engine oil INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2548 of 5598

![INFINITI QX56 2011 Factory Repair Manual

EC-524

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000006218028

SYSTEM — BASIC ENGINE CONTROL SYSTEM

SYMPTO INFINITI QX56 2011 Factory Repair Manual

EC-524

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000006218028

SYSTEM — BASIC ENGINE CONTROL SYSTEM

SYMPTO](/img/42/57033/w960_57033-2547.png)

EC-524

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

SYMPTOM DIAGNOSIS

ENGINE CONTROL SYSTEM SYMPTOMS

Symptom TableINFOID:0000000006218028

SYSTEM — BASIC ENGINE CONTROL SYSTEM

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Low pressure fuel pump circuit 11232 22 3 2 EC-512

Low fuel pressure sensor circuit 4 4EC-483

Fuel pressure regulator system 334444444 4EC-198

Fuel injector circuit 11232 22 2EC-498

Evaporative emission system 334444444 4EC-532

FRP sensor circuit 11222 22 2EC-276EC-279

High pressure fuel pump circuit 4 3

EC-501

Air Positive crankcase ventilation sys-

tem 334444444 41

EC-534

Incorrect idle speed adjustment 1 1 1 1 1 EC-139

Electric throttle control actuator 112332222 2 2EC-460EC-466

IgnitionIncorrect ignition timing adjustment33111 11 1

EC-139

Ignition circuit 11222 22 2EC-506

Main power supply and ground circuit 22333 33 23 EC-168

Revision: 2010 May2011 QX56

Page 2549 of 5598

![INFINITI QX56 2011 Factory Repair Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-525

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Mass air flow sensor circuit

1

12 2

222 2 EC-201

Engine coolant temperature sensor circuit

333

EC-2 INFINITI QX56 2011 Factory Repair Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-525

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Mass air flow sensor circuit

1

12 2

222 2 EC-201

Engine coolant temperature sensor circuit

333

EC-2](/img/42/57033/w960_57033-2548.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-525

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Mass air flow sensor circuit

1

12 2

222 2 EC-201

Engine coolant temperature sensor circuit

333

EC-217

Air fuel ratio (A/F) sensor 1 circuit EC-181

EC-228

EC-232

EC-235

EC-238

Throttle position sensor circuit

22EC-219

EC-288

EC-406

EC-407

EC-475

Accelerator pedal position sensor circuit 3 2 1

EC-468EC-471

EC-478

Knock sensor circuit 2 3

EC-297

Engine oil temperature sensor 4 2 3EC-285

Crankshaft position sensor circuit 2 2EC-299

Camshaft position sensor circuit 3 2EC-303

Vehicle speed signal circuit 2 3 3 3EC-356

Power steering pressure sensor circuit 2 3 3EC-371

ECM 22333333333EC-376EC-378

EC-380

Intake valve timing control solenoid valve cir-

cuit

32 13223 3

EC-193

VVEL control module 3 4 4 3 EC-451EC-452

VVEL actuator motor 3 4 4 3

EC-390

VVEL actuator motor relay 3 4 4 3EC-393

VVEL control shaft position sensor 3 4 4 3EC-387

PNP signal circuit 3 3 3 3 3EC-383

Refrigerant pressure sensor circuit 2 3 3 4EC-520

Electrical load signal circuit 3EC-493

Air conditioner circuit 223333333 3 2HAC-60

ABS actuator and electric unit (control unit) 4BRC-60

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: 2010 May2011 QX56

Page 2550 of 5598

![INFINITI QX56 2011 Factory Repair Manual

EC-526

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Manifold absolut INFINITI QX56 2011 Factory Repair Manual

EC-526

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Manifold absolut](/img/42/57033/w960_57033-2549.png)

EC-526

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.

(continued on next page)

SYSTEM — ENGINE MECHANICAL & OTHER

Manifold absolute pressure sensor circuit 3

EC-210

Battery current sensor 4 5 5 3EC-412EC-420

EC-424

Heated oxygen sensor 2 6 6 6 6 5EC-243EC-249

EC-257

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Fuel Fuel tank 5

5 FL-4

Fuel piping 555 55 5

FL-4

Vapor lock —

Valve deposit 5 555 55 5 —

Poor fuel (Heavy weight gasoline,

Low octane) —

Revision: 2010 May2011 QX56

Page 2551 of 5598

![INFINITI QX56 2011 Factory Repair Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-527

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Air Air duct

55555 5 EM-28

Air cleaner

EM-27

Air leakage from air duct

(Mass air flow sensor — el INFINITI QX56 2011 Factory Repair Manual

ENGINE CONTROL SYSTEM SYMPTOMSEC-527

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Air Air duct

55555 5 EM-28

Air cleaner

EM-27

Air leakage from air duct

(Mass air flow sensor — el](/img/42/57033/w960_57033-2550.png)

ENGINE CONTROL SYSTEM SYMPTOMSEC-527

< SYMPTOM DIAGNOSIS > [VK56VD]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Air Air duct

55555 5 EM-28

Air cleaner

EM-27

Air leakage from air duct

(Mass air flow sensor — electric

throttle control actuator)

5555 EM-28

Electric throttle control actuator

EC-460

Air leakage from intake manifold/

Collector/GasketEM-30

Cranking Battery

111111

11

PG-161

Generator circuit

CHG-13

Starter circuit 3STR-11

Signal plate 6EM-106

PNP signal 4EC-383

Engine Cylinder head

55555 55 5 EM-92

Cylinder head gasket 4 3

Cylinder block

66666 66 6 4

EM-115

Piston

Piston ring

Connecting rod

Bearing

Crankshaft

Va l v e

mecha-

nism Timing chain

55555 55 5 EM-72

Camshaft

EM-77

Intake valve timing controlEM-61

Intake valve

3EM-92

Exhaust valve

Exhaust Exhaust manifold/Tube/Muffler/ Gasket 55555 55 5 EM-42

EX-6Three way catalystSYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: 2010 May2011 QX56

Page 2552 of 5598

![INFINITI QX56 2011 Factory Repair Manual

E C -528

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Lubrica-

tion

Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil coole INFINITI QX56 2011 Factory Repair Manual

E C -528

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Lubrica-

tion

Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil coole](/img/42/57033/w960_57033-2551.png)

E C -528

< SYMPTOM DIAGNOSIS >[VK56VD]

ENGINE CONTROL SYSTEM SYMPTOMS

1 - 6: The numbers refer to the order of inspection.Lubrica-

tion

Oil pan/Oil strainer/Oil pump/Oil

filter/Oil gallery/Oil cooler 55555 55 5 EM-56

EM-60

LU-9

LU-12

LU-14

Oil level (Low)/Filthy oil

LU-7

Cooling

Radiator/Hose/Radiator filler cap

55555 55 45 CO-11

CO-11

Thermostat 5

CO-21

Water pumpCO-19

Water galleryEM-115

Cooling fan

5CO-17

Coolant level (Low)/Contaminat-

ed coolant

CO-8

IVIS (INFINITI Vehicle Immobilizer System —

NATS)11

SEC-48

SYMPTOM

Reference

page

HARD/NO START/RESTART (EXCP. HA)

ENGINE STALL

HESITATION/SURGING/FLAT SPOT

SPARK KNOCK/DETONATION

LACK OF POWER/POOR ACCELERATION

HIGH IDLE/LOW IDLE

ROUGH IDLE/HUNTING

IDLING VIBRATION

SLOW/NO RETURN TO IDLE

OVERHEATS/WATER TEMPERATURE HIGH

EXCESSIVE FUEL CONSUMPTION

EXCESSIVE OIL CONSUMPTION

BATTERY DEAD (UNDER CHARGE)

Warranty symptom code AA AB AC AD AE AF AG AH AJ AK AL AM HA

Revision: 2010 May2011 QX56

Page 2563 of 5598

EM-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EM

A

EM

N

O P

CONTENTS

ENGINE MECHANICAL

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Procedure without Cowl Top Cover ......3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Drain Engine Coolant and Engine

Oil ..............................................................................

4

Precaution for Disconnecting Fuel Piping .................4

Precaution for Handling High Pressure Fuel Sys-

tem ............................................................................

4

Precaution for Removal and Disassembly ................4

Precaution for Inspection, Repair and Replace-

ment ..........................................................................

4

Precaution for Assembly and Installation ..................4

Parts Requiring Angle Tightening .............................5

Precaution for Liquid Gasket .....................................5

Definitions of Bank Names ........................................6

PREPARATION ............................................7

PREPARATION .............................................. .....7

Special Service Tool ........................................... ......7

Commercial Service Tool ..........................................9

BASIC INSPECTION ...................................12

CAMSHAFT VALVE CLEARANCE ............... ....12

Inspection ............................................................ ....12

COMPRESSION PRESSURE ............................16

Inspection ............................................................ ....16

SYMPTOM DIAGNOSIS ..............................18

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

18

NVH Troubleshooting - Engine Noise .............. ....18

Use the Chart Below to Help You Find the C

ause of the Symptom ........................................ ....

19

PERIODIC MAINTENANCE ........................20

DRIVE BELTS ...................................................20

Exploded View ..................................................... ....20

Checking ..................................................................20

Tension Adjustment ................................................20

Removal and Installation .........................................20

Inspection ................................................................21

AIR CLEANER FILTER .....................................22

Exploded View .........................................................22

Removal and Installation .........................................22

SPARK PLUG ...................................................23

Exploded View .........................................................23

Removal and Installation .........................................23

Inspection ................................................................24

REMOVAL AND INSTALLATION ...............25

ENGINE COVER ...............................................25

Exploded View ..................................................... ....25

Removal and Installation .........................................25

DRIVE BELT AUTO TENSIONER AND IDLER

PULLEY .............................................................

26

Exploded View .........................................................26

Removal and Installation .........................................26

AIR CLEANER AND AIR DUCT .......................27

Exploded View .........................................................27

Removal and Installation .........................................27

Inspection ................................................................28

IGNITION COIL .................................................29

Exploded View .........................................................29

Removal and Installation .........................................29

INTAKE MANIFOLD .........................................30

Exploded View .........................................................30

Revision: 2010 May2011 QX56

Page 2564 of 5598

EM-2

Removal and Installation ........................................30

ROCKER COVER ..............................................33

Exploded View ..................................................... ...33

Removal and Installation ........................................33

VVEL ACTUATOR ASSEMBLY ........................36

Exploded View ..................................................... ...36

Removal and Installation ........................................36

Inspection ...............................................................39

EXHAUST MANIFOLD AND THREE WAY

CATALYST ........................................................

40

Exploded View ..................................................... ...40

Removal and Installation ........................................40

Inspection ...............................................................42

HIGH PRESSURE FUEL PUMP AND FUEL

HOSE .................................................................

43

Exploded View ..................................................... ...43

Removal and Installation ........................................43

Inspection ...............................................................46

FUEL INJECTOR AND FUEL TUBE .................48

Exploded View ..................................................... ...48

Removal and Installation ........................................49

Inspection ...............................................................53

OIL PAN (LOWER) AND OIL STRAINER .........54

Exploded View ..................................................... ...54

Removal and Installation ........................................55

Inspection ...............................................................56

OIL PAN (UPPER) .......................................... ...57

Exploded View ..................................................... ...57

Removal and Installation ........................................58

Inspection ...............................................................60

TIMING CHAIN ............................................... ...61

Exploded View ..................................................... ...61

Removal and Installation ........................................62

Inspection ...............................................................72

CAMSHAFT .......................................................74

Exploded View ..................................................... ...74

Removal and Installation ........................................75

Inspection ...............................................................77

CYLINDER HEAD ..............................................86

Exploded View ..................................................... ...86

Removal and Installation ........................................87

Disassembly and Assembly ....................................89

Inspection ............................................................. ...92

OIL SEAL ...........................................................96

FRONT OIL SEAL .................................................. ...96

FRONT OIL SEAL : Removal and Installation ........96

REAR OIL SEAL .................................................... ...96

REAR OIL SEAL : Removal and Installation ...........97

UNIT REMOVAL AND INSTALLATION ....98

ENGINE ASSEMBL Y ..................................... ...98

Exploded View ..................................................... ...98

Removal and Installation .........................................99

Inspection ..............................................................102

UNIT DISASSEMBLY AND ASSEMBLY ..103

ENGINE STAND SETTING ..............................103

Setting .................................................................. .103

ENGINE UNIT ...................................................105

Disassembly ......................................................... .105

Assembly ..............................................................105

CYLINDER BLOCK ..........................................106

Exploded View ..................................................... .106

Disassembly and Assembly ..................................107

Inspection ..............................................................115

HOW TO SELECT PISTON AND BEARING ...125

Description ........................................................... .125

Piston ....................................................................125

Connecting Rod Bearing .....................................126

Main Bearing ........................................................128

SERVICE DATA AND SPECIFICATIONS

(SDS) ........ .................................................

132

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

132

General Specification .......................................... .132

Drive Belts .............................................................132

Spark Plug ............................................................132

Exhaust Manifold ..................................................133

Camshaft ...............................................................133

Cylinder Head ......................................................135

Cylinder Block ......................................................137

Main Bearing ........................................................141

Connecting Rod Bearing .....................................142

Revision: 2010 May2011 QX56

Page 2566 of 5598

EM-4

< PRECAUTION >

PRECAUTIONS

If turning the steering wheel is required with the battery disconnected or discharged, follow the operation pro-

cedure below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position. (At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock wi ll remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect bot h battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button igniti on switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precaution for Drain Engine Coolant and Engine OilINFOID:0000000006289509

Drain engine coolant and engine oil when engine is cooled.

Precaution for Disconnecting Fuel PipingINFOID:0000000006289510

Before starting work, check no fire or sp ark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precaution for Handling High Pressure Fuel SystemINFOID:0000000006289511

High pressure fuel system components are betw een high pressure fuel pump and fuel injector.

Always release fuel pressure and never start the engine when performing removal and installation.

When removing or installing parts without releasing fuel pressure, fuel may be splashed and, if fuel contacts

skin or eyes, it may cause inflammation.

Precaution for Removal and DisassemblyINFOID:0000000006289512

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Cover openings of engine system with tape or the equival ent, if necessary, to seal out foreign materials.

Mark and arrange disassembly parts in an organi zed way for easy troubleshooting and assembly.

When loosening nuts and bolts, as a basic rule, star t with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be used

where noted in the step.

Precaution for Inspection, Repair and ReplacementINFOID:0000000006289513

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precaution for Assembly and InstallationINFOID:0000000006289514

Use torque wrench to tighten bolts or nuts to specification.

When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified,

do exactly as specified.

Replace with new gasket, packing, oil seal or O-ring.

Thoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

Dowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

check that dowel pins are installed in the original position.

Revision: 2010 May2011 QX56

Page 2567 of 5598

PRECAUTIONSEM-5

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Avoid damaging sliding or mating surfaces. Completely re

move foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

Release air within route when refilling after draining engine coolant.

After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

Parts Requiring Angle TighteningINFOID:0000000006289515

Use angle wrench [SST: KV10112100 (BT8653-A)] for the final tightening of the following engine parts:

- Cylinder head bolts

- Main bearing cap bolts

- Main bearing cap sub bolts

- Connecting rod cap bolts

- Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angletightening)

Ensure thread and seat surfaces are clean and coated with engine oil.

Precaution for Liquid GasketINFOID:0000000006289516

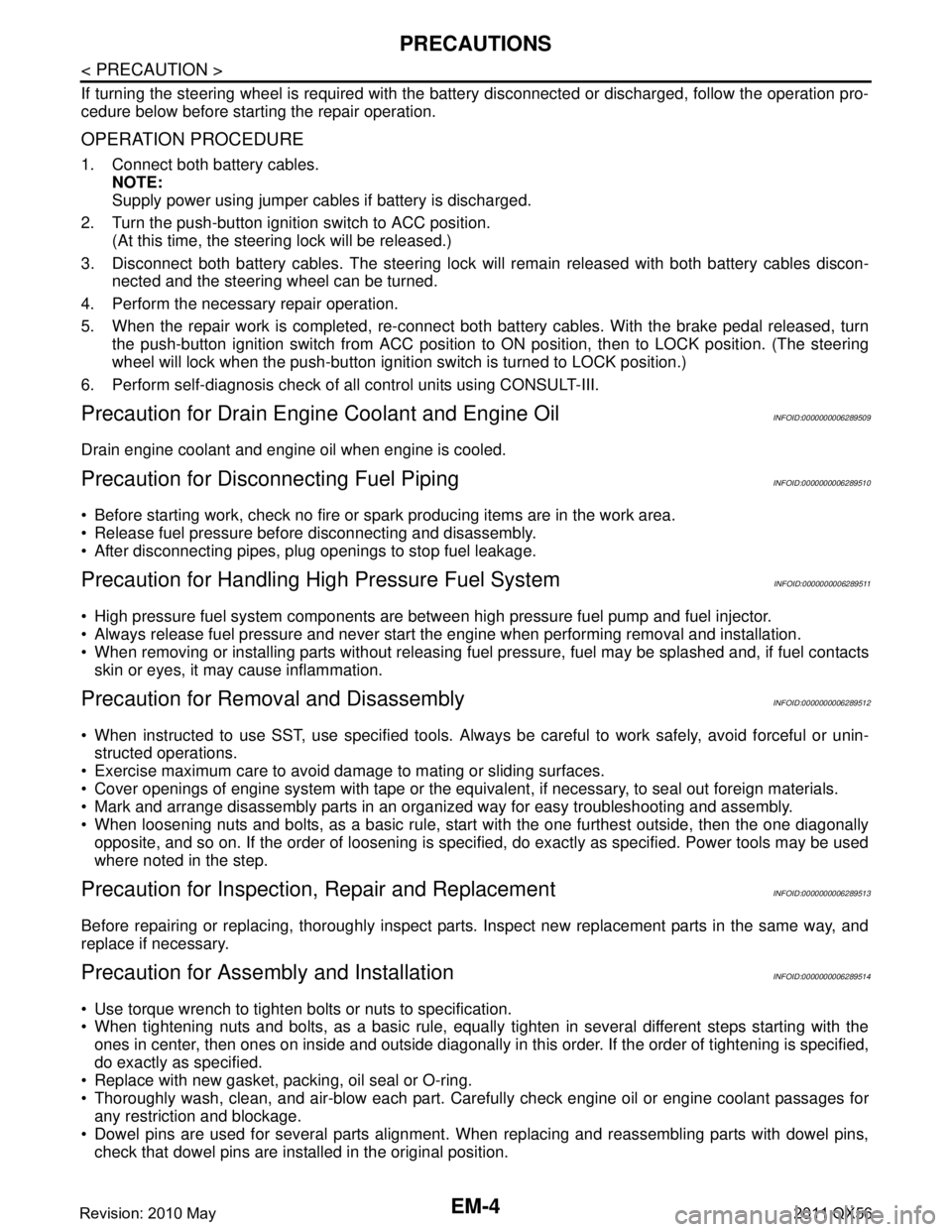

REMOVAL OF LIQUID GASKET SEALING

After removing mounting nuts and bolts, separate the mating sur- face using the seal cutter [SST:KV10111100 (J-37228)] (A) and

remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

Tap the seal cutter to insert it (B), and then slide it (C) by tapping on the side as shown in the figure.

In areas where the seal cutter is difficult to use, lightly tap the parts using a plastic hammer to remove it.

CAUTION:

If for some unavoidable reason a tool such as a screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

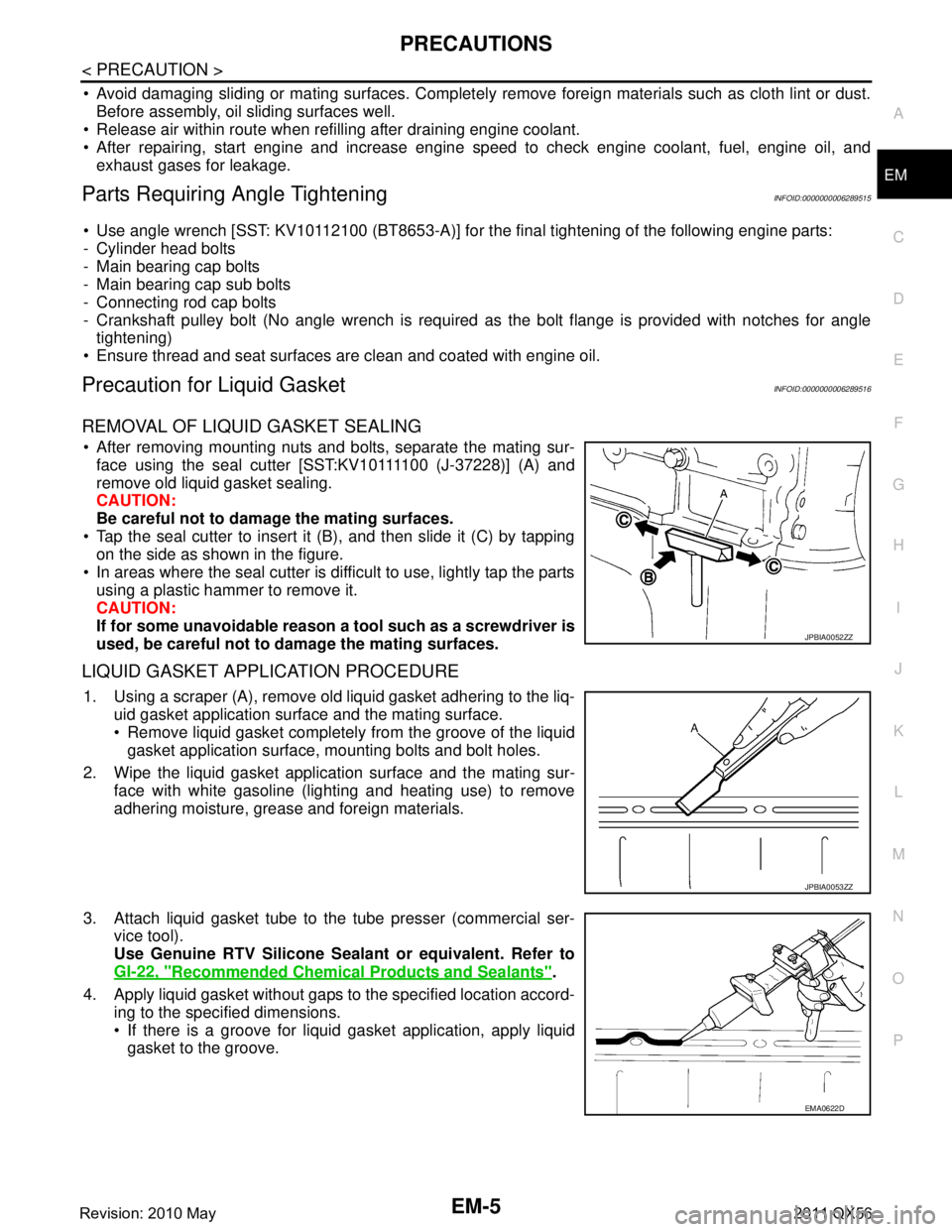

1. Using a scraper (A), remove old liquid gasket adhering to the liq- uid gasket application surface and the mating surface.

Remove liquid gasket completely from the groove of the liquidgasket application surface, mounting bolts and bolt holes.

2. Wipe the liquid gasket application surface and the mating sur- face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to the tube presser (commercial ser- vice tool).

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-22, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without gaps to the specified location accord- ing to the specified dimensions.

If there is a groove for liquid gasket application, apply liquidgasket to the groove.

JPBIA0052ZZ

JPBIA0053ZZ

EMA0622D

Revision: 2010 May2011 QX56

Page 2568 of 5598

EM-6

< PRECAUTION >

PRECAUTIONS

As for bolt holes (B), normally apply liquid gasket inside theholes. Occasionally, it should be applied outside the holes.

Check to read the text of this manual.

Within 5 minutes of liquid gasket application, install the mating component.

If liquid gasket protrudes, wipe it off immediately.

Do not retighten mounting bolts or nuts after the installation.

After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

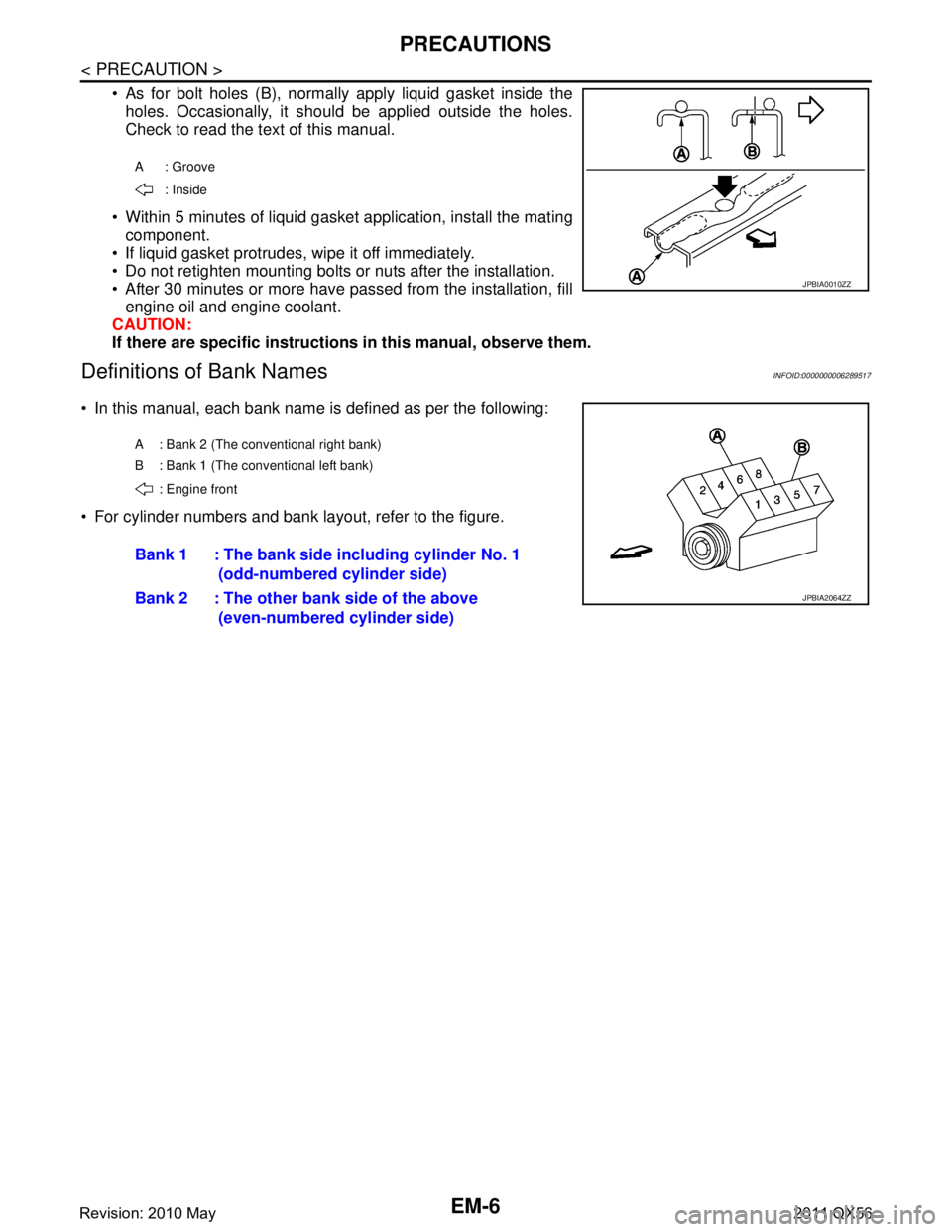

Definitions of Bank NamesINFOID:0000000006289517

In this manual, each bank name is defined as per the following:

For cylinder numbers and bank layout, refer to the figure.

A: Groove

: Inside

JPBIA0010ZZ

A : Bank 2 (The conventional right bank)

B : Bank 1 (The conventional left bank)

: Engine front

Bank 1 : The bank side including cylinder No. 1 (odd-numbered cylinder side)

Bank 2 : The other bank side of the above (even-numbered cylinder side)

JPBIA2064ZZ

Revision: 2010 May2011 QX56