sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4245 of 6020

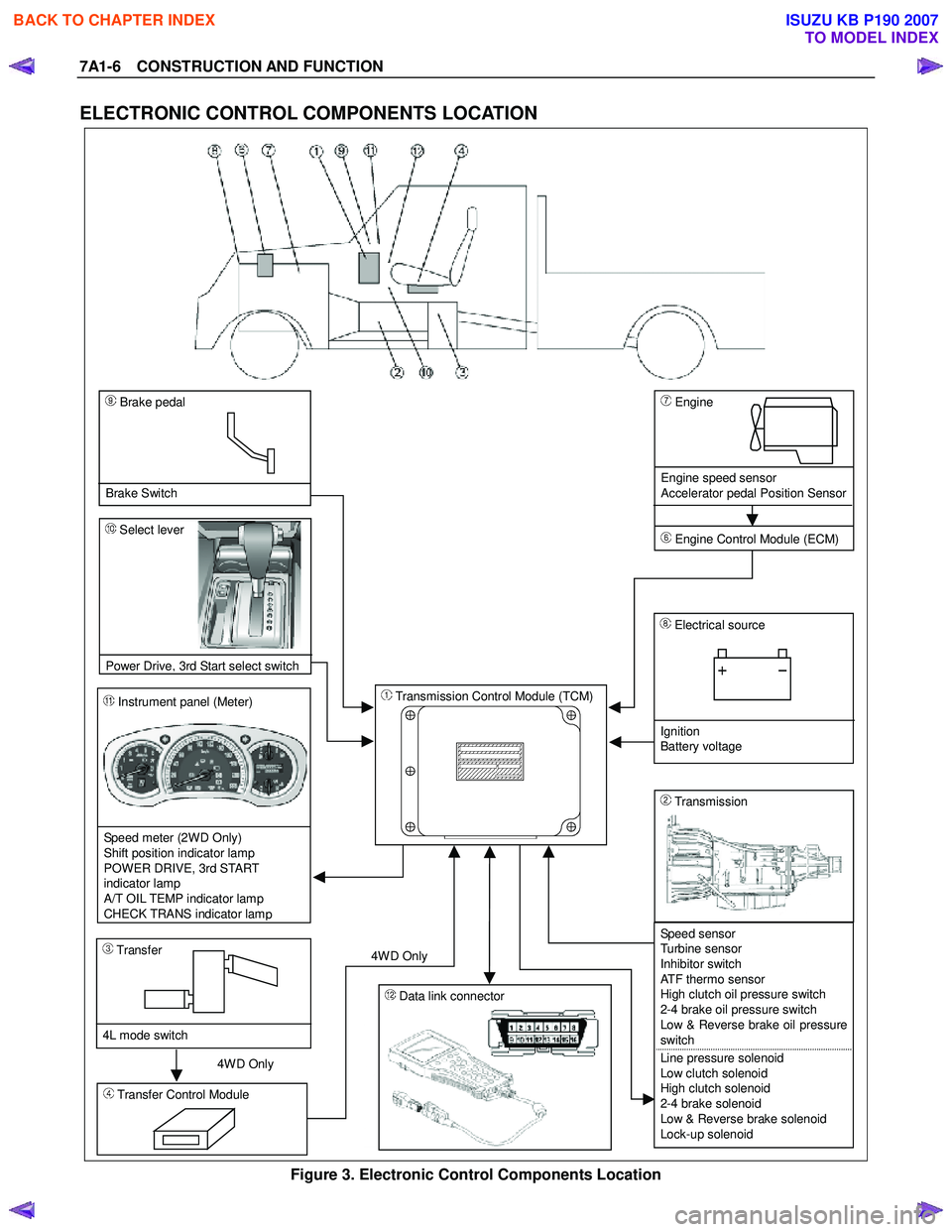

7A1-6 CONSTRUCTION AND FUNCTION

ELECTRONIC CONTROL COMPONENTS LOCATION

4WD Only 4W D Only

Instrument panel (Meter)

Speed meter (2WD Only)

Shift position indicator lamp

POWER DRIVE, 3rd START

indicator lamp

A/T OIL TEMP indicator lamp

CHECK TRANS indicator lam

p

Brake pedal

Brake Switch

Transmission Control Module (TCM)

Electrical source

Ignition

Battery voltage

Speed sensor

Turbine sensor

Inhibitor switch

ATF thermo sensor

High clutch oil pressure switch

2-4 brake oil pressure switch

Low & Reverse brake oil pressure

switch

Line pressure solenoid

Low clutch solenoid

High clutch solenoid

2-4 brake solenoid

Low & Reverse brake solenoid

Lock-up solenoid

Transmission

Transfer Control Module

Transfer

4L mode switch

Engine

Engine speed sensor

Accelerator pedal Position Sensor

Engine Control Module (ECM)

Data link connector

Select lever

Power Drive

, 3rd Start select switch

Figure 3. Electronic Control Components Location

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4253 of 6020

7A1-14 CONSTRUCTION AND FUNCTION

CONTROL VALVE

• Employing the direct electronic control (Direct Electronic Shift Control: DESC) for the clutch pressure has

simplified the oil pressure circuit, reduced the number of functional components and made the control

valve compact.

• The control valve body is divided into the upper body and the lower body. All solenoids, the oil pressure

switch and the ATF thermo sensor are installed to the lower body.

• Three-way valve type solenoids providing high responsibility are employed. Some of the solenoids are

switched between ON and OFF, and others repeat ON and OFF at 50Hz (duty cycle system).

Functionally, some supply output pressure when power is not supplied, and others drain the output

pressure.

• When the solenoid is driven based on the signal from the TCM, the oil pressure is changed.

Figure 22. Construction of Valve Body

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4256 of 6020

CONSTRUCTION AND FUNCTION 7A1-17

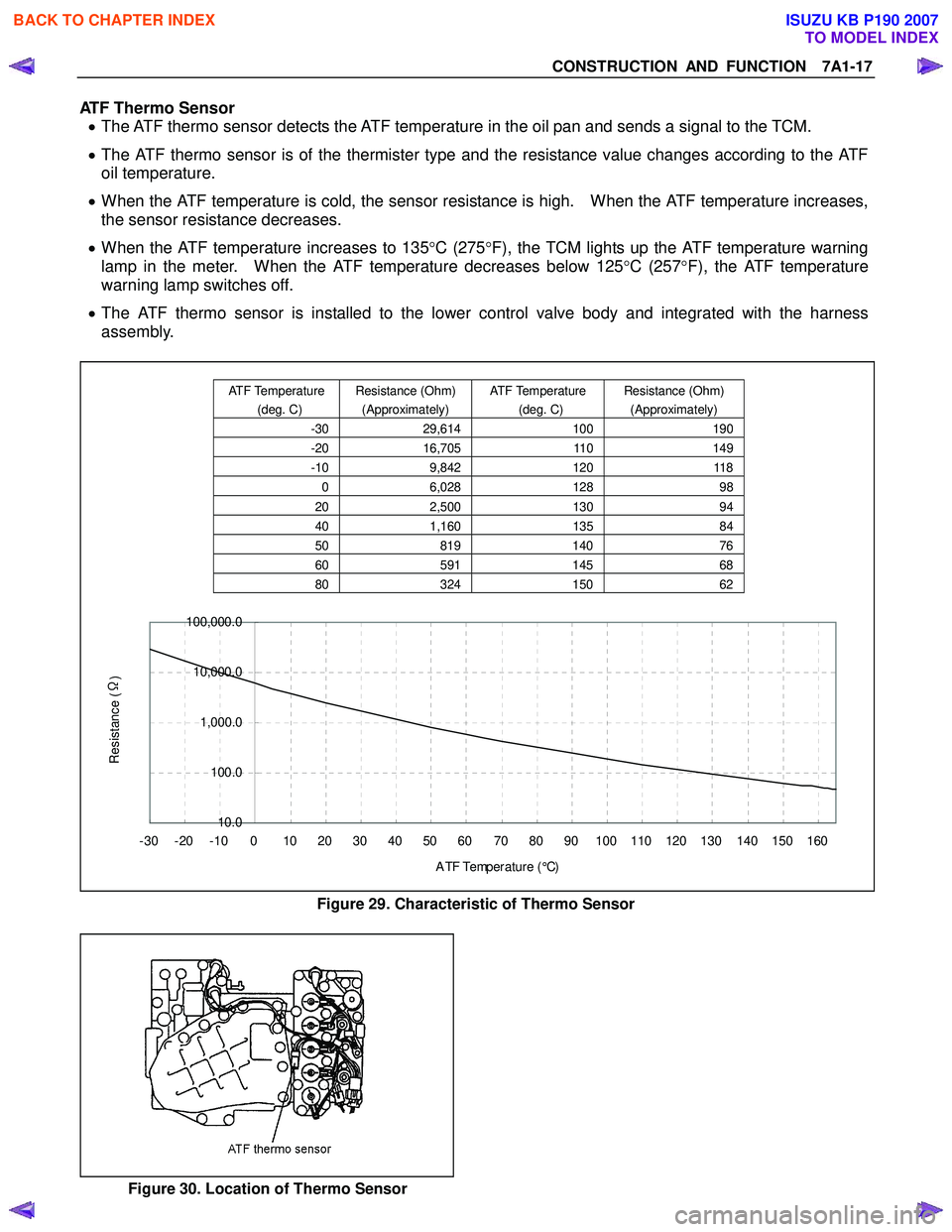

ATF Thermo Sensor • The ATF thermo sensor detects the ATF temperature in the oil pan and sends a signal to the TCM.

• The ATF thermo sensor is of the thermister type and the resistance value changes according to the ATF

oil temperature.

• When the ATF temperature is cold, the sensor resistance is high. When the ATF temperature increases,

the sensor resistance decreases.

• When the ATF temperature increases to 135 °C (275 °F), the TCM lights up the ATF temperature warning

lamp in the meter. When the ATF temperature decreases below 125 °C (257 °F), the ATF temperature

warning lamp switches off.

• The ATF thermo sensor is installed to the lower control valve body and integrated with the harness

assembly.

10.0

100.0

1,000.0

10,000.0

100,000.0

-30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 140 150 160 A TF Temp er a t ur e ( °C)

Resistance (Ω

)

Figure 29. Characteristic of Thermo Sensor

Figure 30. Location of Thermo Sensor

ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately) ATF Temperature

(deg. C) Resistance (Ohm)

(Approximately)

-30 29,614 100190

-20 16,705 110149

-10 9,842 120118

0 6,028 128 98

20 2,500 130 94

40 1,160 135 84

50 819 140 76

60 591 14568

80 324 15062

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4257 of 6020

7A1-18 CONSTRUCTION AND FUNCTION

Terminal Assembly Pin No. Connected to Connected TCMPin No.

6 Line Pressure Solenoid B23

12 Low & Reverse Brake Oil Pressure Switch B12

5 Low & Reverse Brake Duty Solenoid B6

11 Ground Return B22

4 Lock-up Duty Solenoid B17

10 High Clutch Duty Solenoid B8

3 Low Clutch Duty Solenoid B9

9 2-4 Brake Duty Solenoid B7

2 Oil Thermo Sensor B4

8 Oil Thermo Sensor Ground B14

1 High Clutch Oil Pressure Switch B20

7 2-4 Brake Oil Pressure Switch B1

123456

891011127

Terminal AssemblyInhibitor Switch

Figure 31. Pin Assignment Figure 32. Location of Terminal Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4261 of 6020

7A1-22 CONSTRUCTION AND FUNCTION

TURBINE SENSOR

• The turbine sensor is a hall element. It is installed to the front of the transmission case. The turbine

sensor converts the rotations of the reverse & high clutch drum fitted with the input shaft by spline to

pulse signal and sends the signal to the TCM.

• One turn of the reverse & high clutch drum generates 32-pulse signals, which are sent to the TCM.

Figure 38. Turbine Sensor

SPEED SENSOR

• The speed sensor is a hall element. It is installed to the rear of the transmission case. The speed sensor

converts the rotations of the parking gear, fitted with the output shaft by spline, to a pulse signal and

sends the signal to the TCM.

• One turn of the parking gear generates 16-pulse signals, which are sent to the TCM.

Figure 39. Speed Sensor Figure 40. Location of Turbine & Speed Sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4262 of 6020

CONSTRUCTION AND FUNCTION 7A1-23

ACCELERATOR PEDAL POSITION SENSOR

• Opening of the accelerator pedal is converted to an electric signal which is transmitted from ECM to TCM.

• The accelerator pedal position sensor (1) is installed to the accelerator pedal.

Pin

No. W ire Color

Pin Function

1 BLU APP Sensor 3 +5V Reference

2 Not Used

3 ORN/BLU APP Sensor 2 Low Reference

4 BLK APP Sensor 1 Low Reference

5 RED APP Sensor 1 Signal

6 BLU/W HT APP Sensor 3 Signal

7 BLU/RED APP Sensor 3 Low Reference

8 ORN APP Sensor 2 +5V Reference

9 BLU/GRN APP Sensor 2 Signal

10 W HT APP Sensor 1 +5V Reference

RTW 77ASH000501

Figure 41. Accelerator Pedal Position Sensor

Figure 42. Pin Assignment

ENGINE SPEED SENSOR (=CKP SENSOR)

• The engine speed sensor converts the crankshaft from the Crankshaft Position (CKP) sensor rotation to a

pulse signal which is transmitted from ECM to TCM.

Pin

No. W ire Color

Pin Function

1 YEL Sensor Signal

2 BLU Sensor Low Reference

3 GRN Sensor +5V Feed

Figure 43. Crankshaft Position (CKP) Sensor Figure 44. Pin Assignment

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4264 of 6020

CONSTRUCTION AND FUNCTION 7A1-25

TRANSMISSION CONTROL MODULE (TCM)

• The TCM is fitted on the side of the brake pedal via two stud bolts.

• The TCM judges the line pressure, gear shifting point and lock-up operation based on electrical signals

from switches and sensors, and sends the appropriate signals to solenoids.

B9 B8 B7 B6 B5 B4 B3 B2 B1 A9 A8 A7 A6 A5 A4 A3 A2 A1

B18 B17 B16 B15 B14 B13 B12 B11 B10 A18 A17 A16 A15 A14 A13 A12 A11 A10

B24 B23 B22 B21 B20 B19 A24 A23 A22 A21 A20 A19

Connect to White Connector Connect to Grey Connector

Figure 49. Pin Assignment

Pin No. Pin Assignment Pin No.Pin Assignment

B1 2-4 Brake Oil Pressure Switch A1 V BATT (Battery Back-up Power Supply)

B2 2 Position Switch A2 P Position Switch

B3 Turbine Sensor A3 Brake Switch

B4 ATF Thermo Sensor A4 3rd Start Indicator Lamp

B5 Ground A5 K-Line Signal (Tech 2 Serial Communication)

B6 Low & Reverse Brake Duty Solenoid A6 No Connection

B7 2-4 Brake Duty Solenoid A7 Engine Speed Sensor

B8 High Clutch Duty Solenoid A8 No Connection

B9 Low Clutch Duty Solenoid A9 No Connection

B10 N Position Switch A10 Vehicle Speed Sensor Out (2W D Only)

B11 D Position Switch A11 3rd START Select Switch

B12 Low & Reverse Brake Oil Pressure Switch A12 4L Mode Switch (4W D Only)

B13 Vehicle Speed Sensor A13 No Connection

B14 ATF Thermo Sensor Ground A14 No Connection

B15 No Connection A15 No Connection

B16 No Connection A16 Accelerator Pedal Position Sensor

B17 Lock-up Duty Solenoid A17 3 Position Switch

B18 Vign (Ignition Power Supply) A18 DIAG Switch (Test Switch)

B19 R Position Switch A19 A/T OIL TEMP Indicator Lamp

B20 High Clutch Oil Pressure Switch A20 CHECK TRANS Indicator Lamp

B21 L Position Switch A21 POW ER DRIVE Indicator Lamp

B22 Ground (Shift Solenoid) A22 No Connection

B23 Line Pressure Solenoid A23 No Connection

B24 Vign (Ignition Power Supply) A24 POW ER DRIVE Select Switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4267 of 6020

7A1-28 CONSTRUCTION AND FUNCTION

Item Description

Learning function The learning function is provided to correct the oil pressure control timing to engage or

disengage the clutch optimally in order to compensate changes of the engine performance

and changes of the transmission with time. It is controlled to bring the shift time closer to

the value pre-set to the TCM.

Fail-safe function In the case of a malfunction of the vehicle speed sensor, APP sensor, all solenoids or the

inhibitor switch, TCM automatically begins fail-safe control to minimize effects on driving.

The gear is fixed in 3rd gear and the power supply to the solenoid is shut off so that the

solenoid does not work. Lock up clutch is disengaged in this mode.

Self-diagnosis function Parts required for controlling the automatic transmission are provided with a self-diagnosis

function. W hen any trouble occurs, the check trans indicator lamp blinks to warn the driver.

The trouble code is memorized in the TCM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4268 of 6020

CONSTRUCTION AND FUNCTION 7A1-29

CONTROL ITEM, INPUT AND OUTPUT

Control item

Item

Line

pressure control

Gear shift

control

Shift

pattern

selection

Lock-up control Direct

electronic shift

control

(DECS)

Learning control

Fail-safe function

Self-

diagnosis function

Speed sensor

Turbine sensor

Engine speed sensor

Brake switch

Inhibitor switch

Mode select switch

4L switch (4W D Only)

ATF thermo sensor

High clutch oil pressure switch

2-4 brake oil pressure switch

Low & Reverse brake oil pressure

switch

Input

Accelerator Pedal position sensor

Line pressure solenoid

Low clutch solenoid

High clutch solenoid

2-4 brake solenoid

Low & Reverse brake solenoid

Lock-up solenoid

Shift pattern indicator lamp

ATF temperature indicator lamp

Output

Check trans indicator lamp

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4270 of 6020

CONSTRUCTION AND FUNCTION 7A1-31

As a result, the lock-up piston is fitted slowly to the converter cover under pressure securing smooth lock-

up engagement.

Figure 51. Lock-up Control

DIRECT ELECTRIC SHIFT CONTROL (DESC)

Feature

• Based on each switch signal (low & reverse brake pressure, 2-4 brake pressure & high clutch pressure)

and each sensor signal (turbine sensor, speed sensor, engine speed signal & APP position signal), the

duty cycle type solenoid adjusts the clutch pressure to match the engine load and vehicle travel

conditions. Controlling the engagement and disengagement of the clutch and brake pressure is directly

and accurately controlled via TCM, which is different to the previous accumulator type.

Operation

• Instead of the previous system (on/off type of shift solenoid and shift valve), the combination of the duty

cycle type solenoid and the amplifier (Amp) valve are used to adjust the clutch pressure to match the

engine load and vehicle travel conditions, based on the signal from the TCM. Also, the pressure switch

provided in the oil passage of the control valve transmits the oil pressure condition (at that time) to TCM,

enabling the engagement and disengagement control of the clutch and brake to be directly and finely

carried out.

• When the gear is shifted from the 2nd to 3rd, 3rd to 4th (O/D), 4th (O/D) to 3rd and 3rd to 2nd, the clutch

pressures on the engagement side and disengagement side are simultaneously controlled.

As a result, engine racing or clutch drag is prevented which enables a smooth and quick shift response.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007