drain bolt INFINITI QX56 2011 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2665 of 5598

ENGINE STAND SETTINGEM-103

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE STAND SETTING

SettingINFOID:0000000006289579

NOTE:

Explained here is how to disassemble with engine stand s

upporting transmission surface. When using a differ-

ent type of engine stand, note the difference in the steps, etc.

1. Remove the engine assembly from the vehicle. Refer to EM-98, "

Exploded View".

2. Remove crankshaft pulley. Refer to EM-96, "

FRONT OIL SEAL : Removal and Installation".

NOTE:

The drive plate is fixed with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen the crankshaft pul-

ley mounting bolts before installing the engine stand.

3. Remove the parts that may restrict installation of engine to a widely used engine stand. Fix crankshaft with a ring gear stopper [SST: KV10119200 (J-49277)]. Loosen drive plate mounting bolt

with power tool.

Check for deformation or damage of drive plate. Refer to EM-115, "

Inspection".

NOTE:

The procedure is described assuming that you us e a widely used engine stand holding the surface, to

which transmission is installed.

4. Remove pilot converter using the pilot bushing puller (commercial service tool), if necessary.

5. Lift the engine with hoist to inst all it onto the widely used engine stand.

CAUTION:

Use an engine stand that has a load capacity [240 kg (529 lb) or more] large enough for supporting

the engine weight.

If the load capacity of the stand is not adequate, remove the following parts beforehand to reduce the potential risk of overturning the stand.

- Remove intake manifold. Refer to EM-30, "

Exploded View".

- Remove fuel injector and fuel tube assembly. Refer to EM-48, "

Exploded View".

- Remove ignition coil. Refer to EM-29, "

Exploded View".

- Remove rocker cover. Refer to EM-33, "

Exploded View".

- Remove exhaust manifold. Refer to EM-40, "

Exploded View".

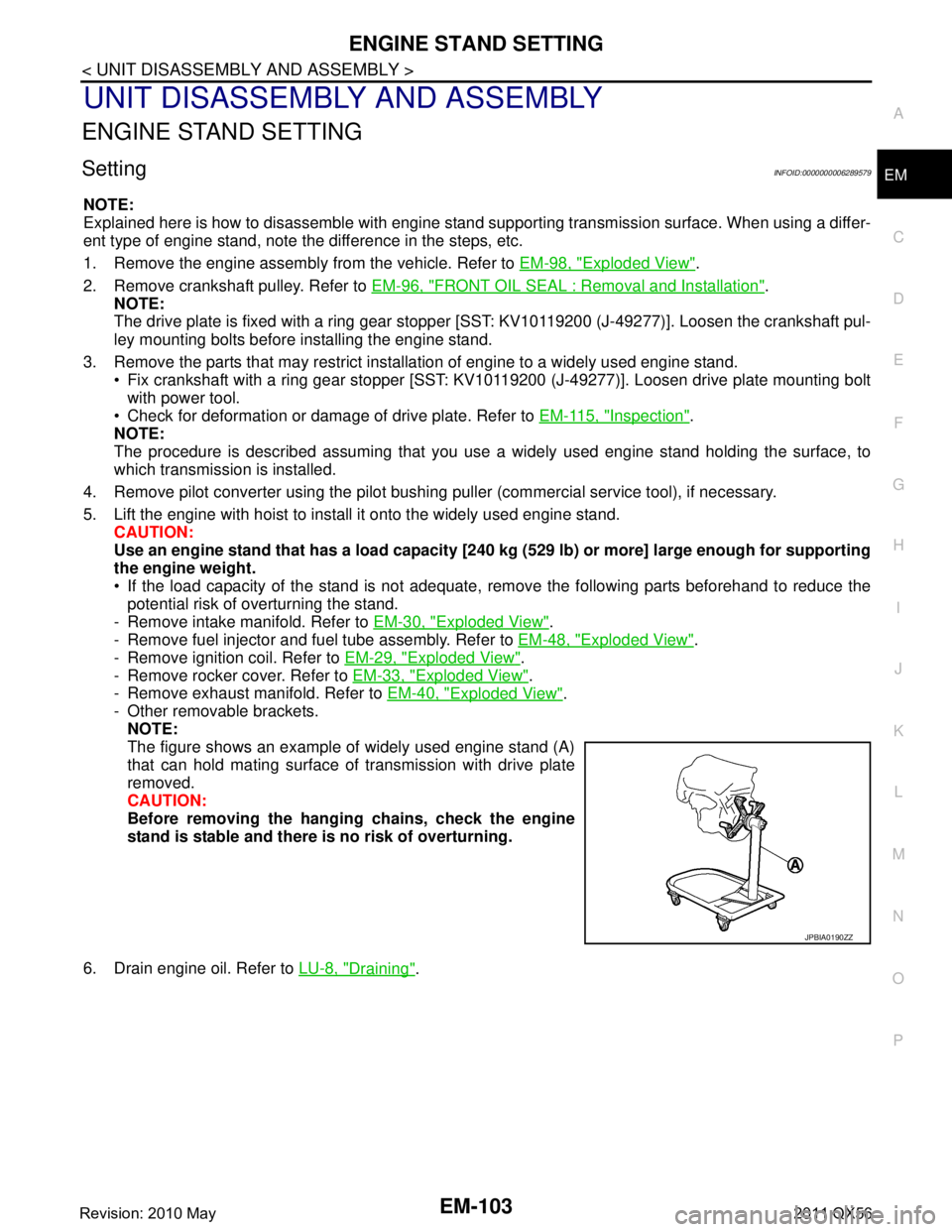

- Other removable brackets. NOTE:

The figure shows an example of widely used engine stand (A)

that can hold mating surface of transmission with drive plate

removed.

CAUTION:

Before removing the hang ing chains, check the engine

stand is stable and there is no risk of overturning.

6. Drain engine oil. Refer to LU-8, "

Draining".

JPBIA0190ZZ

Revision: 2010 May2011 QX56

Page 3092 of 5598

HA-36

< REMOVAL AND INSTALLATION >

COOLER PIPE AND HOSE

9. Partly remove rear half of front fender protector RH. Refer to EXT-23, "FENDER PROTECTOR : Exploded

View".

10. Remove high-pressure pipe.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

LOW-PRESSURE PIPE

LOW-PRESSURE PIPE : Removal and InstallationINFOID:0000000006276176

CAUTION:

Perform lubricant return operation before each re frigeration system disassembly. However, if a large

amount of refrigerant or lubrican t is detected, never perform lubricant return operation. Refer to HA-

22, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-22, "Per-

form Lubricant Return Operation".

2. Drain engine coolant from cooling system. Refer to CO-8, "

Draining".

3. Remove engine cover. Refer to EM-25, "

Removal and Installation".

4. Remove mouting bolt (A) and fixing pawls, and then remove relay box (1).

5. Remove mounting bolts (A), and then remove relay box bracket(1).

6. Remove front water outlet tube assembly mounting nut.

7. Remove mounting nuts, and then disconnec t mounting bracket from the vhiecle.

8. Remove mounting bolt, and then disconnect low-pressure pipe from low-pressure flexible hose. CAUTION:

Cap or wrap the joint of the A/C piping with suitab le material such as vinyl tape to avoid the entry

of air.

9. Remove mounting bolt, and then disconnect low-pressure pipe from expansion valve. CAUTION:

: Pawl

JMIIA0798ZZ

JMIIA0799ZZ

Revision: 2010 May2011 QX56

Page 3099 of 5598

A/C UNIT ASSEMBLYHA-43

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

Perform lubricant return operati on before each refrigeration system disassembly. However, if a large

amount of refrigerant or lubricant is detected, n ever perform lubricant return operation. Refer to HA-

22, "Perform Lubricant Return Operation".

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-20, "Recy-

cle Refrigerant". (If equipped)

2. Drain engine coolant from cooling system. Refer to CO-8, "

Draining".

3. Remove clamps, and then disconnect front heater outlet hose from heater pipe.

CAUTION:

Some coolant may spill when heater hoses are disconnected.

Close off the coolant inlet and outlet on the heater core (2 locations) with shop cloths.

4. Remove mounting bolt, and then disconnect low-pressure pipe and high-pressure pipe from expansion valve.

CAUTION:

Cap or wrap the joint of the A/C piping and expan sion valve with suitable material such as vinyl

tape to avoid the entry of air.

5. Remove instrument panel assembly. Refer to IP-14, "

Removal and Installation".

6. Remove steering column mounting bolt and nuts. Refer to ST-34, "

Removal and Installation".

7. Move steering column assembly to a position where it does not inhibit work.

8. Disconnect harness clips, harness connectors, ground bol ts and blackets from steering member, and then

move the vehicle harness to the position without hindrance for work.

9. Remove mounting nuts, and then remove instrument stay (RH and LH).

10. Remove A/C unit assembly mounting bolts.

11. Remove mounting bolts, and then remove steering member from the vehicle.

12. Disconnect drain hose from A/C unit assembly, and then remove A/C unit assembly from the vehicle.

13. Remove mounting bolts, and then disconnect heater & cooling unit and blower unitassembly.

INSTALLATION

Note the following items, and install in the reverse order of removal.

CAUTION:

Replace O-rings with new ones. Then apply compressor oil to them when installing.

Check for leakages when recharging refrigerant. Refer to HA-18, "

Leak Test".

NOTE:

Refer to CO-9, "

Refilling" when filling radiator with engine coolant.

EVAPORATOR

EVAPORATOR : Removal and InstallationINFOID:0000000006276184

REMOVAL

1. Remove heater & cooling unit assembly. Refer to HA-41, "Exploded View".

2. Remove heater core. Refer to HA-44, "

HEATER CORE : Removal and Installation".

3. Remove mounting screws, and then remove evaporator pipe cover.

4. Remove air mix door motor (RH). Refer to HAC-153, "

AIR MIX DOOR MOTOR : Removal and Installa-

tion".

5. Remove mounting screws, and then remove A/C cover.

6. Remove foot duct LH. Refer to VTL-11, "

FLOOR DUCT 1 : Removal and Installation".

7. Remove mounting screws, and then remove A/C lower case.

8. Remove intake sensor. Refer to HAC-150, "

Removal and Installation".

9. Remove evaporator assembly from heater & cooling unit assembly.

10. Remove mounting bolts, and then remove evaporator from evaporator assembly.

CAUTION:

Cap or wrap the joint of the evaporator and evaporat or pipe assembly with suitable material such as

vinyl tape to avoid the entry of air.

Revision: 2010 May2011 QX56

Page 3103 of 5598

REAR A/C UNITHA-47

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

REAR A/C UNIT ASSEMBLY

REAR A/C UNIT ASSEMBLY : Removal and InstallationINFOID:0000000006276188

REMOVAL

1. Use a refrigerant collecting equipment (for HF C-134a) to discharge the refrigerant. Refer to HA-22, "Per-

form Lubricant Return Operation".

2. Drain engine coolant from cooling system. Refer to HA-22, "

Perform Lubricant Return Operation".

3. Remove rear ventilator duct upper. Refer to VTL-12, "

REAR VENTILATOR DUCT UPPER : Removal and

Installation".

4. Remove rear ventilator duct lower. Refer to VTL-12, "

REAR VENTILATOR DUCT LOWER : Removal and

Installation".

5. Remove mounting bolt, and then disconnect rear cooler unit pipe assembly from rear cooler pipe assem-

bly.

1. Rear blower harness 2. Rear blower motor 3. Rear A/C unit case RH

4. Rear evaporator pipe assembly 5. O-ring 6. Rear expantion valve assembly

7. Rear A/C cooler pipe assembly 8. Pipe bracket 9. Grommet

10. Rear cooler pipe 11. Rear heater outlet tube assembly 12. Blind cap

13. Rear heater inlet tube assembly 14. Clamp 15. Clamp

16. Shild plate 17. Bracket 18. Rear A/C unit case LH

19. Rear evapolator 20. Drain hose 21. Rear air mix door

22. Rear heater core 23. Rear heater pipe clamp 24. Rear A/C unit upper case (front)

25. Rear mode door 26. Rear A/C unit upper case (rear) 27. Air mix door harness

28. Rear intake sensor 29. Packing

Refer to GI-4, "

Components" for symbols in the figure.

JMIIA0641GB

Revision: 2010 May2011 QX56

Page 3375 of 5598

INT-26

< REMOVAL AND INSTALLATION >

FLOOR TRIM

10. Remove the following parts after removing the center console assembly. Remove ground bolt (G).

Disconnect floor harness connectors (A) and (E).

Disconnect yaw rate/side/decel G sensor harness connector (C). Refer to BRC-138, "

Exploded View".

Disconnect diagnosis sensor unit harness connector (D). Refer to SR-26, "

Exploded View".

Remove floor harness clamps (B) and (F).

11. Remove A/T shift selector assembly mounting bolts. Refer to TM-176, "

Removal and Installation".

12. Remove floor duct 1 (LH and RH). Refer to VTL-11, "

FLOOR DUCT 1 : Removal and Installation".

13. Disconnect drain hose (1) and remove instrument stay mounting nuts (A), and then remove instrument stay (2) (LH and RH).

14. Disengage front floor carpet from front floor carpet fixing clips (A).

JMJIA4226ZZ

JMJIA4225ZZ

JMJIA1560ZZ

Revision: 2010 May2011 QX56

Page 4246 of 5598

RF-32

< REMOVAL AND INSTALLATION >

GLASS LID

REMOVAL AND INSTALLATION

GLASS LID

Exploded ViewINFOID:0000000006141245

1. Glass lid 2. TORX bolt 3. Side trim

4. Rear drain connector 5. Rear drain hose 6. Sunroof bracket (LH,RH)

7. Front drain hose 8. Front drain connector 9. Sunroof motor assembly

10. Sunroof unit assembly

JMKIA5212ZZ

Revision: 2010 May2011 QX56

Page 4249 of 5598

SUNROOF MOTOR ASSEMBLYRF-35

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

SUNROOF MOTOR ASSEMBLY

Exploded ViewINFOID:0000000006141248

1. Glass lid 2. TORX bolt 3. Side trim

4. Rear drain connector 5. Rear drain hose 6. Sunroof bracket (LH,RH)

7. Front drain hose 8. Front drain connector 9. Sunroof motor assembly

10. Sunroof unit assembly

JMKIA5212ZZ

Revision: 2010 May2011 QX56

Page 4251 of 5598

SUNROOF UNIT ASSEMBLYRF-37

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

SUNROOF UNIT ASSEMBLY

Exploded ViewINFOID:0000000006141250

REMOVAL

DISASSEMBLY

1. Glass lid 2. TORX bolt 3. Side trim

4. Rear drain connector 5. Rear drain hose 6. Sunroof bracket (LH,RH)

7. Front drain hose 8. Front drain connector 9. Sunroof motor assembly

10. Sunroof unit assembly

JMKIA5212ZZ

Revision: 2010 May2011 QX56

Page 4253 of 5598

SUNROOF UNIT ASSEMBLYRF-39

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

5. Remove grip bracket.

6. Remove sunroof bracket bolts.

7. Remove nuts from the front end and side rail, and then remove sunroof unit assembly from roof panel.

8. Remove sunroof unit assembly through the passenger compartment while being careful not to damage the seats and trim.

INSTALLATION

1. Temporarily tighten the mounting nuts to the side rail of sunroof unit assembly.

2. Temporarily tighten the mounting nuts to the front end of sunroof unit assembly.

3. Temporarily tighten the mounting bolts to the sunroof brackets (LH,RH).

4. Tighten the installation points diagonally excluding the installation points of the sunroof brackets around the roof opening.

5. Tighten the mounting nuts to the front end and side rail.

6. Tighten the sunroof bracket bolts of the vehicl e side, and then tighten the bolt of the rail side.

7. Install the glass lid. NOTE:

After installation, perform fitting adjustment. Refer to RF-33, "

Adjustment".

8. Connect drain hoses.

9. Install headlining. Refer to INT-29, "

Removal and Installation".

Disassembly and AssemblyINFOID:0000000006141252

DISASSEMBLY

1. Remove sunshade stopper mounting from the rear end of sunroof frame.

2. Remove rear drain assembly from sunroof guide assembly.

3. Remove sunshade from the rear end of sunroof frame.

ASSEMBLY

Assemble in the reverse order of disassembly.

Revision: 2010 May2011 QX56

Page 5030 of 5598

STEERING GEAR AND LINKAGEST-43

< REMOVAL AND INSTALLATION >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

4. Remove cotter pin (1), and then loosen the nut.

5. Remove steering outer socket (2) from steering knuckle (3) so as not to damage ball joint boot (4) using suitable ball joint

remover (commercial service tool).

CAUTION:

Temporarily tighten the nut to prevent damage to threads

and to prevent the ball joint remover from suddenly coming

off.

6. Remove high pressure piping and low pressure piping of hydraulic piping, and then drain power steering fluid.

7. Remove power steering solenoid valve harness connector.

8. Remove lower joint fixing bolt (steering gear side).

9. Separate the lower joint from the steering gear assembly. Refer to ST-37, "

Exploded View".

CAUTION:

When removing lower joint, n ever insert a tool, such as a screw driver, into the yoke groove to

pull out the lower joint. In case of the violation of the above, replace lower joint with a new one.

Spiral cable may be cut if steering wheel tu rns while separating steering column assembly and

steering gear assembly. Be sure to secure st eering wheel using string to avoid turning.

10. Remove steering gear assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Spiral cable may be cut if steering wheel turns while separating steering column assembly and steer-

ing gear assembly. Be sure to secure steer ing wheel using string to avoid turning.

When installing lower joint to steering gear assembly, follow the procedure listed below.

- Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub a ssembly and measure the distance of inner socket, and

then measure the intermediat e position of the distance.

- Align rear cover cap projection (A) with the marking position of gear housing assembly (B).

- Install slit part of lower joint (C) aligning with the rear cover cap projection (A). Make sure that the slit part of lower joint (C) is

aligned with rear cover cap projection (A) and the marking position

of gear housing assembly (B).

Never reuse cotter pin and steering gear mounting nut.

Perform inspection after installation. Refer to ST-46, "

Inspection".

Disassembly and AssemblyINFOID:0000000006225609

DISASSEMBLY

CAUTION:

Disassemble and assemble steering gear assembly by fixing the mounting area with a vise using

copper plates.

Clean steering gear assembly with kerosene before disassembling. Be careful to avoid splashing or

applying any kerosene over connector of discharge port or return port.

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

PGIA0063E

: Bolt

JPGIA0038ZZ

Revision: 2010 May2011 QX56