change time INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2864 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESEXT-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

EXT

N

O P

1. Trunk lid dumpers out of adjustment

2. Trunk lid striker out of adjustment

3. Trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing, or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof / headlining area can of ten be traced to one of the following items:

1. Sunroof lid, rail, linkage, or seals making a rattle or light knocking noise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

SEATS

When isolating seat noise it is important to note the position the seat is in and the load placed on the seat

when the noise occurs. These conditions should be duplic ated when verifying and isolating the cause of the

noise.

Causes of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move, or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs c an usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 3007 of 5598

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-43

< BASIC INSPECTION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Circuit InspectionINFOID:0000000006280855

DESCRIPTION

In general, testing electrical circuits is an easy task if it is approached in a logical and organized method. Before beginning it is important to have all available information on the system to be tested. Also, get a thor-

ough understanding of system operation. Then you will be able to use the appropriate equipment and follow

the correct test procedure.

You may have to simulate vehicle vibrations while te sting electrical components. Gently shake the wiring

harness or electrical component to do this.

NOTE:

Refer to GI-37, "

How to Check Terminal" to probe or check terminal.

TESTING FOR “OPENS” IN THE CIRCUIT

Before you begin to diagnose and test the system, you should rough sketch a schematic of the system. This

will help you to logically walk through the diagnosis process. Drawing the sketch will also reinforce your work-

ing knowledge of the system.

Continuity Check Method

The continuity check is used to find an open in the circui t. The digital multimeter (DMM) set on the resistance

function will indicate an open circuit as over limit (no beep tone or no ohms symbol). Check to always start with

the DMM at the highest resistance level.

To help in understanding the diagnosis of open circui ts, please refer to the previous schematic.

Disconnect the battery negative cable.

Start at one end of the circuit and work your way to the other end. (At the fuse block in this example)

Connect one probe of the DMM to the fuse block terminal on the load side.

Connect the other probe to the fuse block (power) side of SW1. Little or no resistance will indicate that por-

tion of the circuit has good continuity. If there were an open in the circuit, the DMM would indicate an over

limit or infinite resistance condition. (point A)

Connect the probes between SW1 and the relay. Little or no resistance will indicate that portion of the circuit

has good continuity. If there were an open in the circuit, t he DMM would indicate an over limit or infinite resis-

tance condition. (point B)

Connect the probes between the relay and the solenoid. Little or no resistance will indicate that portion of the

circuit has good continuity. If there were an open in the ci rcuit, the DMM would indicate an over limit or infi-

nite resistance condition. (point C)

Any circuit can be diagnosed using the approach in the previous example.

Voltage Check Method

To help in understanding the diagnosis of open circui ts please refer to the previous schematic.

In any powered circuit, an open can be found by methodica lly checking the system for the presence of voltage.

This is done by switching the DMM to the voltage function.

Connect one probe of the DMM to a known good ground.

Begin probing at one end of the circuit and work your way to the other end.

With SW1 open, probe at SW1 to check for voltage. voltage: open is further down the circuit than SW1.

OPEN A circuit is open when there is no continuity through a section of the circuit.

SHORT There are two types of shorts.

SHORT CIRCUIT

When a circuit contacts another circuit and causes the normal resistance to

change.

SHORT TO GROUND When a circuit contacts a ground source and grounds the circuit.

SGI846-A

Revision: 2010 May2011 QX56

Page 3037 of 5598

GW-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulatingthe item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knockingnoise

2. Sunvisor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicatingthe conditions can isolate most of these

incidents. Repairs usually consistof insulating with felt cloth tape.

SEATS

When isolating seat noise it's important to note the pos ition the seatis in and the load placed on the seat when

the noise is present. These conditionsshould be duplic ated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspectedcomponents while duplicating the condi-

tions under which the noise occurs. Most of these incidents can be repaired by repositioning the component

orapplying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or onthe engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: 2010 May2011 QX56

Page 3046 of 5598

BACK DOOR WINDOW GLASSGW-17

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

3. Remove rear wiper arm. Refer to WW-74, "Removal and Installation".

4. Remove rear wiper motor. Refer to WW-76, "

Removal and Installation".

5. Remove back door window glass molding using a pliers. Refer to GW-16, "

Exploded View".

6. Apply protective tape around the back door window gl ass to protect the painted surface from damage.

7. Remove glass using piano wire or power cutting tool (A) and an inflatable pump bag (B).

NOTE:

Mark the body and the glass with matching ma rks if the back door window glass is reused.

WARNING:

Always wear safety glasses and heavy gloves to prevent injury.

CAUTION:

Be careful not to scratch the glass when removing.

Never set or stand the glass on its edge . Small chips may develop into cracks.

INSTALLATION

The dam rubber should be installed in position.

Use a genuine Nissan Urethane Adhesive Kit (if available) or an equivalent and follow the instructions pro-

vided with it.

Open a door window while the urethane adhesive is curing. This prevents the glass from being forced out by

passenger compartment air pressure when all door windows are closed.

Inform the customer that the v ehicle should remain stationary until the urethane adhesive has completely

cured (approximately 24 hours). Curing time varies with temperature and humidity.

WARNING:

Keep heat and open flames away as primers and adhesive are flammable.

The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Never

let them come in contact with the skin and eyes.

Use in an open, well ventilated location. Never br eathe the vapors. They may be harmful if inhaled.

Move immediately to an area with fresh air if affected by vapor inhalation.

Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the rear window in case of an accident.

CAUTION:

Perform adjustment of rear wipe r arm stop location. Refer to WW-74, "

Adjustment".

Never use an adhesive which is past its usable term. Shelf life of this product is limited to six

months after the date of manufacture. Carefull y adhere to the expiration or manufacture date

printed on the box.

Keep primers and adhesive in a cool, dry place. Id eally, they should be stored in a refrigerator.

Never leave primers or adhesive cartridge unattended with their caps open or off.

The vehicle should not be driven for at least 24 hours or until the urethane adhesive has com-

pletely cured. Curing time varies depending on temperature and humidity. The curing time

increases under lower temperature and lower humidity.

If the substrate of the glass joining surface on th e back door panel side is exploded to the air,

exchange the back door assembly without recoating.

Never apply paint on the back door panel surface wh ich is in contact with the glass when replacing

the back door assembly.

InspectionINFOID:0000000006220821

REPAIRING WATER LEAKAGE FOR BACK DOOR WINDOW GLASS

Leakage can be repaired without removing the glass.

Determine the extent of leakage if water is leaki ng between the urethane adhesive material and body or glass.

This can be done by applying water to the back door window glass area while pushing glass outward.

PIIB5779E

Revision: 2010 May2011 QX56

Page 3064 of 5598

HA-8

< PRECAUTION >

PRECAUTIONS

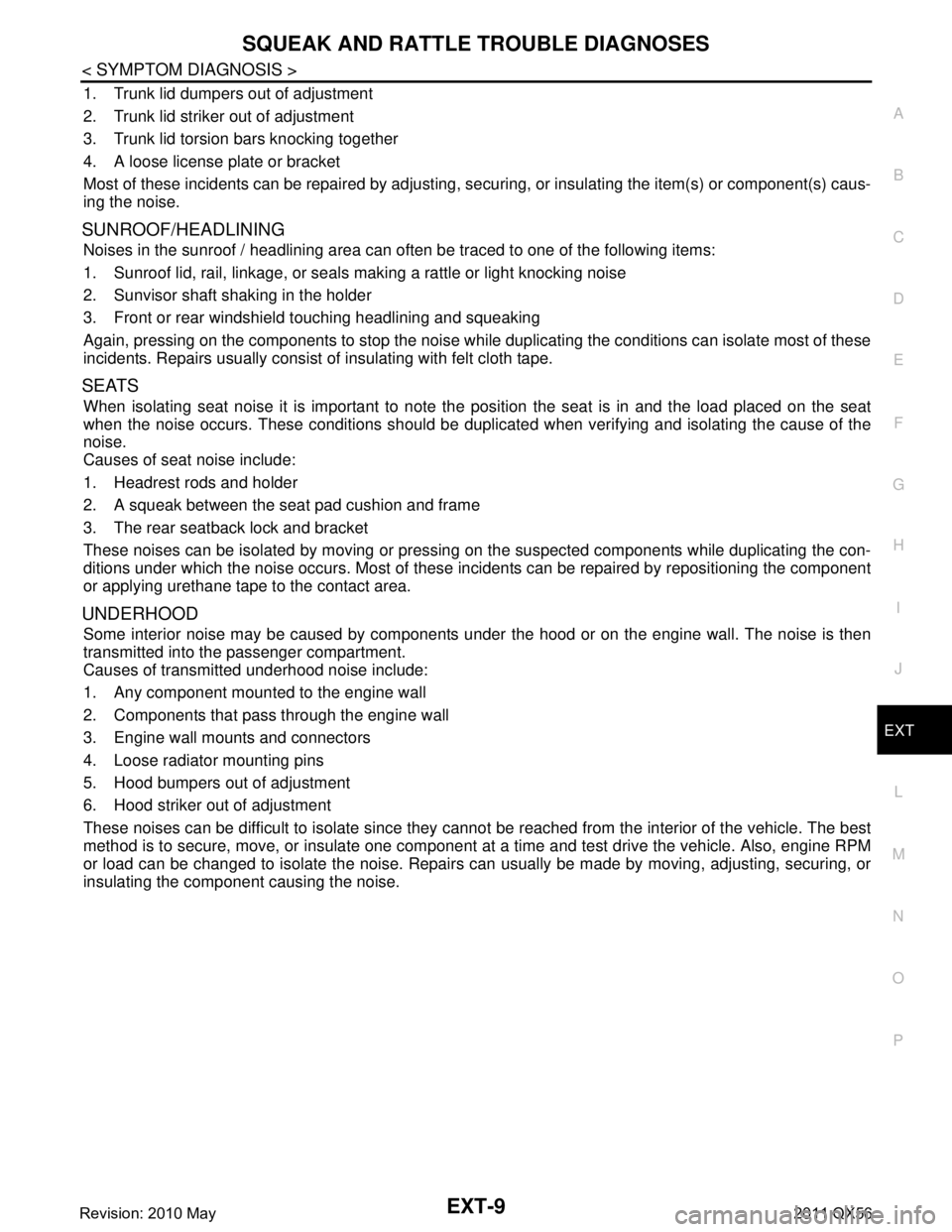

Never attempt to connect HFC-134a (R-134a) service couplers to

the CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

do not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. The hose fitting must

be 1/2″-16 ACME if the scale controls refrigerant flow electronically.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale each three month.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset” and “Enter” at the same time.

2. Press “8787”. “A1” is displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”. “0.00” is displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight ), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digi ts. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press “Shift/Reset” and “Enter” at the same time.

9. Press “6”— the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” is displayed.

11. Press “Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accu racy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Shut-off valve rotati on A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Revision: 2010 May2011 QX56

Page 3138 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

Whe INFINITI QX56 2011 Factory Workshop Manual

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

Whe](/img/42/57033/w960_57033-3137.png)

HAC-32

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

WITHOUT ACCS (ADVANCED CLIMATE CONTROL SYSTEM)

A/C Display

Front air conditioning system state is indicated on the display.

When “STATUS” on multifunction switch is pressed while

front air conditioning system is in the ON position,

the display changes to state indication display of fr ont air conditioning system. When front air conditioning

system is operated while navigation system or audio system is displayed, front air conditioning system state

is indicated in the lower portion of display for several seconds.

When MODE switch is pressed while front air conditioni ng system is in the OFF position, state indication dis-

play is indicated for several seconds.

Display Screen

Controller (Preset Switch)

Intake switch Air inlet changes between recirculation (REC)

⇔ fresh air intake (FRE) each time this switch is

pressed.

Intake switch indicator ON: Recirculation

Intake switch indicator OFF: Fresh air intake

NOTE:

When front air conditioning system is in the OFF position, air inlet can be selected.

When MODE switch and DEF switch is in the D/F or DEF position, air inlet cannot be selected to recirculation (REC).

Temperature control dial

(driver side) Selects set temperature within a range between 18.0

°C (60 °F) – 32.0 °C (90 °F) at a rate of 0.5 °C

(1.0 °F) each time the dial is rotated.

- Clockwise rotation: Set temperature increases.

- Counterclockwise rotation: Set temperature decreases.

NOTE:

When front air conditioning system is in the OFF position, set temperature can be selected only while

front air conditioning system state (when MODE switch is pressed) is indicated on the display.

Temperature control dial

(passenger side) Selects set temperature within a range between 18.0

°C (60 °F) – 32.0 °C (90 °F) at a rate of 0.5 °C

(1.0 °F) each time the dial is rotated.

- Clockwise rotation: Set temperature increases.

- Counterclockwise rotation: Set temperature decreases.

When the temperature control dial is turned, DUAL switch indicator turns ON.

NOTE:

When front air conditioning system is in the OFF position, set temperature can be selected only while

front air conditioning system state (when MODE switch is pressed) is indicated on the display.

Upper ventilator switch Turns the upper ventilator control (switch indicator) between ON

⇔ OFF each time while front blower

fan is activated.

NOTE:

When front air conditioning system is in the OFF position and air outlet is DEF position, upper ven- tilator control cannot be activated.

When front air conditioning system is in the OFF position, upper ventilator control can be selected

only while front air conditioning system state (when MODE switch is pressed) is indicated on the

display.

JMIIA0719GB

Revision: 2010 May2011 QX56

Page 3141 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

OPERATIONHAC-35

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AUTOMATIC AIR CONDITIONING SYSTEM

REAR AUTOMATIC AIR CONDITIONING SY STEM : Switch Name and INFINITI QX56 2011 Factory Workshop Manual

OPERATIONHAC-35

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AUTOMATIC AIR CONDITIONING SYSTEM

REAR AUTOMATIC AIR CONDITIONING SY STEM : Switch Name and](/img/42/57033/w960_57033-3140.png)

OPERATIONHAC-35

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

REAR AUTOMATIC AIR CONDITIONING SYSTEM

REAR AUTOMATIC AIR CONDITIONING SY STEM : Switch Name and Function

INFOID:0000000006275882

FRONT CONTOLLER OPERATION

A/C Display

Rear air conditioning system state is indicated on the front display.

When REAR switch is pressed while air conditioning syst em is in the ON position, the front display changes

to state indication display (rear contro l mode) of rear air conditioning system.

Display screen

Controller (Preset Switch)

With ACCS (advanced climate control system)

Temperature control dial

(passenger side) Selects set temperature within a range between 18.0

°C (60 °F) – 32.0 °C (90 °F) at a rate of 0.5 °C

(1.0 °F) each time the dial is rotated.

- Clockwise rotation: Set temperature increases.

- Counterclockwise rotation: Set temperature decreases.

When the temperature control dial is turned, DUAL switch indicator turns ON.

NOTE:

When front air conditioning system is in the OFF position, set temperature can be selected only while

front air conditioning system state (when MODE switch is pressed) is indicated on the display.

Upper ventilator switch Turns the upper ventila

tor control (switch indicator) between ON ⇔ OFF each time while front blower

fan is activated.

NOTE:

When front air conditioning system is in the OFF position and air outlet is DEF position, upper ven- tilator control cannot be activated.

When front air conditioning system is in the OFF position, upper ventilator control can be selected only while front air conditioning system state (when MODE switch is pressed) is indicated on the

display.

JMIIA0720ZZ

JMIIA0825ZZ

1. AUTO switch 2. Temperature control dial (Driver

side)3. MODE switch

4. REAR switch 5. OFF switch 6. Fan switch

Revision: 2010 May2011 QX56

Page 3144 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

HAC-38

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

- When air flow is small

- When air flow is large

Controller (Preset Switch)

JMIIA0410ZZ

JMIIA0411ZZ

1. Auto intake switch

Switch n INFINITI QX56 2011 Factory Workshop Manual

HAC-38

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

- When air flow is small

- When air flow is large

Controller (Preset Switch)

JMIIA0410ZZ

JMIIA0411ZZ

1. Auto intake switch

Switch n](/img/42/57033/w960_57033-3143.png)

HAC-38

< SYSTEM DESCRIPTION >[AUTOMATIC AIR CONDITIONING]

OPERATION

- When air flow is small

- When air flow is large

Controller (Preset Switch)

JMIIA0410ZZ

JMIIA0411ZZ

1. Auto intake switch

Switch name Function

Auto intake switch Automatic intake control (exhaust gas / outside odor detecting mechanism) mode (switch indicator)

changes between ON ⇔ OFF each time when auto intake switch is pressed while front blower mo-

tor is activated.

When auto intake switch turns ON, front air conditioning system becomes the following status.

- A/C switch: ON

- Air inlet: Recirculation [After approximately 5 minutes, air inlet is switched to automatic intake con- trol (exhaust gas / outside odor detecting mechanism).]

When auto intake switch turns ON ⇒ OFF, air inlet becomes the fresh air intake.

NOTE:

Interlocking condition of A/C switch can be changed. Refer to HAC-70, "

ACCS (ADVANCED CLI-

MATE CONTROL SYSTEM) : Auto Intake Switch Interlocking Movement Change Function".

Auto intake switch does not turn ON during the following status.

- Air outlet: DEF

- Ambient temperature: −2 °C (28 °F) or less

JMIIA0826ZZ

Revision: 2010 May2011 QX56

Page 3275 of 5598

INL-8

< SYSTEM DESCRIPTION >

SYSTEM

The puddle lamp turns ON and OFF by the puddle lamp timer.

BCM judges the vehicle condition with the following items. It activates the puddle lamp timer.

- Ignition switch status

- Door switch signal (except back door)

- Door lock/unlock signal (remote keyless entry receiver, each door request switch)

- Driver side door lock status

Puddle Lamp ON Operation

BCM activates the puddle lamp timer in any of the following conditions to turn the puddle lamp ON for a period

of time.

Any door opens excepting back door.

Any door opens before all doors close excepting back door.

Ignition switch is turned ON → OFF.

Door unlock signal by remote keyless entry rece iver or each door request switch is detected.

Driver side door is locked*.

NOTE:

The timer restarts if new condition is input during the timer operating time.

Puddle Lamp OFF Operation

BCM stops the timer and turns puddle lamp OFF, when any of the following conditions are satisfied.

The puddle lamp timer operating time is expired.

The interior room lamp OFF conditions.

The interior room lamp timer operating time is expired.

PUSH-BUTTON IGNITION SWITCH ILLUMINATION CONTROL

Push-button Ignition Switch Illumination Basic Operation

BCM controls the ON/OFF status of push-button igni tion switch illumination according to vehicle status.

BCM provides the push-button ignition switch illumi nation control signal and the ground to turn the push-but-

ton ignition switch illumination ON.

BCM cuts the ground supply while each illumination (tai l lamp) is ON. BCM switches to the ground control

according to the meter illumination control function. Refer to MWI-16, "

METER ILLUMINATION CONTROL :

System Description".

Heart Beat Operation

BCM repeats brightening and dimming operation of push-button ignition switch illumination when any of the

following conditions are satisfied.

Welcome light function operates.

When ignition switch is OFF and any of the following conditions are satisfied.

- Driver side door changes from closed to open

- Driver side door changes from locked to unlocked

- Intelligent Key ID comparison is OK and driver side door changes from open to closed

- ID comparison by Intelligent Key transponder is OK

Illumination ON Operation

When ignition switch is not OFF or tail lamp turns ON, push-button ignition switch illumination turns ON.

Dimming Operation

When tail lamp turns OFF and ignition switch is turned OFF, push-button ignition switch illumination dims to

50% brightness.

Illumination OFF Operation

Push-button ignition switch illumination turns OFF when ignition switch turns OFF and tail lamp turns from ON

to OFF, while push-button ignition switch illumination is in ON status.

When push-button ignition switch illumination is at 50% brightness or in heartbeat status, and any of the fol-

lowing conditions are satisfied, push-butt on ignition switch illumination turns OFF.

15 seconds after start of heartbeat operation.

When welcome light function is not operating and any on the following conditions is satisfied.

- Driver side door is closed

- Driver side door is locked

- Intelligent Key ID comparison is NG

- Comparison of Intelligent Key ID by transponder is NG

INTERIOR ROOM LAMP BATTERY SAVER SYSTEM

Revision: 2010 May2011 QX56

Page 3276 of 5598

SYSTEMINL-9

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

INTERIOR ROOM LAMP BATTERY SAVER SYSTEM : System DiagramINFOID:0000000006216052

INTERIOR ROOM LAMP BATTERY SA VER SYSTEM : System Description

INFOID:0000000006216053

OUTLINE

Interior room lamp battery saver is controlled by BCM.

BCM turns applicable lamps OFF depending on the vehicle condition. This function prevents the battery

from over-discharging if the driver neglects turning OFF the any lamps.

Applicable lamps

Map lamp

Personal lamp

Foot lamp

Luggage room lamp

Automatic back door close switch illumination

Step lamp

Puddle lamp

Vanity mirror lamp

INTERIOR ROOM LAMP BATTERY SAVER FUNCTION

When the ignition switch is turned to a position other than ON, BCM operates the timer for a period of time to

cut the interior room lamp power supply.

BCM restart the timer when any of the following signals changes while operating the timer.

- Push-button ignition switch status

- Door switch signal (ALL)

- Door lock/unlock signal (remote keyless entry re ceiver, each door request switch, door lock and unlock

switch, door key cylinder switch)

BCM provides the interior room lamp power supply continuously when the ignition switch position is ON.

When welcome light function operates.

NOTE:

JMLIA1189GB

Revision: 2010 May2011 QX56