drain bolt INFINITI QX56 2011 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1967 of 5598

![INFINITI QX56 2011 Factory User Guide

SIDE SHAFTDLN-165

< UNIT DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

DisassemblyINFOID:0000000006222388

1. Drain the differential gear oil if necessary.

2. INFINITI QX56 2011 Factory User Guide

SIDE SHAFTDLN-165

< UNIT DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

DisassemblyINFOID:0000000006222388

1. Drain the differential gear oil if necessary.

2.](/img/42/57033/w960_57033-1966.png)

SIDE SHAFTDLN-165

< UNIT DISASSEMBLY AND ASSEMBLY > [FRONT FINAL DRIVE: R180A]

C

EF

G H

I

J

K L

M A

B

DLN

N

O P

DisassemblyINFOID:0000000006222388

1. Drain the differential gear oil if necessary.

2. Remove the carrier cover bolts

3. Remove carrier cover to insert the seal cutter (A) [SST: KV10111100 (J-37228)] between gear carrier and carrier cover.

CAUTION:

Never damage the mating surface.

Never insert flat-bladed screwdriver, this will damage themating surface.

4. Remove side oil seal (right side) with a suitable tool. CAUTION:

Never damage gear carrier.

5. Remove snap ring (hole side) with a suitable tool.

6. Remove differential side shaft assembly out of gear carrier with a suitable tool.

NOTE:

Tap on differential side shaft assembly from side gear side.

7. Remove snap ring (differential side shaft side).

: Apply multi-purpose grease.

: Apply Genuine Silicone RTV or equivalent. Refer to GI-22, "

Recommended Chemical Products and Sealants".

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

Refer to GI-4, "

Components" for symbols not described above.

PDIA0699E

PDIA0713E

PDIA0714E

JPDID0383ZZ

Revision: 2010 May2011 QX56

Page 2006 of 5598

![INFINITI QX56 2011 Factory User Guide

DLN-204

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

Disassembly

INFOID:0000000006222421

1. Drain gear oil, if necessary.

2. Remove side flanges.

3. Remove rear cov INFINITI QX56 2011 Factory User Guide

DLN-204

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

Disassembly

INFOID:0000000006222421

1. Drain gear oil, if necessary.

2. Remove side flanges.

3. Remove rear cov](/img/42/57033/w960_57033-2005.png)

DLN-204

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

Disassembly

INFOID:0000000006222421

1. Drain gear oil, if necessary.

2. Remove side flanges.

3. Remove rear cover mounting bolts.

4 . R e m o v e r e a r c o v e r t o i n s e r t t h e s e a l c u t t e r [ S S T: K V 1 0 1111 0 0 (J-37228)] between gear carrier and rear cover.

CAUTION:

Never damage the mating surface.

Never insert flat-bladed screwdriver, this may damage themating surface.

5. Using spacers, mount carrier on the attachment (A) [SST:

KV38100800 (J-25604-01)].

6. For proper reinstallation, paint matching marks on one side of the bearing cap.

CAUTION:

For matching marks, use paint. Never damage bearingcaps and gear carrier.

Bearing caps are manufactured as integral molding. Use the matching marks to them in their original positions.

7. Remove bearing caps.

: Apply Genuine Silicone RTV or equivalent. Refer to GI-22, "Recommended Chemical Products and Sealants".

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to GI-22, "

Recommended Chemical Products

and Sealants".

Refer to GI-4, "

Components" for symbols not described above.

PDIA0940E

JSDIA0041ZZ

SDIA1795E

S-PD343

Revision: 2010 May2011 QX56

Page 2012 of 5598

![INFINITI QX56 2011 Factory User Guide

DLN-210

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

16. Using the drift [SST: ST35271000 (J-26091)], drive side oil seals

until it becomes flush with the case end. INFINITI QX56 2011 Factory User Guide

DLN-210

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

16. Using the drift [SST: ST35271000 (J-26091)], drive side oil seals

until it becomes flush with the case end.](/img/42/57033/w960_57033-2011.png)

DLN-210

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

16. Using the drift [SST: ST35271000 (J-26091)], drive side oil seals

until it becomes flush with the case end.

CAUTION:

Never reuse oil seal.

When installing, n ever incline oil seal.

Apply multi-purpose grease onto oil seal lips, and gear oil

onto the circumference of oil seal.

17. Check and adjust drive gear runout, tooth contact, drive gear to drive pinion backlash, and total preload torque. Refer to DLN-

210, "Adjustment".

Recheck above items. Readjust the above description, if neces-

sary.

18. Apply sealant to mating surface of rear cover. Use Genuine Silicone RTV or equivalent. Refer to GI-22,

"Recommended Chemical Products and Sealants".

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

19. Install rear cover on gear carrier and tighten mounting bolts.

20. Install side flange with the following procedure.

a. Attach the protector [SST: KV38108000 ( — )] to side oil seal.

b. After the side flange is inserted and the serrated part of side gear has engaged the serrated part of flange, remove the pro-

tector.

c. Insert the side flange until the se rrated part of the side flange

has engaged the serrated part of the side gear and remove the

protector.

NOTE:

When installation is completed, driving sound of the side flange

turns into a sound that seems to affect the whole final drive.

d. Confirm that the dimension of the side flanges (1) installation measurement (A) in the figure comes into the following.

AdjustmentINFOID:0000000006222423

TOTAL PRELOAD TORQUE

Before inspection and adjustment, drain gear oil.

1. Secure final drive assembly onto an attachment [SST: KV38100800 ( — )].

2. Remove side flanges.

3. Rotate drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

SPD560

PDIA0961E

SDIA0822E

A : 342.2 mm (13.47 in)

JSDIA0185ZZ

Revision: 2010 May2011 QX56

Page 2014 of 5598

![INFINITI QX56 2011 Factory User Guide

DLN-212

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

5. Install bearing caps in their correct locations and tighten bearing

cap mounting bolts.

6. Turn the carrier INFINITI QX56 2011 Factory User Guide

DLN-212

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

5. Install bearing caps in their correct locations and tighten bearing

cap mounting bolts.

6. Turn the carrier](/img/42/57033/w960_57033-2013.png)

DLN-212

< UNIT DISASSEMBLY AND ASSEMBLY >[REAR FINAL DRIVE: R230]

DIFFERENTIAL ASSEMBLY

5. Install bearing caps in their correct locations and tighten bearing

cap mounting bolts.

6. Turn the carrier several times to seat the bearings.

7. Measure the turning torque of the carrier at the drive gear mounting bolts with a spring gauge [SST: — (J-8129)].

8. If the turning torque is outside the specification, use a thicker/ thinner side bearing adjusting washer to adjust. For selecting

adjusting washer, refer to the latest parts information.

CAUTION:

Select a side bearing adjust ing washer for right and left

individually.

9. Record the total amount of washer thickness required for the correct carrier side bearing preload.

DRIVE GEAR RUNOUT

1. Remove rear cover. Refer to DLN-204, "Disassembly".

2. Fit a dial indicator to the drive gear back face.

3. Rotate the drive gear to measure runout.

If the runout is outside of the repair limit, check drive gearassembly condition; foreign material may be caught between

drive gear and differential case, or differential case or drive

gear may be deformed, etc.

CAUTION:

Replace drive gear and dri ve pinion gear as a set.

TOOTH CONTACT

Before inspection and adjustment, drain gear oil.

1. Remove rear cover. Refer to DLN-204, "

Disassembly".

SDIA1795E

Specification : 34.2 – 39.2N (3.5 – 4.0 kg,

7.7 – 8.8 lb) of pulling force

at the drive gear bolt

SPD194A

If the turning torque is less

than the specified range:Use a thicker thrust wash-

er.

If the turning torque is

greater than the specifica-

tion: Use a thinner thrust wash-

er.

SPD772

Drive gear runout : Refer to

DLN-222, "Drive

Gear Runout".

SPD886

Revision: 2010 May2011 QX56

Page 2566 of 5598

EM-4

< PRECAUTION >

PRECAUTIONS

If turning the steering wheel is required with the battery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect bot h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Drain Engine Coolant and Engine OilINFOID:0000000006289509

Drain engine coolant and engine oil when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000006289510

Before starting work, check no fire or sp ark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Handling High Pressure Fuel SystemINFOID:0000000006289511

High pressure fuel system components are betw een high pressure fuel pump and fuel injector.

Always release fuel pressure and never start the engine when performing removal and installation.

When removing or installing parts without releasing fuel pressure, fuel may be splashed and, if fuel contacts

skin or eyes, it may cause inflammation.

Precaution for Removal and DisassemblyINFOID:0000000006289512

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Cover openings of engine system with tape or the equival ent, if necessary, to seal out foreign materials.

Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

When loosening nuts and bolts, as a basic rule, star t with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000006289513

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000006289514

Use torque wrench to tighten bolts or nuts to specification.

When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

Replace with new gasket, packing, oil seal or O-ring.

Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

Revision: 2010 May2011 QX56

Page 2567 of 5598

PRECAUTIONSEM-5

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Avoid damaging sliding or mating surfaces. Completely re

move foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Parts Requiring Angle TighteningINFOID:0000000006289515

Use angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

- Cylinder head bolts

- Main bearing cap bolts

- Main bearing cap sub bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angletightening)

Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000006289516

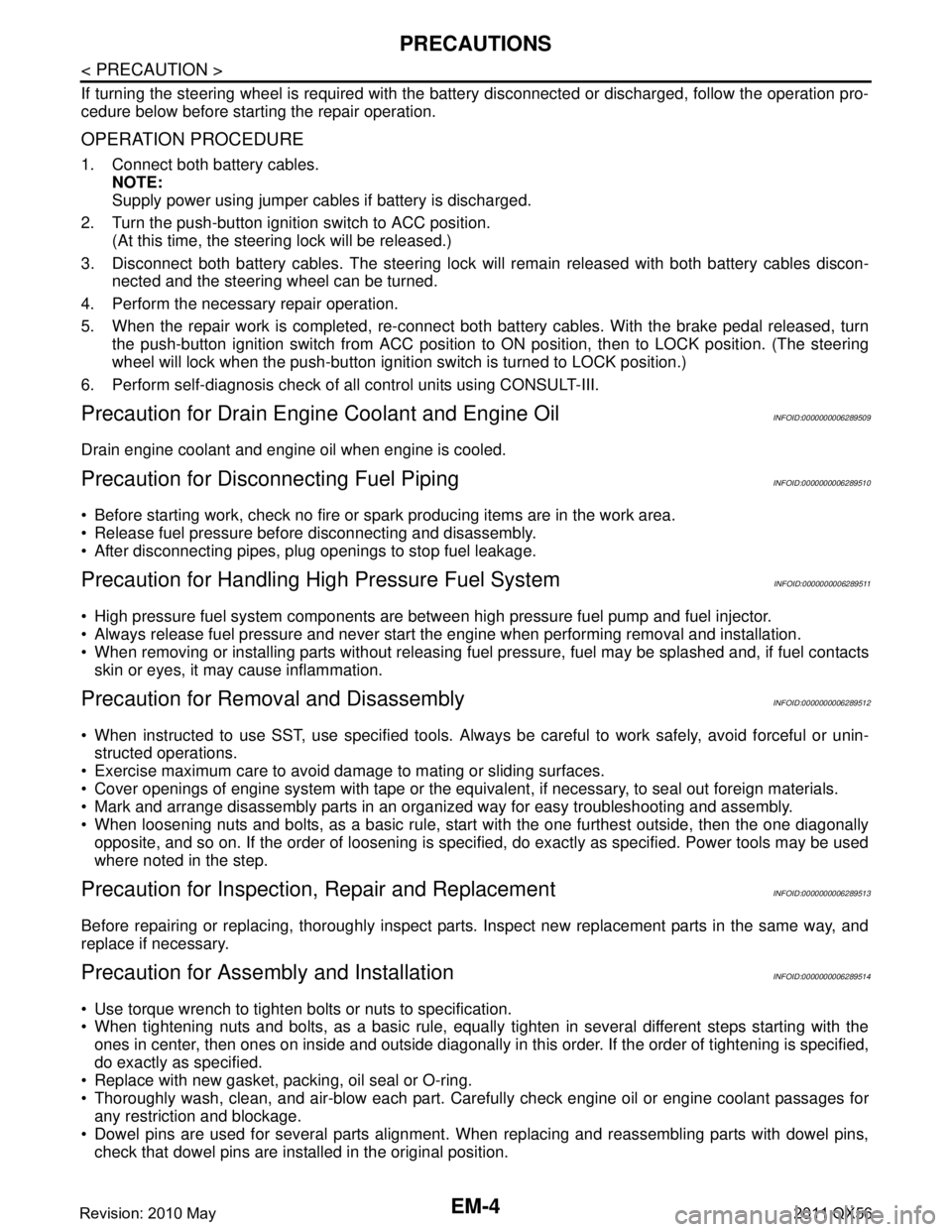

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur- face using the seal cutter [SST:KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

In areas where the seal cutter is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason a tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

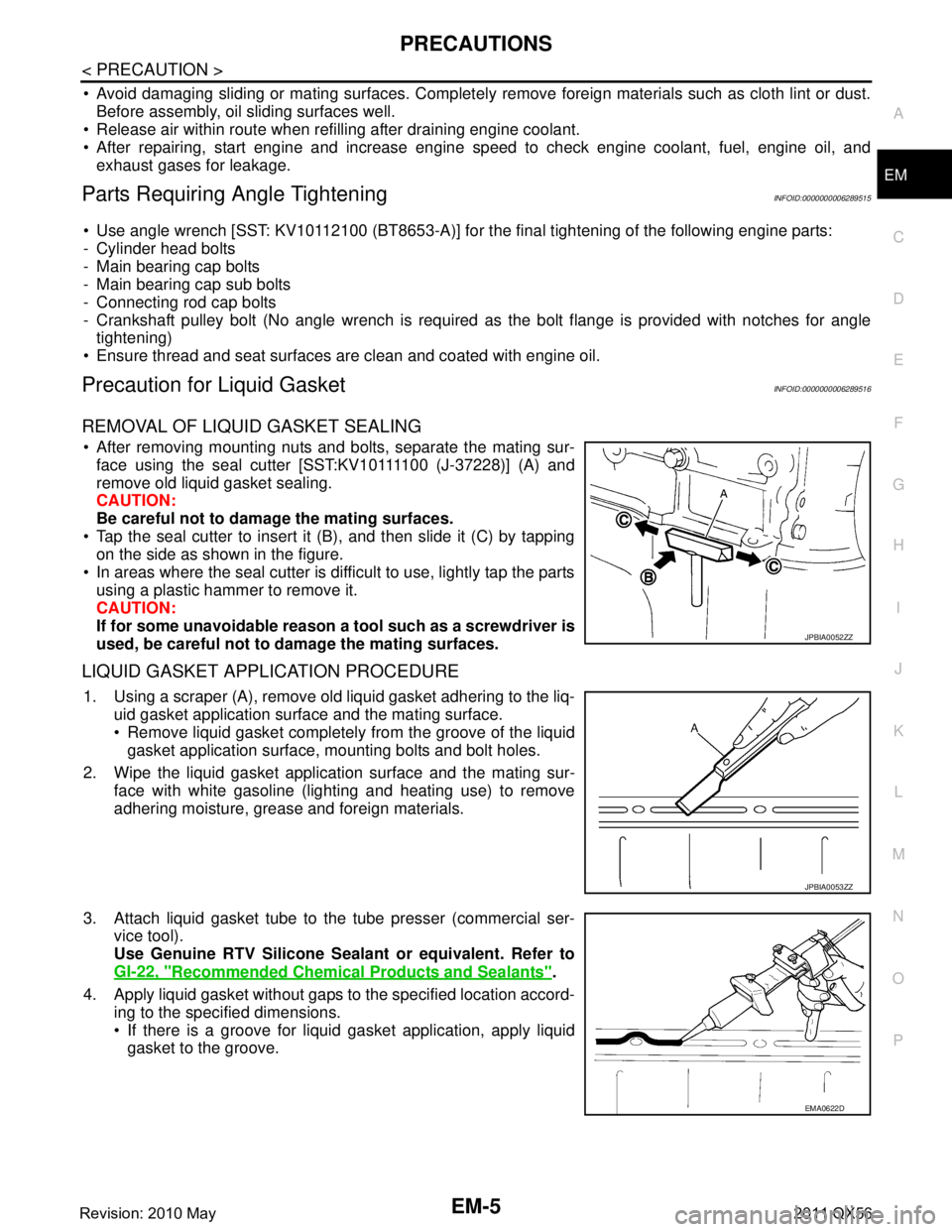

1. Using a scraper (A), remove old liquid gasket adhering to the liq- uid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser (commercial ser- vice tool).

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without gaps to the specified location accord- ing to the specified dimensions.

If there is a groove for liquid gasket application, apply liquidgasket to the groove.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

Revision: 2010 May2011 QX56

Page 2617 of 5598

OIL PAN (LOWER) AND OIL STRAINEREM-55

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000006289560

REMOVAL

WARNING:

To avoid the danger of being scalded, never

drain engine oil when engine is hot.

1. Drain engine oil. Refer to LU-8, "

Draining".

2. Remove protector A and protector B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

3. Remove front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or

TM-208, "

4WD : Exploded View" (4WD models).

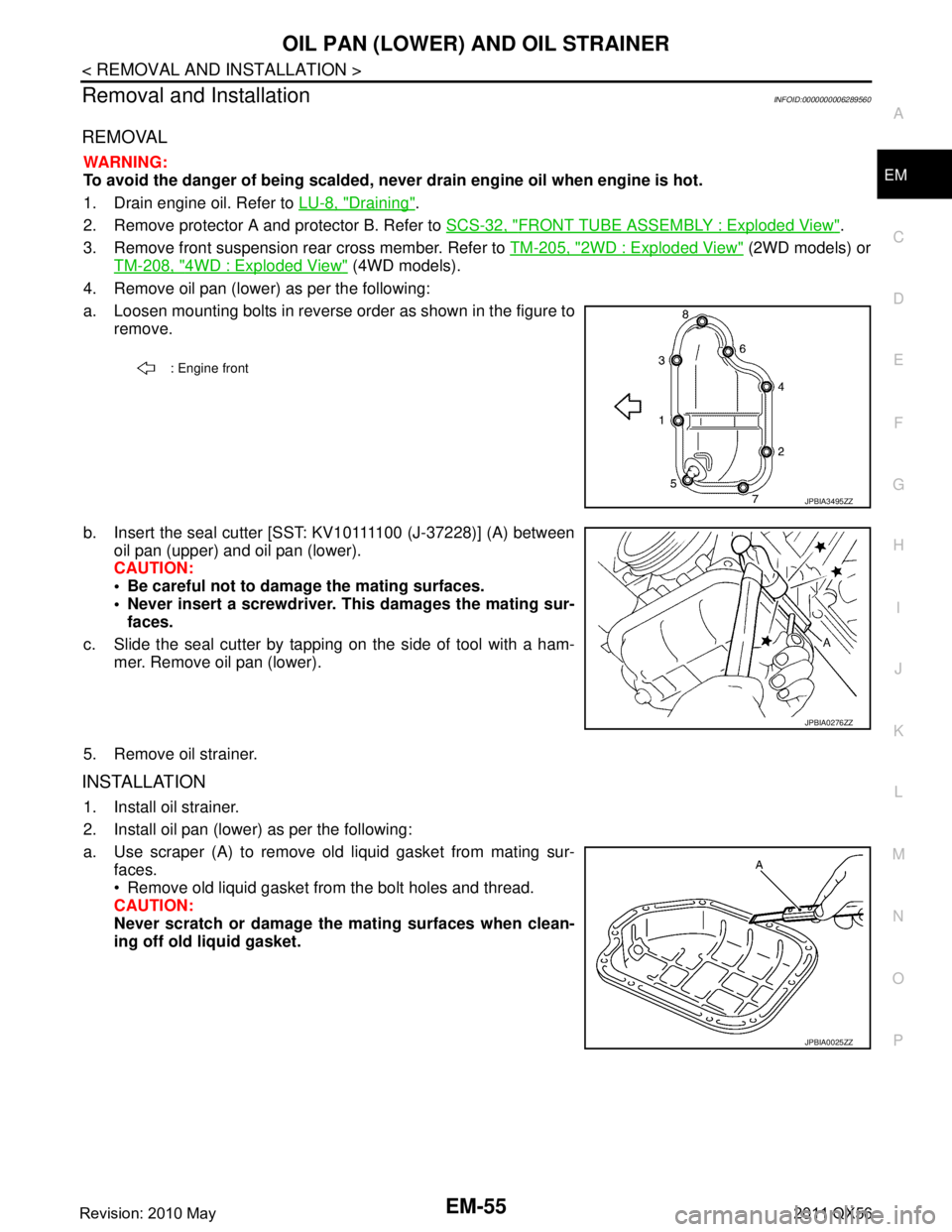

4. Remove oil pan (lower) as per the following:

a. Loosen mounting bolts in reverse order as shown in the figure to remove.

b. Insert the seal cutter [SST: KV10111100 (J-37228)] (A) between oil pan (upper) and oil pan (lower).

CAUTION:

Be careful not to damage the mating surfaces.

Never insert a screwdriver. This damages the mating sur-faces.

c. Slide the seal cutter by tapping on the side of tool with a ham- mer. Remove oil pan (lower).

5. Remove oil strainer.

INSTALLATION

1. Install oil strainer.

2. Install oil pan (lower) as per the following:

a. Use scraper (A) to remove old liquid gasket from mating sur- faces.

Remove old liquid gasket from the bolt holes and thread.

CAUTION:

Never scratch or damage th e mating surfaces when clean-

ing off old liquid gasket.

: Engine front

JPBIA3495ZZ

JPBIA0276ZZ

JPBIA0025ZZ

Revision: 2010 May2011 QX56

Page 2618 of 5598

EM-56

< REMOVAL AND INSTALLATION >

OIL PAN (LOWER) AND OIL STRAINER

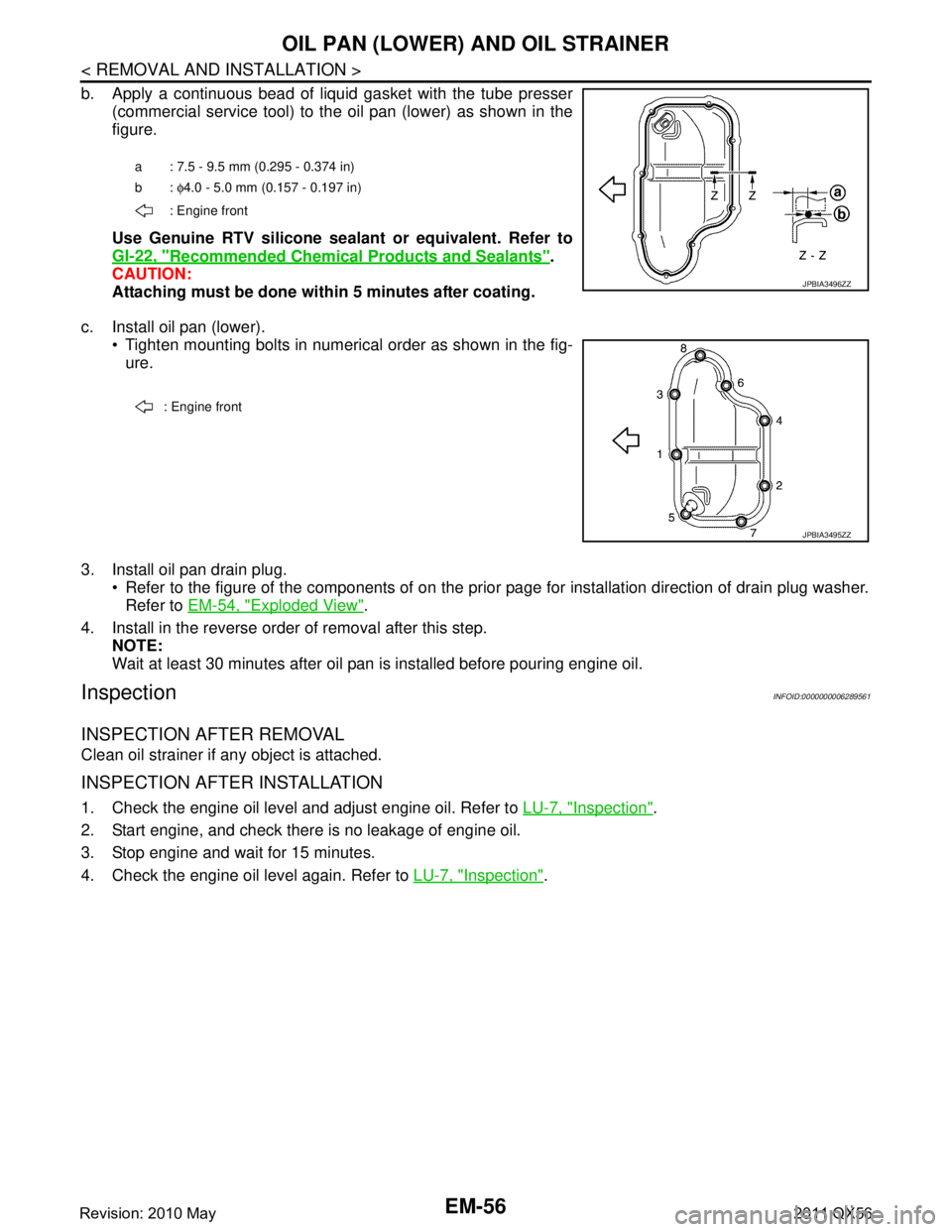

b. Apply a continuous bead of liquid gasket with the tube presser(commercial service tool) to the oil pan (lower) as shown in the

figure.

Use Genuine RTV silicone seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

CAUTION:

Attaching must be done with in 5 minutes after coating.

c. Install oil pan (lower). Tighten mounting bolts in numerical order as shown in the fig-ure.

3. Install oil pan drain plug. Refer to the figure of the components of on the prior page for installation direction of drain plug washer.Refer to EM-54, "

Exploded View".

4. Install in the reverse order of removal after this step. NOTE:

Wait at least 30 minutes after oil pan is installed before pouring engine oil.

InspectionINFOID:0000000006289561

INSPECTION AFTER REMOVAL

Clean oil strainer if any object is attached.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and adjust engine oil. Refer to LU-7, "Inspection".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 15 minutes.

4. Check the engine oil level again. Refer to LU-7, "

Inspection".

a : 7.5 - 9.5 mm (0.295 - 0.374 in)

b: φ4.0 - 5.0 mm (0.157 - 0.197 in)

: Engine front

JPBIA3496ZZ

: Engine front

JPBIA3495ZZ

Revision: 2010 May2011 QX56

Page 2620 of 5598

EM-58

< REMOVAL AND INSTALLATION >

OIL PAN (UPPER)

Removal and Installation

INFOID:0000000006289563

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain engine oil when engine is hot.

1. Remove oil filter. Refer to LU-9, "

Removal and Installation".

2. Remove oil cooler. Refer to LU-11, "

Exploded View".

3. Move A/C compressor to the position without the hindrance for work. Refer to HA-30, "

Exploded View".

4. Remove oil level gauge and oil level gauge guide.

5. Remove oil pressure switch and oil temperature sensor if necessary.

6. Remove rear plate cover.

7. Remove protector A and protector B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

8. Remove front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or

TM-208, "

4WD : Exploded View" (4WD models).

9. Remove steering gear assembly. Refer to ST-41, "

Exploded View".

10. Remove front final drive assembly. Refer to DLN-162, "

Exploded View".

11. Remove oil pan (lower). Refer to EM-54, "

Exploded View".

12. Remove oil strainer. Refer to EM-54, "

Exploded View".

13. Remove bolts fixing oil pan (upper) to transmission assembly.

14. Remove oil pan (upper) as per the following:

a. Loosen mounting bolts in the reverse order as shown in the fig- ure with power tool to remove.

NOTE:

Disregard No. 9, 16 when loosening.

b. Insert a suitable tool into the notch at oil pan (upper) (1) as shown.

Pry off case by moving a suitable tool.

CAUTION:

Be careful not to damage the mating surfaces.

15. Remove O-ring from bottom of cylinder block and oil pump.

16. Remove oil pressure switch and oil temperature sensor, if necessary.

INSTALLATION

1. Install oil pan (upper) as per the following:

: Engine front

JPBIA3502ZZ

: Engine front

JPBIA2299ZZ

Revision: 2010 May2011 QX56

Page 2662 of 5598

EM-100

< UNIT REMOVAL AND INSTALLATION >

ENGINE ASSEMBLY

3. Install engine slinger on both front right and front left sides of theengine.

4. Hoist the slinger to obtain room for engine assembly. CAUTION:

Use an engine lifter to prevent the engine slinger from fall-

ing and damaging the rocker cover.

REMOVAL

Outline

At first, remove the transmission and transfer assemb ly, steering gear and front final drive facing downward.

Then remove the engine.

Preparation

1. Remove engine cover. Refer to EM-25, "Exploded View".

2. Release fuel pressure. Refer to EC-153, "

Work Procedure".

3. Remove battery and tray. Refer to PG-164, "

Exploded View".

4. Remove the following components and related parts: Hood assembly. Refer to DLK-215, "

Exploded View".

Front under cover. Refer to EXT-25, "

Exploded View".

Front road wheel and tires. Refer to WT-64, "

Exploded View".

5. Drain engine oil. Refer to LU-8, "

Draining".

6. Drain engine coolant. Refer to CO-8, "

Draining".

CAUTION:

Perform this step when engine is cold.

Never spill engine coolant on drive belts.

7. Drain power steering fluid. Refer to ST-54, "

Exploded View".

Engine Room Front

1. Remove drive belt. Refer to EM-20, "Exploded View".

2. Remove fan shroud. Refer to CO-13, "

Exploded View".

3. Remove cooling fan and fan coupling. Refer to CO-16, "

Exploded View".

4. Remove radiator hoses (upper and lower).

5. Remove radiator.

Vehicle Underbody

1. Remove exhaust front tube. Refer to EX-5, "Exploded View".

2. Remove protector A and B. Refer to SCS-32, "

FRONT TUBE ASSEMBLY : Exploded View".

3. Remove front suspension rear cross member. Refer to TM-205, "

2WD : Exploded View" (2WD models) or

TM-208, "

4WD : Exploded View" (4WD models).

4. Remove oil cooler. Refer to LU-11, "

Exploded View".

A : Engine front slinger (bank 2)

B : Engine front slinger (bank 1)

Slinger bolts:

: 45.0 N·m (4.6 kg-m, 33 ft-lb)

JPBIA3969ZZ

JPBIA2507ZZ

Revision: 2010 May2011 QX56