washer fluid INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 493 of 5598

BRAKE PIPINGBR-23

< REMOVAL AND INSTALLATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

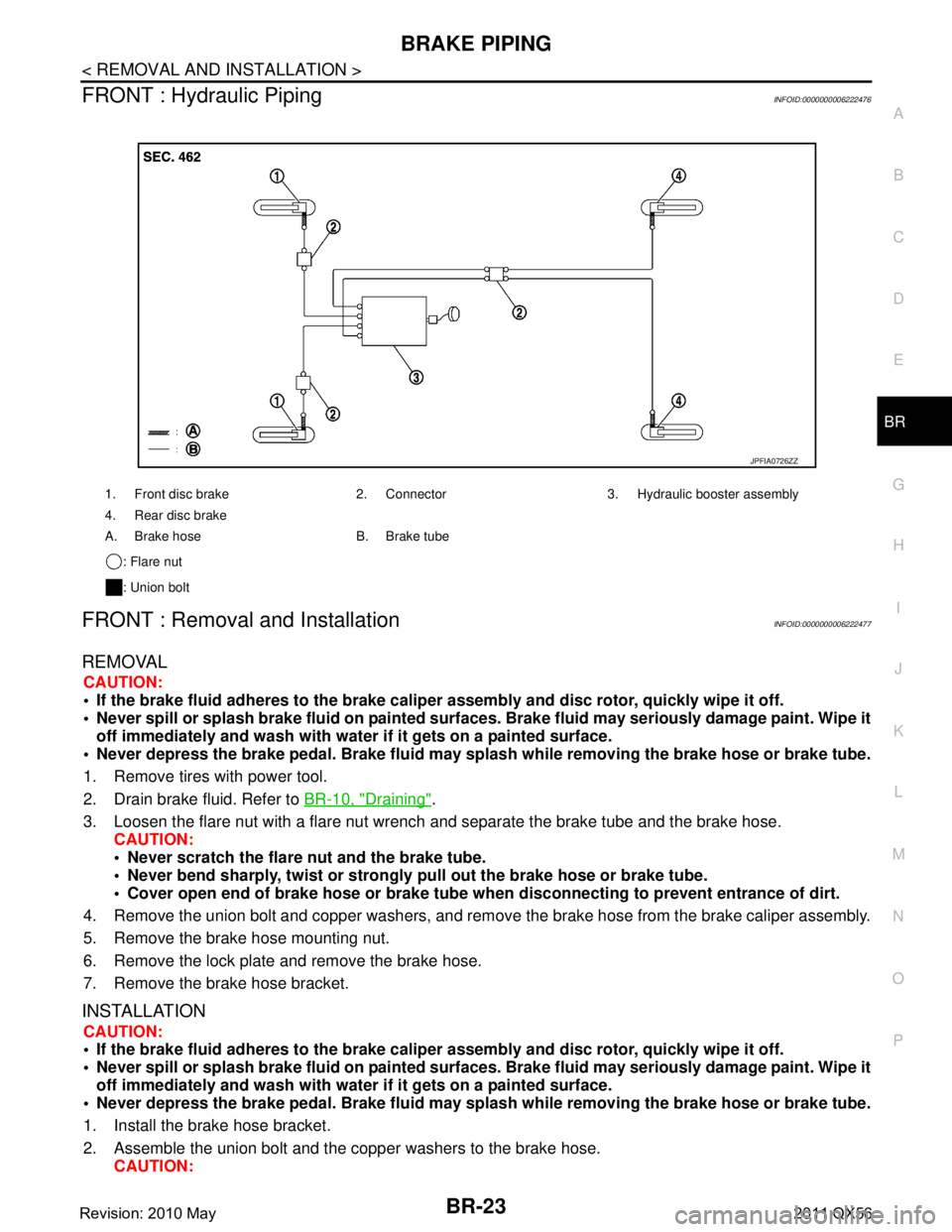

FRONT : Hydraulic PipingINFOID:0000000006222476

FRONT : Removal and InstallationINFOID:0000000006222477

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose.

CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the brake hose mounting nut.

6. Remove the lock plate and remove the brake hose.

7. Remove the brake hose bracket.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Install the brake hose bracket.

2. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0726ZZ

Revision: 2010 May2011 QX56

Page 494 of 5598

BR-24

< REMOVAL AND INSTALLATION >

BRAKE PIPING

Never reuse the copper washer.

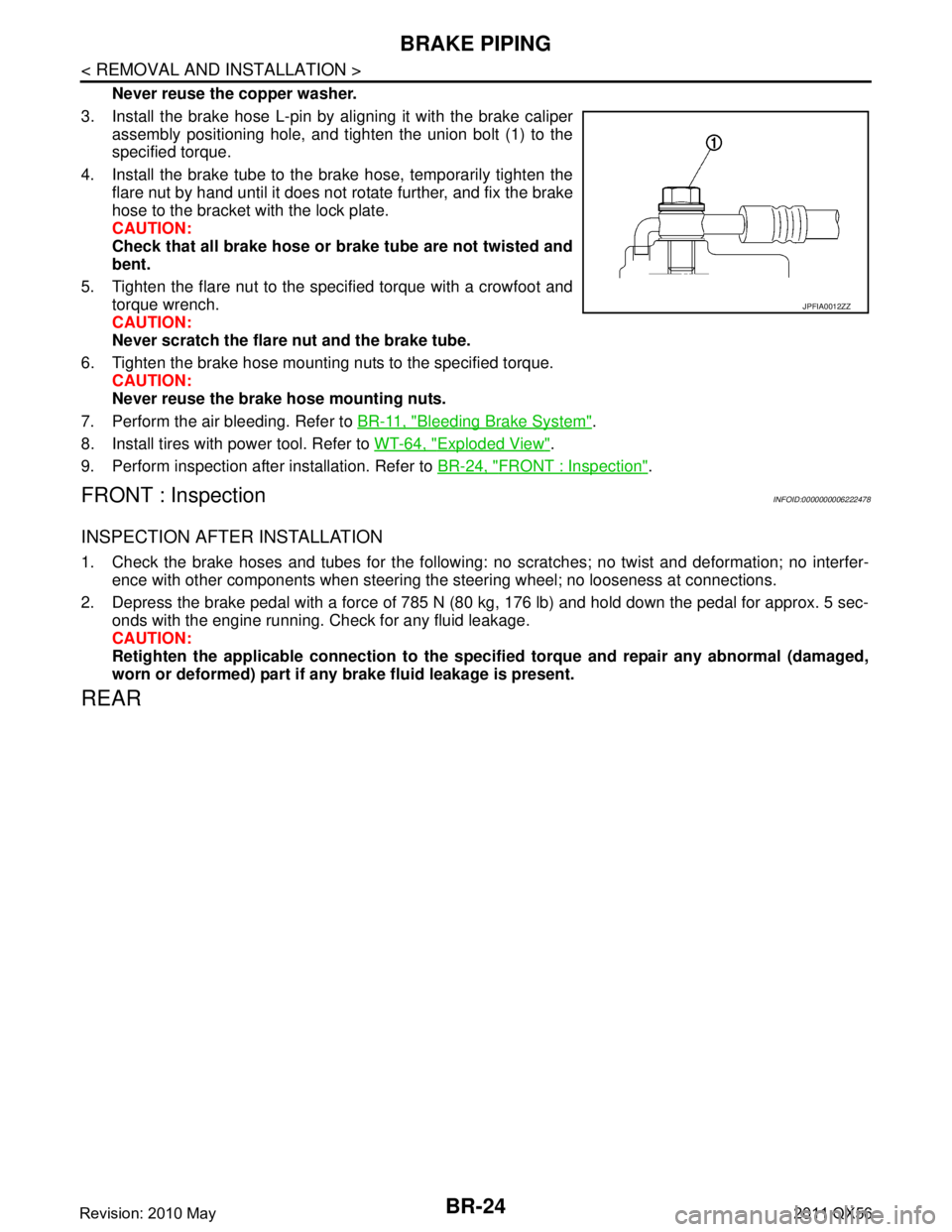

3. Install the brake hose L-pin by aligning it with the brake caliper assembly positioning hole, and tighten the union bolt (1) to the

specified torque.

4. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

5. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

6. Tighten the brake hose mounting nuts to the specified torque. CAUTION:

Never reuse the brake hose mounting nuts.

7. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

8. Install tires with power tool. Refer to WT-64, "

Exploded View".

9. Perform inspection after installation. Refer to BR-24, "

FRONT : Inspection".

FRONT : InspectionINFOID:0000000006222478

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

2. Depress the brake pedal with a force of 785 N (80 kg, 176 lb) and hold down the pedal for approx. 5 sec- onds with the engine running. Check for any fluid leakage.

CAUTION:

Retighten the applicable connection to the specified torque and repair any abnormal (damaged,

worn or deformed) part if any brake fluid leakage is present.

REAR

JPFIA0012ZZ

Revision: 2010 May2011 QX56

Page 496 of 5598

BR-26

< REMOVAL AND INSTALLATION >

BRAKE PIPING

REAR : Removal and Installation

INFOID:0000000006222481

REMOVAL

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Remove tires with power tool.

2. Drain brake fluid. Refer to BR-10, "

Draining".

3. Loosen the flare nut with a flare nut wrench and separate the brake tube and the brake hose. CAUTION:

Never scratch the flare nut and the brake tube.

Never bend sharply, twist or strongly pull out the brake hose or brake tube.

Cover open end of brake hose or brake tube wh en disconnecting to prevent entrance of dirt.

4. Remove the union bolt and copper washers, and remove the brake hose from the brake caliper assembly.

5. Remove the lock plate and remove the brake hose.

INSTALLATION

CAUTION:

If the brake fluid adheres to the brake caliper assembly and disc rotor, quickly wipe it off.

Never spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it

off immediately and wash with wate r if it gets on a painted surface.

Never depress the brake pedal. Brake fluid may spl ash while removing the brake hose or brake tube.

1. Assemble the union bolt and the copper washers to the brake hose. CAUTION:

Never reuse the copper washer.

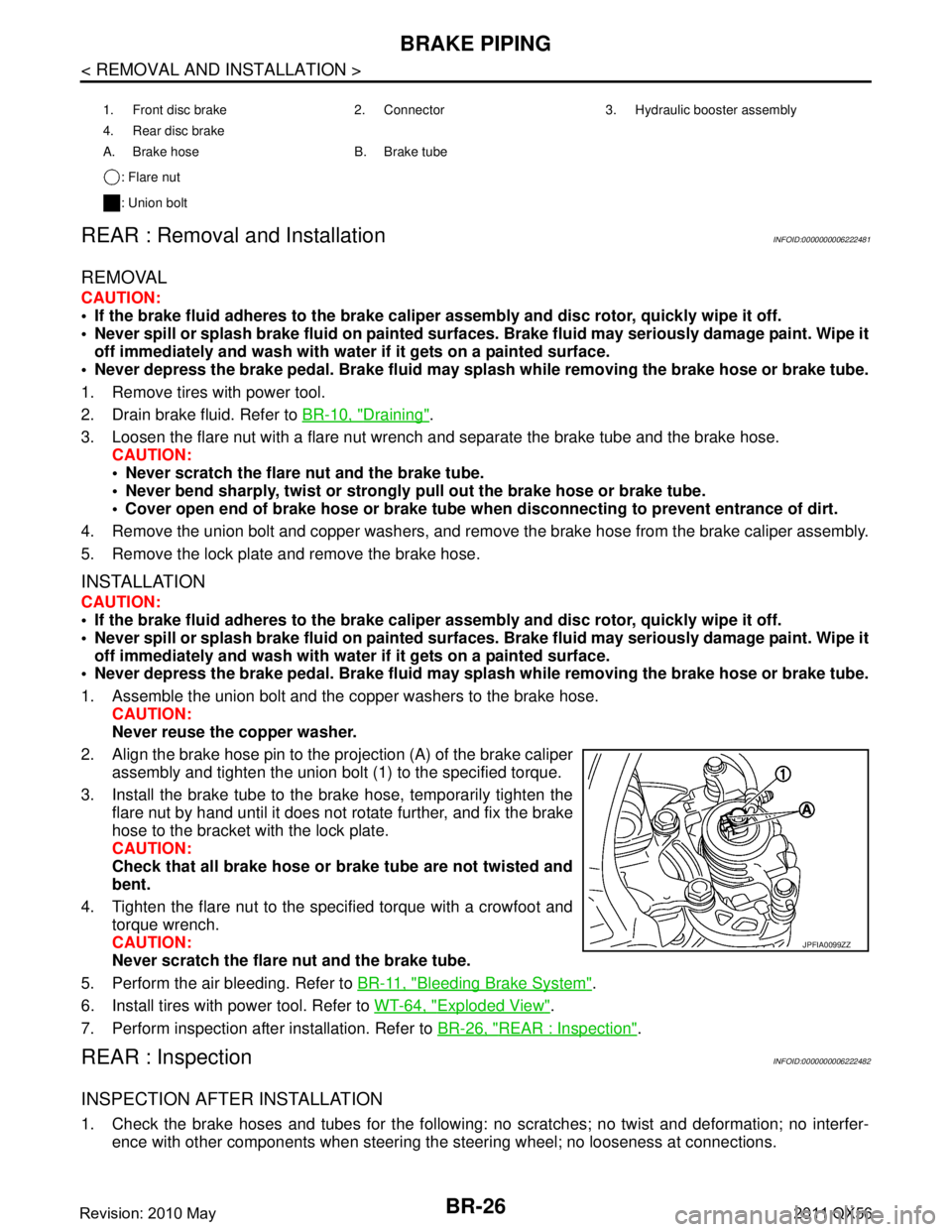

2. Align the brake hose pin to the projection (A) of the brake caliper

assembly and tighten the union bolt (1) to the specified torque.

3. Install the brake tube to the brake hose, temporarily tighten the flare nut by hand until it does not rotate further, and fix the brake

hose to the bracket with the lock plate.

CAUTION:

Check that all brake hose or brake tube are not twisted and

bent.

4. Tighten the flare nut to the specified torque with a crowfoot and torque wrench.

CAUTION:

Never scratch the flare nut and the brake tube.

5. Perform the air bleeding. Refer to BR-11, "

Bleeding Brake System".

6. Install tires with power tool. Refer to WT-64, "

Exploded View".

7. Perform inspection after installation. Refer to BR-26, "

REAR : Inspection".

REAR : InspectionINFOID:0000000006222482

INSPECTION AFTER INSTALLATION

1. Check the brake hoses and tubes for the following: no scratches; no twist and deformation; no interfer-

ence with other components when steering the steering wheel; no looseness at connections.

1. Front disc brake 2. Connector 3. Hydraulic booster assembly

4. Rear disc brake

A. Brake hose B. Brake tube

: Flare nut

: Union bolt

JPFIA0099ZZ

Revision: 2010 May2011 QX56

Page 1922 of 5598

![INFINITI QX56 2011 Factory Service Manual

DLN-120

< REMOVAL AND INSTALLATION >[TRANSFER: ATX90A]

TRANSFER FLUID TEMPERATURE SENSOR

TRANSFER FLUID TEMPERATURE SENSOR

Exploded ViewINFOID:0000000006222346

Removal and InstallationINFOID:00000000 INFINITI QX56 2011 Factory Service Manual

DLN-120

< REMOVAL AND INSTALLATION >[TRANSFER: ATX90A]

TRANSFER FLUID TEMPERATURE SENSOR

TRANSFER FLUID TEMPERATURE SENSOR

Exploded ViewINFOID:0000000006222346

Removal and InstallationINFOID:00000000](/img/42/57033/w960_57033-1921.png)

DLN-120

< REMOVAL AND INSTALLATION >[TRANSFER: ATX90A]

TRANSFER FLUID TEMPERATURE SENSOR

TRANSFER FLUID TEMPERATURE SENSOR

Exploded ViewINFOID:0000000006222346

Removal and InstallationINFOID:0000000006222347

REMOVAL

1. Drain transfer fluid. Refer to

DLN-106, "Draining".

2. Disconnect the transfer fluid temperature sensor connector.

3. Remove the transfer fluid temperature sensor.

4. Perform inspection after removal. Refer to DLN-120, "

Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

Perform inspection after installation. Refer to DLN-120, "

Inspection".

After refilling new transfer fluid, perform learning of transfer fluid viscosity. Refer to DLN-47, "

Work Proce-

dure".

InspectionINFOID:0000000006222348

INSPECTION AFTER REMOVAL

Check the washer assembled transfer fluid temperat ure sensor for wear, crack and damage. Replace the

transfer fluid temperature sensor if there is malfunction.

INSPECTION AFTER INSTALLATION

After driving, check the surface fitt ing transfer fluid temperature sensor to transfer assembly for fluid leakage.

1. Transfer assembly 2. Transfer fluid temperature sensor

: Vehicle front

Refer to GI-4, "

Components" for symbols not described above.

JPDIE0285GB

Revision: 2010 May2011 QX56

Page 2969 of 5598

HOW TO USE THIS MANUALGI-5

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

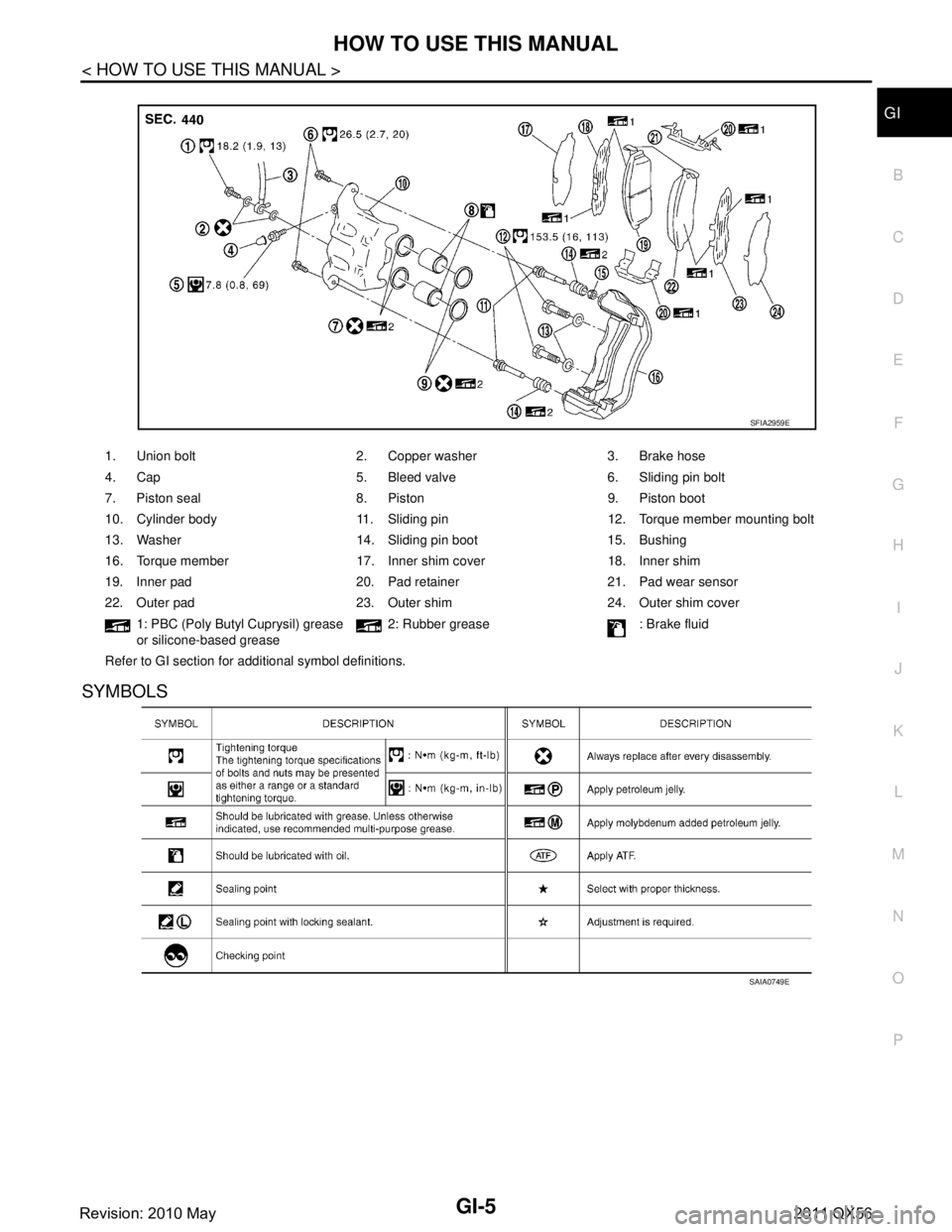

SYMBOLS

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover 1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease 2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Revision: 2010 May2011 QX56

Page 2992 of 5598

GI-28

< PRECAUTION >

PRECAUTIONS

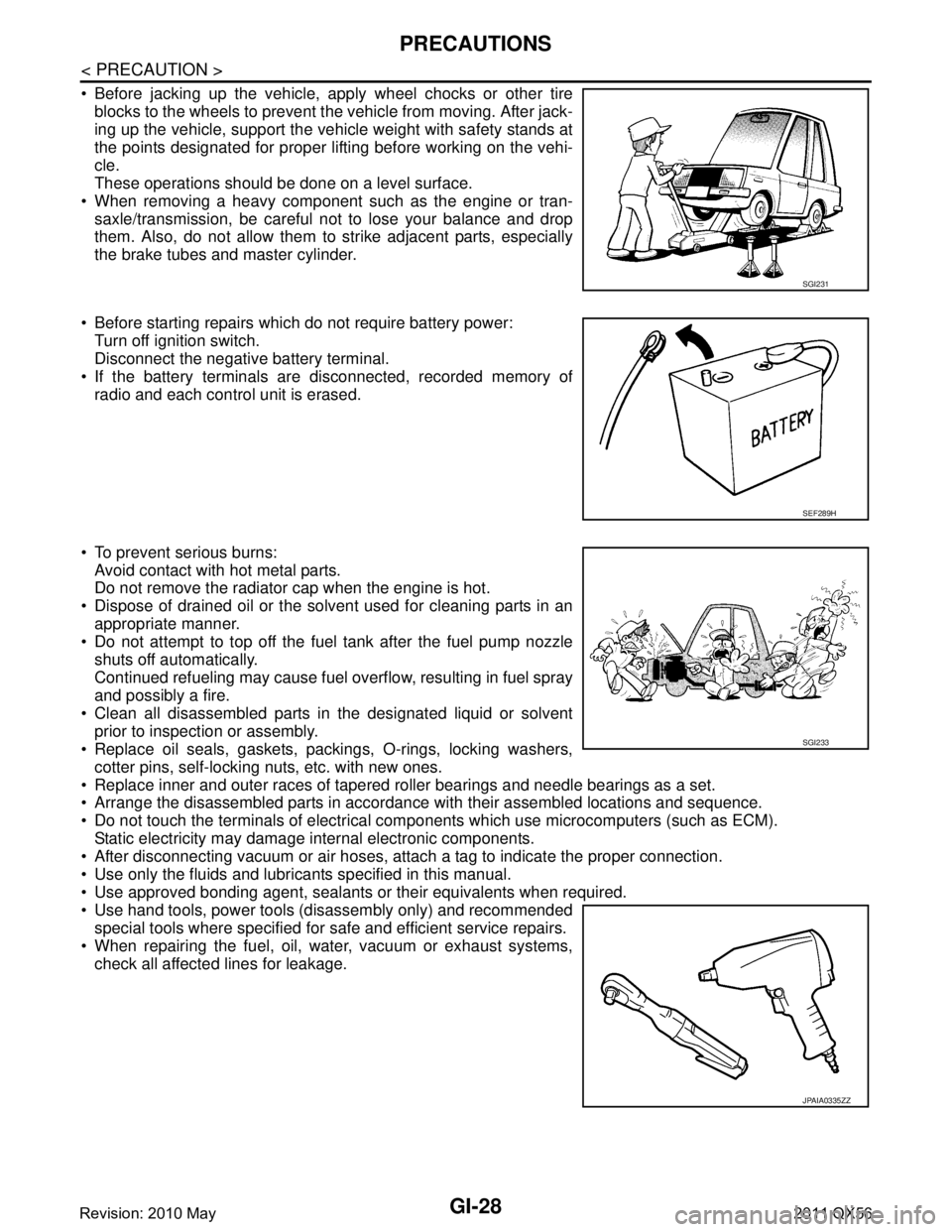

Before jacking up the vehicle, apply wheel chocks or other tireblocks to the wheels to prevent t he vehicle from moving. After jack-

ing up the vehicle, support the vehicle weight with safety stands at

the points designated for proper lifting before working on the vehi-

cle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or tran- saxle/transmission, be careful not to lose your balance and drop

them. Also, do not allow them to strike adjacent parts, especially

the brake tubes and master cylinder.

Before starting repairs which do not require battery power: Turn off ignition switch.

Disconnect the negative battery terminal.

If the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

To prevent serious burns: Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

Dispose of drained oil or the solvent used for cleaning parts in an appropriate manner.

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray

and possibly a fire.

Clean all disassembled parts in the designated liquid or solvent prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and needle bearings as a set.

Arrange the disassembled parts in accordance with their assembled locations and sequence.

Do not touch the terminals of electrical com ponents which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, atta ch a tag to indicate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents when required.

Use hand tools, power tools (disassembly only) and recommended special tools where specified for safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leakage.

SGI231

SEF289H

SGI233

JPAIA0335ZZ

Revision: 2010 May2011 QX56

Page 3661 of 5598

![INFINITI QX56 2011 Factory Service Manual

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal oper INFINITI QX56 2011 Factory Service Manual

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal oper](/img/42/57033/w960_57033-3660.png)

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load. Refer to LU-17, "

EngineOilPressure".

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification. Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-22, "

Recommended Chemical Prod-

ucts and Sealants".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

DrainingINFOID:0000000006289617

WARNING:

Be careful not to burn yourself, as th e engine and engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as

possible.

1. Warm up the engine, and check for any oil leaks.

2. Stop the engine and wait for at least 10 minutes.

3. Remove drain plug and oil filler cap to drain the old oil.

RefillingINFOID:0000000006289618

1. Install drain plug with new washer. CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-10, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

JPBIA0074ZZ

Oil pressure switch torque : Refer to EM-57, "Exploded View".

Tightening torque : Refer to EM-54, "

Exploded View".

Engine oil capacity : Refer to LU-17, "

Periodical Maintenance Specification".

Revision: 2010 May2011 QX56

Page 3675 of 5598

GENERAL MAINTENANCEMA-5

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should

be checked periodically (e.g. each time you check the engine oil or refuel).

Seats Check seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restrains move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seatbacks. —

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage. MA-34

Accelerator pedal

Check the pedal for smooth operation and make sure the pedal does not catch

or require uneven effort. Keep the floor mats away from the pedal. —

Brakes Check that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

booster Check the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Be sure to

keep the floor mats away from the pedal. BR-7

BR-15

Parking brake

Check that the lever or pedal has the proper travel and make sure that the ve-

hicle is held securely on a fairly steep hill when only the parking brake is ap-

plied. PB-3

Automatic transmis-

sion “Park” mecha-

nismCheck that the lock release button on the selector lever operates properly and

smoothly. On a fairly steep hill check that the vehicle is held securely with the

selector lever in the P (Park) position without applying any brakes.

—

Item

Reference page

Item Reference page

Windshield washer

fluid Check that there is adequate fluid in the tank. —

Engine coolant level Check the coolant level when the engine is cold. MA-12

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections. MA-16

Brake fluid levels

Make sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoir(s). MA-28

Battery

Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines. Vehicles operated in high temperatures or under severe conditions re-

quire frequent checks of the battery fluid level. PG-159

Engine drive belts

Make sure that no belt is frayed, worn, cracked or oily. MA-12

Engine oil levelCheck the level on the oil level gauge after parking the vehicle on a level spot

and turning off the engine. LU-7

Power steering fluid

level and linesCheck the level on the dipstick with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.

MA-32

Exhaust system

Make sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it. MA-21

Underbody

The underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around

the exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate. —

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately. —

Revision: 2010 May2011 QX56

Page 3687 of 5598

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

FUEL LINES : InspectionINFOID:0000000006394850

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leakage, cracks, damage, loose connections, chafing or

deterioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

AIR CLEANER FILTER : Removal and InstallationINFOID:0000000006394838

REMOVAL

NOTE:

The viscous paper type filter does not need cleaning between replacement intervals.

Replace the air filter as necessary for periodic maintenance. Refer to MA-6, "

Introduction of Periodic Mainte-

nance".

1. Unhook clips, and lift air cleaner case (upper).

2. Remove air cleaner filter from air cleaner case.

INSTALLATION

Install is the reverse order of removal.

ENGINE OIL

ENGINE OIL : DrainingINFOID:0000000006394841

WARNING:

Be careful not to burn yourself, as th e engine and engine oil may be hot.

Prolonged and repeated contact with used engine oil may cau se skin cancer; try to avoid direct skin

contact with used oil. If skin contact is made, w ash thoroughly with soap or hand cleaner as soon as

possible.

1. Warm up the engine, and check for any oil leaks.

2. Stop the engine and wait for at least 10 minutes.

3. Remove drain plug and oil filler cap to drain the old oil.

ENGINE OIL : RefillingINFOID:0000000006394842

1. Install drain plug with new washer. CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specificat ion and viscosity:

Refer to MA-10, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

A : Engine

B : Fuel line

C : Fuel tank

JPBIA0129ZZ

Tightening torque : Refer to EM-54, "Exploded View".

Engine oil capacity : Refer to LU-17, "

Periodical Maintenance Specification".

Revision: 2010 May2011 QX56

Page 3746 of 5598

MWI

MWI-3

C

DE

F

G H

I

J

K L

M B

A

O P

THE LOW WASHER FLUID WARNING CON-

TINUES DISPLAYING, or DOES NOT DIS-

PLAY .............................................................. ....

81

Description .......................................................... ....81

Diagnosis Procedure ...............................................81

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY ..........

82

Description .......................................................... ....82

Diagnosis Procedure ...............................................82

THE AMBIENT TEMPERATURE DISPLAY IS

INCORRECT .......................................................

83

Description .......................................................... ....83

Diagnosis Procedure ...............................................83

NORMAL OPERATING CONDITION .................84

INFORMATION DISPLAY ..................................... ....84

INFORMATION DISPLAY : Description ..................84

REMOVAL AND INSTALLATION ...............85

COMBINATION METER ...................................85

Exploded View ..................................................... ....85

Removal and Installation .........................................85

Disassembly and Assembly .....................................85

TRIP RESET AND ILLUMINATION CON-

TROL SWITCH ..................................................

86

Exploded View .........................................................86

Removal and Installation .........................................86

TRIP COMPUTER SWITCH ..............................87

Exploded View .........................................................87

Removal and Installation .........................................87

CLOCK ..............................................................88

Exploded View .........................................................88

Removal and Installation .........................................88

Revision: 2010 May2011 QX56