drain bolt INFINITI QX56 2011 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5036 of 5598

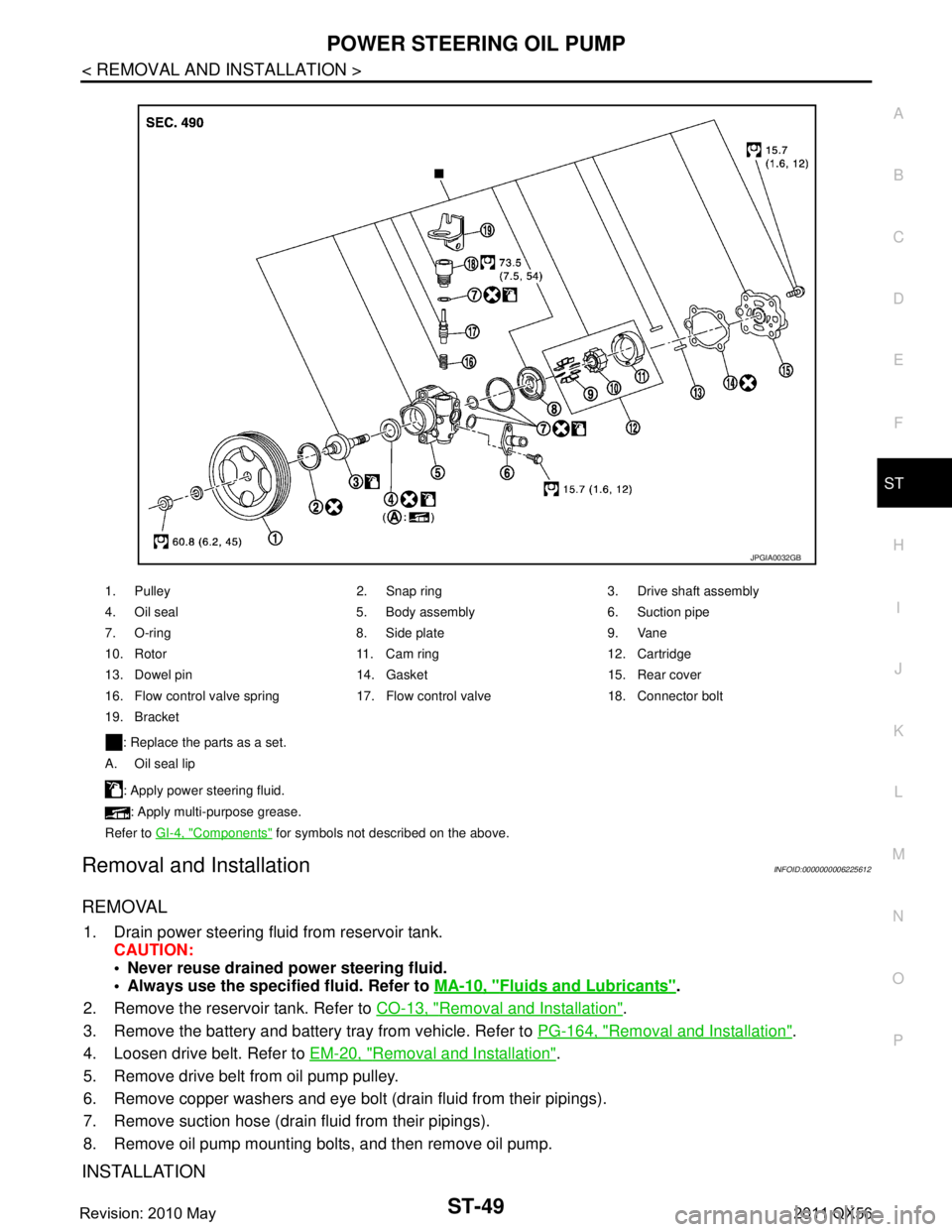

POWER STEERING OIL PUMPST-49

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

Removal and InstallationINFOID:0000000006225612

REMOVAL

1. Drain power steering fluid from reservoir tank. CAUTION:

Never reuse drained power steering fluid.

Always use the specified fluid. Refer to MA-10, "

Fluids and Lubricants".

2. Remove the reservoir tank. Refer to CO-13, "

Removal and Installation".

3. Remove the battery and battery tray from vehicle. Refer to PG-164, "

Removal and Installation".

4. Loosen drive belt. Refer to EM-20, "

Removal and Installation".

5. Remove drive belt from oil pump pulley.

6. Remove copper washers and eye bolt (drain fluid from their pipings).

7. Remove suction hose (drain fluid from their pipings).

8. Remove oil pump mounting bolts, and then remove oil pump.

INSTALLATION

1. Pulley 2. Snap ring 3. Drive shaft assembly

4. Oil seal 5. Body assembly 6. Suction pipe

7. O-ring 8. Side plate 9. Vane

10. Rotor 11. Cam ring 12. Cartridge

13. Dowel pin 14. Gasket 15. Rear cover

16. Flow control valve spring 17. Flow control valve 18. Connector bolt

19. Bracket

: Replace the parts as a set.

A. Oil seal lip

: Apply power steering fluid.: Apply multi-purpose grease.

Refer to GI-4, "

Components" for symbols not described on the above.

JPGIA0032GB

Revision: 2010 May2011 QX56

Page 5185 of 5598

![INFINITI QX56 2011 Factory Owners Guide

A/T FLUID COOLERTM-97

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

A/T FLUID COOLER

CleaningINFOID:0000000006233276

Whenever an A/T is replaced, the A/ T fluid cooler mounted i INFINITI QX56 2011 Factory Owners Guide

A/T FLUID COOLERTM-97

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

A/T FLUID COOLER

CleaningINFOID:0000000006233276

Whenever an A/T is replaced, the A/ T fluid cooler mounted i](/img/42/57033/w960_57033-5184.png)

A/T FLUID COOLERTM-97

< BASIC INSPECTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

A/T FLUID COOLER

CleaningINFOID:0000000006233276

Whenever an A/T is replaced, the A/ T fluid cooler mounted in the radiator must be inspected and cleaned.

Metal debris and friction material, if present, can becom e trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can bl ock or restrict the flow of ATF. In either case, mal-

function of the newly se rviced A/T may result.

Debris, if present, may build up as ATF enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CLEANING PROCEDURE

1. Position an oil pan under the A/T inlet and outlet cooler hoses.

2. Identify the inlet and outlet fluid cooler hoses.

3. Disconnect the A/T fluid cooler inlet and outlet rubber hoses

from the steel cooler tubes or by-pass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any ATF that remains in the cooler hoses to drain into the oil pan.

5. Insert the extension adapter hose of a can of Transmission Cooler Cleaner (Nissan P/N 999MP-AM006) into the cooler out-

let hose.

CAUTION:

Wear safety glasses and rubber gloves when spraying theTransmission Cooler Cleaner.

Spray Transmission Cooler Cleaner only with adequate

ventilation.

Avoid contact with eyes and skin.

Never breath vapors or spray mist.

6. Hold the hose and can as high as possible and spray Transmis- sion Cooler Cleaner in a continuous stream into the cooler outlet

hose until ATF flows out of the cooler inlet hose for 5 seconds.

7. Insert the tip of an air gun into the end of the cooler outlet hose.

8. Wrap a shop rag around the air gun tip and of the cooler outlet hose.

9. Blow compressed air regulated to 5 to 9 kg/cm

2 (71 to 128 psi)

through the cooler outlet hose for 10 seconds to force out any

remaining ATF.

10. Repeat steps 5 through 9 three additional times.

11. Position an oil pan under the banjo bolts that connect the A/T fluid cooler steel lines to the A/T.

12. Remove the banjo bolts.

13. Flush each steel line from the cooler side back toward the A/T by spraying Transmission Cooler Cleaner in a continuous stream for 5 seconds.

14. Blow compressed air regulated to 5 to 9 kg/cm

2 (71 to 128 psi) through each steel line from the cooler

side back toward the A/T for 10 seconds to force out any remaining ATF.

15. Ensure all debris is removed from the steel cooler lines.

16. Ensure all debris is removed from the banjo bolts and fittings.

17. Perform “DIAGNOSIS PROCEDURE”.

JPDIA0711GB

JPDIA0712GB

JPDIA0713GB

Revision: 2010 May2011 QX56

Page 5270 of 5598

![INFINITI QX56 2011 Factory Owners Guide

TM-182

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

CONTROL VALVE & TCM

Exploded ViewINFOID:0000000006226899

Removal and InstallationINFOID:0000000006226900

REMOVAL

1. Drain ATF thr INFINITI QX56 2011 Factory Owners Guide

TM-182

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

CONTROL VALVE & TCM

Exploded ViewINFOID:0000000006226899

Removal and InstallationINFOID:0000000006226900

REMOVAL

1. Drain ATF thr](/img/42/57033/w960_57033-5269.png)

TM-182

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

CONTROL VALVE & TCM

Exploded ViewINFOID:0000000006226899

Removal and InstallationINFOID:0000000006226900

REMOVAL

1. Drain ATF through drain plug.

1. A/T 2. Snap ring 3. Control valve & TCM

4. Oil pan gasket 5. Oil pan 6. Clip

7. Oil pan mounting bolt 8. Overflow plug 9. Drain plug

10. Drain plug gasket 11. Magnet 12. Clip

13. Joint connector

Refer to

GI-4, "

Components" for symbols in the figure.

JSDIA1755GB

Revision: 2010 May2011 QX56

Page 5272 of 5598

![INFINITI QX56 2011 Factory Owners Guide

TM-184

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

9. Remove bolts and clip (1) from the control valve & TCM.

*: Reamer bolt

10. Remove the control valve & TCM from transmission ca INFINITI QX56 2011 Factory Owners Guide

TM-184

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

9. Remove bolts and clip (1) from the control valve & TCM.

*: Reamer bolt

10. Remove the control valve & TCM from transmission ca](/img/42/57033/w960_57033-5271.png)

TM-184

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

CONTROL VALVE & TCM

9. Remove bolts and clip (1) from the control valve & TCM.

*: Reamer bolt

10. Remove the control valve & TCM from transmission case.

CAUTION:

When removing, be careful wi th the manual valve (1) notch

and manual plate (2) height. Remove it vertically.

11. Remove joint connector (1) from the control valve & TCM using a flat-bladed screwdriver (A).

12. Disconnect TCM connector (A). CAUTION:

Be careful not to damage connector.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Be careful not to damage connector when installing any connector.

Never reuse joint connector.

Apply ATF to O-ring of joint connector.

Never reuse drain plug and drain plug gasket. In addition, install new drain plug and drain plug gas-

ket after adjustment of A/T fluid filling.

Refer to the following when installing the control valve & TCM to transmission case.

: Vehicle front

Bolt symbol Length mm (in) Number of bolts A 43 (1.69) 3

B 40 (1.57) 2

C 54 (2.13) 6

D 50 (1.97) 2

E* 50 (1.97) 1

JPDIA1105ZZ

JPDIA0012ZZ

JSDIA1718ZZ

JSDIA1813ZZ

Revision: 2010 May2011 QX56

Page 5275 of 5598

![INFINITI QX56 2011 Factory Owners Guide

PARKING COMPONENTSTM-187

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PARKING COMPONENTS

2WD

2WD : Exploded ViewINFOID:0000000006233258

2WD : Removal and InstallationIN INFINITI QX56 2011 Factory Owners Guide

PARKING COMPONENTSTM-187

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PARKING COMPONENTS

2WD

2WD : Exploded ViewINFOID:0000000006233258

2WD : Removal and InstallationIN](/img/42/57033/w960_57033-5274.png)

PARKING COMPONENTSTM-187

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

PARKING COMPONENTS

2WD

2WD : Exploded ViewINFOID:0000000006233258

2WD : Removal and InstallationINFOID:0000000006233259

REMOVAL

1. Drain ATF through drain plug.

2. Separate propeller shaft assembly. Refer to DLN-143, "

Exploded View".

3. Support A/T assembly with a transmission jack. CAUTION:

When setting transmission jack, be careful not to allow it to collide against the drain plug.

4. Remove rear engine mounting cross member with power tool. Refer to TM-205, "

2WD : Exploded View".

5. Remove engine mounting insulator (rear). Refer to TM-205, "

2WD : Exploded View".

1. Parking actuator support 2. Parking pawl 3. Return spring

4. Pawl shaft 5. Parking gear 6. Seal ring

7. Output shaft 8. Bearing race 9. Needle bearing

10. Self-sealing bolt 11. Bracket 12. Rear extension

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

Refer to GI-4, "

Components" for symbols not described on the above.

JSDIA1926GB

Revision: 2010 May2011 QX56

Page 5278 of 5598

![INFINITI QX56 2011 Factory Owners Guide

TM-190

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

PARKING COMPONENTS

16. Remove return spring (1) from parking pawl (2).

INSTALLATION

Note the following, and install in the reverse order of removal.

INFINITI QX56 2011 Factory Owners Guide

TM-190

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

PARKING COMPONENTS

16. Remove return spring (1) from parking pawl (2).

INSTALLATION

Note the following, and install in the reverse order of removal.](/img/42/57033/w960_57033-5277.png)

TM-190

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

PARKING COMPONENTS

16. Remove return spring (1) from parking pawl (2).

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Never reuse seal rings and drain plug gasket.

Apply petroleum jelly to n

eedle bearing and seal rings.

Insert the tip of parking rod between the parki ng pawl and the parking actuator support when assem-

bling the rear extension assembly.

Refer to the followings installing rear extension assembly.

- Apply recommended sealant (Genuine Anaerobic Liquid Gasket or

equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".) to rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc. from

the transmission case and rear extension assembly mounting

surfaces.

- Tighten rear extension assembly bolts to the specified torque.

2WD : InspectionINFOID:0000000006233260

INSPECTION AFTER REMOVAL

SCIA6180J

Sealant starting

point and end-

point (A) : Start and finish

point shall be in

the center of two bolts.

Overlap width of

sealant starting

point and end-

point (B) : 3 – 5 mm (0.12 – 0.20 in)

Sealant width (C) : 1.0 – 2.0 mm (0.04 – 0.08 in)

Sealant height (C) : 0.4 – 1.0 mm (0.016 – 0.04 in)

JSDIA1855ZZ

1: Bracket

A: Bolt

B : Self-sealing bolt

JSDIA1845ZZ

Revision: 2010 May2011 QX56

Page 5283 of 5598

![INFINITI QX56 2011 Factory Owners Guide

OUTPUT SPEED SENSORTM-195

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

OUTPUT SPEED SENSOR

2WD

2WD : Exploded ViewINFOID:0000000006228119

2WD : Removal and Installation INFINITI QX56 2011 Factory Owners Guide

OUTPUT SPEED SENSORTM-195

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

OUTPUT SPEED SENSOR

2WD

2WD : Exploded ViewINFOID:0000000006228119

2WD : Removal and Installation](/img/42/57033/w960_57033-5282.png)

OUTPUT SPEED SENSORTM-195

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

OUTPUT SPEED SENSOR

2WD

2WD : Exploded ViewINFOID:0000000006228119

2WD : Removal and InstallationINFOID:0000000006228120

REMOVAL

1. Disconnect the battery cabl e from the negative terminal.

2. Drain ATF through drain plug.

3. Separate propeller shaft assembly. Refer to DLN-143, "

Exploded View".

1. A/T 2. Oil pan gasket 3. Oil pan

4. Clip 5. Oil pan mounting bolt 6. Overflow plug

7. Drain plug 8. Drain plug gasket 9. Magnet

10. Output speed sensor 11. Self-sealing bolt 12. Bracket

13. Rear extension

*: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

Refer to GI-4, "

Components" for symbols not described on the above.

JSDIA1925GB

Revision: 2010 May2011 QX56

Page 5285 of 5598

![INFINITI QX56 2011 Factory Owners Guide

OUTPUT SPEED SENSORTM-197

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

12. Disconnect output speed sensor connector (A). CAUTION:

Be careful not to damage connector

13. INFINITI QX56 2011 Factory Owners Guide

OUTPUT SPEED SENSORTM-197

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

12. Disconnect output speed sensor connector (A). CAUTION:

Be careful not to damage connector

13.](/img/42/57033/w960_57033-5284.png)

OUTPUT SPEED SENSORTM-197

< REMOVAL AND INSTALLATION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

12. Disconnect output speed sensor connector (A). CAUTION:

Be careful not to damage connector

13. Disengage terminal clips ( ).

14. Remove output speed sensor (1) from transmission case.

CAUTION:

Never subject it to impact by dropping or hitting it.

Never disassemble.

Never allow metal filings, etc. to get on the sensor's frontedge magnetic area.

Never place in an area affected by magnetism.

INSTALLATION

Note the following, and install in the reverse order removal.

CAUTION:

Insert the tip of parking rod between the parkin g pole and the parking actuator support when assem-

bling the rear ext ension assembly.

Never reuse drain plug gasket.

Refer to the followings when installing output speed sensor.

CAUTION:

Never subject it to impact by dropping or hitting it.

Never disassemble.

Never allow metal filings, etc. to get on the sensor's front edge magnetic area.

Never place in an area affected by magnetism.

Refer to the followings when installing rear extension assembly.

- Apply recommended sealant (Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".) to rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc. from

transmission case and rear extension assembly mounting

surfaces.

JPDIA1104ZZ

: Bolt

JSDIA1885ZZ

Sealant starting

point and end-

point (A) : Start and finish point shall be in

the center of two bolts.

Overlap width of

sealant starting

point and end-

point (B) : 3 – 5 mm (0.12 – 0.20 in)

Sealant width (C) : 1.0 – 2.0 mm (0.04 – 0.08 in)

Sealant height (C) : 0.4 – 1.0 mm (0.016 – 0.04 in)

JSDIA1855ZZ

Revision: 2010 May2011 QX56

Page 5286 of 5598

![INFINITI QX56 2011 Factory Owners Guide

TM-198

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

OUTPUT SPEED SENSOR

- Tighten rear extension assembly bolts to the specified torque.

Refer to the followings when installing oil pan (2) (with oil INFINITI QX56 2011 Factory Owners Guide

TM-198

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

OUTPUT SPEED SENSOR

- Tighten rear extension assembly bolts to the specified torque.

Refer to the followings when installing oil pan (2) (with oil](/img/42/57033/w960_57033-5285.png)

TM-198

< REMOVAL AND INSTALLATION >[7AT: RE7R01B]

OUTPUT SPEED SENSOR

- Tighten rear extension assembly bolts to the specified torque.

Refer to the followings when installing oil pan (2) (with oil pan gas-

ket) and clips (1) to transmission case.

CAUTION:

Never reuse oil pan gasket and oil pan mounting bolts.

Install oil pan gasket in the di rection to align hole position.

Install it so that drain plug comes to the position as shown

in the figure.

Be careful not to pinch harnesses.

Completely remove all moisture, oil and ol d gasket, etc. from oil pan mounting surface.

- Tighten oil pan mounting bolts to the specified torque in numerical

order shown in the figure after temporarily tightening them. Tighten

necessary oil pan mounting bolts with specified torque.

2WD : Inspection and AdjustmentINFOID:0000000006228121

INSPECTION AFTER REMOVAL

Check foreign materials in oil pan to help determine causes of mal-

function. If the ATF is very dark, smells burned, or contains foreign

particles, the frictional material (clutches, band) may need replace-

ment. A tacky film that will not wipe clean indicates varnish build up.

Varnish can cause valves, servo, and clutches to stick and can

inhibit pump pressure.

If frictional material is det ected, perform A/T fluid cooler

cleaning. Refer to TM-97, "

Cleaning".

INSPECTION AFTER INSTALLATION

Check A/T fluid leakage Refer to TM-175, "Inspection".

1: Bracket

A: Bolt

B : Self-sealing bolt

JSDIA1845ZZ

: Vehicle front

: Oil pan mounting bolt

: Vehicle front

JSDIA1591ZZ

JSDIA1592GB

SCIA5199E

Revision: 2010 May2011 QX56

Page 5304 of 5598

![INFINITI QX56 2011 Factory Owners Guide

TM-216

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

4WD MODELS

13. Snap ring 14. Oil pan gasket 15. Oil pan

16. Clip 17. Oil pan mounting bolt 18. Overflow plug

19. Drain plu INFINITI QX56 2011 Factory Owners Guide

TM-216

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

4WD MODELS

13. Snap ring 14. Oil pan gasket 15. Oil pan

16. Clip 17. Oil pan mounting bolt 18. Overflow plug

19. Drain plu](/img/42/57033/w960_57033-5303.png)

TM-216

< UNIT DISASSEMBLY AND ASSEMBLY >[7AT: RE7R01B]

TRANSMISSION ASSEMBLY

4WD MODELS

13. Snap ring 14. Oil pan gasket 15. Oil pan

16. Clip 17. Oil pan mounting bolt 18. Overflow plug

19. Drain plug 20. Drain plug gasket 21. Magnet

22. Clip 23. Control valve & TCM 24. Joint connector

25. Transmission case 26. Retaining pin 27. Output speed sensor

28. Needle bearing 29. Parking gear 30. Seal ring

31. Output shaft 32. Bearing race

Refer to

GI-4, "

Components" for symbols in the figure.

1. Parking actuator support 2. Parking pawl 3. Pawl shaft

4. Return spring 5. Needle bearing 6. Rear extension

7. Self-sealing bolt 8. Rear oil seal 9. Bracket *: Apply Genuine Anaerobic Liquid Gasket or equivalent. Refer to GI-22, "

Recommended Chemical Products and Sealants".

Refer to GI-4, "

Components" for symbols in the figure.

JSDIA1841GB

Revision: 2010 May2011 QX56