maintenance INFINITI QX56 2011 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2582 of 5598

EM-20

< PERIODIC MAINTENANCE >

DRIVE BELTS

PERIODIC MAINTENANCE

DRIVE BELTS

Exploded ViewINFOID:0000000006289524

CheckingINFOID:0000000006289525

WARNING:

Be sure to perform the these steps when engine is stopped.

Check that the indicator (C) (notch on fixed side) of each auto-tensioner is within the possible use range (A).

NOTE:

Check the each auto-tensioners indication when the engine is cold.

When new drive belts is installed, the indicator (notch on fixed side) should be within the range (B) in the\

figure.

Visually check all drive belts for wear, damage or cracks.

If the indicator (notch on fixed side) is out of the possible use range or drive belts are damaged, replace drive

belts.

Tension AdjustmentINFOID:0000000006289526

Refer to EM-132, "Drive Belts".

Removal and InstallationINFOID:0000000006289527

REMOVAL

1. Move reservoir tank to the position without the hindrance for work. Refer to CO-13, "Exploded View".

1. Drive belt 2. Power steering oil pump pulley 3. Alternator pulley

4. Crankshaft pulley 5. A/C compressor 6. Idler pulley

7. Cooling fan pulley 8. Water pump pulley 9. Drive belt auto-tensioner

A. Possible use range B. Range when new drive belt is in-

stalledC. Indicator

D. View D

JPBIA3264ZZ

Revision: 2010 May2011 QX56

Page 2583 of 5598

DRIVE BELTSEM-21

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

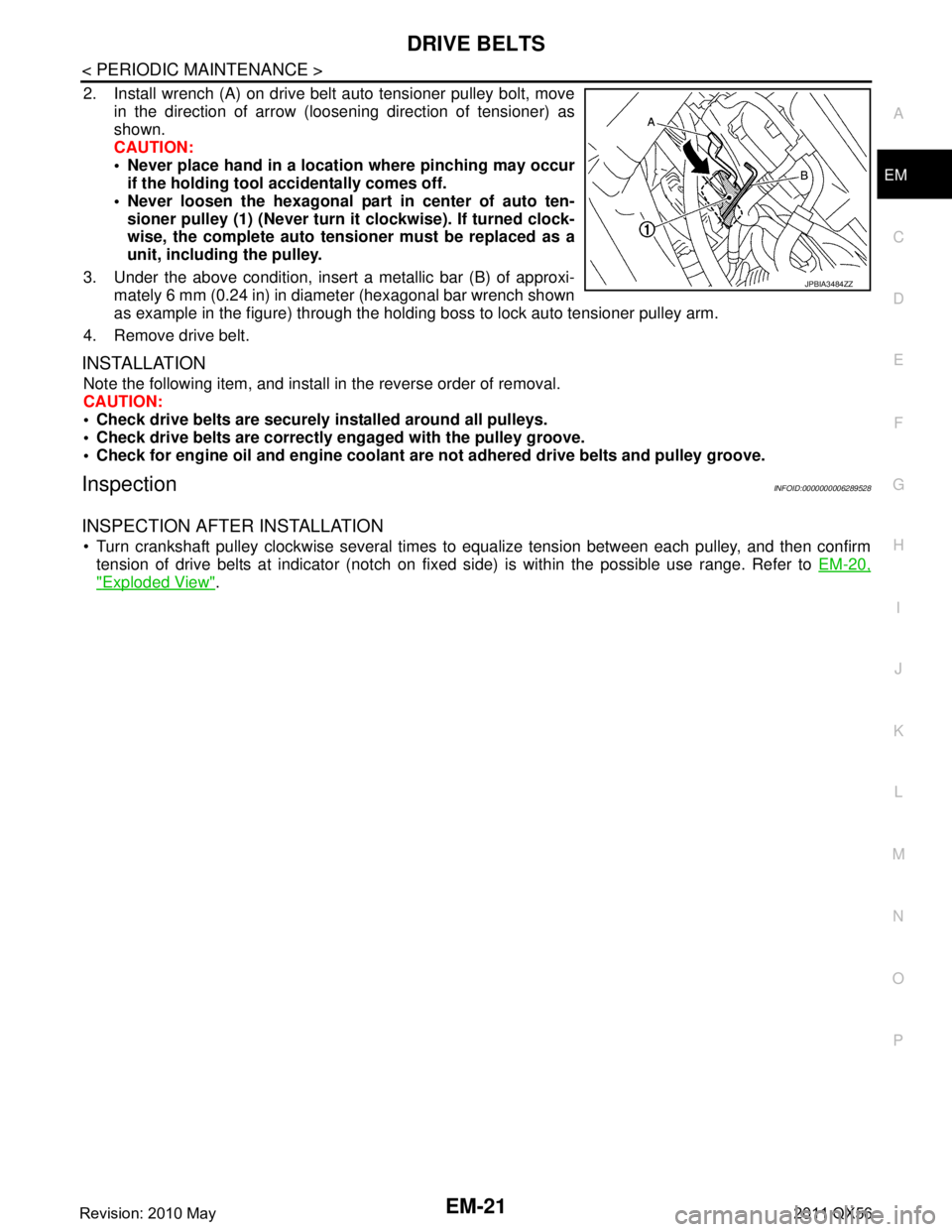

2. Install wrench (A) on drive belt auto tensioner pulley bolt, move

in the direction of arrow (loosening direction of tensioner) as

shown.

CAUTION:

Never place hand in a location where pinching may occurif the holding tool accidentally comes off.

Never loosen the hexagonal part in center of auto ten- sioner pulley (1) (Never turn it clockwise). If turned clock-

wise, the complete auto tensioner must be replaced as a

unit, including the pulley.

3. Under the above condition, insert a metallic bar (B) of approxi- mately 6 mm (0.24 in) in diameter (hexagonal bar wrench shown

as example in the figure) through the holding boss to lock auto tensioner pulley arm.

4. Remove drive belt.

INSTALLATION

Note the following item, and install in the reverse order of removal.

CAUTION:

Check drive belts are securely installed around all pulleys.

Check drive belts are correctly engaged with the pulley groove.

Check for engine oil and engine coolant ar e not adhered drive belts and pulley groove.

InspectionINFOID:0000000006289528

INSPECTION AFTER INSTALLATION

Turn crankshaft pulley clockwise several times to equalize tension between each pulley, and then confirm

tension of drive belts at indicator (notch on fixed side) is within the possible use range. Refer to EM-20,

"Exploded View".

JPBIA3484ZZ

Revision: 2010 May2011 QX56

Page 2584 of 5598

EM-22

< PERIODIC MAINTENANCE >

AIR CLEANER FILTER

AIR CLEANER FILTER

Exploded ViewINFOID:0000000006289529

Removal and InstallationINFOID:0000000006289530

REMOVAL

NOTE:

The viscous paper type filter does not need cleaning between replacement intervals.

Replace the air filter as necessary for periodic maintenance. Refer to MA-6, "

Introduction of Periodic Mainte-

nance".

1. Unhook clips, and lift air cleaner case (upper).

2. Remove air cleaner filter from air cleaner case.

INSTALLATION

Install is the reverse order of removal.

1. Resonator 2. Adapter 3. Air cleaner case (lower)

4. Air cleaner filter 5. Air cleaner case (upper) 6. Mass air flow sensor

7. Air duct 8. Clamp

Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3260GB

Revision: 2010 May2011 QX56

Page 2585 of 5598

SPARK PLUGEM-23

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

SPARK PLUG

Exploded ViewINFOID:0000000006289531

Removal and InstallationINFOID:0000000006289532

REMOVAL

1. Remove engine cover. Refer to

EM-25, "Exploded View".

2. Remove ignition coil. Refer to EM-29, "

Exploded View".

3. Remove spark plug with a spark plug wrench (commercial ser- vice tool).

INSTALLATION

Note the following item, installa is the reverse order of removal.

CAUTION:

1. Ignition coil (No. 2, 4) 2. Ignition coil (No. 6, 8) 3. Spark plug

4. Rocker cover (bank 2) 5. Rocker cover (bank 1) 6. Ignition coil (No. 1, 3)

7. Ignition coil (No. 5, 7)

Refer to GI-4, "

Components" for symbols in the figure.

JSBIA0388GB

a : 14 mm (0.55 in)

JPBIA0030ZZ

Revision: 2010 May2011 QX56

Page 2586 of 5598

EM-24

< PERIODIC MAINTENANCE >

SPARK PLUG

Install ignition coil marked with an identification mark (A) on

cylinder No. 5, 6, 7 and 8.

InspectionINFOID:0000000006289533

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

Never drop or impact spark plug.

Never use a wire brush for cleaning.

If plug tip is covered with carbon, use spark plug cleaner to clean.

Measure spark plug gap. When it exceeds the limit, replace spark plug even if it is within the speci-

fied replacement mileage. Refer to EM-132, "

Spark Plug".

Spark plug gap adjustment is not required between replace-

ment intervals.

: Engine front

JPBIA3471ZZ

Spark plug (Standard type) : Refer to EM-132, "Spark Plug".

Cleaner air pressure : Less than 588 kPa (5.9 bar, 6 kg/cm

2, 85 psi)

Cleaning time : Less than 20 seconds

SMA773C

JPBIA0031ZZ

Revision: 2010 May2011 QX56

Page 2705 of 5598

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Removal and Installation ..................................... ......2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE .........................4

EXHAUST SYSTEM ...........................................4

Inspection ............................................................ .....4

REMOVAL AND INSTALLATION ................5

EXHAUST SYSTEM ...........................................5

Exploded View ..................................................... .....5

Removal and Installation ..........................................5

Inspection .................................................................6

Revision: 2010 May2011 QX56

Page 2708 of 5598

EX-4

< PERIODIC MAINTENANCE >

EXHAUST SYSTEM

PERIODIC MAINTENANCE

EXHAUST SYSTEM

InspectionINFOID:0000000006289694

Check exhaust pipes, muffler and mounting for improper attachment,

leakage, cracks, damage or deterioration.

• If damage is found, repair or replace damaged parts.

SMA211A

Revision: 2010 May2011 QX56

Page 2713 of 5598

EXL-3

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

EXTERIOR LAMP FUSE ................................ ....85

Diagnosis Procedure ........................................... ....85

HEADLAMP (HI) CIRCUIT .................................86

Component Function Check ................................ ....86

Diagnosis Procedure ...............................................86

HEADLAMP (LO) CIRCUIT ................................88

Component Function Check ................................ ....88

Diagnosis Procedure ...............................................88

XENON HEADLAMP ..........................................90

Diagnosis Procedure ........................................... ....90

HEADLAMP LEVELIZER CIRCUIT ...................91

Component Function Check ................................ ....91

Diagnosis Procedure ...............................................91

HEADLAMP AIMING SYSTEM (MANUAL) .......93

Component Inspection ........................................ ....93

FRONT FOG LAMP CIRCUIT ............................94

Component Function Check ................................ ....94

Diagnosis Procedure ...............................................94

PARKING LAMP CIRCUIT ............................. ....96

Component Function Check ................................ ....96

Diagnosis Procedure ...............................................96

FRONT SIDE MARKER LAMP CIRCUIT ...........98

Component Function Check ................................ ....98

Diagnosis Procedure ...............................................98

TURN SIGNAL LAMP CIRCUIT .........................99

Component Function Check ................................ ....99

Diagnosis Procedure ...............................................99

OPTICAL SENSOR ..........................................102

Component Function Check ................................ ..102

Diagnosis Procedure .............................................102

HAZARD SWITCH .......................................... ..105

Component Function Check ................................ ..105

Diagnosis Procedure .............................................105

AFS SWITCH ....................................................107

Component Function Check ................................ ..107

Diagnosis Procedure .............................................107

Component Inspection ..........................................108

TAIL LAMP CIRCUIT .......................................109

BODY SIDE ........................................................... ..109

BODY SIDE : Component Function Check ...........109

BODY SIDE : Diagnosis Procedure ......................109

BACK DOOR SIDE ................................................ ..110

BACK DOOR SIDE : Component Function Check ..110

BACK DOOR SIDE : Diagnosis Procedure ...........111

LICENSE PLATE LAMP CIRCUIT ...................112

Component Function Check ................................ ..112

Diagnosis Procedure .............................................112

SYMPTOM DIAGNOSIS ............................113

EXTERIOR LIGHTING SYSTEM SYMPTOMS .113

Symptom Table ................................................... ..113

NORMAL OPERATING CONDITION .............116

Description .............................................................116

BOTH SIDE HEADLAMPS DO NOT SWITCH

TO HIGH BEAM ..............................................

117

Description .............................................................117

Diagnosis Procedure .............................................117

BOTH SIDE HEADLAMPS (LO) ARE NOT

TURNED ON ...................................................

118

Description ........................................................... ..118

Diagnosis Procedure .............................................118

PARKING, LICENSE PLATE, SIDE MARKER

AND TAIL LAMPS ARE NOT TURNED ON ...

119

Description .............................................................119

Diagnosis Procedure .............................................119

BOTH SIDE FRONT FOG LAMPS ARE NOT

TURNED ON ...................................................

120

Description ........................................................... ..120

Diagnosis Procedure .............................................120

PERIODIC MAINTENANCE ......................121

HEADLAMP AIMING ADJUSTMENT .............121

description ........................................................... ..121

Aiming Adjustment Procedure ...............................122

FRONT FOG LAMP AIMING ADJUSTMENT .123

Description .............................................................123

Aiming Adjustment Procedure ...............................123

REMOVAL AND INSTALLATION .............125

FRONT COMBINATION LAMP ......................125

Exploded View ..................................................... ..125

Removal and Installation .......................................125

Replacement .........................................................126

Disassembly and Assembly ...................................127

FRONT FOG LAMP ........................................128

Exploded View .......................................................128

Removal and Installation .......................................128

Replacement .........................................................128

SIDE TURN SIGNAL LAMP ............................130

Exploded View .......................................................130

Removal and Installation .......................................130

OPTICAL SENSOR .........................................131

Exploded View .......................................................131

Removal and Installation .......................................131

LIGHTING & TURN SIGNAL SWITCH ...........132

Exploded View .......................................................132

Revision: 2010 May2011 QX56

Page 2715 of 5598

![INFINITI QX56 2011 Factory Repair Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO INFINITI QX56 2011 Factory Repair Manual

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFO](/img/42/57033/w960_57033-2714.png)

PRECAUTIONSEXL-5

< PRECAUTION > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006450052

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SRS AIR BAG” and “SEAT BELT” of this

Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision that would result in air ba g inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIR BAG”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

When working near the Air Bag Diagnosis Sensor Unit or other Air Bag System sensors with the

ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s)

with a hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly

causing serious injury.

When using air or electric power tools or hammers , always switch the ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Revision: 2010 May2011 QX56

Page 2831 of 5598

![INFINITI QX56 2011 Factory Repair Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio INFINITI QX56 2011 Factory Repair Manual

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

preparatio](/img/42/57033/w960_57033-2830.png)

HEADLAMP AIMING ADJUSTMENTEXL-121

< PERIODIC MAINTENANCE > [XENON TYPE]

C

D

E

F

G H

I

J

K

M A

B

EXL

N

O P

PERIODIC MAINTENANCE

HEADLAMP AIMING ADJUSTMENT

descriptionINFOID:0000000006213990

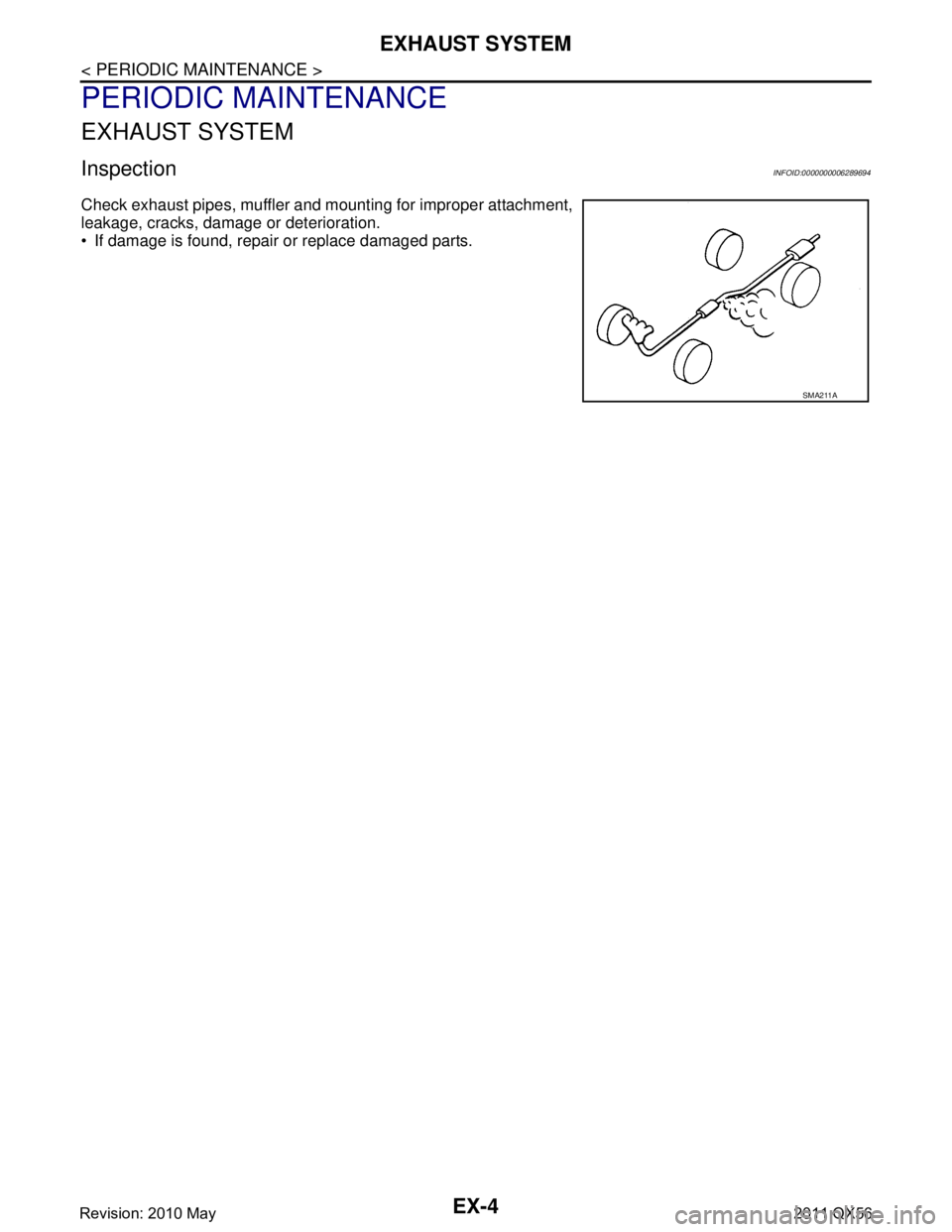

preparation before adjusting

NOTE:

for details, refer to the regulations in your own country.

perform aiming if the vehicle front body has been repaired and/or the headlamp assembly has been

replaced.

before performing aiming adjustment, check the following. adjust the tire pressure to the specification.

fill with fuel, engine coolant and each oil.

maintain the unloaded vehicle condition. (remove luggage from the passenger compartment and the lug- gage room.)

NOTE:

do not remove the temporary tire, jack and on-vehicle tool.

wipe out dirt on the headlamp.

CAUTION:

never use organic solvent (thinner, gasoline etc.)

ride alone on the driver seat.

aiming adjustment screw

JMLIA1319ZZ

A. Headlamp RH HI /LO (UP/DOWN)

adjustment screw B. Headlamp LH HI/LO (UP/DOWN)

adjustment screw

: Vehicle center

Revision: 2010 May2011 QX56