torque ISUZU AXIOM 2002 Service Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2002, Model line: AXIOM, Model: ISUZU AXIOM 2002Pages: 2100, PDF Size: 19.35 MB

Page 694 of 2100

5C±14

POWER±ASSISTED BRAKE SYSTEM

Brake Pipe

Removal

1. Raise the vehicle and support it with suitable safety

stands.

2. Remove wheel and tire assembly as necessary.

3. Clean dirt, grease, and other foreign material off the

pipe fittings at both ends.

4. Remove brake pipe (1).

330RW011

5. Remove plastic clip (2).

330RW002

Installation

To install, follow the removal steps in the reverse order,

noting the following points.

1. Tighten the brake pipes to the specified torque.

Master cylinder and Proportioning and Bypass

valve sides

Torque: 15 N´m (11 lb ft)

Others

Torque: 16 N´m (12 lb ft)

After installing the brake pipes, bleed the brakes as

described in this section.

Page 695 of 2100

5C±15 POWER±ASSISTED BRAKE SYSTEM

P & B (Proportioning and Bypass) Valve

P & B (Proportioning and Bypass)

Valve Sectional View

350RW014

Legend

(1) Master Cylinder (Secondary)

(2) Master Cylinder (Primary)

(3) Rear Brake

(4) Front Brake

The P&B valve contains two sections, each serving a

different function.

The proportioning section of the P&B valve proportions

outlet pressure to the rear brakes after a predetermined

rear input pressure has been reached. This is done to

prevent rear wheel lock up on the vehicles with light rear

wheel loads. The valve has a by±pass feature which

assures full system pressure to the rear brakes in the

event of front brake system malfunction. Also full front

pressure is retained in the event of rear brake

malfunction.

The P&B valve is not repairable and must be replaced as

complete assembly.

Removal

1. The P&B valve is not repairable and must be replaced

as a complete assembly. Care must be taken to

prevent brake fluid from contacting any painted

surface.

2. Remove hydraulic pipes (1) and plug the pipes (1) to

prevent the loss of fluid or the entrance of dirt.

3. Remove bolt (3).

4. Remove P&B valve (2).

350RW026

Installation

1. Install P&B valve (2).

2. Install bolt (3) and tighten the bolt to the specified

torque.

Torque: 22 N´m (16 lb ft)

3. Install hydraulic pipes (1) and tighten the bolt to the

specified torque.

Torque: 15 N´m (11 lb ft)

4. After installing the brake pipes, bleed the brakes as

refer to

Bleeding Brake Hydraulic System in this

section.

Page 696 of 2100

5C±16

POWER±ASSISTED BRAKE SYSTEM

Main Data and Specifications

Torque Specifications

E05R200001

Page 697 of 2100

5C±17 POWER±ASSISTED BRAKE SYSTEM

Brake Pedal

Checking Pedal Height

The push rod serves as the brake pedal stopper when the

pedal is fully released. Brake pedal height adjustment

should be performed as follows:

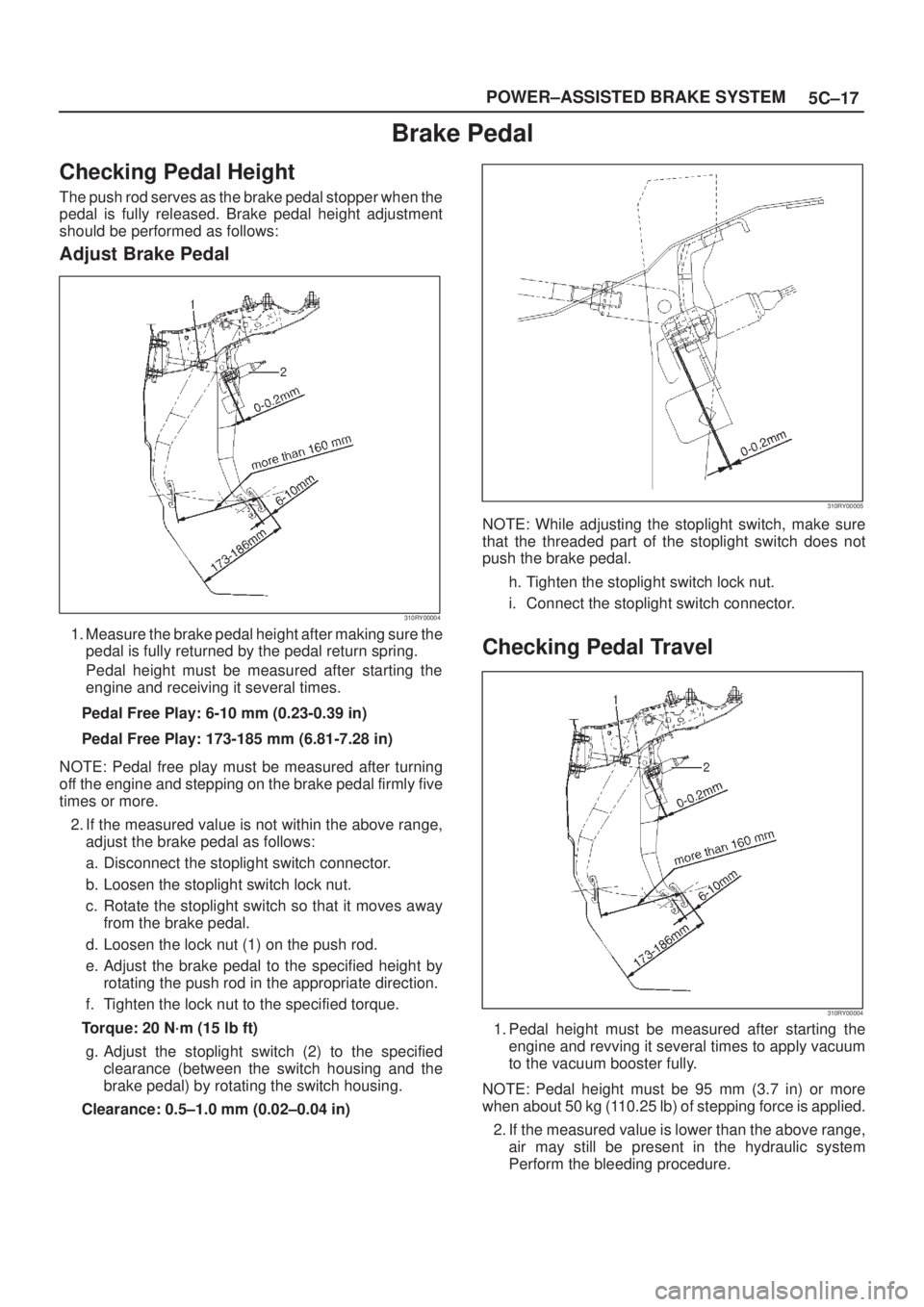

Adjust Brake Pedal

310RY00004

1. Measure the brake pedal height after making sure the

pedal is fully returned by the pedal return spring.

Pedal height must be measured after starting the

engine and receiving it several times.

Pedal Free Play: 6-10 mm (0.23-0.39 in)

Pedal Free Play: 173-185 mm (6.81-7.28 in)

NOTE: Pedal free play must be measured after turning

off the engine and stepping on the brake pedal firmly five

times or more.

2. If the measured value is not within the above range,

adjust the brake pedal as follows:

a. Disconnect the stoplight switch connector.

b. Loosen the stoplight switch lock nut.

c. Rotate the stoplight switch so that it moves away

from the brake pedal.

d. Loosen the lock nut (1) on the push rod.

e. Adjust the brake pedal to the specified height by

rotating the push rod in the appropriate direction.

f. Tighten the lock nut to the specified torque.

Torque: 20 N´m (15 lb ft)

g. Adjust the stoplight switch (2) to the specified

clearance (between the switch housing and the

brake pedal) by rotating the switch housing.

Clearance: 0.5±1.0 mm (0.02±0.04 in)

310RY00005

NOTE: While adjusting the stoplight switch, make sure

that the threaded part of the stoplight switch does not

push the brake pedal.

h. Tighten the stoplight switch lock nut.

i. Connect the stoplight switch connector.

Checking Pedal Travel

310RY00004

1. Pedal height must be measured after starting the

engine and revving it several times to apply vacuum

to the vacuum booster fully.

NOTE: Pedal height must be 95 mm (3.7 in) or more

when about 50 kg (110.25 lb) of stepping force is applied.

2. If the measured value is lower than the above range,

air may still be present in the hydraulic system

Perform the bleeding procedure.

Page 698 of 2100

5C±18

POWER±ASSISTED BRAKE SYSTEM

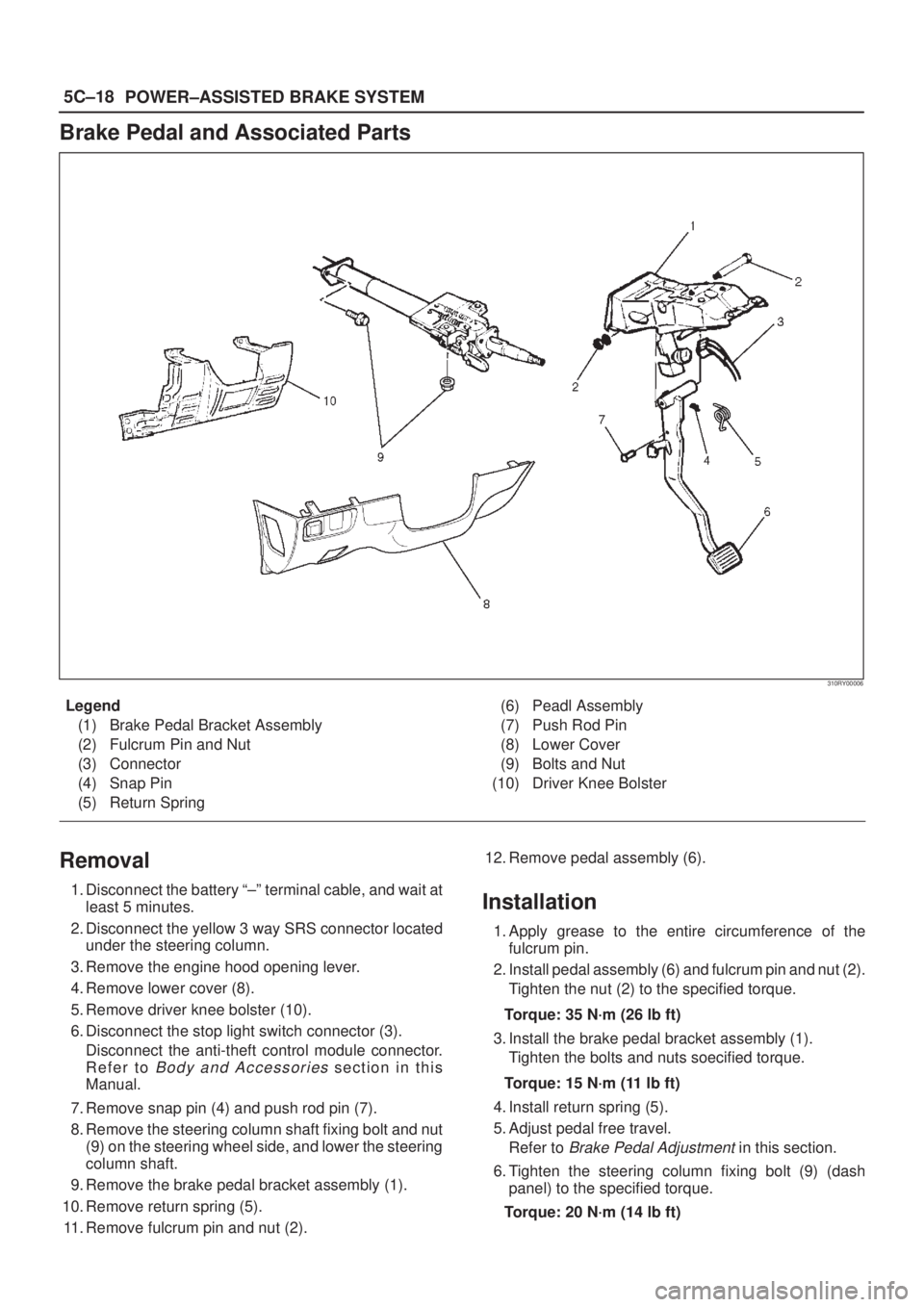

Brake Pedal and Associated Parts

310RY00006

Legend

(1) Brake Pedal Bracket Assembly

(2) Fulcrum Pin and Nut

(3) Connector

(4) Snap Pin

(5) Return Spring(6) Peadl Assembly

(7) Push Rod Pin

(8) Lower Cover

(9) Bolts and Nut

(10) Driver Knee Bolster

Removal

1. Disconnect the battery ª±º terminal cable, and wait at

least 5 minutes.

2. Disconnect the yellow 3 way SRS connector located

under the steering column.

3. Remove the engine hood opening lever.

4. Remove lower cover (8).

5. Remove driver knee bolster (10).

6. Disconnect the stop light switch connector (3).

Disconnect the anti-theft control module connector.

Refer to

Body and Accessories section in this

Manual.

7. Remove snap pin (4) and push rod pin (7).

8. Remove the steering column shaft fixing bolt and nut

(9) on the steering wheel side, and lower the steering

column shaft.

9. Remove the brake pedal bracket assembly (1).

10. Remove return spring (5).

11. Remove fulcrum pin and nut (2).12. Remove pedal assembly (6).

Installation

1. Apply grease to the entire circumference of the

fulcrum pin.

2. Install pedal assembly (6) and fulcrum pin and nut (2).

Tighten the nut (2) to the specified torque.

Torque: 35 N´m (26 lb ft)

3. Install the brake pedal bracket assembly (1).

Tighten the bolts and nuts soecified torque.

Torque: 15 N´m (11 lb ft)

4. Install return spring (5).

5. Adjust pedal free travel.

Refer to

Brake Pedal Adjustment in this section.

6. Tighten the steering column fixing bolt (9) (dash

panel) to the specified torque.

Torque: 20 N´m (14 lb ft)

Page 699 of 2100

5C±19 POWER±ASSISTED BRAKE SYSTEM

7. Tighten the steering column fixing nut (9) (Cross

Beam) to the specified torque.

Torque: 17 N´m (12 lb ft)

8. Apply grease to the entire circumference of the Push

rod pin (7).

9. Install push rod pin (7).

10. Install snap pin (4).

11. Connect the anti-theft control module connector.

Refer to

Body and Accessories section in this

manual.12. Connect the stop light switch connector (3).

13. Install driver knee bolster (10) and lower cover (8).

14. Install the engine hood opening lever.

15. Connect the yellow 3 way SRS connector located

under the steering column.

16. Connect the battery ª±º terminal cable.

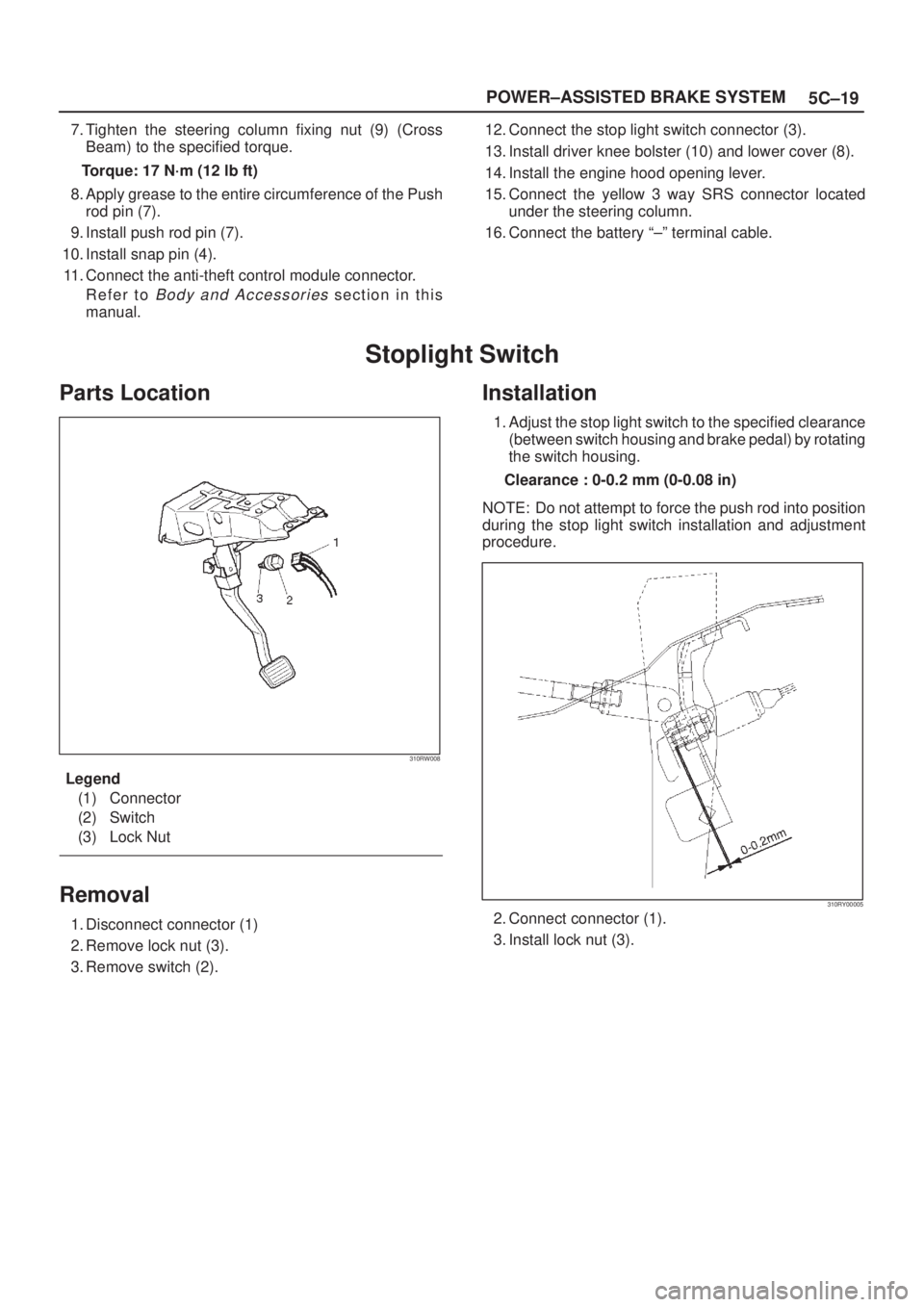

Stoplight Switch

Parts Location

310RW008

Legend

(1) Connector

(2) Switch

(3) Lock Nut

Removal

1. Disconnect connector (1)

2. Remove lock nut (3).

3. Remove switch (2).

Installation

1. Adjust the stop light switch to the specified clearance

(between switch housing and brake pedal) by rotating

the switch housing.

Clearance : 0-0.2 mm (0-0.08 in)

NOTE: Do not attempt to force the push rod into position

during the stop light switch installation and adjustment

procedure.

310RY00005

2. Connect connector (1).

3. Install lock nut (3).

Page 700 of 2100

5C±20

POWER±ASSISTED BRAKE SYSTEM

Main Data and Specifications

General Specifications

Pedal free play6±10 mm (0.23 ±0.39 in)

Pedal Height173±185 mm (6.81±7.28 in)

Torque Specifications

310RY00007

Page 703 of 2100

5C±23 POWER±ASSISTED BRAKE SYSTEM

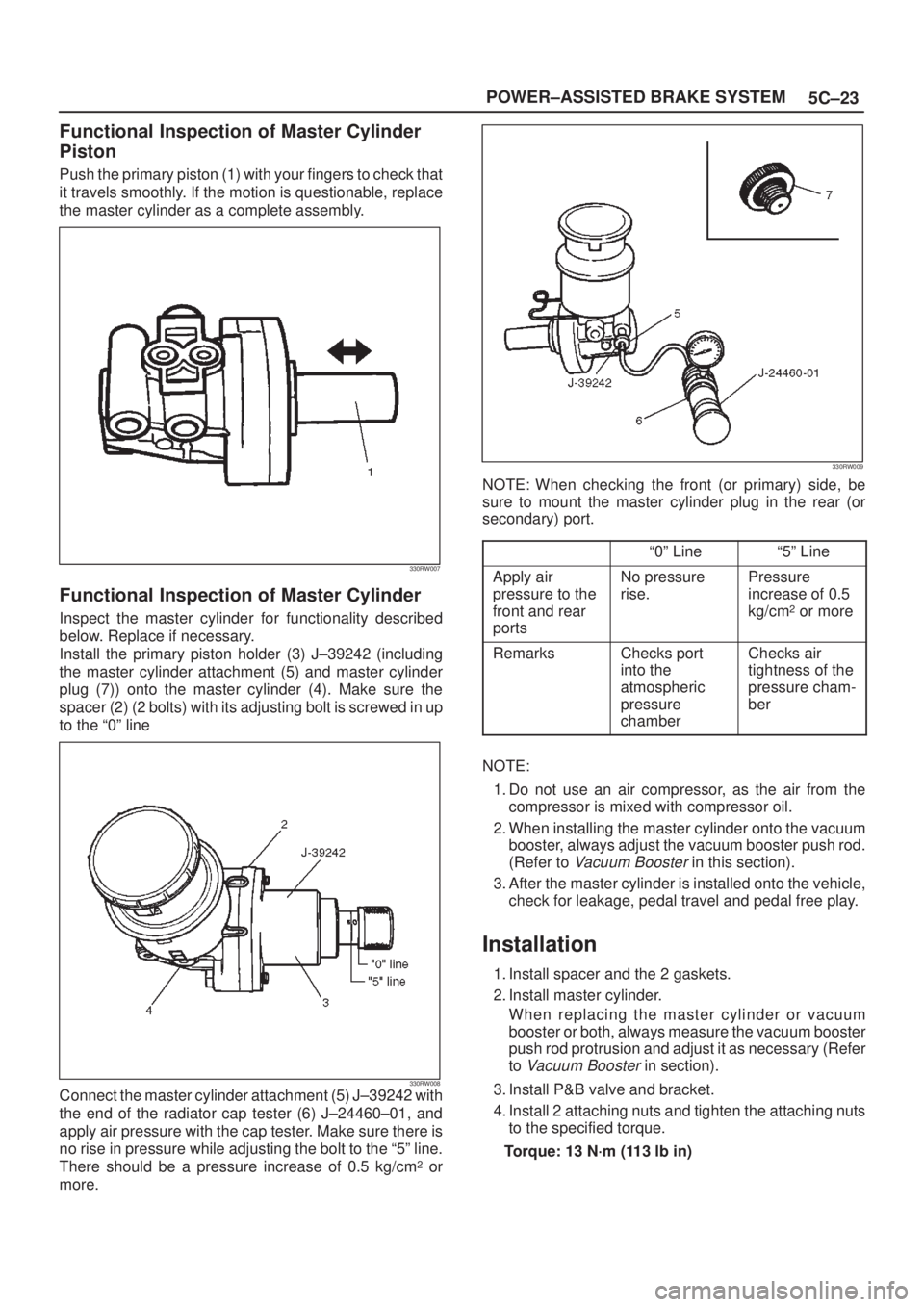

Functional Inspection of Master Cylinder

Piston

Push the primary piston (1) with your fingers to check that

it travels smoothly. If the motion is questionable, replace

the master cylinder as a complete assembly.

330RW007

Functional Inspection of Master Cylinder

Inspect the master cylinder for functionality described

below. Replace if necessary.

Install the primary piston holder (3) J±39242 (including

the master cylinder attachment (5) and master cylinder

plug (7)) onto the master cylinder (4). Make sure the

spacer (2) (2 bolts) with its adjusting bolt is screwed in up

to the ª0º line

330RW008Connect the master cylinder attachment (5) J±39242 with

the end of the radiator cap tester (6) J±24460±01, and

apply air pressure with the cap tester. Make sure there is

no rise in pressure while adjusting the bolt to the ª5º line.

There should be a pressure increase of 0.5 kg/cm

2 or

more.

330RW009

NOTE: When checking the front (or primary) side, be

sure to mount the master cylinder plug in the rear (or

secondary) port.

ª0º Lineª5º Line

Apply air

pressure to the

front and rear

portsNo pressure

rise.Pressure

increase of 0.5

kg/cm

2 or more

RemarksChecks port

into the

atmospheric

pressure

chamberChecks air

tightness of the

pressure cham-

ber

NOTE:

1. Do not use an air compressor, as the air from the

compressor is mixed with compressor oil.

2. When installing the master cylinder onto the vacuum

booster, always adjust the vacuum booster push rod.

(Refer to

Vacuum Booster in this section).

3. After the master cylinder is installed onto the vehicle,

check for leakage, pedal travel and pedal free play.

Installation

1. Install spacer and the 2 gaskets.

2. Install master cylinder.

When replacing the master cylinder or vacuum

booster or both, always measure the vacuum booster

push rod protrusion and adjust it as necessary (Refer

to

Vacuum Booster in section).

3. Install P&B valve and bracket.

4. Install 2 attaching nuts and tighten the attaching nuts

to the specified torque.

Torque: 13 N´m (113 lb in)

Page 704 of 2100

5C±24

POWER±ASSISTED BRAKE SYSTEM

5. Install brake pipes and tighten the brake pipe to the

specified torque.

Master cylinder and P&B valve sides

Torque: 15 N´m (11 lb ft)

Others

Torque: 16 N´m (12 lb ft)

6. Connect electrical connector.

Main Data and Specifications

General Specifications

TypeDual±circuit

Piston bore

diameter25.4 mm (1.000 in)

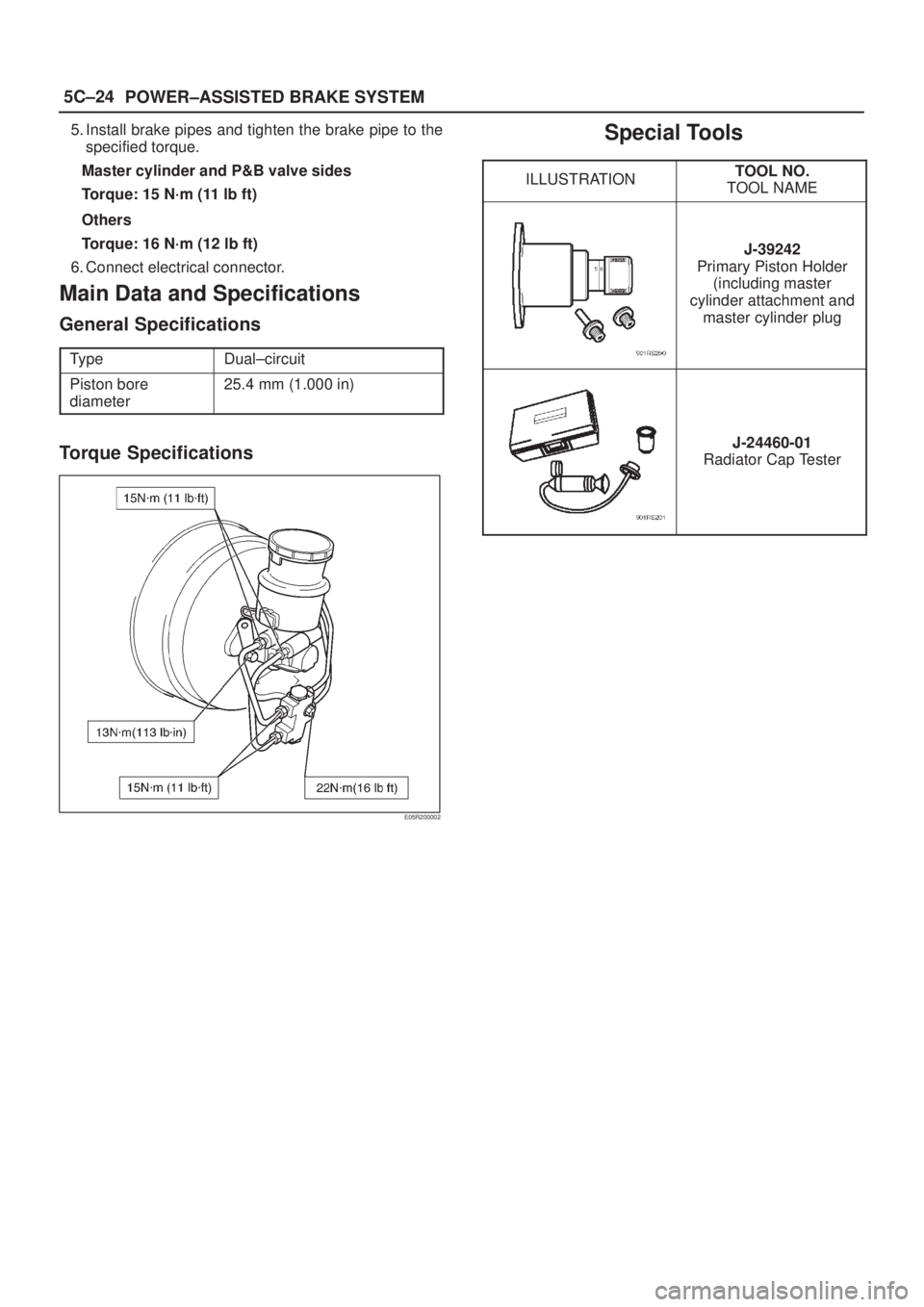

Torque Specifications

E05R200002

Special Tools

ILLUSTRATIONTOOL NO.

TOOL NAME

J-39242

Primary Piston Holder

(including master

cylinder attachment and

master cylinder plug

J-24460-01

Radiator Cap Tester

Page 707 of 2100

5C±27 POWER±ASSISTED BRAKE SYSTEM

4. Measure dimension (4).

Dimension (4) (Standard): ±0.1±0.1 mm

(±0.0039±0.0039 in)

331RW002

5. If dimension (4) is out of the standard range, adjust

push rod using the Push Rod Support J±39241.

331RW003

6. Mount plate and seal assembly in vacuum booster

front shell. Then install the retainer.

7. Install vacuum booster fixing nut and tighten the

specified torque.

Torque: 15 N´m (11 lb ft)

8. Install yoke clevis.

9. Connect vacuum hose and make sure that the arrow

on the hose points in the direction of the engine.

10. Install master cylinder, refer to

Master Cylinder

Installation

in this section.