ECU INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4237 of 5598

SUNROOF DOES NOT OPERATE PROPERLYRF-23

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

SYMPTOM DIAGNOSIS

SUNROOF DOES NOT OPERATE PROPERLY

DescriptionINFOID:0000000006141238

When auto operation does not operated.

When does not stop fully open or fully closed operation.

Diagnosis ProcedureINFOID:0000000006141239

1.PERFORM INITIALIZATION PROCEDURE

Initialization procedure is executed and operation is confirmed.

Refer to RF-17, "

ADDITIONAL SERVICE WHEN REPLACING CO NTROL UNIT : Special Repair Require-

ment".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK SUNROOF MOTOR ASSEMBLY POWER SUPPLY AND GROUND CIRCUIT

Check sunroof motor assembly power supply and ground circuit.

Refer to RF-18, "

DiagnosisProcedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace the malfunctioning parts.

3.CHECK VEHICLE SPEED SIGNAL CIRCUIT

Check vehicle speed signal circuit.

Refer to RF-20, "

DiagnosisProcedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace the malfunctioning parts.

4.CHECK SUNROOF SWITCH

Check sunroof switch.

Refer to RF-21, "

ComponentFunctionCheck".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair or replace the malfunctioning parts.

5.CONFIRM THE OPERATION

Confirm the operation again.

Is the result normal?

YES >> Check intermittent incident. Refer to GI-40, "Intermittent Incident".

NO >> GO TO 1.

Revision: 2010 May2011 QX56

Page 4241 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-27

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following items:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-cl utch on M/T models, drive position on A/T models).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, che ck ASIST for Technical Service Bulletins (TSBs) related

to the concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Chassis ear: J-39570, engine ear, and mechanics stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

Removing the component(s) in the area that is / are suspected to be the cause of the noise.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

Tapping or pushing/pulling the component(s) that is / are suspected to be the cause of the noise.

Do not tap or push/pull the component(s) with excessive force, otherwise the noise is eliminated only tempo-

rarily.

Feeling for a vibration by hand by touching the component(s ) that is / are suspected to be the cause of the

noise.

Placing a piece of paper between components that are suspected to be the cause of the noise.

Looking for loose components and contact marks. Refer to RF-28, "

Inspection Procedure".

REPAIR THE CAUSE

If the cause is a loose component, tighten the component securely.

If the cause is insufficient clearance between components:

- Separate components by repositioning or loosening and retightening the components, if possible.

- Insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape, or ure-

thane tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through the authorized NISSAN Parts

Department.

CAUTION:

Never use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSA N Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100 ×135 mm (3.937 ×5.315 in)

76884-71L01: 60 ×85 mm (2.362 ×3.346 in)

76884-71L02: 15 ×25 mm (0.591 ×0.984 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.772 in) thick, 50 ×50 mm (1.969 ×1.969 in)

73982-50Y00: 10 mm (0.394 in) thick, 50 ×50 mm (1.969 ×1.969 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.181 in) thick, 30 ×50 mm (1.181 ×1.969in)

FELT CLOTHTAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

Revision: 2010 May2011 QX56

Page 4243 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESRF-29

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

RF

N

O P

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing, or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof / headlining area can of ten be traced to one of the following items:

1. Sunroof lid, rail, linkage, or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Causes of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move, or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 4250 of 5598

RF-36

< REMOVAL AND INSTALLATION >

SUNROOF MOTOR ASSEMBLY

Removal and Installation

INFOID:0000000006141249

REMOVAL

CAUTION:

Before removing sunroof motor, ch eck that glass lid is fully closed.

After removing sunroof motor, never attempt to rotate sunroof motor assembly as a single unit.

1. Remove the headlining. Refer to INT-29, "

Removal and Installation".

2. Disconnect connector from sunroof motor assembly.

3. Remove sunroof motor assembly mounting screws, and then remove sunroof motor assembly.

INSTALLATION

CAUTION:

Before installing the sunroof motor assembly, be su re to the place the link and wire assembly in the

symmetrical and full y closed position.

1. Move the sunroof motor assembly laterally by littl e so that the gear is completely engaged into the wire on

the sunroof unit assembly and mounting surface bec omes parallel. Then secure the sunroof motor

assembly with screw.

2. Install the headlining. Refer to INT-29, "

Removal and Installation".

Revision: 2010 May2011 QX56

Page 4263 of 5598

RSU-8

< REMOVAL AND INSTALLATION >

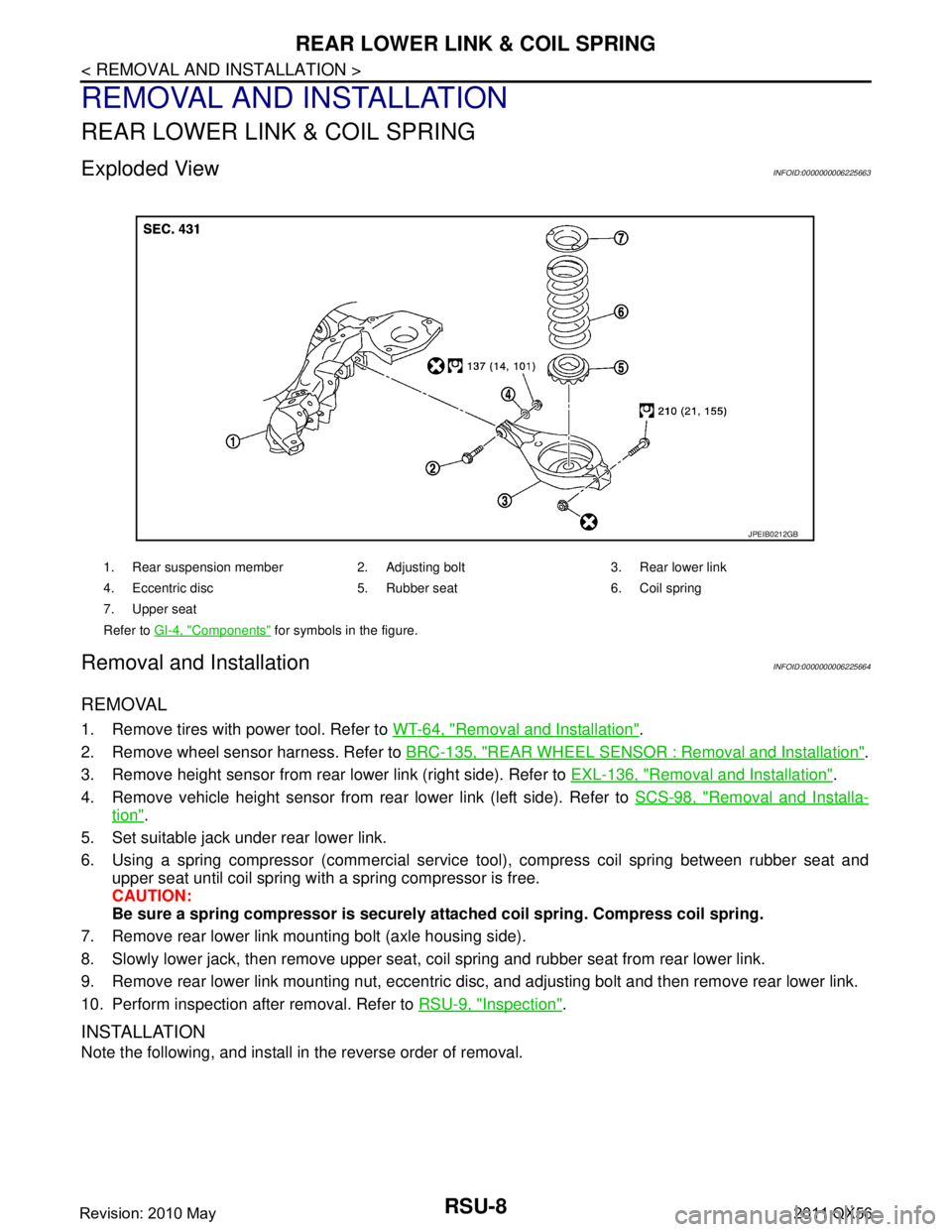

REAR LOWER LINK & COIL SPRING

REMOVAL AND INSTALLATION

REAR LOWER LINK & COIL SPRING

Exploded ViewINFOID:0000000006225663

Removal and InstallationINFOID:0000000006225664

REMOVAL

1. Remove tires with power tool. Refer to WT-64, "Removal and Installation".

2. Remove wheel sensor harness. Refer to BRC-135, "

REAR WHEEL SENSOR : Removal and Installation".

3. Remove height sensor from rear lower link (right side). Refer to EXL-136, "

Removal and Installation".

4. Remove vehicle height sensor from rear lower link (left side). Refer to SCS-98, "

Removal and Installa-

tion".

5. Set suitable jack under rear lower link.

6. Using a spring compressor (commercial service tool), compress coil spring between rubber seat and upper seat until coil spring with a spring compressor is free.

CAUTION:

Be sure a spring compressor is securely at tached coil spring. Compress coil spring.

7. Remove rear lower link mounting bolt (axle housing side).

8. Slowly lower jack, then remove upper seat, co il spring and rubber seat from rear lower link.

9. Remove rear lower link mounting nut, eccentric disc, and adjusting bolt and then remove rear lower link.

10. Perform inspection after removal. Refer to RSU-9, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

1. Rear suspension member 2. Adjusting bolt 3. Rear lower link

4. Eccentric disc 5. Rubber seat 6. Coil spring

7. Upper seat

Refer to GI-4, "

Components" for symbols in the figure.

JPEIB0212GB

Revision: 2010 May2011 QX56

Page 4279 of 5598

SB-4

< REMOVAL AND INSTALLATION >

FRONT SEAT BELT

REMOVAL AND INSTALLATION

FRONT SEAT BELT

SEAT BELT RETRACTOR

SEAT BELT RETRACTOR : InspectionINFOID:0000000006217615

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies including retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in seri ous personal injury in an accident. Seat belt assemblies not in use dur-

ing a collision should also be re placed if either damage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (e xcept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioners must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation as per the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis with CONSULT-III and air bag warning lamp. Refer to SRC-14, "

Description".

3. Check that the seat belt retractor, s eat belt anchor and buckle bolts are tightened firmly.

4. Check the shoulder seat belt guide and shoulder belt height adjuster for front seats. Check that guide

swivels freely and that webbing lays flat and does not bind in guide. Check that height adjuster operates

properly and holds securely.

5. Check retractor operation:

a. Fully extend the seat belt webbing and c heck for twists, tears or other damage.

b. Allow the seat belt to retract. Check that webbing retu rns smoothly and completely into the retractor. If the

seat belt does not return smoothly, wipe the inside of the loops with a clean paper cloth. Dirt build-up in the

loops of the upper anchors can cause the seat belts to retract slowly.

c. Fasten the seat belt. Check that seat belt returns sm oothly and completely to the retractor. If the webbing

does not return smoothly, the cause may be an accumulation of dust or dirt. Use the “SEAT BELT TAPE

SET” and perform the following steps.

Inspect the front seat belt through-anchor

1. Pull the seat belt out to a length of 500 mm (19.69 in) or more.

2. Fix the seat belt at the center pillar webbing opening with a clip or other device.

3. Pass a thin wire through the through-anchor webbing opening. Hold both ends of the wire and pull it tightly while moving it up and down several times along the webbing opening surface to remove dirt

stuck there.

4. Any dirt that cannot be removed with the wir e can be removed by cleaning the opening with a clean

cloth.

5. Apply tape at the point where the webbi ng contacts the through-anchor webbing opening.

NOTE:

Apply the tape so that there is no slack or wrinkling.

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above if necessary to check the other seat belts.

Revision: 2010 May2011 QX56

Page 4282 of 5598

FRONT SEAT BELTSB-7

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

1. Remove the outer anchor cover.

2. Remove the outer anchor mounting anchor bolt.

2. Remove the front kicking plate inner and rear kicking plate inner. Refer to INT-20, "

KICKING PLATE

INNER : Removal and Installation".

3. Remove the center pillar lower garnish. Refer to INT-22, "

CENTER PILLAR LOWER GARNISH : Removal

and Installation".

4. Remove the center pillar upper garnish. Refer to INT-22, "

CENTER PILLAR UPPER GARNISH : Removal

and Installation".

5. Remove the shoulder anchor mounting anchor nut and then remove the shoulder anchor.

6. Remove seat belt pre-tensioner retractor. 1. Disconnect the pre-crash seat belt connector.

2. Disconnect the seat belt pre-tensioner connector. CAUTION:

For installing/removing seat belt pre-tensioner con-

nector, insert thin screwdriver wrapped in tape into

notch, lift lock and remove connector.

Install connector with lock raised, and push lock into

connector.

After installing the connector, check that the lock is

pushed securely into it.

3. Remove the seat belt pre-tensioner retractor mounting anchor bolt and screw.

INSTALLATION

Install in the reverse order of removal.

SEAT BELT BUCKLE

SEAT BELT BUCKLE : InspectionINFOID:0000000006217618

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies in cluding retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in serious personal inju ry in an accident. Seat belt assemblies not in use dur-

ing a collision should also be replaced if either da mage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (exc ept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident (i.e. to rn webbing, bent retractor or guide, etc.).

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioner must be replaced even if t he seat belts were not in use during the collision in

which the air bags were deployed.

PRELIMINARY CHECKS

1. Check the seat belt warning lamp for proper operation as pen the following:

a. Turn ignition switch ON. The seat belt warning lamp should illuminate.

b. Fasten driver seat belt. The seat belt warning lamp should turn OFF.

2. If the air bag warning lamp is blinking, perform self-diagnosis using CONSULT-III and air bag warning

lamp. Refer to SRC-14, "

Description".

PHIA0953J

Revision: 2010 May2011 QX56

Page 4284 of 5598

FRONT SEAT BELTSB-9

< REMOVAL AND INSTALLATION >

C

DE

F

G

I

J

K L

M A

B

SB

N

O P

2. Disconnect the Lap pre-tensioner harness connector. CAUTION:

For installing/removing lap pre-tensioner connector,insert thin screwdriver wrapped in tape into notch, lift lock

and remove connector.

Install connector with lock ra ised, and push lock into con-

nector.

After installing the connector, check that the lock is pushed securely into it.

3. Remove trim retainer from seat cushion si de, and then remove lap pre-tensioner harness clamp.

4. Remove the lap pre-tensioner harness connector and harness clamp located under the seat cushion.

5. Remove the mounting anchor bolt of the lap pre-tensioner.

INSTALLATION

Install in the reverse order of removal.

PHIA0953J

Revision: 2010 May2011 QX56

Page 4295 of 5598

SB-20

< REMOVAL AND INSTALLATION >

THIRD SEAT BELT

4. Remove the rear kicking plate inner. Refer to INT-20, "KICKING PLATE INNER : Removal and Installa-

tion".

5. Remove the luggage side lower finisher (LH/RH). Refer to INT-36, "

LUGGAGE SIDE LOWER FINISHER :

Removal and Installation".

6. Remove the roof garnish. Refer to INT-29, "

Removal and Installation".

7. Remove the back pillar garnish (LH/RH). Refer to INT-37, "

BACK PILLAR GARNISH : Removal and

Installation".

8. Remove the shoulder anchor mounting anchor bolt and then remove the shoulder anchor.

9. Remove the seat belt retractor mounting anchor bolt and then remove the third seat belt retractor.

THIRD SEAT BELT CENTER RETRACTOR

1. Remove the roof garnish. Refer to INT-29, "Removal and Installation".

2. Remove headlining assembly rear clips. Refer to INT-29, "

Removal and Installation".

3. Slightly lower the headlining assembly rear and secure work space.

4. Remove the seat belt guide plate anchor bolt.

5. Remove the center seat belt retractor mounting anchor bolt and screw and then remove the center seat

belt retractor.

INSTALLATION

Install in the reverse order of removal.

SEAT BELT BUCKLE

SEAT BELT BUCKLE : InspectionINFOID:0000000006217630

AFTER A COLLISION

WARNING:

Inspect all seat belt assemblies in cluding retractors and attached hardware after any collision.

NISSAN/INFINITI recommends that all seat belt assemblies in use during a collision be replaced

unless the collision was minor and th e belts show no damage and continue to operate properly. Fail-

ure to do so could result in seri ous personal injury in an accident. Seat belt assemblies not in use dur-

ing a collision should also be re placed if either damage or improper operation was noted. Seat belt

pre-tensioners should be replaced even if the seat be lts were not in use during a frontal collision in

which the air bags were deployed.

Replace any seat belt assembly (including anchor bolts) if:

The seat belt is in use at the time of a collision (e xcept for minor collisions and the belts, retractors and buck-

les show no damage and continue to operate properly).

The seat belt is damaged in an accident. (i.e. to rn webbing, bent retractor or guide, etc.)

The seat belt attaching point is damaged in an accident . Inspect the seat belt attaching area for damage or

distortion and repair if necessary before installing a new seat belt assembly.

Anchor bolts are deformed or worn out.

The seat belt pre-tensioner must be replaced even if t he seat belts were not in use during the collision in

which the air bags are deployed.

PRELIMINARY CHECKS

1. Check that the seat belt retractor, s eat belt anchor and buckle bolts are tightened firmly.

2. Repeat step above if necessary to check the other seat belts.

Revision: 2010 May2011 QX56

Page 4298 of 5598

SBC-1

RESTRAINTS

C

DE

F

G

I

J

K L

M

SECTION SBC

A

B

SBC

N

O P

CONTENTS

SEAT BELT CONTROL SYSTEM

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Seat Belt Service ...............................3

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Component Description .............................................6

SYSTEM ..............................................................7

PRE-CRASH SEAT BELT SYSTEM ...........................7

PRE-CRASH SEAT BELT SYSTEM : System Di-

agram .................................................................. ......

7

PRE-CRASH SEAT BELT SYSTEM : System De-

scription .....................................................................

7

PRE-CRASH SEAT BELT SYSTEM : Fail Safe ........9

SEAT BELT WARNING LAMP SYSTEM ..................10

SEAT BELT WARNING LAMP SYSTEM : System

Diagram ............................................................... ....

10

SEAT BELT WARNING LAMP SYSTEM : System

Description ..............................................................

10

DIAGNOSIS SYSTEM (PRE-CRASH SEAT

BELT) .................................................................

11

CONSULT-III Function ........................................ ....11

ECU DIAGNOSIS INFORMATION ..............13

PRE-CRASH SEAT BELT CONTROL UNIT

(DRIVER SIDE) ............................................... ....

13

Reference Value ................................................. ....13

Fail Safe ..................................................................14

DTC Index ...............................................................16

PRE-CRASH SEAT BELT CONTROL UNIT

(PASSENGER SIDE) ........................................

17

Reference Value .................................................. ....17

Fail Safe ..................................................................17

WIRING DIAGRAM ......................................19

PRE-CRASH SEAT BELT SYSTEM .................19

Wiring Diagram .................................................... ....19

SEAT BELT WARNING SYSTEM ....................26

Wiring Diagram ........................................................26

BASIC INSPECTION ...................................31

DIAGNOSIS AND REPAIR WORKFLOW ........31

Work Flow ............................................................ ....31

DTC/CIRCUIT DIAGNOSIS .........................33

U0126 ST ANG SEN SIG ..................................33

Description ........................................................... ....33

DTC Logic ................................................................33

Diagnosis Procedure ...............................................33

U0428 STRG ANGL CAL ..................................34

Description ...............................................................34

DTC Logic ................................................................34

Diagnosis Procedure ...............................................34

U1000 CAN COMM CIRCUIT ...........................35

Description ...............................................................35

DTC Logic ................................................................35

B2451 SEAT BLT MTR DR CIRC .....................36

DTC Logic ................................................................36

Diagnosis Procedure ...............................................36

B2452 SEAT BLT MTR AS CIRC .....................37

DTC Logic ................................................................37

Diagnosis Procedure ...............................................37

B2453 BR STROKE SEN CIRC ........................38

Revision: 2010 May2011 QX56