height INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2659 of 5598

OIL SEALEM-97

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

REAR OIL SEAL : Removal and InstallationINFOID:0000000006289575

REMOVAL

1. Remove transmission assembly. Refer to

TM-205, "2WD : Exploded View" (2WD models) or TM-208,

"4WD : Exploded View" (4WD models).

2. Remove drive plate. Refer to EM-106, "

Exploded View".

3. Remove rear oil seal with a suitable tool. CAUTION:

Be careful not to damage crankshaft and cylinder block.

INSTALLATION

1. Install rear oil seal. Install rear oil seal so that each seal lip is oriented as shown in

the figure.

Press in rear oil seal (1) to the position as shown in the figure.

Using a suitable drift [outer diameter 101 mm (3.98 in)], press-fit until the height of rear oil seal is level with the mounting surface.

Check the garter spring is in position and seal lips are not inverted. CAUTION:

Be careful not to damage crankshaft and cylinder block.

Press-fit straight and avoid cau sing burrs or tilting oil seal.

2. Install in the reverse order of removal after this step.

SBIA0360E

A : Oil seal lip

B : Dust seal lip : Engine inside

: Engine outside

JPBIA0054ZZ

B : Rear oil seal retainer rear end face

a : 0 - 0.5 mm (0 - 0.020 in)

JPBIA0152ZZ

SBIA0360E

Revision: 2010 May2011 QX56

Page 2685 of 5598

CYLINDER BLOCKEM-123

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Cut a plastigage slightly shorter than the bearing width,

and place it in crankshaft axial direction, avoiding oil

holes.

Install main bearing to cylinder block and main bearing cap, and tighten main bearing cap bolts with main

bearing cap to the specified torque. Refer to EM-107, "

Disassembly and Assembly" for the tightening proce-

dure.

CAUTION:

Never rotate crankshaft.

Remove main bearing cap and bearings, and using the scale on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is the

same as that described in the “Method by Calculation”.

MAIN BEARING CRUSH HEIGHT

When main bearing cap is removed after being tightened to thespecified torque with main bearings (1) installed, the tip end of

bearing must protrude. Refer to EM-107, "

Disassembly and

Assembly" for the tightening procedure.

If the standard is not met, replace main bearings.

CONNECTING ROD BEARING CRUSH HEIGHT

When connecting rod bearing cap is removed after being tightened to the specified torque with connecting rod bearings (1) installed,

the tip end of bearing must protrude. Refer to EM-107, "

Disassem-

bly and Assembly" for the tightening procedure.

If the standard is not met, replace connecting rod bearings.

MAIN BEARING CAP BOLT OUTER DIAMETER

Measure the outer diameters (A), (B) at two positions as shown in

the figure.

If reduction appears in (A) range, regard it (B).

If it exceeds the limit (large difference in dimensions), replace main bearing cap bolts with new one.

MAIN BEARING CAP SUB BOLT OUTER DIAMETER

JPBIA0231ZZ

A : Crush height

Standard : There must be crush height.

JPBIA0233ZZ

A : Crush height

Standard : There must be crush height.

JPBIA0233ZZ

c : 20 mm (0.79 in)

d : 55 mm (2.17 in)

e : 12 mm (0.47 in)

Limit [(B) – (A)] : 0.15 mm (0.0059 in)

JPBIA2280ZZ

Revision: 2010 May2011 QX56

Page 2695 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-133

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

Exhaust ManifoldINFOID:0000000006289592

EXHAUST MANIFOLD

Unit: mm (in)

CamshaftINFOID:0000000006289593

EXHAUST CAMSHAFT

Unit: mm (in)

*: Total indicator reading

INTAKE CAMSHAFT

Unit: mm (in)

*1: Total indicator reading

VA LV E L I F T E R

Unit: mm (in)

VALVE CLEARANCE

Gap

Standard 1.1 (0.043)

Limit 1.25 (0.049)

Items Limit

Surface distortion Exhaust manifold 0.7 (0.028)

Items Standard Limit

Exhaust camshaft journal oil clearance 0.030 - 0.071 (0.0012 - 0.0028) 0.150 (0.0059)

VVEL ladder asse mbly bracket inner diameter (EXH side) 26.000 - 26.021 (1.0236 - 1.0244) —

Exhaust camshaft journal diameter 25.935 - 25.955 (1.0211 - 1.0218) —

Exhaust camshaft end play 0.115 - 0.188 (0.0045 - 0.0074) 0.24 (0.0094)

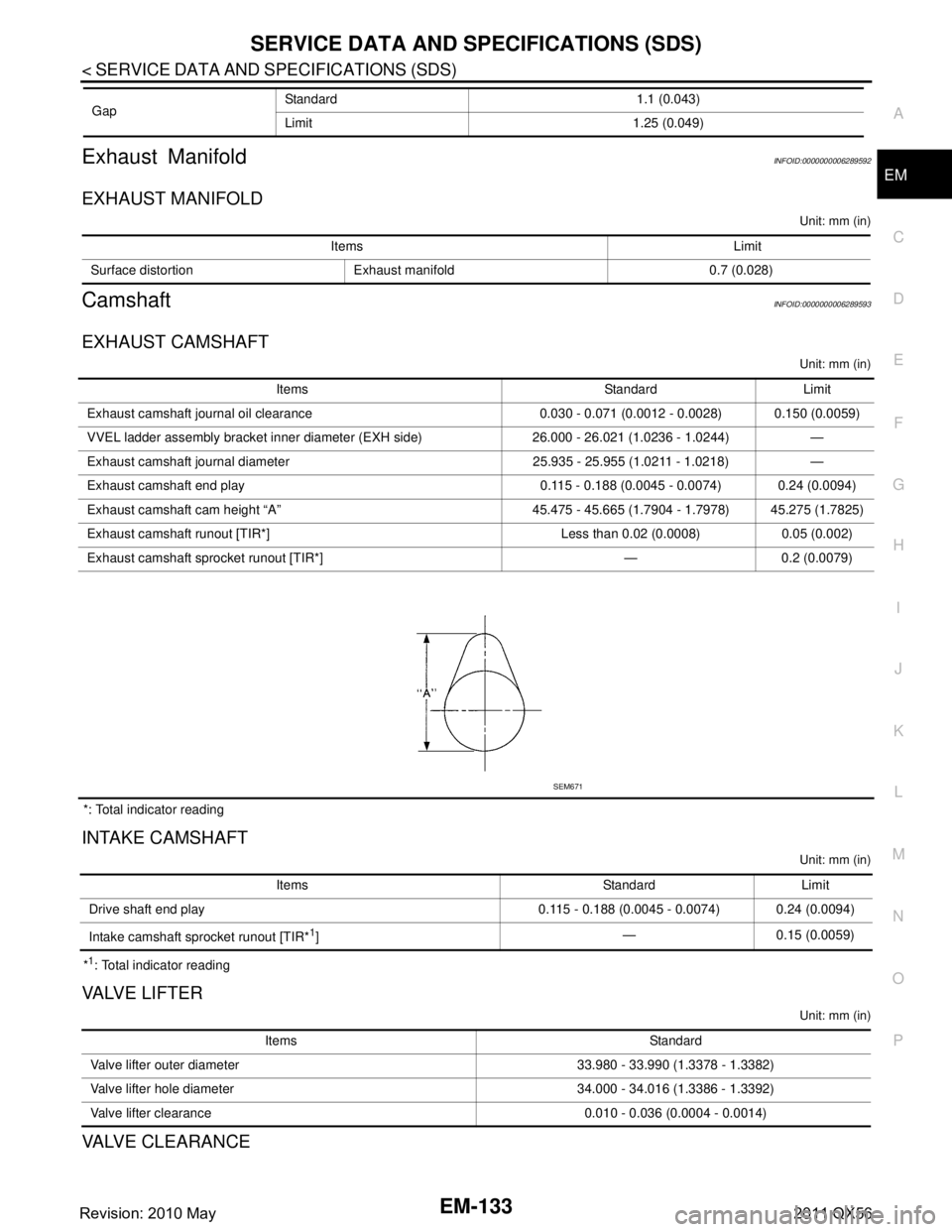

Exhaust camshaft cam height “A” 45.475 - 45.665 (1.7904 - 1.7978) 45.275 (1.7825)

Exhaust camshaft runout [TIR*] Less than 0.02 (0.0008) 0.05 (0.002)

Exhaust camshaft sprocket runout [TIR*] — 0.2 (0.0079)

SEM671

Items Standard Limit

Drive shaft end play 0.115 - 0.188 (0.0045 - 0.0074) 0.24 (0.0094)

Intake camshaft sprocket runout [TIR*

1] — 0.15 (0.0059)

Items Standard

Valve lifter outer diameter 33.980 - 33.990 (1.3378 - 1.3382)

Valve lifter hole diameter 34.000 - 34.016 (1.3386 - 1.3392)

Valve lifter clearance 0.010 - 0.036 (0.0004 - 0.0014)

Revision: 2010 May2011 QX56

Page 2697 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-135

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

Cylinder HeadINFOID:0000000006289594

CYLINDER HEAD

Unit: mm (in)

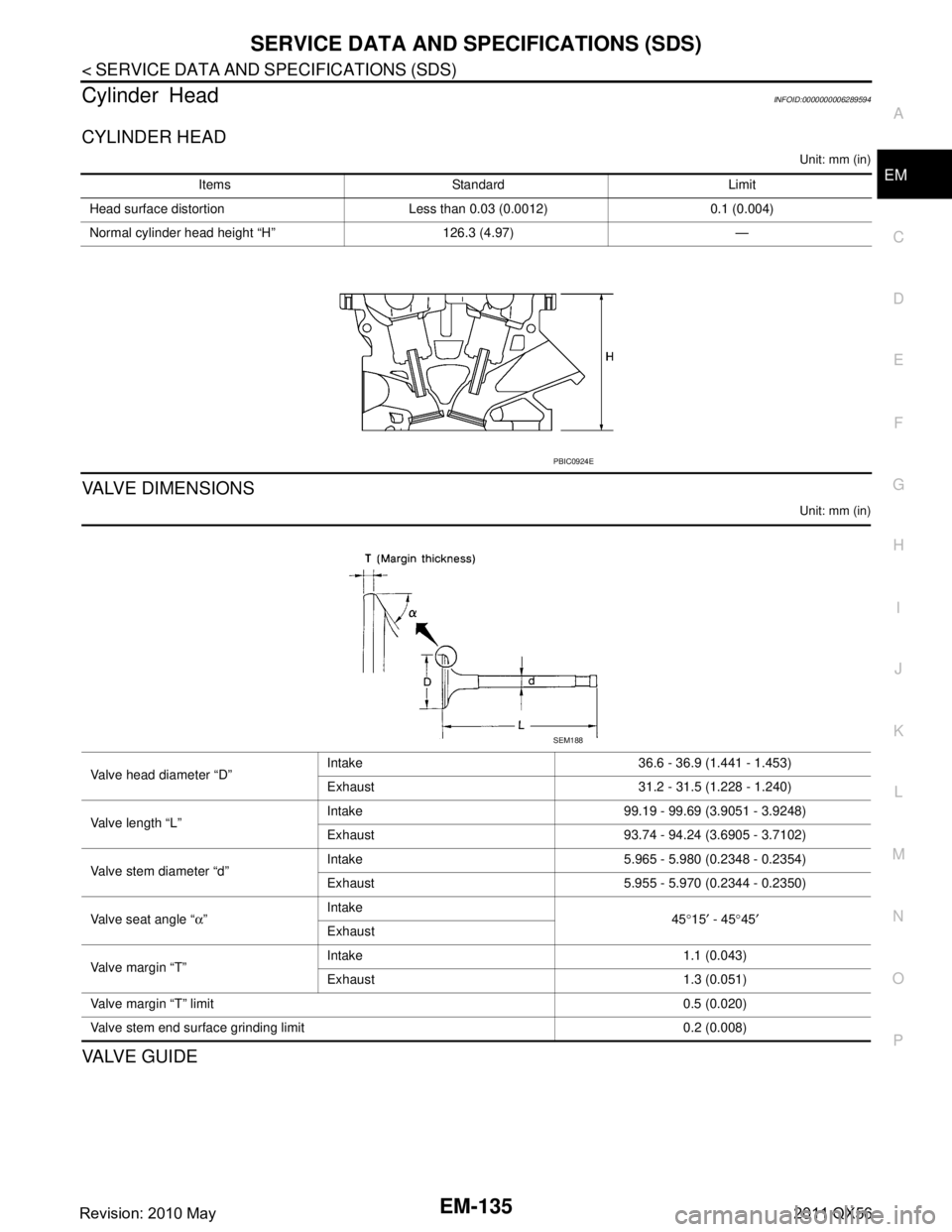

VALVE DIMENSIONS

Unit: mm (in)

VA LV E G U I D E

Items Standard Limit

Head surface distortion Less than 0.03 (0.0012) 0.1 (0.004)

Normal cylinder head height “H” 126.3 (4.97) —

PBIC0924E

Valve head diameter “D” Intake 36.6 - 36.9 (1.441 - 1.453)

Exhaust 31.2 - 31.5 (1.228 - 1.240)

Valve length “L” Intake 99.19 - 99.69 (3.9051 - 3.9248)

Exhaust 93.74 - 94.24 (3.6905 - 3.7102)

Valve stem diameter “d” Intake 5.965 - 5.980 (0.2348 - 0.2354)

Exhaust 5.955 - 5.970 (0.2344 - 0.2350)

Valve seat angle “ α” Intake

45°15 ′ - 45 °45 ′

Exhaust

Valve margin “T” Intake 1.1 (0.043)

Exhaust 1.3 (0.051)

Valve margin “T” limit 0.5 (0.020)

Valve stem end surface grinding limit 0.2 (0.008)

SEM188

Revision: 2010 May2011 QX56

Page 2699 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-137

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*1: Diameter made by intersection point of conic angles “

α1” and “ α2”

*

2: Diameter made by intersection point of conic angles “ α2” and “ α3”

*

3: Machining data

*

4: Parts settings are for exhaust side only

VALVE SPRING

Cylinder BlockINFOID:0000000006289595

CYLINDER BLOCK

Unit: mm (in)

Angle “ α2” 88°75 ′ - 90 °25 ′

Angle “ α3” 11 9 - 1 2 1°

Contacting width “W”*

3Intake 1.0 - 1.4 (0.039 - 0.055)

Exhaust 1.2 - 1.6 (0.047 - 0.063)

Height “h” Intake 5.9 - 6.0 (0.232 - 0.236) —

Exhaust 5.9 - 6.0 (0.232 - 0.236)

4.95 - 5.05 (0.1949 - 0.1988)*

4

Depth “H” 6.0 (0.236)

ItemStandard

Intake Exhaust

Free height 47.28 mm (1.8614 in) 48.06 mm (1.8921 in)

Pressure Installation

166 - 188 N (16.9 - 19.2 kg, 37 - 42 lb)

at 41.0 mm (1.614 in) 166 - 188 N (16.9 - 19.2 kg, 37 - 42 lb)

at 34.45 mm (1.3563 in)

Valve open 541 - 611 N (55.2 - 62.3 kg, 122 - 137 lb)

at 29.6 mm (1.165 in) 320.1 - 360.1 N (32.7 - 36.7 kg, 72 - 81 lb)

at 24.65 mm (0.9705 in)

Identification color Light green Light blue

Item Limit

Intake Exhaust

Out-of-square 2.1 mm (0.083 in) 2.0 mm (0.079 in)

Surface flatness Limit 0.1 (0.004)

Main bearing housing inner diameter Standard 68.944 - 68.968 (2.7143 - 2.7153)

Cylinder bore Inner diameter StandardGrade No. 1 98.000 - 98.010 (3.8583 - 3.8587)

Grade No. 2 98.010 - 98.020 (3.8587 - 3.8590)

Grade No. 3 98.020 - 98.030 (3.8590 - 3.8594)

Wear limit 0.2 (0.008)

Out-of-round Limit0.015 (0.0006)

Ta p e r 0.010 (0.0004)

Revision: 2010 May2011 QX56

Page 2712 of 5598

EXL-2

EXTERIOR LAMP BATTERY SAVER SYSTEM :

System Description .................................................

21

DIAGNOSIS SYSTEM (BCM) ............................22

COMMON ITEM ..................................................... ...22

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) ................................................. ...

22

HEADLAMP ........................................................... ...23

HEADLAMP : CONSULT-III Function (BCM -

HEAD LAMP) ..........................................................

23

FLASHER ............................................................... ...25

FLASHER : CONSULT-III Function (BCM -

FLASHER) ..............................................................

25

DIAGNOSIS SYSTEM (IPDM E/R) ....................27

Diagnosis Description .......................................... ...27

CONSULT-III Function (IPDM E/R) ........................29

DIAGNOSIS SYSTEM (AFS) .............................32

CONSULT-III Function (ADAPTIVE LIGHT) ........ ...32

ECU DIAGNOSIS INFORMATION ..............34

BCM, IPDM E/R .............................................. ...34

List of ECU Reference ......................................... ...34

AFS CONTROL UNIT ........................................35

Reference Value .................................................. ...35

Fail-Safe .................................................................38

DTC Inspection Priority Chart .................................39

DTC Index ..............................................................39

WIRING DIAGRAM .....................................40

EXTERIOR LIGHTING SYSTEM .................... ...40

Wiring Diagram .................................................... ...40

BASIC INSPECTION ...................................59

DIAGNOSIS AND REPAIR WORKFLOW ...... ...59

Work Flow ............................................................ ...59

INSPECTION AND ADJUSTMENT ...................61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) .............. ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : De-

scription ..................................................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (AFS CONTROL UNIT) : Special

Repair Requirement ...............................................

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) ................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Descrip-

tion ....................................................................... ...

61

ADDITIONAL SERVICE WHEN REPLACING

CONTROL UNIT (HEIGHT SENSOR) : Special

Repair Requirement ............................................. ...

61

LEVELIZER ADJUSTMENT ......................................61

LEVELIZER ADJUSTMENT : Description ..............61

LEVELIZER ADJUSTMENT : Special Repair Re-

quirement ............................................................. ...

61

DTC/CIRCUIT DIAGNOSIS ........................63

B2503, B2504 SWIVEL ACTUATOR ............. ...63

DTC Logic ............................................................ ...63

Diagnosis Procedure ...............................................64

Component Inspection ............................................67

B2513 HEIGHT SENSOR UNUSUAL [FR] .......68

DTC Logic ............................................................ ...68

Diagnosis Procedure ...............................................68

B2514 HEIGHT SENSOR UNUSUAL [RR] .......71

DTC Logic ............................................................ ...71

Diagnosis Procedure ...............................................71

B2516 SHIFT SIGNAL [P, R] ............................74

DTC Logic ............................................................ ...74

Diagnosis Procedure ...............................................74

B2517 VEHICLE SPEED SIGNAL ....................75

DTC Logic ............................................................ ...75

Diagnosis Procedure ...............................................75

B2519 LEVELIZER CALIBRATION ..................76

DTC Logic ............................................................ ...76

Diagnosis Procedure ...............................................76

B2521 ECU CIRCUIT ........................................77

DTC Logic ............................................................ ...77

Diagnosis Procedure ...............................................77

C0126 STEERING ANGLE SENSOR SIGNAL ...80

DTC Logic ............................................................ ...80

Diagnosis Procedure ...............................................80

C0428 STEERING ANGLE SENSOR CALI-

BRATION ...........................................................

81

DTC Logic ............................................................ ...81

Diagnosis Procedure ...............................................81

U1000 CAN COMM CIRCUIT ............................82

Description ........................................................... ...82

DTC Logic ...............................................................82

Diagnosis Procedure ...............................................82

U1010 CONTROL UNIT (CAN) .........................83

DTC Logic ............................................................ ...83

Diagnosis Procedure ...............................................83

POWER SUPPLY AND GROUND CIRCUIT .....84

AFS CONTROL UNIT ............................................. ...84

AFS CONTROL UNIT : Diagnosis Procedure .........84

Revision: 2010 May2011 QX56

Page 2714 of 5598

EXL-4

HAZARD SWITCH ...........................................133

Exploded View ..................................................... ..133

AFS SWITCH ...................................................134

Exploded View ..................................................... ..134

Removal and Installation .......................................134

AFS CONTROL UNIT ......................................135

Exploded View ..................................................... ..135

Removal and Installation .......................................135

HEIGHT SENSOR ............................................136

Exploded View ..................................................... ..136

Removal and Installation .......................................136

REAR COMBINATION LAMP .........................138

Exploded View ..................................................... ..138

Removal and Installation .......................................138

HIGH-MOUNTED STOP LAMP .......................140

Exploded View ..................................................... .140

Removal and Installation .......................................140

BACK-UP LAMP ............................................ ..141

Exploded View ..................................................... .141

Removal and Installation .......................................141

Replacement .........................................................142

LICENSE PLATE LAMP ...................................143

Exploded View ..................................................... .143

Removal and Installation .......................................143

Replacement .........................................................143

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

145

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

145

Bulb Specifications ............................................... .145

Revision: 2010 May2011 QX56

Page 2717 of 5598

![INFINITI QX56 2011 Factory Repair Manual

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM INFINITI QX56 2011 Factory Repair Manual

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM](/img/42/57033/w960_57033-2716.png)

COMPONENT PARTSEXL-7

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

*1: With headlamp aiming control system (manual) models

*2: With AFS system models

EXTERIOR LIGHTING SYSTEM : Component DescriptionINFOID:0000000006213888

1. Combination meter 2. BCM

Refer to BCS-4, "

BODY CONTROL

SYSTEM : Compon ent Parts Loca-

tion"

3. Optical sensor

4. IPDM E/R Refer to PCS-4, "

Component Parts

Location"

5. ECM

Refer to EC-16, "

Component Parts

Location"

6. Parking lamp

7. Front turn signal lamp 8. Front fog lamp 9. Headlamp

10. Front side marker lamp 11. Combination switch 12. Headlamp aiming switch*

1

13. Front door switch (driver side) 14.

Steering angle sensor*2

Refer to BRC-10, "Component Parts

Location"

15. License plate lamp

16. Tail lamp 17. Rear turn signal lamp 18. Rear side marker lamp

19. Hazard switch 20. Side turn signal lamp 21. Headlamp swivel actuator

22. Headlamp aiming motor 23. AFS switch*

224.Rear height sensor*2

25.AFS control unit*226.Front height sensor*2

A. Front combination lamp (back) B. View with instrument driver lower

panel (LH)C. Rear suspension member (RH)

D. View with instrument lower cover E. Front suspension arm (RH)

Part Description

BCM Controls the exterior lighting system.

ECM*

1Transmits engine speed signal to AFS control unit. (via CAN communication)

TCM*

1Transmits Shift position signal to AFS control unit. (via CAN communication)

IPDM E/R Controls the integrated relay, and supplies voltage to the load according to the request

from BCM (via CAN communication).

AFS control unit*

1AFS control unit judges the vehicle condition from each signal. AFS control unit con-

trols AFS function and the headlamp aiming.

Combination meter Outputs the vehicle speed signal (8-pulse) to AFS control unit.

Blinks the turn signal indicator lamp and outputs the turn signal operating sound with

integrated buzzer according to the request from BCM (via CAN communication).

Turns the tail lamp indicator lamp and high beam indicator lamp ON according to the

request from BCM (via CAN communication).

Turns the AFS OFF indicator lamp ON/OFF /blinking according to the request from

AFS control unit (via CAN communication).

Headlamp assembly Xenon bulb Refer to

EXL-8, "

FRONT COMBINATION LAMP : Xenon Headlamp".

HID control unit Refer to EXL-9, "

FRONT COMBINATION LAMP : HID control unit".

High beam solenoid Refer to EXL-9, "

FRONT COMBINATION LAMP : High Beam Solenoid".

Aiming motor Refer to EXL-9, "

FRONT COMBINATION LAMP : Aiming Motor".

Swivel actuator*

1Refer to EXL-9, "FRONT COMBINATION LAMP : Swivel Actuator".

Height sensor*

1

The height sensor is installed to the front suspension member and rear suspension member.

The height sensor detects the suspension arm displacement as the vehicle height change.

The height sensor transmits the height sensor signal to AFS control unit.

NOTE:

The sensor angle of the unloaded vehicle position is the reference value.

Optical sensor Optical sensor converts the outside brightness (lux) to voltage and transmits the opti-

cal sensor signal to BCM.

Revision: 2010 May2011 QX56

Page 2725 of 5598

![INFINITI QX56 2011 Factory Repair Manual

SYSTEMEXL-15

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE ADAPTIVE FRONT-LIGHTI NG SYSTEM : System DiagramINFOID:0000000006213899

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTE INFINITI QX56 2011 Factory Repair Manual

SYSTEMEXL-15

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE ADAPTIVE FRONT-LIGHTI NG SYSTEM : System DiagramINFOID:0000000006213899

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTE](/img/42/57033/w960_57033-2724.png)

SYSTEMEXL-15

< SYSTEM DESCRIPTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

ACTIVE ADAPTIVE FRONT-LIGHTI NG SYSTEM : System DiagramINFOID:0000000006213899

ACTIVE ADAPTIVE FRONT-LIGHTING SYSTEM : System DescriptionINFOID:0000000006213900

OUTLINE

AFS (ACTIVE ADAPTIVE FRONT-LIGHTING SY STEM) is controlled by AFS control unit.

AFS has AFS control (swivel control) and the headlamp auto aiming control.

- AFS control swivels the headlamp to the steering direction.

- Headlamp auto aiming control moves the headlamp light axis up/down according to the vehicle height.

AFS (ADAPTIVE FRONT-LIGHTING SYSTEM)

AFS Control Description

AFS control unit controls the headlamp (right) only when the steering wheel is turned rightward, and the

headlamp (left) only when the steering wheel is turned leftward.

AFS control unit detects the vehicle condition nec essary for AFS control with the following signals.

- AFS switch signal

- Vehicle speed signal (received from combination meter via CAN communication)

- Steering angle sensor signal (received from steering angle sensor via CAN communication)

- Shift position signal (received from TCM via CAN communication)

- Low beam status signal (received from IPDM E/R via CAN communication)

- Engine speed signal (received from ECM via CAN communication)

When the operation conditions are satisfied, AFS c ontrol unit controls the swivel angle depending on the

steering angle and the vehicle speed.

AFS operation condition- Swivel actuator initialization completed

- AFS “ON”(AFS OFF indicator lamp “OFF”)

- Headlamp ON

- While the engine running

- Selector lever position other than “P” or “R”

- Vehicle speed approximately 25 km/h (15.5 MPH) or more (Left swivel only; Right swivel activates regardless of the vehicle speed.)

Swivel Actuator Initialization

AFS control unit performs the swivel actuator in itialization when detecting that the engine starts.

JMLIA1077GB

Revision: 2010 May2011 QX56

Page 2726 of 5598

![INFINITI QX56 2011 Factory Repair Manual

EXL-16

< SYSTEM DESCRIPTION >[XENON TYPE]

SYSTEM

- Swivels the headlamp to the vehicle-center side until it hits the stopper.

- Returns the swivel angle from the stopper. Completes t

he initializatio INFINITI QX56 2011 Factory Repair Manual

EXL-16

< SYSTEM DESCRIPTION >[XENON TYPE]

SYSTEM

- Swivels the headlamp to the vehicle-center side until it hits the stopper.

- Returns the swivel angle from the stopper. Completes t

he initializatio](/img/42/57033/w960_57033-2725.png)

EXL-16

< SYSTEM DESCRIPTION >[XENON TYPE]

SYSTEM

- Swivels the headlamp to the vehicle-center side until it hits the stopper.

- Returns the swivel angle from the stopper. Completes t

he initialization with regarding the returned position

as the swivel angle 0 ° (straight-forward position).

Swivel Operation

AFS control unit transmits the drive signal to the sw ivel actuator when activation conditions are satisfied.

And swivels the headlamp.

- The swivel starts after steering approximately 20 ° or more from straight-forward position.

NOTE:

The steering angle differs between right turn and left turn.

- The swivel angle becomes the maximum angle toward t he driving direction if the steering angle is approxi-

mately 90 ° or more depending on the vehicle speed. The swivel angle is maintained by shutting off the drive

signal.

- The swivel starts, and returns to the swivel angle 0 ° (straight-forward position) when the steering is returned

to the straight-forward position.

AFS control unit returns the swivel angle to the strai ght-forward position, and stops the swivel regardless of

the steering angle if the operation condition is not satisfied while the swivel angle is 0°.

AFS OFF Indicator Lamp

AFS control unit transmits AFS OFF indicator lamp signal to the combination meter via CAN communication.

Combination meter turns AFS OFF indicator lamp ON /OFF/blinking according to AFS OFF indicator lamp

signal.

- AFS OFF indicator lamp is turned ON for 1 second for the AFS OFF indicator lamp bulb check when the igni-

tion switch is turned ON. AFS OFF indicator lamp is turned OFF within 1 second when the engine starts.

- AFS OFF indicator lamp turns ON when AFS is switched to “OFF” by operating AFS switch.

- AFS OFF indicator lamp blinks (1 second each) if AFS control unit detects a specific DTC.

NOTE:

Combination meter blinks AFS OFF indicator lamp (approximately 1 second each) if AFS OFF indicator

lamp signal is not received from AFS control unit.

HEADLAMP AUTO AIMING

Headlamp Auto Aiming Control Description

AFS control unit controls the headl amp light axis height appropriately according to the vehicle height.

AFS control unit detects the vehicle condition necessa ry for headlamp auto aiming control with the following

signals.

- Height sensor signals (front and rear)

- Vehicle speed signal (received from combination meter via CAN communication)

- Low beam status signal (received from IPDM E/R via CAN communication)

- Engine speed signal (received from ECM via CAN communication)

When the operation conditions are satisfied, AFS cont rol unit transmits the aiming motor drive signal for

adjusting the headlamp axis height.

Headlamp auto aiming operation condition- Headlamp ON

- While the engine running

- Vehicle speed (Control mode is switched according to the driving condition.)

Headlamp Auto Aiming Operation

AFS control unit calculates the vehicle pitch angle fr om the front and rear height sensor signal. AFS control

unit judges the angle for adjusting the axis gap from the preset position.

AFS control unit controls the headlamp axis by c hanging the aiming motor drive signal output according to

the front and rear vehicle height when detecting the follo wing vehicle condition. Output is maintained if other

condition than following is detected.

- Engine starts.

- Headlamp is turned ON.

- Vehicle posture becomes stable after changing the v ehicle posture change is detected with the headlamp

ON and the vehicle stopped.

- Vehicle speed is maintained with the headlamp ON and the vehicle driven.

CAUTION:

Adjusted axis position may differ from the preset position although the headlamp auto aiming acti-

vates properly if the suspension is replaced or worn.

Revision: 2010 May2011 QX56