clutch INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4743 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

SEC-136

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226300

DTC DETECTION INFINITI QX56 2011 Factory Workshop Manual

SEC-136

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226300

DTC DETECTION](/img/42/57033/w960_57033-4742.png)

SEC-136

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226300

DTC DETECTION LOGIC

NOTE:

If DTC B210F is displayed with DTC U1000, first

perform the trouble diagnosis for DTC U1000. Refer to PCS-

28, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Shift selector lever to the P position.

2. Turn ignition switch ON and wait 1 second or more.

3. Shift selector lever to the N position and wait 1 second or more.

4. Shift selector lever to any position other than P and N, and wait 1 second or more.

5. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-136, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226301

1.CHECK DTC OF BCM

Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Perform the trouble diagnosis relat ed to the detected DTC. Refer to BCS-57, "DTCIndex".

NO >> GO TO 2.

2.CHECK DTC OF TCM

Check DTC in “Self Diagnostic Result ” mode of “TCM” using CONSULT-III.

Is DTC detected?

YES >> Perform the trouble diagnosis relat ed to the detected DTC. Refer to TM-78, "DTC Index".

NO >> GO TO 3.

3.CHECK IPDM E/R SIGNAL CIRCUIT OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Disconnect A/T assembly connector.

4. Check continuity between IPDM E/R harnes s connector and A/T assembly harness connector.

5. Check continuity between IP DM E/R harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B210F INTER LOCK/PNP SW ON There is a difference between P/N position

signal from TCM and P/N position signal from

BCM (CAN). Harness or connectors

(CAN communication line is open or

shorted.)

Harness or connectors (TCM circuit is open or shorted.)

A/T assembly (TCM)

IPDM E/R

BCM

IPDM E/R A/T assembly Continuity

Connector Terminal Connector Terminal

E15 48 F51 9 Existed

Revision: 2010 May2011 QX56

Page 4744 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-137

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R. INFINITI QX56 2011 Factory Workshop Manual

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-137

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R.](/img/42/57033/w960_57033-4743.png)

B210F SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-137

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace harness.

(+)

(–) Continuity

IPDM E/R

Connector Terminal E15 48 Ground Not existed

Revision: 2010 May2011 QX56

Page 4745 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

SEC-138

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B2110 SHIFT POSITION/C

LUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226302

DTC DETECTIO INFINITI QX56 2011 Factory Workshop Manual

SEC-138

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B2110 SHIFT POSITION/C

LUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226302

DTC DETECTIO](/img/42/57033/w960_57033-4744.png)

SEC-138

< DTC/CIRCUIT DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCH

B2110 SHIFT POSITION/C

LUTCH INTERLOCK SWITCH

DTC LogicINFOID:0000000006226302

DTC DETECTION LOGIC

NOTE:

If DTC B2110 is displayed with DTC U1000, first per form the trouble diagnosis for DTC U1000. Refer to PCS-

28, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Shift selector lever to the P position.

2. Turn ignition switch ON and wait 1 second or more.

3. Shift selector lever to the N position and wait 1 second or more.

4. Shift selector lever to any position other than P and N, and wait 1 second or more.

5. Check DTC in “Self Diagnostic Result” mode of “IPDM E/R” using CONSULT-III.

Is DTC detected?

YES >> Go to SEC-138, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000006226303

1.CHECK DTC OF BCM

Check DTC in “Self Diagnostic Result” mode of “BCM” using CONSULT-III.

Is DTC detected?

YES >> Perform the trouble diagnosis relat ed to the detected DTC. Refer to BCS-57, "DTCIndex".

NO >> GO TO 2.

2.CHECK DTC OF TCM

Check DTC in “Self Diagnostic Result ” mode of “TCM” using CONSULT-III.

Is DTC detected?

YES >> Perform the trouble diagnosis relat ed to the detected DTC. Refer to TM-78, "DTC Index".

NO >> GO TO 3.

3.CHECK IPDM E/R SIGNAL CIRCUIT OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Disconnect A/T assembly connector.

4. Check continuity between IPDM E/R harnes s connector and A/T assembly harness connector.

5. Check continuity between IP DM E/R harness connector and ground.

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

B2110 INTER LOCK/PNP SW OFF There is a difference between P/N position

signal from TCM and P/N position signal from

BCM (CAN). Harness or connectors

(CAN communication line is open or

shorted.)

Harness or connectors (TCM circuit is open or shorted.)

A/T assembly (TCM)

IPDM E/R

BCM

IPDM E/R A/T assembly Continuity

Connector Terminal Connector Terminal

E15 48 F51 9 Existed

Revision: 2010 May2011 QX56

Page 4746 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-139

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R. INFINITI QX56 2011 Factory Workshop Manual

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-139

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R.](/img/42/57033/w960_57033-4745.png)

B2110 SHIFT POSITION/CLUTCH INTERLOCK SWITCHSEC-139

< DTC/CIRCUIT DIAGNOSIS > [WITH INTELLIGENT KEY SYSTEM]

C

D

E

F

G H

I

J

L

M A

B

SEC

N

O P

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-32, "Removal and Installation".

NO >> Repair or replace harness.

(+)

(–) Continuity

IPDM E/R

Connector Terminal E15 48 Ground Not existed

Revision: 2010 May2011 QX56

Page 5087 of 5598

STARTER MOTORSTR-19

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

STR

NP

O

Pinion/Clutch Check

1. Inspect pinion teeth.

Replace pinion if teeth are worn or damaged. (Also check condition of ring gear teeth.)

2. Inspect reduction gear teeth. Replace reduction gear if teeth are worn or dam aged. (Also check condition of armature shaft gear

teeth.)

3. Check to see if pinion locks in one directi on and rotates smoothly in the opposite direction.

If it locks or rotates in both directions, or unusual resistance is evident, replace.

Revision: 2010 May2011 QX56

Page 5089 of 5598

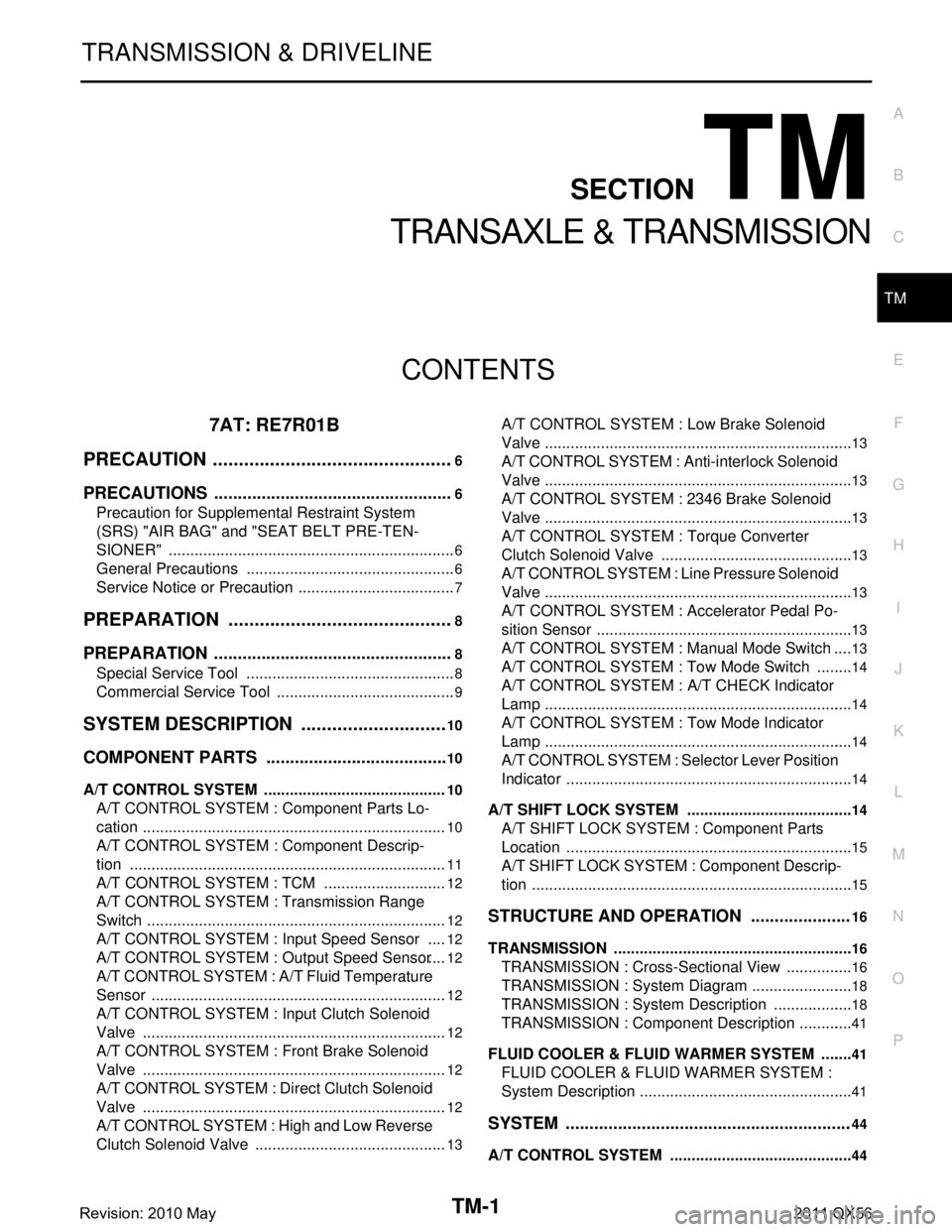

TM-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION TM

A

B

TM

N

O P

CONTENTS

TRANSAXLE & TRANSMISSION

7AT: RE7R01B

PRECAUTION ................ ...............................

6

PRECAUTIONS .............................................. .....6

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

6

General Precautions .................................................6

Service Notice or Precaution .....................................7

PREPARATION ............................................8

PREPARATION .............................................. .....8

Special Service Tool ........................................... ......8

Commercial Service Tool ..........................................9

SYSTEM DESCRIPTION .............................10

COMPONENT PARTS ................................... ....10

A/T CONTROL SYSTEM ...........................................10

A/T CONTROL SYSTEM : Component Parts Lo-

cation ................................................................... ....

10

A/T CONTROL SYSTEM : Component Descrip-

tion ...................................................................... ....

11

A/T CONTROL SYSTEM : TCM .............................12

A/T CONTROL SYSTEM : Transmission Range

Switch .................................................................. ....

12

A/T CONTROL SYSTEM : Input Speed Sensor .....12

A/T CONTROL SYSTEM : Output Speed Sensor ....12

A/T CONTROL SYSTEM : A/ T Fluid Temperature

Sensor ................................................................. ....

12

A/T CONTROL SYSTEM : Input Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Front Brake Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : Direct Clutch Solenoid

Valve ................................................................... ....

12

A/T CONTROL SYSTEM : High and Low Reverse

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Low Brake Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Anti-interlock Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : 2346 Brake Solenoid

Valve ........................................................................

13

A/T CONTROL SYSTEM : Torque Converter

Clutch Solenoid Valve ......................................... ....

13

A/T CONTROL SYSTEM : Line Pressure Solenoid

Valve .................................................................... ....

13

A/T CONTROL SYSTEM : Accelerator Pedal Po-

sition Sensor ........................................................ ....

13

A/T CONTROL SYSTEM : Manual Mode Switch ....13

A/T CONTROL SYSTEM : To w Mode Switch .........14

A/T CONTROL SYSTEM : A/T CHECK Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Tow Mode Indicator

Lamp .................................................................... ....

14

A/T CONTROL SYSTEM : Selector Lever Position

Indicator ............................................................... ....

14

A/T SHIFT LOCK SYSTEM ................................... ....14

A/T SHIFT LOCK SYSTEM : Component Parts

Location ...................................................................

15

A/T SHIFT LOCK SYSTEM : Component Descrip-

tion ...........................................................................

15

STRUCTURE AND OPERATION .....................16

TRANSMISSION .................................................... ....16

TRANSMISSION : Cross-Sectional View ................16

TRANSMISSION : System Diagram ........................18

TRANSMISSION : System Description ...................18

TRANSMISSION : Component Description .............41

FLUID COOLER & FLUID WARMER SYSTEM .... ....41

FLUID COOLER & FLUID WARMER SYSTEM :

System Description ..................................................

41

SYSTEM ............................................................44

A/T CONTROL SYSTEM ....................................... ....44

Revision: 2010 May2011 QX56

Page 5092 of 5598

TM-4

Component Inspection (Shift Lock Solenoid) ........159

SELECTOR LEVER POSITION INDICATOR ..161

Component Function Check ................................ ..161

Diagnosis Procedure .............................................161

Component Inspection (Selector Lever Position

Indicator) ................................................................

163

SYMPTOM DIAGNOSIS ............................165

SYSTEM SYMPTOM ...................................... .165

Symptom Table ................................................... ..165

PERIODIC MAINTENANCE ..................... ..175

A/T FLUID ....................................................... .175

Inspection ............................................................ ..175

REMOVAL AND INSTALLATION ..............176

A/T SHIFT SELECTOR ................................... .176

Exploded View ..................................................... ..176

Removal and Installation .......................................176

Inspection and Adjustment ....................................177

CONTROL CABLE ..........................................178

Exploded View ..................................................... ..178

Removal and Installation .......................................178

Inspection and Adjustment ....................................179

SELECTOR LEVER POSITION INDICATOR ..180

Removal and Installation ..................................... ..180

TOW MODE SWITCH ......................................181

Removal and Installation ..................................... ..181

CONTROL VALVE & TCM ..............................182

Exploded View ..................................................... ..182

Removal and Installation .......................................182

Inspection and Adjustment ....................................186

PARKING COMPONENTS ..............................187

2WD ........................................................................ ..187

2WD : Exploded View ............................................187

2WD : Removal and Installation ............................187

2WD : Inspection ...................................................190

REAR OIL SEAL ..............................................192

2WD ........................................................................ ..192

2WD : Exploded View ............................................192

2WD : Removal and Installation ............................192

2WD : Inspection ...................................................193

4WD ........................................................................ ..193

4WD : Exploded View ............................................193

4WD : Removal and Installation ............................193

4WD : Inspection and Adjustment .........................194

OUTPUT SPEED SENSOR .............................195

2WD ........................................................................ ..195

2WD : Exploded View ...........................................195

2WD : Removal and Installation ............................195

2WD : Inspection and Adjustment .........................198

AIR BREATHER HOSE ....................................199

2WD ........................................................................ .199

2WD : Exploded View ...........................................199

2WD : Removal and Installation ............................199

4WD ........................................................................ .200

4WD : Exploded View ...........................................200

4WD : Removal and Installation ............................200

FLUID COOLER SYSTEM ...............................202

Exploded View ..................................................... .202

Removal and Installation .......................................202

Inspection and Adjustment ....................................204

UNIT REMOVAL AND INSTALLATION ...205

TRANSMISSION ASSEMBLY ..........................205

2WD ........................................................................ .205

2WD : Exploded View ...........................................205

2WD : Removal and Installation ............................205

2WD : Inspection and Adjustment .........................207

4WD ........................................................................ .207

4WD : Exploded View ...........................................208

4WD : Removal and Installation ............................208

4WD : Inspection and Adjustment .........................210

UNIT DISASSEMBLY AND ASSEMBLY ..211

TRANSMISSION ASSEMBLY ..........................211

Exploded View ..................................................... .211

Oil Channel ...........................................................222

Location of Needle Bearings and Bearing Races .222

Location of Snap Rings .........................................225

Disassembly ..........................................................226

Assembly ..............................................................243

Inspection ..............................................................267

OIL PUMP, 2346 BRAKE, FRONT BRAKE

PISTON .............................................................

270

Exploded View ..................................................... .270

Disassembly ..........................................................270

Assembly ..............................................................274

Inspection and Adjustment ....................................277

UNDER DRIVE CARRIER, FRONT BRAKE

HUB ..................................................................

279

Exploded View ..................................................... .279

Disassembly ..........................................................279

Assembly ..............................................................280

Inspection ..............................................................280

FRONT CARRIER, INPUT CLUTCH, REAR

INTERNAL GEAR .............................................

282

Exploded View ..................................................... .282

Disassembly ..........................................................283

Revision: 2010 May2011 QX56

Page 5093 of 5598

TM-5

CEF

G H

I

J

K L

M A

B

TM

N

O P

Assembly .............................................................

..

284

Inspection ..............................................................286

MID SUN GEAR, REAR SUN GEAR, HIGH

AND LOW REVERSE CLUTCH HUB ..............

287

Exploded View .................................................... ..287

Disassembly ..........................................................287

Assembly ...............................................................289

Inspection ..............................................................291

HIGH AND LOW REVERSE CLUTCH .............292

Exploded View .................................................... ..292

Disassembly ..........................................................292

Assembly ...............................................................293

Inspection ..............................................................293

DIRECT CLUTCH .............................................294

Exploded View .................................................... ..294

Disassembly ..........................................................294

Assembly ............................................................. ..294

Inspection ..............................................................295

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... ...........................................

296

SERVICE DATA AND SPECIFICATIONS

(SDS) ...............................................................

296

General Specification .......................................... ..296

Vehicle Speed at Which Gear Shifting Occurs ......296

Vehicle Speed at Which Lock-up Occurs/Releas-

es ...........................................................................

297

Stall Speed ............................................................297

Torque Converter ..................................................297

Total End Play .......................................................298

Reverse Brake Clearance .....................................298

Front Brake Clearance ..........................................298

2346 Brake Clearance ...........................................298

Revision: 2010 May2011 QX56

Page 5095 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop r INFINITI QX56 2011 Factory Workshop Manual

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop r](/img/42/57033/w960_57033-5094.png)

PRECAUTIONSTM-7

< PRECAUTION > [7AT: RE7R01B]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

Disassembly should be done in a clean work area.

Use lint-free paper or towels for wiping parts clean. Common shop rags can leave fibers that could interfere

with the operation of the transmission.

Place disassembled parts in order for easier and proper assembly.

All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

Gaskets, seals and O-rings should be repl aced any time the A/T is disassembled.

It is very important to perform func tional tests whenever they are indicated.

The valve body contains precision parts and requires extreme care when parts are removed and serviced.

Place disassembled valve body parts in order for easier and proper assembly. Care will also prevent springs

and small parts from becoming scattered or lost.

Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings and

seals, or hold bearings and washers in place during assembly. Never use grease.

Extreme care should be taken to avoid damage to O-rings, seals and gaskets when assembling.

When the A/T drain plug is removed, only some of the ATF is drained. Old ATF will remain in torque con- verter and ATF cooling system.

Always follow the procedures under “Changing” when changing ATF. Refer to TM-94, "

Changing".

Occasionally, the parking gear may be locked with the to rque insufficiently released, when stopping the vehi-

cle by shifting the selector lever from “D” or “R” to “P” position with the brake pedal depressed.

In this case, the shock with a thud caused by the abrupt release of torque may occur when shifting the selec-

tor lever from “P” posit ion to other positions.

However, this symptom is not a malfunction which results in the damage of parts.

Service Notice or PrecautionINFOID:0000000006274263

ATF COOLER SERVICE

If ATF contains frictional material (clutches, bands, etc. ), or if an A/T is repaired, overhauled, or replaced,

inspect and clean the A/T fluid cooler mounted in the radiat or or replace the radiator. Flush cooler lines using

cleaning solvent and compressed air after repair. For A/T fluid cooler cleaning procedure, refer to TM-97,

"Cleaning". For radiator replacement, refer to CO-13, "Exploded View".

Revision: 2010 May2011 QX56

Page 5096 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

TM-8

< PREPARATION >[7AT: RE7R01B]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000006226736

Tool number

(Kent-Moore No.)

Tool nameDescription

ST33400001

(J-26082)

Drift

a: 60 m INFINITI QX56 2011 Factory Workshop Manual

TM-8

< PREPARATION >[7AT: RE7R01B]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000006226736

Tool number

(Kent-Moore No.)

Tool nameDescription

ST33400001

(J-26082)

Drift

a: 60 m](/img/42/57033/w960_57033-5095.png)

TM-8

< PREPARATION >[7AT: RE7R01B]

PREPARATION

PREPARATION

PREPARATION

Special Service ToolINFOID:0000000006226736

Tool number

(Kent-Moore No.)

Tool nameDescription

ST33400001

(J-26082)

Drift

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia. Installing rear oil seal (2WD)

Installing oil pump housing oil seal

KV31102400

(J-34285 and J-34285-87)

Clutch spring compressor

a: 320 mm (12.60 in)

b: 174 mm (6.85 in) Installing reverse brake

return spring retainer

Removing and installing 2346 brake spring retain- er

KV31103800

Clutch spring compressor

1. M12 ×1.75P Removing and installing front brake spring retainer

ST25850000

(J-25721-A)

Sliding hammer

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in)

d: M12X1.75P Remove oil pump assembly

NT086

NT423

JSDIA1749ZZ

NT422

Revision: 2010 May2011 QX56