INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4081 of 5598

PG-162

< BASIC INSPECTION >

FUSE INSPECTION

FUSE INSPECTION

How To CheckINFOID:0000000006275774

If fuse is blown, be sure to eliminate cause of malfunction beforeinstalling new fuse.

Use fuse of specified rating. Never use fuse of more than specified

rating.

Do not partially install fuse; always insert it into fuse holder prop- erly.

Remove fuse for “ELECTRICAL PARTS (BAT)” if vehicle is not used for a long period of time.

CEL083

Revision: 2010 May2011 QX56

Page 4082 of 5598

PG

FUSIBLE LINK INSPECTIONPG-163

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

B A

O P

N

FUSIBLE LINK INSPECTION

How To CheckINFOID:0000000006275775

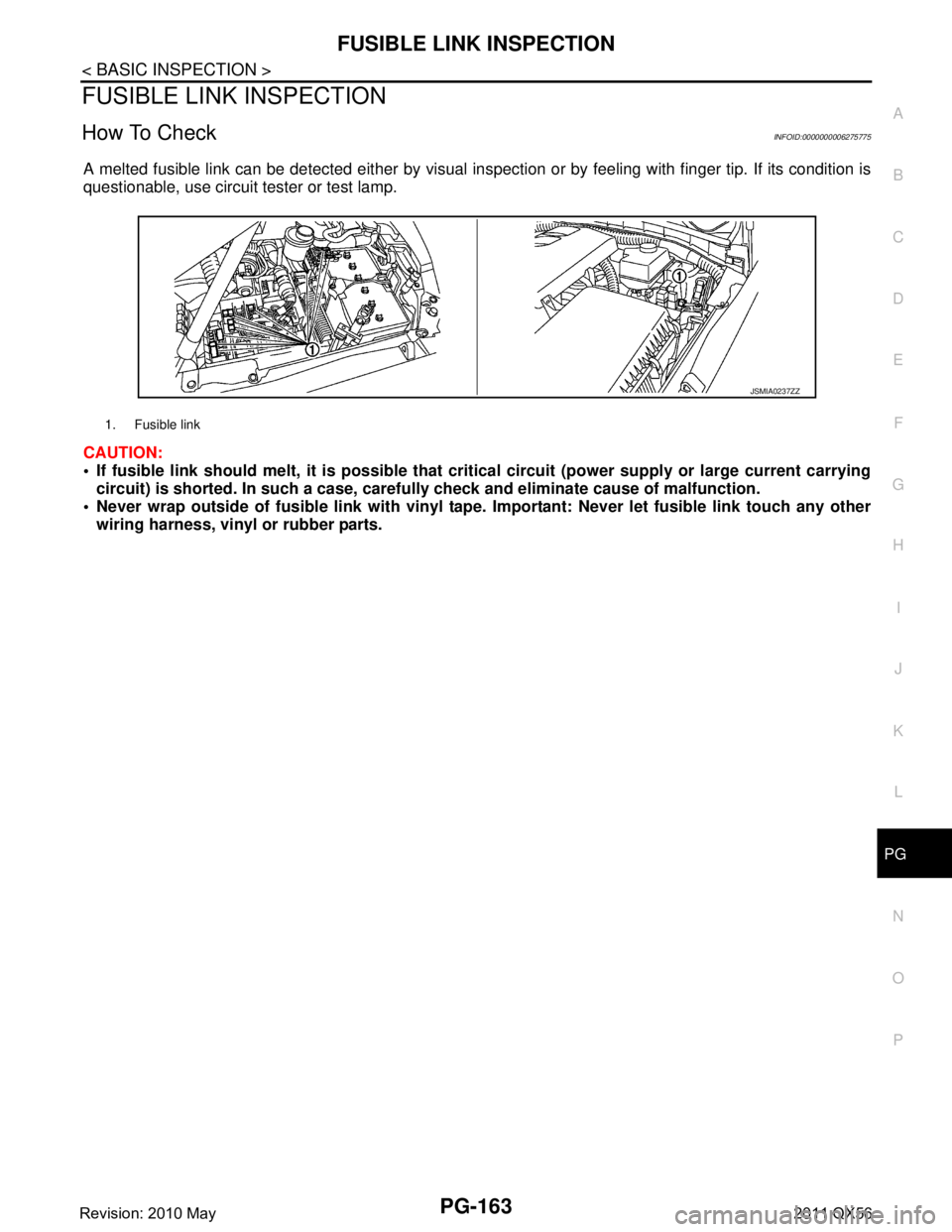

A melted fusible link can be detected either by visual ins

pection or by feeling with finger tip. If its condition is

questionable, use circuit tester or test lamp.

CAUTION:

If fusible link should melt, it is possible that critical circuit (pow er supply or large current carrying

circuit) is shorted. In such a case, careful ly check and eliminate cause of malfunction.

Never wrap outside of fusi ble link with vinyl tape. Important: N ever let fusible link touch any other

wiring harness, vinyl or rubber parts.

1. Fusible link

JSMIA0237ZZ

Revision: 2010 May2011 QX56

Page 4083 of 5598

PG-164

< REMOVAL AND INSTALLATION >

BATTERY

REMOVAL AND INSTALLATION

BATTERY

Exploded ViewINFOID:0000000006275779

Removal and InstallationINFOID:0000000006275780

REMOVAL

1. Remove cover of battery positive terminal.

2. Loosen battery terminal nuts, and disconnect both battery cables from battery terminals.

CAUTION:

When disconnecting, disconnect the battery cable from the negative terminal first.

3. Remove battery fix frame mounting nuts and battery fix frame.

4. Remove battery.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

When connecting, connect the battery cable to the positive terminal first.

Reset electronic systems as necessary. Refer to GI-65, "

ADDITIONAL SERVICE WHEN REMOVING BAT-

TERY NEGATIVE TERMINAL : Required Procedure After Battery Disconnection".

1 : Battery fix frame

Refer to GI-4, "

Components" for symbols in the figure.

JSMIA0238GB

Revision: 2010 May2011 QX56

Page 4084 of 5598

PG

BATTERY TERMINAL WITH FUSIBLE LINKPG-165

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

B A

O P

N

BATTERY TERMINAL WI

TH FUSIBLE LINK

Exploded ViewINFOID:0000000006275781

Removal and InstallationINFOID:0000000006275782

REMOVAL

1. Disconnect the battery cabl e from the negative terminal.

2. Remove cover of battery positive terminal.

3. Remove harness mounting nut and battery te rminal with fusible link mounting nut.

4. Disconnect harness connector and remove battery terminal with fusible link.

INSTALLATION

Install in the reverse order of removal.

1 : Battery terminal with fusible link

2 : Harness connector

Refer to GI-4, "

Components" for symbols in the figure.

JSMIA0239GB

Revision: 2010 May2011 QX56

Page 4085 of 5598

PG-166

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

BatteryINFOID:0000000006275783

Ty p e11 5 D 3 1 R

20 hour rate capacity [V – Ah] 12 – 82

Cold cranking current (For reference value) [A] 782

Revision: 2010 May2011 QX56

Page 4086 of 5598

PWC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

D

E

F

G H

I

J

L

M

SECTION PWC

A

B

PWC

N

O P

CONTENTS

POWER WINDOW CONTROL SYSTEM

PRECAUTION ................ ...............................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

4

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location ................................ ......6

Component Description .............................................7

SYSTEM ..............................................................8

System Diagram ................................................. ......8

System Description ...................................................8

Fail-safe ..................................................................10

DIAGNOSIS SYSTEM (BCM) ............................11

COMMON ITEM ..................................................... ....11

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

11

RETAIND PWR ...................................................... ....12

RETAIND PWR : CONSULT-III Function (BCM -

RETAINED PWR) ...................................................

12

ECU DIAGNOSIS INFORMATION ..............13

BCM (BODY CONTROL MODULE) ............... ....13

List of ECU Reference ........................................ ....13

POWER WINDOW MAIN SWITCH ....................14

Reference Value ................................................. ....14

Fail-safe ..................................................................15

FRONT POWER WINDOW SWITCH (PAS-

SENGER SIDE) ..................................................

16

Reference Value ................................................. ....16

Fail-safe ..................................................................17

REAR POWER WINDOW SWITCH LH ............18

Reference Value .................................................. ....18

Fail-safe ...................................................................19

REAR POWER WINDOW SWITCH RH ............20

Reference Value ......................................................20

Fail-safe ...................................................................21

WIRING DIAGRAM ......................................22

POWER WINDOW SYSTEM .............................22

Wiring Diagram .................................................... ....22

BASIC INSPECTION ...................................30

DIAGNOSIS AND REPAIR WORKFLOW ........30

Work Flow ............................................................ ....30

ADDITIONAL SERVICE WHEN REMOVING

BATTERY NEGATIVE TERMINAL ...................

31

Description ...............................................................31

Work Procedure .......................................................31

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT ................................................

32

Description ...............................................................32

Work Procedure .......................................................32

SYSTEM INITIALIZATION ................................33

Description ........................................................... ....33

Work Procedure .......................................................33

CHECK ANTI-PINCH FUNCTION .....................34

Description ...............................................................34

Work Procedure .......................................................34

DTC/CIRCUIT DIAGNOSIS .........................35

POWER SUPPLY AND GROUND CIRCUIT ....35

POWER WINDOW MAIN SWITCH ........................ ....35

POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ................................................................

35

Revision: 2010 May2011 QX56

Page 4087 of 5598

PWC-2

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) ................................................................

36

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) : Diagnosis Procedure .........................

36

REAR POWER WINDOW SWITCH ....................... ...37

REAR POWER WINDOW SWITCH : Diagnosis

Procedure ...............................................................

37

POWER WINDOW MOTOR ...............................39

DRIVER SIDE ......................................................... ...39

DRIVER SIDE : Component Function Check .........39

DRIVER SIDE : Diagnosis Procedure ....................39

PASSENGER SIDE ................................................ ...39

PASSENGER SIDE : Component Function Check

...

40

PASSENGER SIDE : Diagnosis Procedure ........ ...40

REAR LH ................................................................ ...40

REAR LH : Component Function Check ................41

REAR LH : Diagnosis Procedure ............................41

REAR RH ............................................................... ...41

REAR RH : Component Function Check ................41

REAR RH : Diagnosis Procedure ...........................42

ENCODER .........................................................43

DRIVER SIDE ......................................................... ...43

DRIVER SIDE : Component Function Check .........43

DRIVER SIDE : Diagnosis Procedure ....................43

PASSENGER SIDE ................................................ ...45

PASSENGER SIDE : Component Function Check

...

45

PASSENGER SIDE : Diagnosis Procedure ........ ...45

REAR LH ................................................................ ...47

REAR LH : Component Function Check ................47

REAR LH : Diagnosis Procedure ............................47

REAR RH ............................................................... ...49

REAR RH : Component Function Check ................49

REAR RH : Diagnosis Procedure ...........................50

DOOR KEY CYLINDER SWITCH ......................53

Component Function Check ................................ ...53

Diagnosis Procedure ..............................................53

Component Inspection ............................................54

POWER WINDOW SERIAL LINK .....................55

POWER WINDOW MAIN SWITCH ........................ ...55

POWER WINDOW MAIN SWITCH : Component

Function Check .......................................................

55

POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ...............................................................

55

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) ............................................................. ...

56

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) : Component Function Check ..............

56

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) : Diagnosis Procedure .........................

56

REAR POWER WINDOW SWITCH LH .................. ...57

REAR POWER WINDOW SWITCH LH : Compo-

nent Function Check ...............................................

58

REAR POWER WINDOW SWITCH LH : Diagno-

sis Procedure ..........................................................

58

REAR POWER WINDOW SWITCH RH ................. ...59

REAR POWER WINDOW SWITCH RH : Compo-

nent Function Check ...............................................

59

REAR POWER WINDOW SWITCH RH : Diagno-

sis Procedure ..........................................................

59

SYMPTOM DIAGNOSIS ............................61

POWER WINDOWS DO NOT OPERATE

WITH POWER WINDOW MAIN SWITCH ...... ...

61

Diagnosis Procedure ............................................ ...61

DRIVER SIDE POWER WINDOW ALONE

DOES NOT OPERATE ......................................

62

Diagnosis Procedure ............................................ ...62

FRONT PASSENGER SIDE POWER WIN-

DOW DOES NOT OPERATE ............................

63

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED ................................................................. ...

63

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED : Diagnosis Procedure .............................

63

WHEN FRONT POWER WINDOW SWITCH (PAS-

SENGER SIDE) IS OPERATED ............................. ...

63

WHEN FRONT POWER WINDOW SWITCH

(PASSENGER SIDE) IS OPERATED : Diagnosis

Procedure ...............................................................

63

WHEN BOTH POWER WINDOW MAIN SWITCH

AND FRONT POWER WINDOW SWITCH ARE

OPERATED ............................................................ ...

63

WHEN BOTH POWER WINDOW MAIN SWITCH

AND FRONT POWER WINDOW SWITCH ARE

OPERATED : Diagnosis Procedure ........................

63

REAR LH SIDE POWER WINDOW ALONE

DOES NOT OPERATE ......................................

64

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED ................................................................. ...

64

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED : Diagnosis Procedure .............................

64

WHEN REAR POWER WINDOW SWITCH LH IS

OPERATED ............................................................ ...

64

WHEN REAR POWER WINDOW SWITCH LH IS

OPERATED : Diagnosis Procedure ........................

64

Revision: 2010 May2011 QX56

Page 4088 of 5598

PWC-3

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

WHEN BOTH POWER WINDOW MAIN SWITCH

AND REAR POWER WINDOW SWITCH LH ARE

OPERATED ...........................................................

....

64

WHEN BOTH POWER WINDOW MAIN SWITCH

AND REAR POWER WINDOW SWITCH LH ARE

OPERATED : Diagnosis Procedure ........................

64

REAR RH SIDE POWER WINDOW ALONE

DOES NOT OPERATE .......................................

65

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED ................................................................ ....

65

WHEN POWER WINDOW MAIN SWITCH IS OP-

ERATED : Diagnosis Procedure .............................

65

WHEN REAR POWER WINDOW SWITCH RH IS

OPERATED ........................................................... ....

65

WHEN REAR POWER WINDOW SWITCH RH IS

OPERATED : Diagnosis Procedure ........................

65

WHEN BOTH POWER WINDOW MAIN SWITCH

AND REAR POWER WINDOW SWITCH RH ARE

OPERATED ........................................................... ....

65

WHEN BOTH POWER WINDOW MAIN SWITCH

AND REAR POWER WINDOW SWITCH RH ARE

OPERATED : Diagnosis Procedure ........................

65

AUTO OPERATION DOES NOT OPERATE

BUT MANUAL OPERATE NORMALLY ............

66

DRIVER SIDE ........................................................ ....66

DRIVER SIDE : Diagnosis Procedure .....................66

PASSENGER SIDE ...................................................66

PASSENGER SIDE : Diagnosis Procedure ........ ....66

REAR LH ............................................................... ....66

REAR LH : Diagnosis Procedure ............................66

REAR RH ............................................................... ....67

REAR RH : Diagnosis Procedure ............................67

ANTI-PINCH FUNCTION DOES NOT OPER-

ATE ....................................................................

68

Diagnosis Procedure ........................................... ....68

POWER WINDOW RETAINED POWER

FUNCTION DOES NOT OPERATE NORMAL-

LY ......................................................................

69

Diagnosis Procedure ...............................................69

DOOR KEY CYLINDER SWITCH DOES NOT

OPERATE POWER WINDOWS ........................

70

Diagnosis Procedure ...............................................70

KEYLESS POWER WINDOW DOWN DOES

NOT OPERATE .................................................

71

Diagnosis Procedure ...............................................71

POWER WINDOW LOCK SWITCH DOES

NOT FUNCTION ................................................

72

Diagnosis Procedure ...............................................72

POWER WINDOW SWITCH DOES NOT IL-

LUMINATE ........................................................

73

DRIVER SIDE ......................................................... ....73

DRIVER SIDE : Diagnosis Procedure .....................73

PASSENGER SIDE ....................................................73

PASSENGER SIDE : Diagnosis Procedure ........ ....73

REAR LH ................................................................ ....73

REAR LH : Diagnosis Procedure .............................73

REAR RH ............................................................... ....73

REAR RH : Diagnosis Procedure ............................73

REMOVAL AND INSTALLATION ...............74

POWER WINDOW MAIN SWITCH ...................74

Removal and Installation ..................................... ....74

Revision: 2010 May2011 QX56

Page 4089 of 5598

PWC-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006237825

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision that would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation after Battery Disconnect

INFOID:0000000006217263

NOTE:

Before removing and installing any control units, first tu rn the push-button ignition switch to the LOCK posi-

tion, then disconnect bot h battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnos is according to self-diagnosis results.

For vehicle with steering lock unit, if the battery is disconnected or discharged, the steering wheel will lock and

cannot be turned.

If turning the steering wheel is required with the bat tery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

Revision: 2010 May2011 QX56

Page 4090 of 5598

PRECAUTIONSPWC-5

< PRECAUTION >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of a ll control units using CONSULT-III.

Revision: 2010 May2011 QX56