audio INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 1382 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side rada INFINITI QX56 2011 Factory Workshop Manual

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side rada](/img/42/57033/w960_57033-1381.png)

DAS

HANDLING PRECAUTIONDAS-417

< SYSTEM DESCRIPTION > [BSW]

C

D

E

F

G H

I

J

K L

M B

N P A

HANDLING PRECAUTION

Precautions for Blind Spot WarningINFOID:0000000006223856

SIDE RADAR HANDLING

Side radar for BSW system is located inside the rear bumper.

Always keep the rear bumper near the side radar clean.

Do not attach a sticker (including transparent material), install an accessory or paintwork near the side radar.

Do not strike or damage the areas around the side radar.

Do not strike, damage, and scratch the side radar, especially the vent seal (gray circular) area, under repair.

PRECAUTIONS FOR BLIND SPOT WARNING

The BSW system is not a replacement for proper driving procedure and are not designed to prevent contact

with vehicles or objects. When changing lanes, always us e the side and rear mirrors and turn and look in the

direction driver will move to ensure it is safe to change lanes. Never rely solely on the BSW system.

The BSW system may not provide a warning for v ehicles that pass through the detection zone quickly.

Do not use the BSW system when towing a trai ler because the system may not function properly.

Excessive noise (e.g. audio system volume, open vehicle window) will interfere with the chime sound, and it may not be heard.

The side radar may not be able to detect and activate BSW when certain objects are present such as:

- Pedestrians, bicycles, animals.

- Several types of vehicles such as motorcycles.

- Oncoming vehicles.

- Vehicles remaining in the detection z one when driver accelerate from a stop.

- A vehicle merging into an adjacent lane at a speed approximately the same as vehicle.

- A vehicle approaching rapidly from behind.

- A vehicle which vehicle overtakes rapidly.

Severe weather or road spray conditions may reduce t he ability of the side radar to detect other vehicles.

The side radar detection zone is designed based on a standard lane width. When driving in a wider lane, the

side radar may not detect vehicles in an adjacent lane. When driving in a narrow lane, the side radar may

detect vehicles driving two lanes away.

The side radar are designed to ignore most stationary objects, however objects such as guardrails, walls,

foliage and parked vehicles may occasionally be det ected. This is a normal operating condition.

Revision: 2010 May2011 QX56

Page 1487 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacem INFINITI QX56 2011 Factory Workshop Manual

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacem](/img/42/57033/w960_57033-1486.png)

DAS-522

< SYMPTOM DIAGNOSIS >[BSW]

NORMAL OPERATING CONDITION

NORMAL OPERATING CONDITION

DescriptionINFOID:0000000006223980

PRECAUTIONS FOR BLIND SPOT WARNING (BSW)

The BSW system is not a replacement for proper dr

iving procedure and are not designed to prevent contact

with vehicles or objects. When changing lanes, always us e the side and rear mirrors and turn and look in the

direction driver will move to ensure it is safe to change lanes. Never rely solely on the BSW system.

The BSW system may not provide a warning for vehi cles that pass through the detection zone quickly.

Do not use the BSW system when towing a traile r because the system may not function properly.

Excessive noise (e.g. audio system volume, open vehi cle window) will interfere with the chime sound, and it

may not be heard.

The side radar may not be able to detect and activate BSW when certain objects are present such as:

- Pedestrians, bicycles, animals.

- Several types of vehicles such as motorcycles.

- Oncoming vehicles.

- Vehicles remaining in the detection z one when driver accelerate from a stop.

- A vehicle merging into an adjacent lane at a speed approximately the same as vehicle.

- A vehicle approaching rapidly from behind.

- A vehicle which vehicle overtakes rapidly.

Severe weather or road spray conditions may reduce t he ability of the side radar to detect other vehicles.

The side radar detection zone is designed based on a standard lane width. When driving in a wider lane, the

side radar may not detect vehicles in an adjacent l ane. When driving in a narrow lane, the side radar may

detect vehicles driving two lanes away.

The side radar are designed to ignore most stationary objects, however objects such as guardrails, walls,

foliage and parked vehicles may occasionally be detected. This is a normal operating condition.

Revision: 2010 May2011 QX56

Page 1747 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESDLK-211

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

DLK

N

O P

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is be visible or does not fit. Will only last a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006226060

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks to

repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Revision: 2010 May2011 QX56

Page 2863 of 5598

EXT-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confir m that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006367801

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56

Page 2978 of 5598

GI-14

< HOW TO USE THIS MANUAL >

ABBREVIATIONS

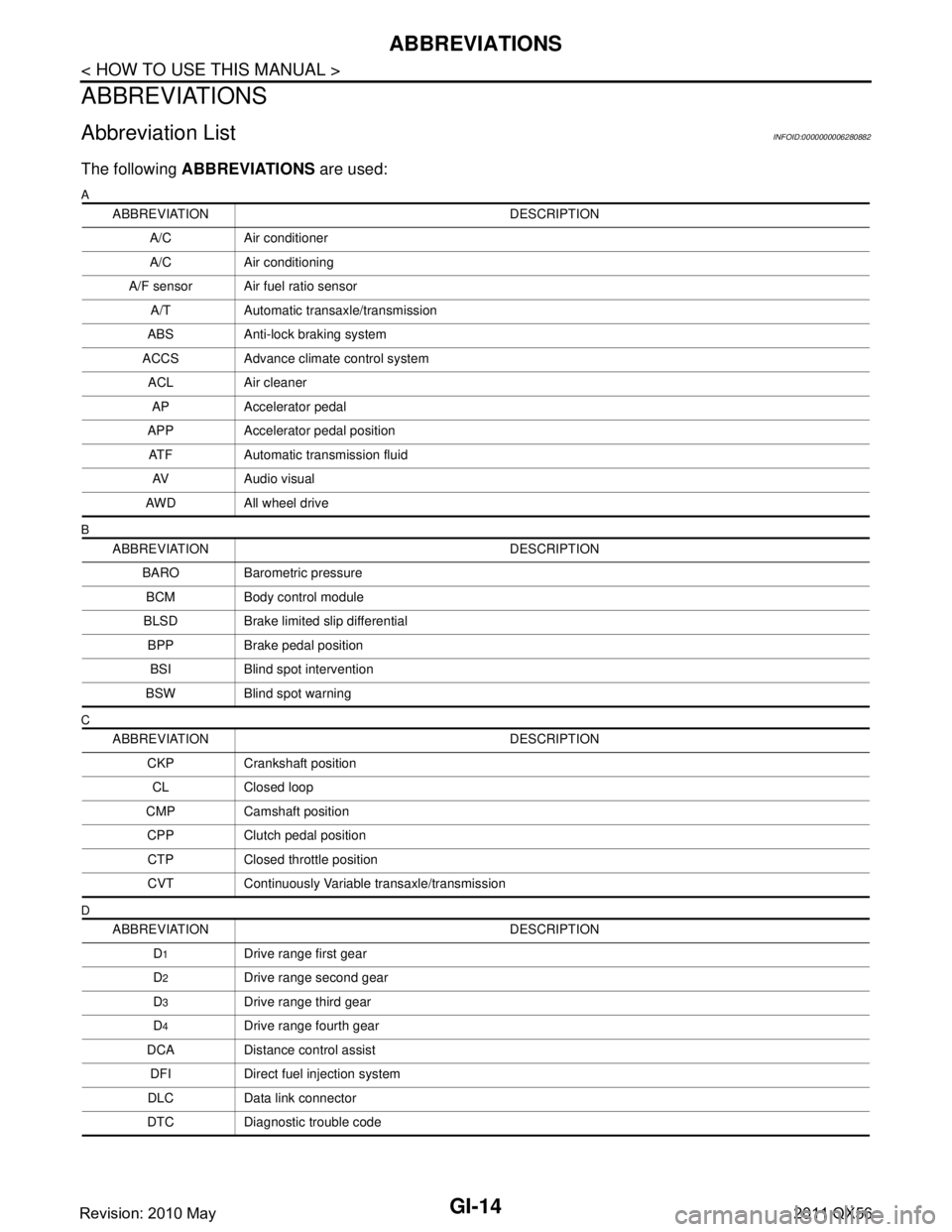

ABBREVIATIONS

Abbreviation ListINFOID:0000000006280882

The following ABBREVIATIONS are used:

A

B

C

D

ABBREVIATION DESCRIPTION

A/C Air conditioner

A/C Air conditioning

A/F sensor Air fuel ratio sensor A/T Automatic transaxle/transmission

ABS Anti-lock braking system

ACCS Advance climate control system ACL Air cleaner

AP Accelerator pedal

APP Accelerator pedal position ATF Automatic transmission fluid AV Audio visual

AWD All wheel drive

ABBREVIATION DESCRIPTION BARO Barometric pressureBCM Body control module

BLSD Brake limited slip differential BPP Brake pedal positionBSI Blind spot intervention

BSW Blind spot warning

ABBREVIATION DESCRIPTION CKP Crankshaft positionCL Closed loop

CMP Camshaft position CPP Clutch pedal positionCTP Closed throttle position

CVT Continuously Variable transaxle/transmission

ABBREVIATION DESCRIPTION D

1Drive range first gear

D

2Drive range second gear

D

3Drive range third gear

D

4Drive range fourth gear

DCA Distance control assist DFI Direct fuel injection system

DLC Data link connector

DTC Diagnostic trouble code

Revision: 2010 May2011 QX56

Page 3036 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

68370-4B000: 15 ×25 mm (0.59 ×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that will be visible or not fit. Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006108036

Refer to Table of Contents for specific component removal and installationinformation.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturatethe area with silicone, you

will not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to thecenter console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on startsand stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the Nissan Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put intothe trunk by the owner.

In addition look for:

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

Revision: 2010 May2011 QX56

Page 3136 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

HAC-30

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

OPERATION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONING S

YSTEM : Switch Name and Function

INFOID:000000 INFINITI QX56 2011 Factory Workshop Manual

HAC-30

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

OPERATION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONING S

YSTEM : Switch Name and Function

INFOID:000000](/img/42/57033/w960_57033-3135.png)

HAC-30

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

OPERATION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONING S

YSTEM : Switch Name and Function

INFOID:0000000006275881

WITH ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

When “STATUS” on multifunction switch is pressed while front air conditioning system is in the ON position,

the display changes to state indication display of fr ont air conditioning system. When front air conditioning

system is operated while navigation system or audio system is displayed, front air conditioning system state

is indicated in the lower portion of display for several seconds.

When MODE switch is pressed while front air conditioni ng system is in the OFF position, state indication dis-

play is indicated for several seconds.

Display Screen

Controller (Preset Switch)

Switch Operation

JMIIA0821GB

1. AUTO switch 2. Temperature control dial (Driver

side)3. MODE switch

4. OFF switch 5. A/C switch 6. Upper ventilator switch

7. Temperature control dial (passenger side) 8. DUAL switch 9. Intake switch

10. Fan switch 11. DEF switch

JMIIA0823ZZ

Revision: 2010 May2011 QX56

Page 3138 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

Whe INFINITI QX56 2011 Factory Workshop Manual

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

Whe](/img/42/57033/w960_57033-3137.png)

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

When “STATUS” on multifunction switch is pressed while

front air conditioning system is in the ON position,

the display changes to state indication display of fr ont air conditioning system. When front air conditioning

system is operated while navigation system or audio system is displayed, front air conditioning system state

is indicated in the lower portion of display for several seconds.

When MODE switch is pressed while front air conditioni ng system is in the OFF position, state indication dis-

play is indicated for several seconds.

Display Screen

Controller (Preset Switch)

Intake switch Air inlet changes between recirculation (REC)

⇔ fresh air intake (FRE) each time this switch is

pressed.

Intake switch indicator ON: Recirculation

Intake switch indicator OFF: Fresh air intake

NOTE:

When front air conditioning system is in the OFF position, air inlet can be selected.

When MODE switch and DEF switch is in the D/F or DEF position, air inlet cannot be selected to recirculation (REC).

Temperature control dial

(driver side) Selects set temperature within a range between 18.0

°C (60 °F) – 32.0 °C (90 °F) at a rate of 0.5 °C

(1.0 °F) each time the dial is rotated.

- Clockwise rotation: Set temperature increases.

- Counterclockwise rotation: Set temperature decreases.

NOTE:

When front air conditioning system is in the OFF position, set temperature can be selected only while

front air conditioning system state (when MODE switch is pressed) is indicated on the display.

Temperature control dial

(passenger side) Selects set temperature within a range between 18.0

°C (60 °F) – 32.0 °C (90 °F) at a rate of 0.5 °C

(1.0 °F) each time the dial is rotated.

- Clockwise rotation: Set temperature increases.

- Counterclockwise rotation: Set temperature decreases.

When the temperature control dial is turned, DUAL switch indicator turns ON.

NOTE:

When front air conditioning system is in the OFF position, set temperature can be selected only while

front air conditioning system state (when MODE switch is pressed) is indicated on the display.

Upper ventilator switch Turns the upper ventilator control (switch indicator) between ON

⇔ OFF each time while front blower

fan is activated.

NOTE:

When front air conditioning system is in the OFF position and air outlet is DEF position, upper ven- tilator control cannot be activated.

When front air conditioning system is in the OFF position, upper ventilator control can be selected

only while front air conditioning system state (when MODE switch is pressed) is indicated on the

display.

JMIIA0719GB

Revision: 2010 May2011 QX56

Page 3358 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confi rm that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006220270

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56

Page 3399 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confi rm that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006425524

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56