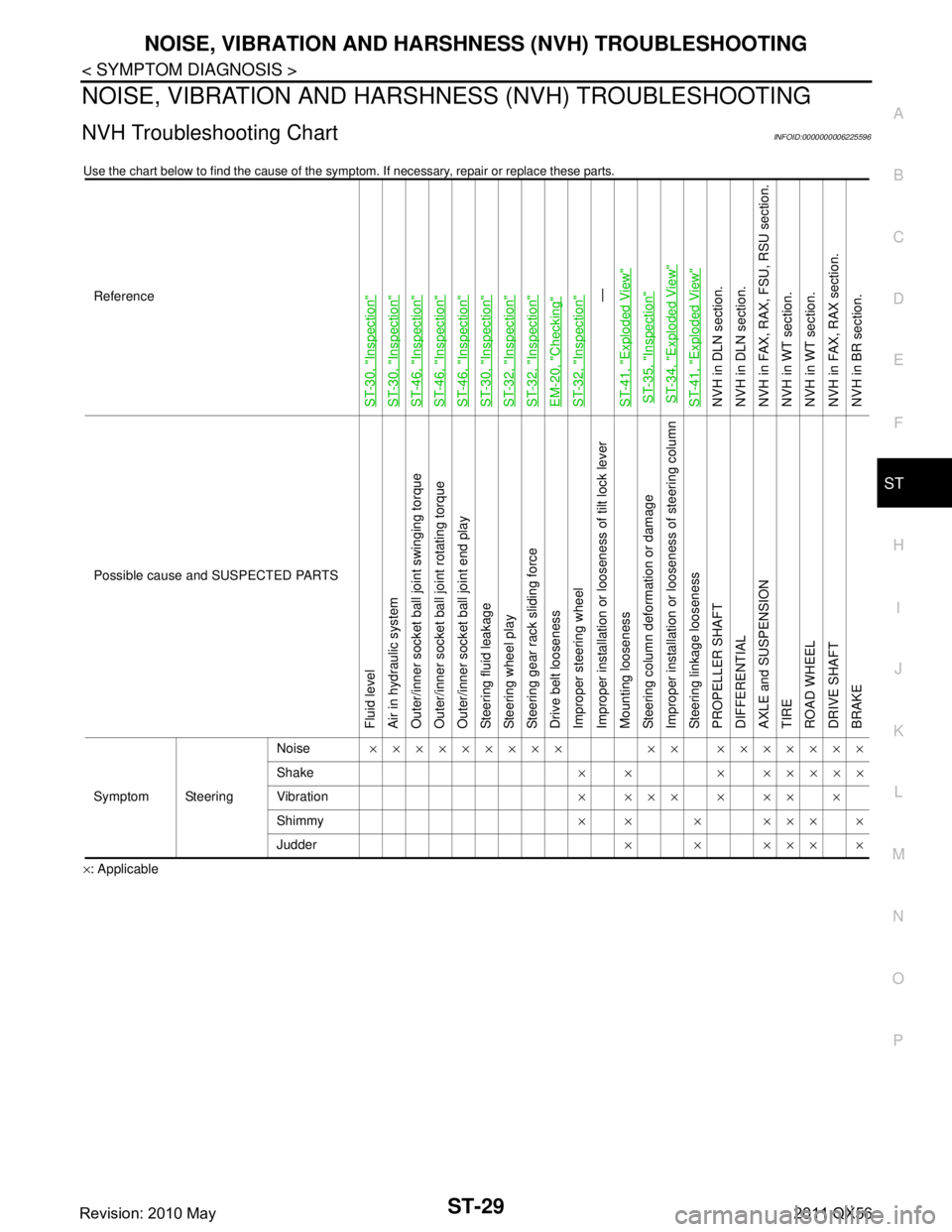

NVH Troubleshooting ChartINFOID:0000000006225596

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference

ST-30, "

Inspection

"

ST-30, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-46, "

Inspection

"

ST-30, "

Inspection

"

ST-32, "

Inspection

"

ST-32, "

Inspection

"

EM-20, "

Checking

"

ST-32, "

Inspection

"—

ST-41, "

Exploded View

"

ST-35, "

Inspection

"

ST-34, "

Exploded View

"

ST-41, "

Exploded View

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX, RAX, FSU, RSU section.

NVH in WT section.

NVH in WT section.

NVH in FAX, RAX section.

NVH in BR section.

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer/inner socket ball joint swinging torque

Outer/inner socket ball joint rotating torque

Outer/inner socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting looseness

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRE

ROAD WHEEL

DRIVE SHAFT

BRAKE

Symptom Steering Noise

××××××××× ×× ×××××××

Shake × × × ×××××

Vibration ××××××××

Shimmy ×× × ××××

Judder ××××××

Revision: 2010 May2011 QX56

Page 5036 of 5598

POWER STEERING OIL PUMPST-49

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

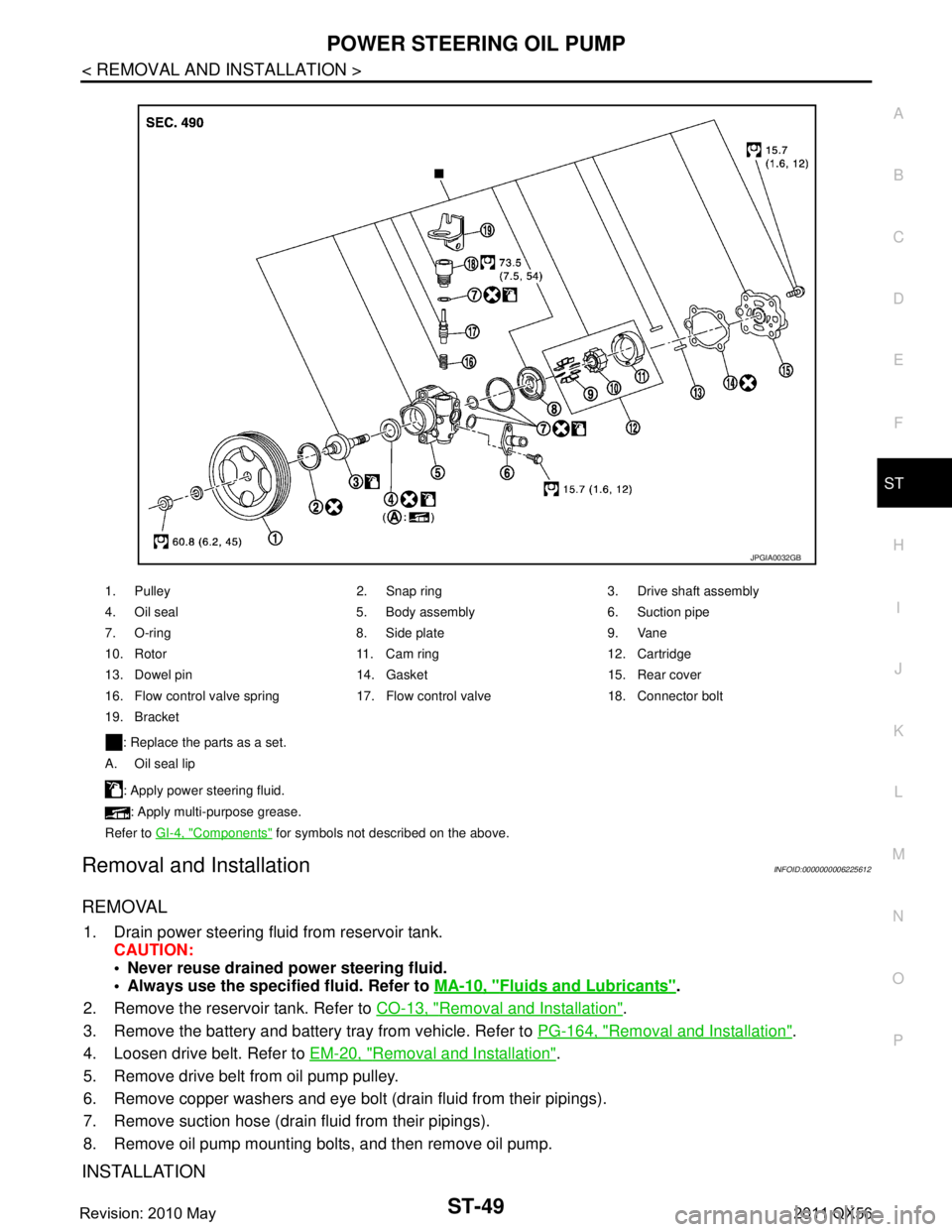

Removal and InstallationINFOID:0000000006225612

REMOVAL

1. Drain power steering fluid from reservoir tank. CAUTION:

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

2. Remove the reservoir tank. Refer to CO-13, "

Removal and Installation".

3. Remove the battery and battery tray from vehicle. Refer to PG-164, "

Removal and Installation".

4. Loosen drive belt. Refer to EM-20, "

Removal and Installation".

5. Remove drive belt from oil pump pulley.

6. Remove copper washers and eye bolt (drain fluid from their pipings).

7. Remove suction hose (drain fluid from their pipings).

8. Remove oil pump mounting bolts, and then remove oil pump.

INSTALLATION

1. Pulley 2. Snap ring 3. Drive shaft assembly

4. Oil seal 5. Body assembly 6. Suction pipe

7. O-ring 8. Side plate 9. Vane

10. Rotor 11. Cam ring 12. Cartridge

13. Dowel pin 14. Gasket 15. Rear cover

16. Flow control valve spring 17. Flow control valve 18. Connector bolt

19. Bracket

: Replace the parts as a set.

A. Oil seal lip

: Apply power steering fluid.: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPGIA0032GB

Revision: 2010 May2011 QX56