height INFINITI QX56 2011 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2278 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

EC-254

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0138, P0158 HO2S2

11 .CHECK HEATED OXYGEN SENSOR 2

Refer to EC-254, "

Component Inspection (HO2 sensor 2)".

Is the inspection result normal?

YES >> GO TO 13 INFINITI QX56 2011 Factory Workshop Manual

EC-254

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0138, P0158 HO2S2

11 .CHECK HEATED OXYGEN SENSOR 2

Refer to EC-254, "

Component Inspection (HO2 sensor 2)".

Is the inspection result normal?

YES >> GO TO 13](/img/42/57033/w960_57033-2277.png)

EC-254

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0138, P0158 HO2S2

11 .CHECK HEATED OXYGEN SENSOR 2

Refer to EC-254, "

Component Inspection (HO2 sensor 2)".

Is the inspection result normal?

YES >> GO TO 13.

NO >> GO TO 12.

12.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

Before installing new oxygen sensor, clean exh aust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

>> INSPECTION END

13.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (HO2 sensor 2)INFOID:0000000006217820

1.INSPECTION START

Will CONSULT-III be used?

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

WITH CONSULT-III

1. Start engine and warm it up to the normal operating temperature.

2. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

3. Let engine idle for 1 minute.

4. Select “FUEL INJECTION” in “ACT IVE TEST” mode, and select “HO2S2 (B1)/(B2)” as the monitor item

with CONSULT-III.

5. Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)/(B2)” should be above 0.74 V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18 V at least once when the “FUEL INJECTION” is −25%.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 6.

3.CHECK HEATED OXYGEN SENSOR 2-I

WITHOUT CONSULT-III

1. Start engine and warm it up to the normal operating temperature.

JMBIA1573GB

Revision: 2010 May2011 QX56

Page 2279 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

P0138, P0158 HO2S2EC-255

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between INFINITI QX56 2011 Factory Workshop Manual

P0138, P0158 HO2S2EC-255

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between](/img/42/57033/w960_57033-2278.png)

P0138, P0158 HO2S2EC-255

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and keep the engine speed between 3,500 and

4,000 rpm for at least 1 minute under no load.

4. Let engine idle for 1 minute.

5. Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 4.

4.CHECK HEATED OXYGEN SENSOR 2-II

Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK HEATED OXYGEN SENSOR 2-III

Check the voltage between ECM harness connector terminals under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 6.

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any heated oxygen sensor which has been dr opped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

ECM

Condition Voltage

Connector +–

Te r m i n a l Te r m i n a l

F110 96

[HO2S2

(bank 1)] 100Revving up to 4,000 rpm under no load at

least 10 times The voltage should be above 0.74 V at

least once during this procedure.

The voltage should be below 0.18 V at

least once during this procedure.

87

[HO2S2

(bank 2)]

ECM

Condition Voltage

Connector +–

Te r m i n a l Te r m i n a l

F110 96

[HO2S2

(bank 1)] 100 Keeping engine at idle for 10 minutes The voltage should be above 0.74 V at

least once during this procedure.

The voltage should be below 0.18 V at

least once during this procedure.

87

[HO2S2

(bank 2)]

ECM

Condition Voltage

Connector +–

Te r m i n a l Te r m i n a l

F110 96

[HO2S2

(bank 1)] 100Coasting from 80 km/h (50 MPH) with se-

lector lever in the D position The voltage should be above 0.74 V at

least once during this procedure.

The voltage should be below 0.18 V at

least once during this procedure.

87

[HO2S2

(bank 2)]

Revision: 2010 May2011 QX56

Page 2284 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

EC-260

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

3. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or sh INFINITI QX56 2011 Factory Workshop Manual

EC-260

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

3. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or sh](/img/42/57033/w960_57033-2283.png)

EC-260

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

3. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK HEATED OXYGEN SENSOR 2

Refer to EC-260, "

Component Inspection (HO2 sensor 2)".

Is the inspection result normal?

YES >> GO TO 6.

NO >> GO TO 5.

5.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

Before installing new oxygen sensor, clean exh aust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

>> INSPECTION END

6.CHECK INTERMITTENT INCIDENT

Refer to GI-40, "

Intermittent Incident".

>> INSPECTION END

Component Inspection (HO2 sensor 2)INFOID:0000000006217824

1.INSPECTION START

Will CONSULT-III be used?

Will CONSULT-III be used?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK HEATED OXYGEN SENSOR 2

WITH CONSULT-III

1. Start engine and warm it up to the normal operating temperature.

2. Start engine and keep the engine speed between 3,500 and 4,000 rpm for at least 1 minute under no load.

3. Let engine idle for 1 minute.

4. Select “FUEL INJECTION” in “ACT IVE TEST” mode, and select “HO2S2 (B1)/(B2)” as the monitor item

with CONSULT-III.

5. Check “HO2S2 (B1)/(B2)” at idle speed when adjusting “FUEL INJECTION” to ±25%.

“HO2S2 (B1)/(B2)” should be above 0.74 V at least once when the “FUEL INJECTION” is +25%.

“HO2S2 (B1)/(B2)” should be below 0.18 V at least once when the “FUEL INJECTION” is −25%.

Is the inspection result normal?

YES >> INSPECTION END

JMBIA1573GB

Revision: 2010 May2011 QX56

Page 2286 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

EC-262

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any h INFINITI QX56 2011 Factory Workshop Manual

EC-262

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any h](/img/42/57033/w960_57033-2285.png)

EC-262

< DTC/CIRCUIT DIAGNOSIS >[VK56VD]

P0139, P0159 HO2S2

6.REPLACE HEATED OXYGEN SENSOR 2

Replace malfunctioning heated oxygen sensor 2. Refer to EM-40, "

Exploded View".

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7

in) onto a hard surface such as a concrete floor; use a new one.

Before installing new oxygen sensor, clean exh aust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

>> INSPECTION END

Revision: 2010 May2011 QX56

Page 2513 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Rep INFINITI QX56 2011 Factory Workshop Manual

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Rep](/img/42/57033/w960_57033-2512.png)

P2A00, P2A03 A/F SENSOR 1EC-489

< DTC/CIRCUIT DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

4. Also check harness for short to power.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

8.CHECK A/F SENSOR 1 HEATER

Refer to EC-182, "

Component Inspection (A/F Sensor 1 Heater)".

Is the inspection result normal?

YES >> GO TO 9.

NO >> GO TO 10.

9.CHECK INTERMITTENT INCIDENT

Perform GI-40, "

Intermittent Incident".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Repair or replace malfunctioning part.

10.REPLACE AIR FUEL RATIO (A/F) SENSOR 1

Replace air fuel ratio (A/F) sensor 1. Refer to EX-5, "

Exploded View".

CAUTION:

Discard any A/F sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

Before installing new A/F senso r, clean exhaust system threads using Oxygen Sensor Thread

Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize lubricant

(commercial service tool).

Will CONSULT-III be used?

YES >> GO TO 11.

NO >> GO TO 12.

11 .CONFIRM A/F ADJUSTMENT DATA

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR” mode with CONSULT-III.

3. Check that “0.000” is di splayed on CONSULT-III screen.

Is

“0.000” displayed?

YES >> INSPECTION END

NO >> GO TO 12.

12.CLEAR THE MIXTURE RATIO SELF-LEARNING VALUE

Clear the mixture ratio self-learning value. Refer to EC-152, "

Work Procedure".

Will CONSULT-III be used?

YES >> GO TO 13.

NO >> INSPECTION END

13.CONFIRM A/F ADJUSTMENT DATA

WITH CONSULT-III

1. Turn ignition switch ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR” mode with CONSULT-III.

3. Check that “0.000” is di splayed on CONSULT-III screen.

>> INSPECTION END

DTC A/F sensor 1 ECM

Continuity

Bank Connector Terminal Connector Terminal

P2A00 1 F67 6 F11094

Existed

P2A03 2 F68 6 74

Revision: 2010 May2011 QX56

Page 2641 of 5598

CAMSHAFTEM-79

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

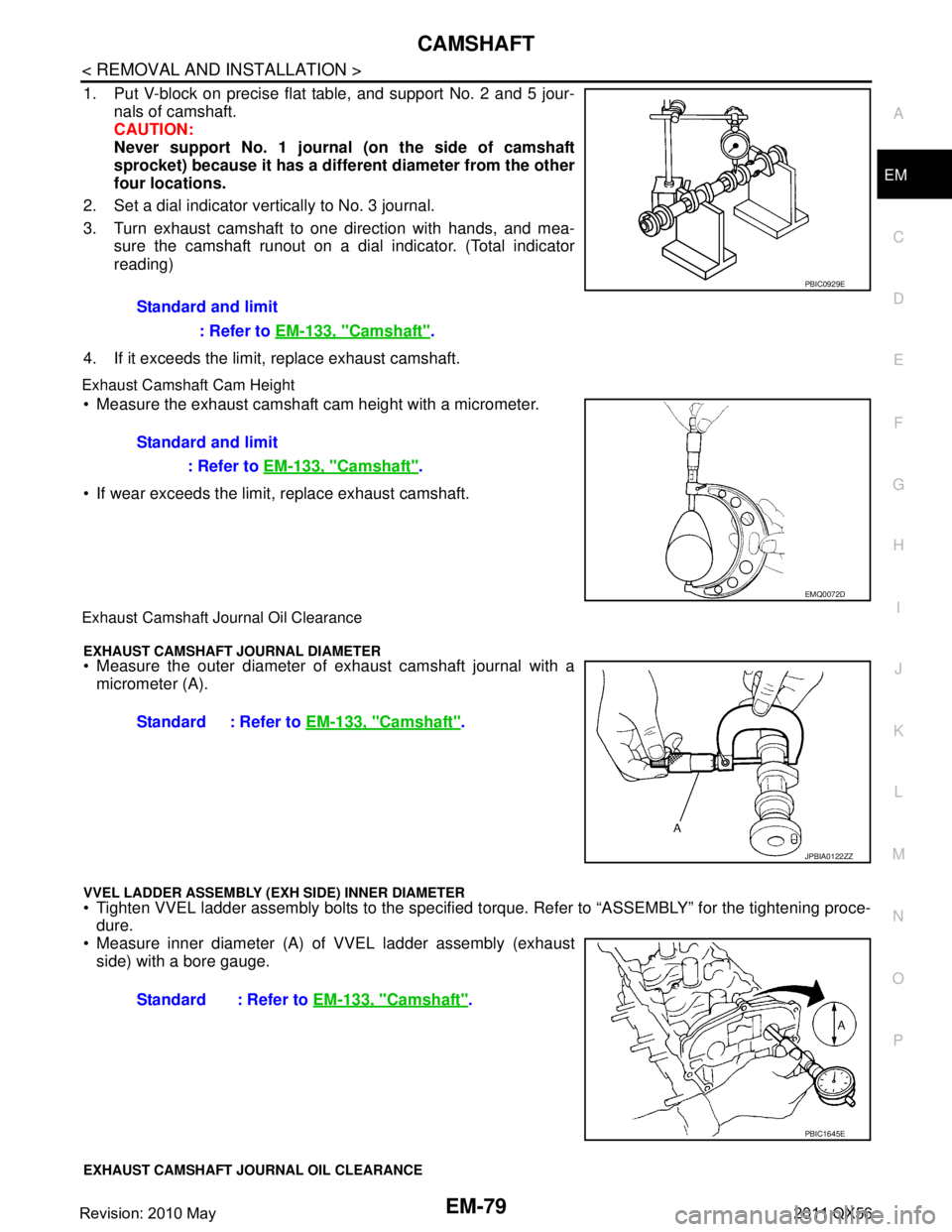

1. Put V-block on precise flat table, and support No. 2 and 5 jour-

nals of camshaft.

CAUTION:

Never support No. 1 journal (on the side of camshaft

sprocket) because it has a different diameter from the other

four locations.

2. Set a dial indicator vertically to No. 3 journal.

3. Turn exhaust camshaft to one direction with hands, and mea- sure the camshaft runout on a dial indicator. (Total indicator

reading)

4. If it exceeds the limit, replace exhaust camshaft.

Exhaust Camshaft Cam Height

Measure the exhaust camshaft cam height with a micrometer.

If wear exceeds the limit, replace exhaust camshaft.

Exhaust Camshaft Journal Oil Clearance

EXHAUST CAMSHAFT JOURNAL DIAMETER

Measure the outer diameter of exhaust camshaft journal with a micrometer (A).

VVEL LADDER ASSEMBLY (EXH SIDE) INNER DIAMETER Tighten VVEL ladder assembly bolts to the specifi ed torque. Refer to “ASSEMBLY” for the tightening proce-

dure.

Measure inner diameter (A) of VVEL ladder assembly (exhaust side) with a bore gauge.

EXHAUST CAMSHAFT JOURNAL OIL CLEARANCE

Standard and limit

: Refer to EM-133, "

Camshaft".

PBIC0929E

Standard and limit

: Refer to EM-133, "

Camshaft".

EMQ0072D

Standard : Refer to EM-133, "Camshaft".

JPBIA0122ZZ

Standard : Refer to EM-133, "Camshaft".

PBIC1645E

Revision: 2010 May2011 QX56

Page 2643 of 5598

CAMSHAFTEM-81

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

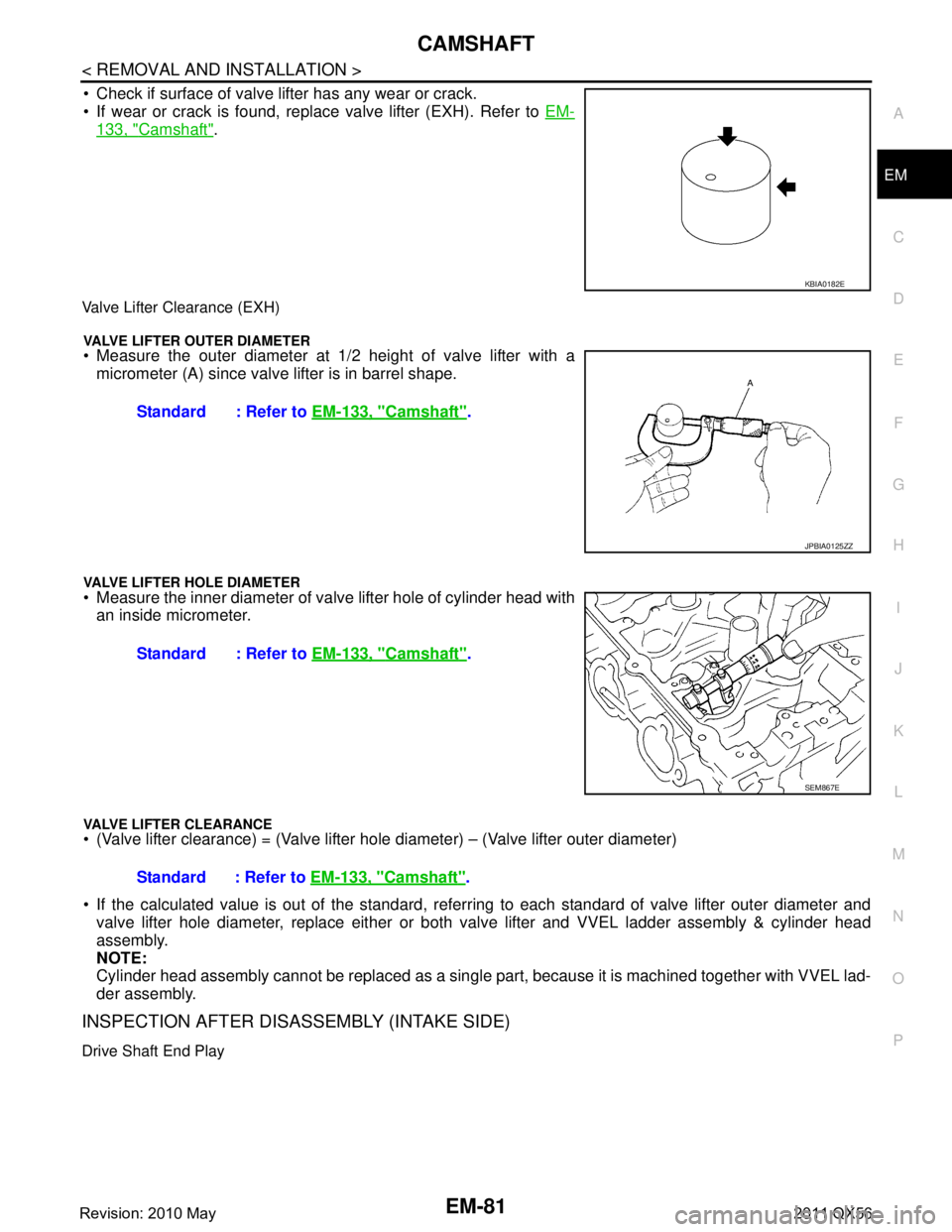

Check if surface of valve lifter has any wear or crack.

If wear or crack is found, replace valve lifter (EXH). Refer to

EM-

133, "Camshaft".

Valve Lifter Clearance (EXH)

VALVE LIFTER OUTER DIAMETER Measure the outer diameter at 1/2 height of valve lifter with a

micrometer (A) since valve lifter is in barrel shape.

VALVE LIFTER HOLE DIAMETER Measure the inner diameter of va lve lifter hole of cylinder head with

an inside micrometer.

VALVE LIFTER CLEARANCE (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

If the calculated value is out of the standard, referr ing to each standard of valve lifter outer diameter and

valve lifter hole diameter, replace either or both valve lifter and VVEL ladder assembly & cylinder head

assembly.

NOTE:

Cylinder head assembly cannot be replaced as a single pa rt, because it is machined together with VVEL lad-

der assembly.

INSPECTION AFTER DISASSEMBLY (INTAKE SIDE)

Drive Shaft End Play

KBIA0182E

Standard : Refer to EM-133, "Camshaft".

JPBIA0125ZZ

Standard : Refer to EM-133, "Camshaft".

SEM867E

Standard : Refer to EM-133, "Camshaft".

Revision: 2010 May2011 QX56

Page 2645 of 5598

CAMSHAFTEM-83

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

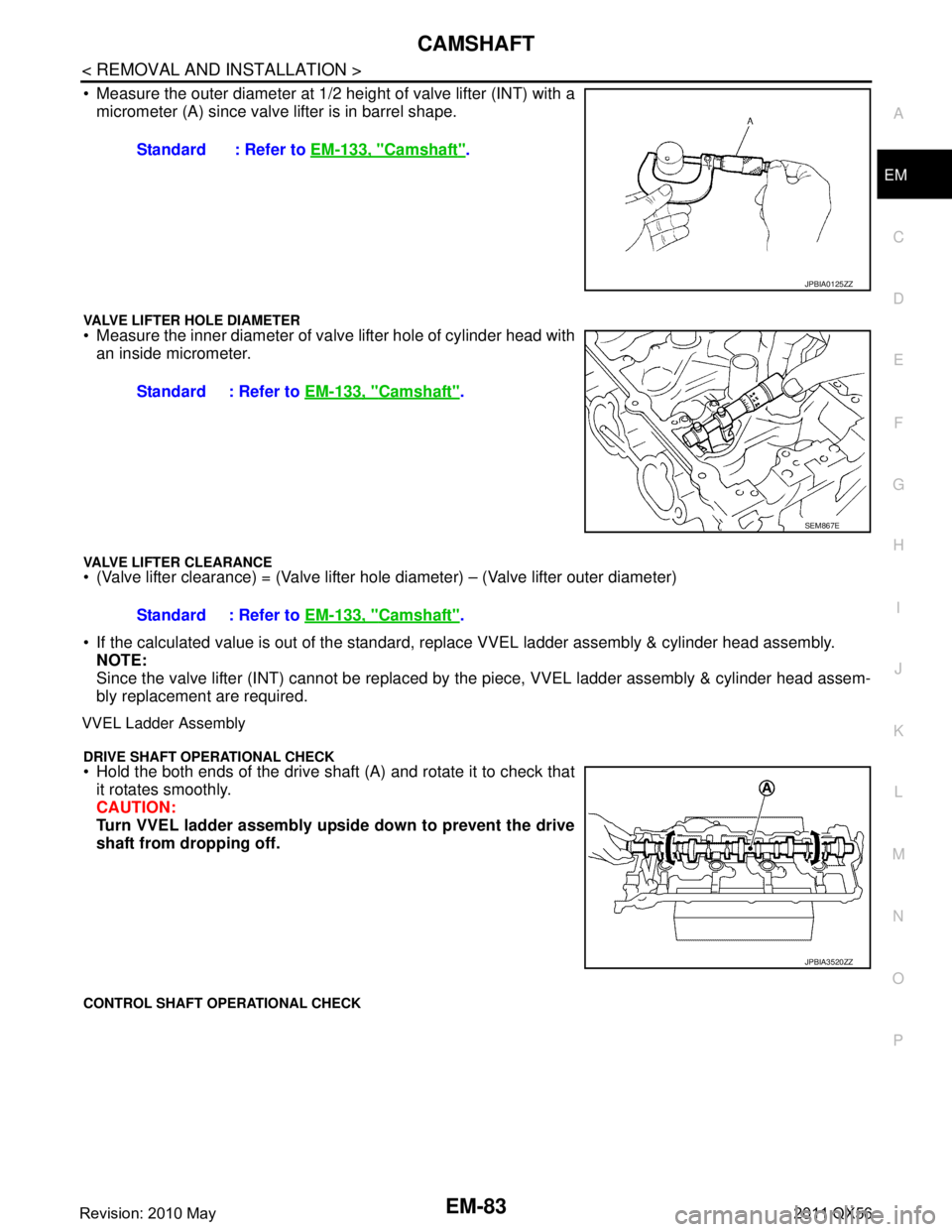

Measure the outer diameter at 1/2

height of valve lifter (INT) with a

micrometer (A) since valve lifter is in barrel shape.

VALVE LIFTER HOLE DIAMETER Measure the inner diameter of va lve lifter hole of cylinder head with

an inside micrometer.

VALVE LIFTER CLEARANCE (Valve lifter clearance) = (Valve lifter hole diameter) – (Valve lifter outer diameter)

If the calculated value is out of the standard, r eplace VVEL ladder assembly & cylinder head assembly.

NOTE:

Since the valve lifter (INT) cannot be replaced by t he piece, VVEL ladder assembly & cylinder head assem-

bly replacement are required.

VVEL Ladder Assembly

DRIVE SHAFT OPERATIONAL CHECK Hold the both ends of the drive shaft (A) and rotate it to check that it rotates smoothly.

CAUTION:

Turn VVEL ladder assembly upside down to prevent the drive

shaft from dropping off.

CONTROL SHAFT OPERATIONAL CHECK

Standard : Refer to EM-133, "Camshaft".

JPBIA0125ZZ

Standard : Refer to EM-133, "Camshaft".

SEM867E

Standard : Refer to EM-133, "Camshaft".

JPBIA3520ZZ

Revision: 2010 May2011 QX56

Page 2654 of 5598

![INFINITI QX56 2011 Factory Workshop Manual

EM-92

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

a. Apply new engine oil on new valve oil seal joint and seal lip.

b. Using the valve oil seal drift [SST: KV10115600 (J-38958)] (A),press fit valve se INFINITI QX56 2011 Factory Workshop Manual

EM-92

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

a. Apply new engine oil on new valve oil seal joint and seal lip.

b. Using the valve oil seal drift [SST: KV10115600 (J-38958)] (A),press fit valve se](/img/42/57033/w960_57033-2653.png)

EM-92

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

a. Apply new engine oil on new valve oil seal joint and seal lip.

b. Using the valve oil seal drift [SST: KV10115600 (J-38958)] (A),press fit valve seal to height (b) shown in figure.

4. Install valve. NOTE:

Larger diameter valves are for intake side.

5. Install valve spring (with valve spring seat). Install narrow pitch (B) end [paint mark (C)] to cylinder headside (valve spring seat side).

6. Install valve spring retainer.

7. Install valve collet. Compress valve spring with the valve spring compressor [SST:

KV10116200 (J26336-A)] (A), the attachment [SST:

KV10115900 (J26336-20)] (C) and the adapter [SST:

KV10109220 ( — )] (B). Install valve collet with a magnet

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

Tap valve stem edge lightly with plastic hammer after installa- tion to check its installed condition.

InspectionINFOID:0000000006289573

INSPECTION AFTER DISASSEMBLY

Cylinder Head Bolt s Outer Diameter

Cylinder head bolts are tightened by plastic zone tightening

method. Whenever the size difference between (B) and (A)

exceeds the limit, replace them with new one.

If reduction of outer diameter appears in a position other than (A),

use it as (A) point. Height (b)

Intake, Exhaust : 14.3 - 14.9 mm (0.563 - 0.587 in)

JPBIA1367ZZ

A : Wide pitch

: Cylinder head side

Paint mark color

Intake : Light green

Exhaust : Light blue

JPBIA0179ZZ

JPBIA1365ZZ

Limit [(B) - (A)] : 0.18 mm (0.0071 in)

c : 55 mm (2.17 in)

d : 12 mm (0.47 in)

JPBIA2144ZZ

Revision: 2010 May2011 QX56

Page 2656 of 5598

EM-94

< REMOVAL AND INSTALLATION >

CYLINDER HEAD

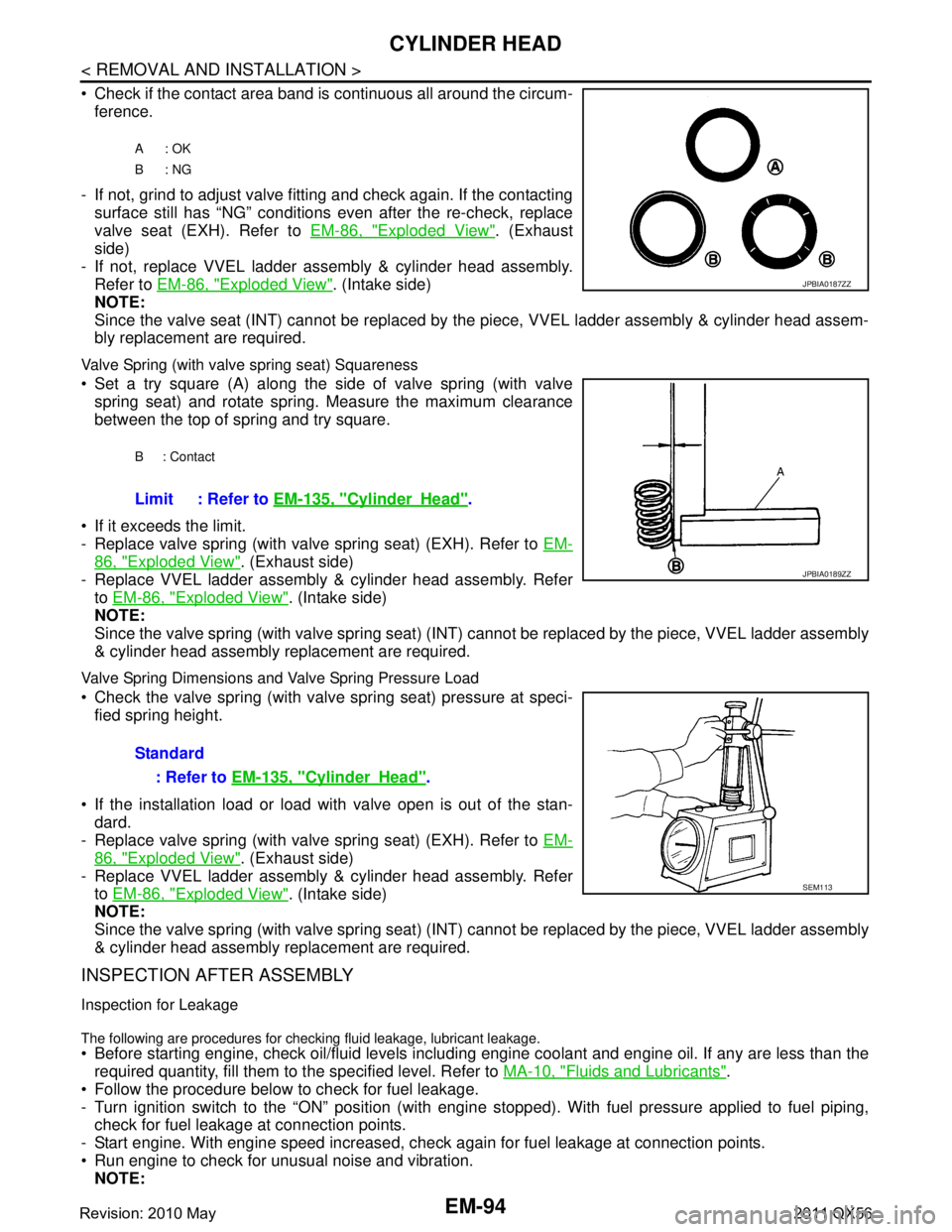

Check if the contact area band is continuous all around the circum-ference.

- If not, grind to adjust valve fitting and check again. If the contacting surface still has “NG” conditions even after the re-check, replace

valve seat (EXH). Refer to EM-86, "

Exploded View". (Exhaust

side)

- If not, replace VVEL ladder assembly & cylinder head assembly. Refer to EM-86, "

Exploded View". (Intake side)

NOTE:

Since the valve seat (INT) cannot be replaced by t he piece, VVEL ladder assembly & cylinder head assem-

bly replacement are required.

Valve Spring (with valve spring seat) Squareness

Set a try square (A) along the side of valve spring (with valve

spring seat) and rotate spring. Measure the maximum clearance

between the top of spring and try square.

If it exceeds the limit.

- Replace valve spring (with valve spring seat) (EXH). Refer to EM-

86, "Exploded View". (Exhaust side)

- Replace VVEL ladder assembly & cylinder head assembly. Refer

to EM-86, "

Exploded View". (Intake side)

NOTE:

Since the valve spring (with valve spring seat) (INT) c annot be replaced by the piece, VVEL ladder assembly

& cylinder head assembly replacement are required.

Valve Spring Dimensions and Valve Spring Pressure Load

Check the valve spring (with valve spring seat) pressure at speci- fied spring height.

If the installation load or load with valve open is out of the stan- dard.

- Replace valve spring (with valve spring seat) (EXH). Refer to EM-

86, "Exploded View". (Exhaust side)

- Replace VVEL ladder assembly & cylinder head assembly. Refer to EM-86, "

Exploded View". (Intake side)

NOTE:

Since the valve spring (with valve spring seat) (INT) c annot be replaced by the piece, VVEL ladder assembly

& cylinder head assembly replacement are required.

INSPECTION AFTER ASSEMBLY

Inspection for Leakage

The following are procedures for checking fluid leakage, lubricant leakage.

Before starting engine, check oil/fluid levels includi ng engine coolant and engine oil. If any are less than the

required quantity, fill them to the specified level. Refer to MA-10, "

Fluids and Lubricants".

Follow the procedure below to check for fuel leakage.

- Turn ignition switch to the “ON” position (with engi ne stopped). With fuel pressure applied to fuel piping,

check for fuel leakage at connection points.

- Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration. NOTE:

A: OK

B: NG

JPBIA0187ZZ

B : Contact

Limit : Refer to EM-135, "CylinderHead".

JPBIA0189ZZ

Standard

: Refer to EM-135, "

CylinderHead".

SEM113

Revision: 2010 May2011 QX56