turn signal INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 4995 of 5598

ST-8

< SYSTEM DESCRIPTION >

COMPONENT PARTS

Furthermore, the heated steering wheel incorporates a heating element and a thermostat to control heated

steering wheel temperatures.

Heating element: Heat is generated by the passage of an electric current.

Thermostat: ON/OFF operation of power supply at a certain temperature.

Heated Steering Wheel SwitchINFOID:0000000006225579

Controls the heated steering wheel relay and operates the heated steering wheel system.

The heated steering wheel switch incorporates a ti mer and turns OFF the heated steering wheel relay when

operating time reaches a certain time.

- Timer: ON/OFF operation of the heated st eering wheel relay at a certain time.

Turns the indicator lamp ON when the system is activated.

Heated Steering Wheel RelayINFOID:0000000006225580

Operates the heated steering system with the control signal from the heated steering wheel switch.

Revision: 2010 May2011 QX56

Page 5046 of 5598

STC-1

STEERING

C

DE

F

H I

J

K L

M

SECTION STC

A

B

STC

N

O P

CONTENTS

STEERING CONTROL SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

2

SYSTEM DESCRIPTION ..............................4

COMPONENT PARTS ................................... .....4

Component Parts Location .................................. ......4

Component Description .............................................4

Power Steering Control Unit ......................................4

Power Steering Solenoid Valve .................................4

SYSTEM ..............................................................5

EPS SYSTEM ........................................ ......................5

EPS SYSTEM : System De scription .........................5

EPS SYSTEM : Fail-Safe ..........................................6

ECU DIAGNOSIS INFO RMATION ...............8

POWER STEERING CONTROL UNIT ........... .....8

Reference Value ................................................. ......8

Fail-Safe ....................................................................9

WIRING DIAGRAM ......................................10

ELECTRONICALLY CONTROLLED POWER

STEERING SYSTEM ...................................... ....

10

Wiring Diagram ................................................... ....10

BASIC INSPECTION ...................................13

DIAGNOSIS AND REPAIR WORK FLOW .......13

Work Flow ............................................................ ....13

DTC/CIRCUIT DIAGNOSIS .........................14

POWER SUPPLY AND GROUND CIRCUIT ....14

Diagnosis Procedure ........................................... ....14

POWER STEERING SOLENOID VALVE .........16

Component Function Check ....................................16

Diagnosis Procedure ...............................................16

Component Inspection .............................................17

ENGINE SPEED SIGNAL CIRCUIT ..................18

Diagnosis Procedure ........................................... ....18

VEHICLE SPEED SIGNAL CIRCUIT ................20

Diagnosis Procedure ...............................................20

SYMPTOM DIAGNOSIS ..............................22

UNBALANCE STEERING WHEEL TURNING

FORCE (TORQUE VARIATION) .......................

22

Description ........................................................... ....22

Diagnosis Procedure ...............................................22

REMOVAL AND INSTALLATION ...............23

POWER STEERING CONTROL UNIT ..............23

Removal and Installation ..................................... ....23

Revision: 2010 May2011 QX56

Page 5051 of 5598

STC-6

< SYSTEM DESCRIPTION >

SYSTEM

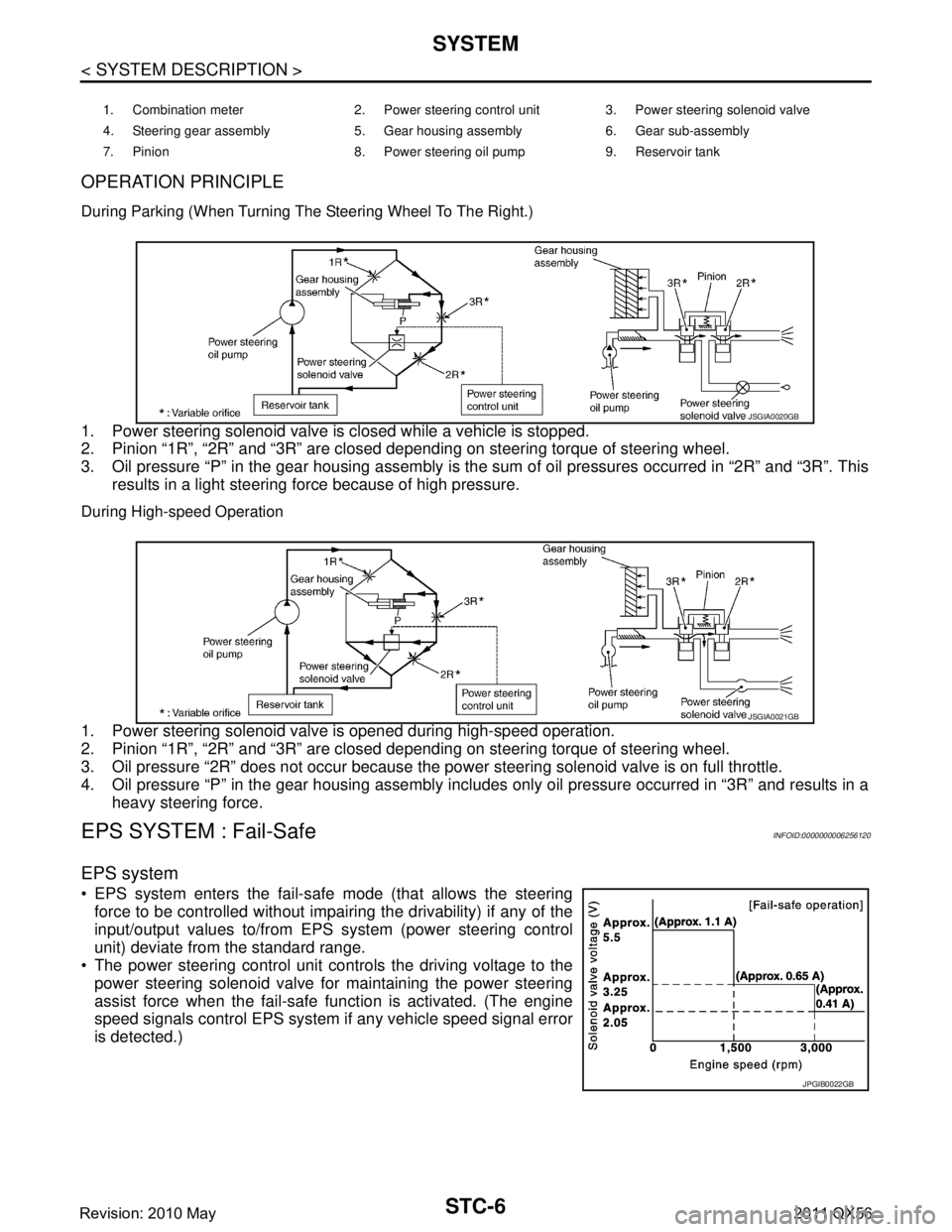

OPERATION PRINCIPLE

During Parking (When Turning The Steering Wheel To The Right.)

1. Power steering solenoid valve is closed while a vehicle is stopped.

2. Pinion “1R”, “2R” and “3R” are closed depending on steering torque of steering wheel.

3. Oil pressure “P” in the gear housing assembly is the sum of oil pressures occurred in “2R” and “3R”. Thisresults in a light steering force because of high pressure.

During High-speed Operation

1. Power steering solenoid valve is opened during high-speed operation.

2. Pinion “1R”, “2R” and “3R” are closed depending on steering torque of steering wheel.

3. Oil pressure “2R” does not occur because the pow er steering solenoid valve is on full throttle.

4. Oil pressure “P” in the gear housing assembly includes only oil pressure occurred in “3R” and results in a heavy steering force.

EPS SYSTEM : Fail-Safe INFOID:0000000006256120

EPS system

EPS system enters the fail-safe mode (that allows the steering

force to be controlled without impairi ng the drivability) if any of the

input/output values to/from EPS system (power steering control

unit) deviate from the standard range.

The power steering control unit controls the driving voltage to the

power steering solenoid valve for maintaining the power steering

assist force when the fail-safe function is activated. (The engine

speed signals control EPS system if any vehicle speed signal error

is detected.)

1. Combination meter 2. Power steering control unit 3. Power steering solenoid valve

4. Steering gear assembly 5. Gear housing assembly 6. Gear sub-assembly

7. Pinion 8. Power steering oil pump 9. Reservoir tank

JSGIA0020GB

JSGIA0021GB

JPGIB0022GB

Revision: 2010 May2011 QX56

Page 5052 of 5598

SYSTEMSTC-7

< SYSTEM DESCRIPTION >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

Error area and root cause Cancel condition

Engine speed is 1,500 rpm or more and there is no vehicle speed signal input for

over 10 seconds during vehicle travel. When a vehicle speed signal of 2 km/h (1.2

MPH) or more is inputted.

Ignition switch is turned OFF to ON.

Vehicle speed signal has abruptly dropped from 30 km/h (19 MPH) or more to 2

km/h (1.2 MPH) or less within 1.4 seconds.

Revision: 2010 May2011 QX56

Page 5054 of 5598

POWER STEERING CONTROL UNITSTC-9

< ECU DIAGNOSIS INFORMATION >

C

DE

F

H I

J

K L

M A

B

STC

N

O PCAUTION:

When using circuit tester or osci lloscope to measure voltage for in spection, be sure not to forcibly

extend any connector terminals.

Fail-Safe INFOID:0000000006256122

EPS system

EPS system enters the fail-safe mode (that allows the steering

force to be controlled without impair ing the drivability) if any of the

input/output values to/from EPS system (power steering control

unit) deviate from the standard range.

The power steering control unit controls the driving voltage to the

power steering solenoid valve for maintaining the power steering

assist force when the fail-safe function is activated. (The engine

speed signals control EPS system if any vehicle speed signal error

is detected.)

10

(B/SB) Ground Engine speed signal Input Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000

rpm

Te r m i n a l N o .

(Wire color) Description

Condition Value (Approx.)

+ - Signal name Input/

OutputJPBIA3352ZZ

JPBIA3354ZZ

JPGIB0022GB

Error area and root cause Cancel condition

Engine speed is 1,500 rpm or more and there is no vehicle speed signal input for

over 10 seconds during vehicle travel. When a vehicle speed signal of 2 km/h (1.2

MPH) or more is inputted.

Ignition switch is turned OFF to ON.

Vehicle speed signal has abruptly dropped from 30 km/h (19 MPH) or more to 2

km/h (1.2 MPH) or less within 1.4 seconds.

Revision: 2010 May2011 QX56

Page 5061 of 5598

STC-16

< DTC/CIRCUIT DIAGNOSIS >

POWER STEERING SOLENOID VALVE

POWER STEERING SOLENOID VALVE

Component Function CheckINFOID:0000000006256126

1.CHECK POWER STEERING SOLENOID VALVE OPERATION

Check changes in steering force from a halt condition to high-speed driving.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Check the power steering solenoid valve. Refer to STC-16, "

Diagnosis Procedure".

Diagnosis Procedure INFOID:0000000006256127

1.CHECK POWER STEERING SOLENOID VALVE SIGNAL

1. Turn the ignition switch OFF.

2. Check the voltage between power steering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN POWER STEERING SO LENOID VALVE AND POWER STEERING CON-

TROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect power steering solenoid valve harness connector.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between power steering solenoid valve harness connector and the power steering

control unit harness connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK POWER STEERING SOLENOID VALVE

Check the power steering solenoid valve. Refer to STC-17, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace gear-sub assembly. Refer to ST-43, "

Disassembly and Assembly".

Power steering control unit

— Condition Voltage (Approx.)

Connector Terminal

M108 1 Ground Vehicle speed: 0 km/h (0 MPH)

(Engine is running)

4.4 – 6.6 V

Vehicle speed: 100 km/h (62 MPH) 2.4 – 3.6 V

Power steering solenoid valve Power steering control unit Continuity

Connector Terminal Connector Terminal

F45 1

M108 1 Existed

25Existed

Power steering control unit — Continuity

Connector Terminal

M108 1

Ground Not existed

5

Revision: 2010 May2011 QX56

Page 5063 of 5598

STC-18

< DTC/CIRCUIT DIAGNOSIS >

ENGINE SPEED SIGNAL CIRCUIT

ENGINE SPEED SIGNAL CIRCUIT

Diagnosis ProcedureINFOID:0000000006256129

1.PERFORM ECM SELF-DIAGNOSIS

With CONSULT-III

Perform “ENGINE” self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to EC-98, "DTC Index".

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN ECM AND POWER STEERING CONTROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect ECM harness connectors.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between ECM harness connecto r and power steering control unit harness connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK ENGINE SPEED SIGNAL (ECM)

1. Connect ECM harness connectors.

2. Check the signal between ECM harness connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace ECM. Refer to EC-143, "

Description".

ECM Power steering control unit

Continuity

Connector Terminal Connector Terminal

E80 169 M108 10 Existed

Power steering control unit — Continuity

Connector Terminal

M108 10 Ground Not existed

ECM — Condition Voltage (Approx.)

Connector Terminal

E80 169 Ground Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000 rpm

JPBIA3352ZZ

JPBIA3354ZZ

Revision: 2010 May2011 QX56

Page 5064 of 5598

ENGINE SPEED SIGNAL CIRCUITSTC-19

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

H I

J

K L

M A

B

STC

N

O P

4.CHECK ENGINE SPEED SIGNAL (P OWER STEERING CONTROL UNIT)

1. Turn the ignition switch OFF.

2. Connect power steering control unit harness connector.

3. Check the signal between power steering control unit harness connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace power steering control unit. Refer to STC-23, "

Removal and Installation".

5.CHECK TERMINALS AND HARNESS CONNECTORS

Check the power steering control unit pin terminal s for damage or loose connection with harness connector.

Check the ECM pin terminals for damage or loose connection with harness connector.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Repair or replace error-detected parts.

Power steering control unit — Condition Voltage (Approx.)

Connector Terminal

M108 10 Ground Engine is running

Warm-up condition

Idle speed

Engine is running

Warm-up condition

Engine speed: Approx. 2,000 rpm

JPBIA3352ZZ

JPBIA3354ZZ

Revision: 2010 May2011 QX56

Page 5065 of 5598

STC-20

< DTC/CIRCUIT DIAGNOSIS >

VEHICLE SPEED SIGNAL CIRCUIT

VEHICLE SPEED SIGNAL CIRCUIT

Diagnosis ProcedureINFOID:0000000006256130

1.PERFORM COMBINATION METER SELF-DIAGNOSIS

With CONSULT-III

Perform “METER/M&A” self-diagnosis. Refer to MWI-30, "

CONSULT-III Function".

Is any DTC detected?

YES >> Check the DTC.

NO >> GO TO 2.

2.CHECK HARNESS BETWEEN COMBINATION ME TER AND POWER STEERING CONTROL UNIT

1. Turn the ignition switch OFF.

2. Disconnect combination meter harness connector.

3. Disconnect power steering control unit harness connector.

4. Check the continuity between combination meter harness connector and power steering control unit har-

ness connector.

5. Check the continuity between power st eering control unit harness connector and ground.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK VEHICLE SPEED SIGN AL (COMBINATION METER)

1. Connect combination meter harness connector.

2. Check the combination meter input/output standard values. Refer to MWI-35, "

Reference Value".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace combination meter Refer to MWI-85, "

Removal and Installation".

4.CHECK VEHICLE SPEED SIGNAL (POWER STEERING CONTROL UNIT)

1. Turn the ignition switch OFF.

2. Connect power steering control unit harness connector.

3. Check the signal between power steering cont rol unit harness connector and ground with oscilloscope.

Combination meter Power steering control unit

Continuity

Connector Terminal Connector Terminal

M34 30 M108 8 Existed

Power steering control unit —Continuity

Connector Terminal

M108 8 Ground Not existed

Power steering control unit — Condition Voltage (Approx.)

Connector Terminal

M108 8 Ground Vehicle speed: 40 km/h (25 MPH)

CAUTION:

Check air pressure of tire under

standard condition.NOTE:

The maximum voltage varies de-

pending on the specification (desti-

nation unit).

JSNIA0015GB

Revision: 2010 May2011 QX56

Page 5067 of 5598

STC-22

< SYMPTOM DIAGNOSIS >

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIATION)

SYMPTOM DIAGNOSIS

UNBALANCE STEERING WHEEL TURNING FORCE (TORQUE VARIA-

TION)

Description INFOID:0000000006256131

Hard steering when fully turning the steering wheel.

Light steering when driving at a high speed.

Diagnosis Procedure INFOID:0000000006256132

1.CHECK SYSTEM FOR POWER SUPPLY AND GROUND

Perform trouble diagnosis for power supply and ground. Refer to STC-14, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK SYSTEM FOR VEHICLE SPEED SIGNAL

Perform trouble diagnosis for vehicle speed signal. Refer to STC-20, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace error-detected parts.

3.CHECK SYSTEM FOR ENGINE SPEED SIGNAL

Perform trouble diagnosis for engine speed signal. Refer to STC-18, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK SYSTEM FOR POWER STEERING SOLENOID VALVE

Perform trouble diagnosis for power steering solenoid valve. Refer to STC-16, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> Perform the symptom diagnosis for the steering system. Refer to ST-29, "NVH Troubleshooting

Chart".

NO >> Repair or replace error-detected parts.

Revision: 2010 May2011 QX56