oil capacity ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 55 of 6020

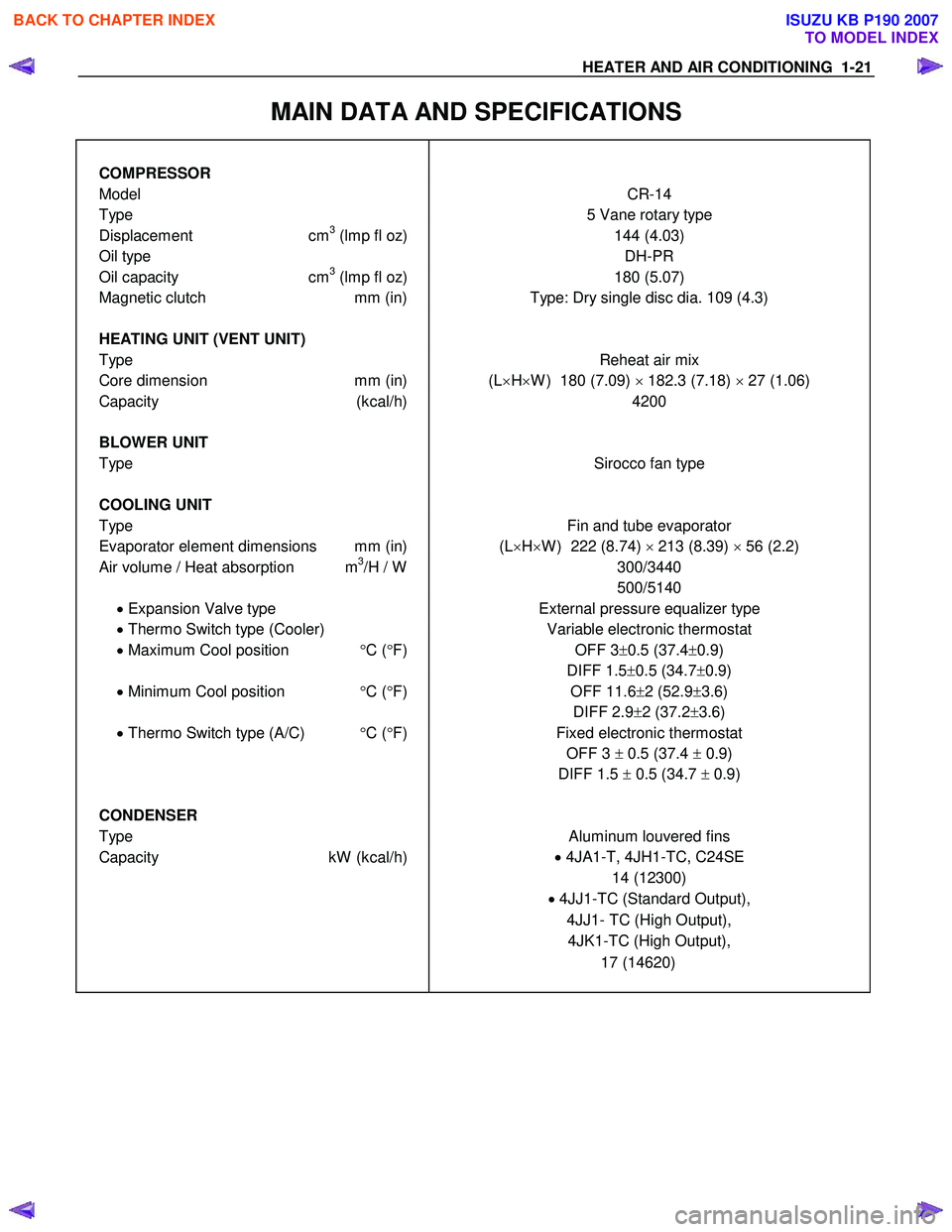

HEATER AND AIR CONDITIONING 1-21

MAIN DATA AND SPECIFICATIONS

COMPRESSOR

Model CR-14

Type 5 Vane rotary type

Displacement cm3 (lmp fl oz) 144 (4.03)

Oil type DH-PR

Oil capacity cm3 (lmp fl oz) 180 (5.07)

Magnetic clutch mm (in) Type: Dry single disc dia. 109 (4.3)

HEATING UNIT (VENT UNIT)

Type Reheat air mix

Core dimension mm (in) (L×H ×W ) 180 (7.09) × 182.3 (7.18) × 27 (1.06)

Capacity (kcal/h) 4200

BLOWER UNIT

Type Sirocco fan type

COOLING UNIT

Type Fin and tube evaporator

Evaporator element dimensions mm (in) (L×H ×W ) 222 (8.74) × 213 (8.39) × 56 (2.2)

Air volume / Heat absorption m3/H / W

300/3440

500/5140

• Expansion Valve type External pressure equalizer type

• Thermo Switch type (Cooler) Variable electronic thermostat

• Maximum Cool position °C ( °F) OFF 3± 0.5 (37.4 ±0.9)

DIFF 1.5 ±0.5 (34.7 ±0.9)

• Minimum Cool position °C ( °F)

OFF 11.6

±2 (52.9 ±3.6)

DIFF 2.9 ±2 (37.2 ±3.6)

• Thermo Switch type (A/C) °C ( °F) Fixed electronic thermostat

OFF 3 ± 0.5 (37.4 ± 0.9)

DIFF 1.5 ± 0.5 (34.7 ± 0.9)

CONDENSER

Type Aluminum louvered fins

Capacity kW (kcal/h) •

4JA1-T, 4JH1-TC, C24SE

14 (12300)

• 4JJ1-TC (Standard Output),

4JJ1- TC (High Output), 4JK1-TC (High Output),

17 (14620)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 85 of 6020

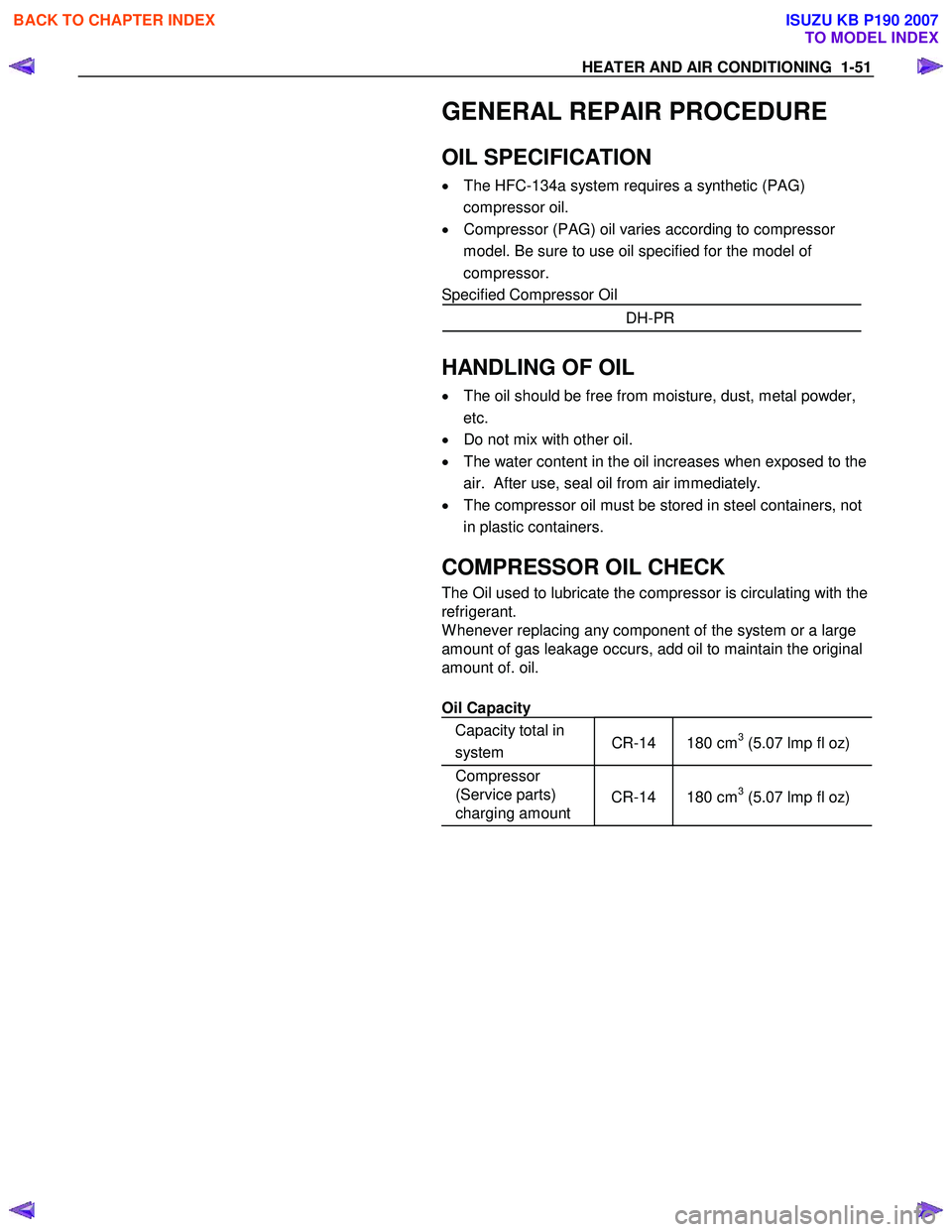

HEATER AND AIR CONDITIONING 1-51

GENERAL REPAIR PROCEDURE

OIL SPECIFICATION

•

The HFC-134a system requires a synthetic (PAG)

compressor oil.

• Compressor (PAG) oil varies according to compressor

model. Be sure to use oil specified for the model of

compressor.

Specified Compressor Oil

DH-PR

HANDLING OF OIL

•

The oil should be free from moisture, dust, metal powder,

etc.

• Do not mix with other oil.

• The water content in the oil increases when exposed to the

air. After use, seal oil from air immediately.

• The compressor oil must be stored in steel containers, not

in plastic containers.

COMPRESSOR OIL CHECK

The Oil used to lubricate the compressor is circulating with the

refrigerant.

W henever replacing any component of the system or a large

amount of gas leakage occurs, add oil to maintain the original

amount of. oil.

Oil Capacity

Capacity total in

system CR-14 180 cm

3 (5.07 lmp fl oz)

Compressor

(Service parts)

charging amount

CR-14

180 cm3 (5.07 lmp fl oz)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 87 of 6020

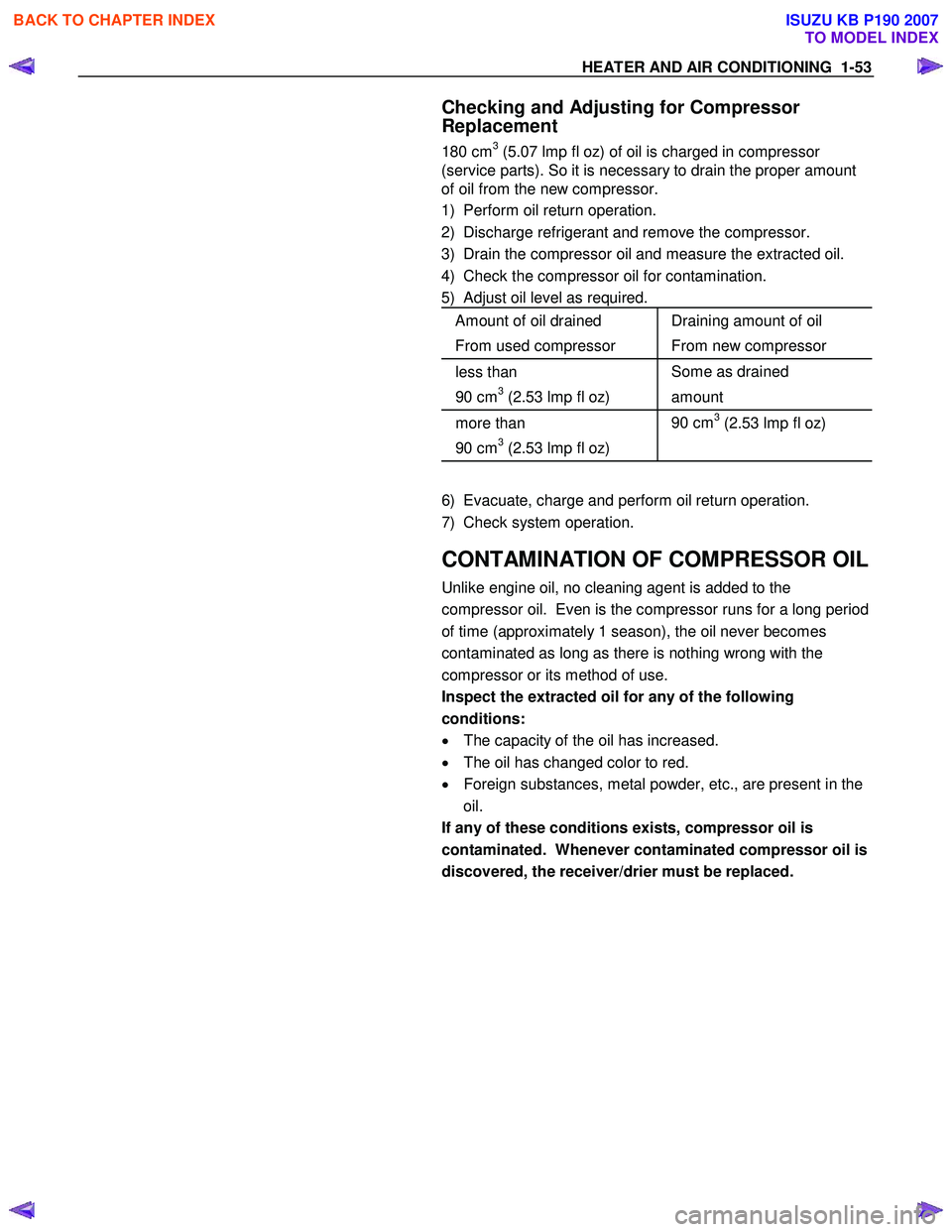

HEATER AND AIR CONDITIONING 1-53

Checking and Adjusting for Compressor

Replacement

180 cm3 (5.07 lmp fl oz) of oil is charged in compressor

(service parts). So it is necessary to drain the proper amount

of oil from the new compressor.

1) Perform oil return operation.

2) Discharge refrigerant and remove the compressor.

3) Drain the compressor oil and measure the extracted oil.

4) Check the compressor oil for contamination.

5) Adjust oil level as required.

Amount of oil drained

From used compressor Draining amount of oil

From new compressor

less than

90 cm

3 (2.53 lmp fl oz) Some as drained

amount

more than

90 cm

3 (2.53 lmp fl oz) 90 cm

3 (2.53 lmp fl oz)

6) Evacuate, charge and perform oil return operation.

7) Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even is the compressor runs for a long period

of time (approximately 1 season), the oil never becomes

contaminated as long as there is nothing wrong with the

compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

• The capacity of the oil has increased.

• The oil has changed color to red.

• Foreign substances, metal powder, etc., are present in the

oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated compressor oil is

discovered, the receiver/drier must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 447 of 6020

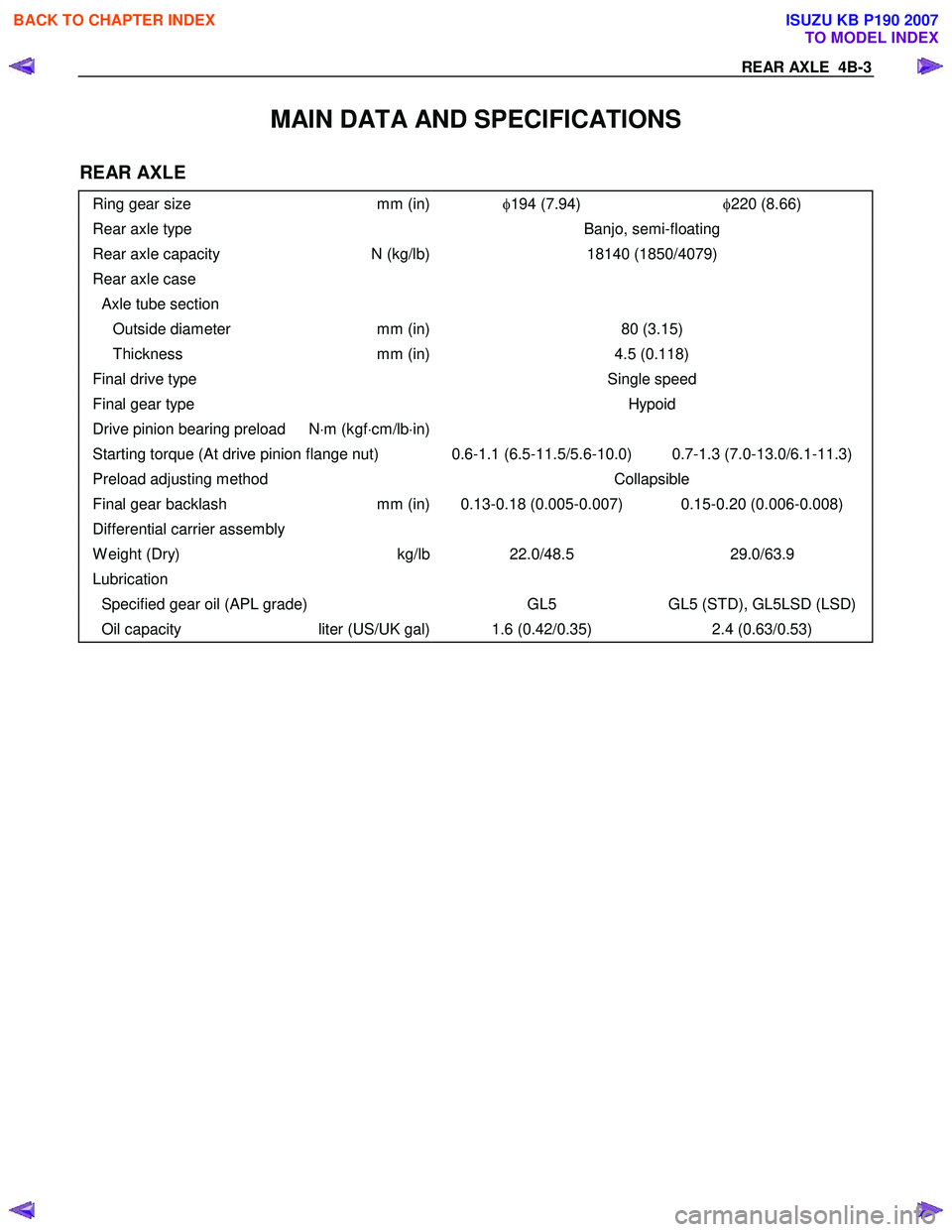

REAR AXLE 4B-3

MAIN DATA AND SPECIFICATIONS

REAR AXLE

Ring gear size mm (in)φ194 (7.94) φ220 (8.66)

Rear axle type Banjo, semi-floating

Rear axle capacity N (kg/lb)18140 (1850/4079)

Rear axle case

Axle tube section

Outside diameter mm (in)80 (3.15)

Thickness mm (in)4.5 (0.118)

Final drive type Single speed

Final gear type Hypoid

Drive pinion bearing preload N⋅m (kgf ⋅cm/lb ⋅in)

Starting torque (At drive pinion flange nut) 0.6-1.1 (6.5-11.5/5.6-10.0) 0.7-1.3 (7.0-13.0/6.1-11.3)

Preload adjusting method Collapsible

Final gear backlash mm (in) 0.13-0.18 (0.005-0.007) 0.15-0.20 (0.006-0.008)

Differential carrier assembly

W eight (Dry) kg/lb22.0/48.5 29.0/63.9

Lubrication

Specified gear oil (APL grade) GL5 GL5 (STD), GL5LSD (LSD)

Oil capacity liter (US/UK gal) 1.6 (0.42/0.35) 2.4 (0.63/0.53)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 452 of 6020

4B-8 REAR AXLE

SERVICING

Rear Axle Oil Replacement

Oil Capacity liters (US/UK gal.)

Specified gear oil GL5 (API grade)(STD)

GL5LSD (LSD)

φ220mm 2.4 (0.63/0.53)

φ194mm 1.6 (0.42/0.35)

Filler Plug and Drain Plug Torque N ⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

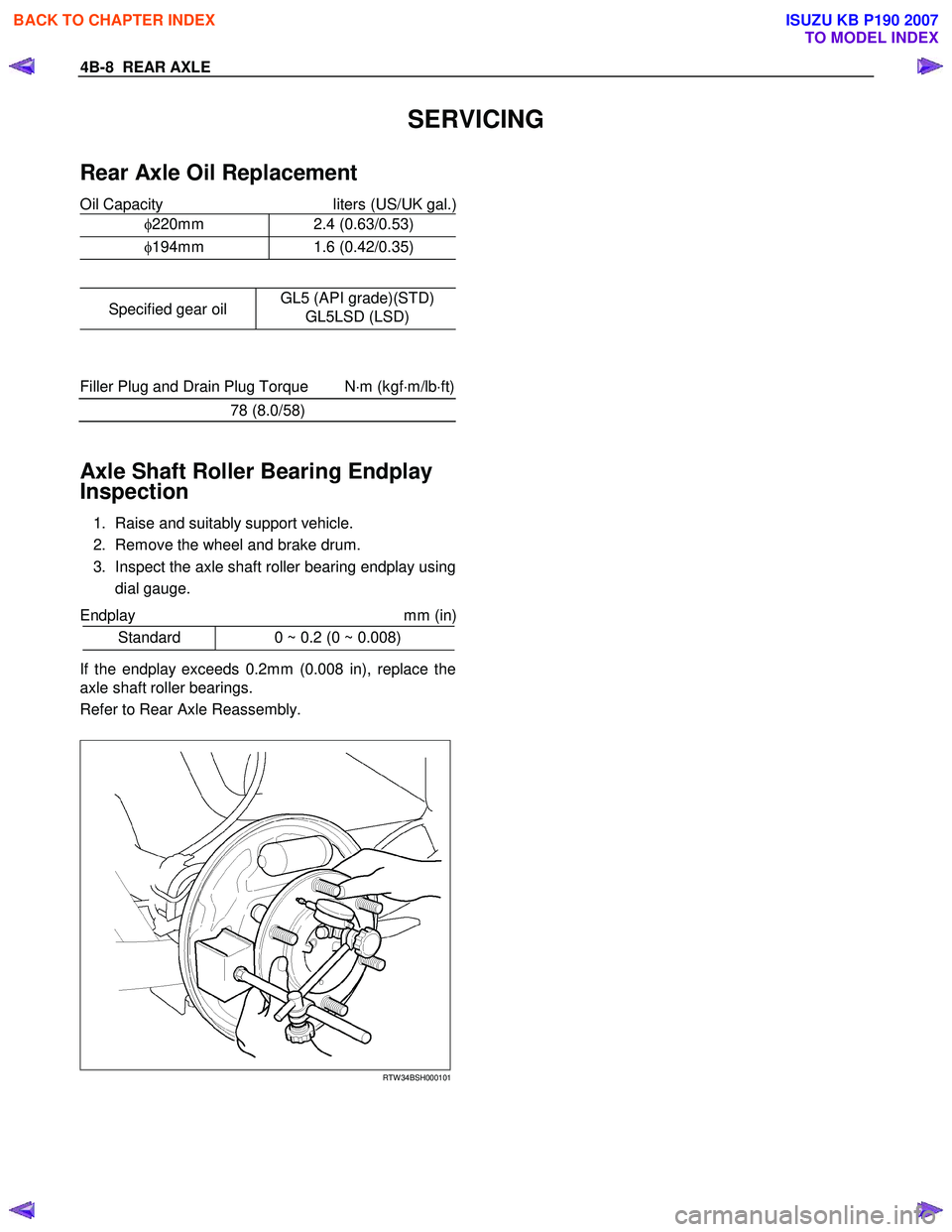

Axle Shaft Roller Bearing Endplay

Inspection

1. Raise and suitably support vehicle.

2. Remove the wheel and brake drum.

3. Inspect the axle shaft roller bearing endplay using dial gauge.

Endplay mm (in

)

Standard 0 ~ 0.2 (0 ~ 0.008)

If the endplay exceeds 0.2mm (0.008 in), replace the

axle shaft roller bearings.

Refer to Rear Axle Reassembly.

RTW 34BSH000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 507 of 6020

FRONT WHEEL DRIVE 4C1-3

MAIN DATA AND SPECIFICATIONS

FRONT AXLE AND DIFFERENTIAL

Ring gear size mm (in) φ

φφ

φ

194 (7.6)

Axle tube

Type It consists of the duce, a cast iron housing and the Axle tube.

Gear type Hypoid

Gear ratio (to 1) 3.583, 3.727, 3.909, 4.100, 4.300, 4.555, 4.777, 5.125

Differential type Two pinion

Specified gear oil (APL grade) GL-5

Oil capacity liter 1.4

(US/UK gal.) (0.4/0.31)

Axle shaft type Constant velocity joint (Barfield joint type and double offset joint).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 589 of 6020

SHIFT ON THE FLY SYSTEM 4C2-11

5. Actuator • Clean the actuator contact surface with the housing.

•

Apply liquid gasket to the contact surface on the

actuator side.

• Align shift arm with the groove of sleeve and install the

actuator.

4. Bolt

Tighten bolts to specified torque.

Actuator Bolt Torque N⋅m (kgf ⋅m/lb ⋅in)

9 (0.9/78)

3. Front Axle Drive Shaft (LH side)

2. Bolt • Install front axle drive shaft and mounting bracket.

• Tighten fitting bolts to specified tightening torque.

Bolt Torque N⋅m (kgf ⋅m/lb ⋅ft)

116 (11.8/85)

1. Filler Plug • Pour specified amount of differential gear oil.

Front Differential Oil Capacity liter (US/UK gal)

1.4 (0.37/0.31)

Actuator Housing Oil Capacity liter (US/UK gal) 0.12 (0.03/0.03)

• Install filler plug through packing and tighten to

specified torque.

Filler Plug Torque N⋅m (kgf ⋅m/lb ⋅ft)

78 (8.0/58)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 787 of 6020

6 – 2 TROUBLESHOOTING

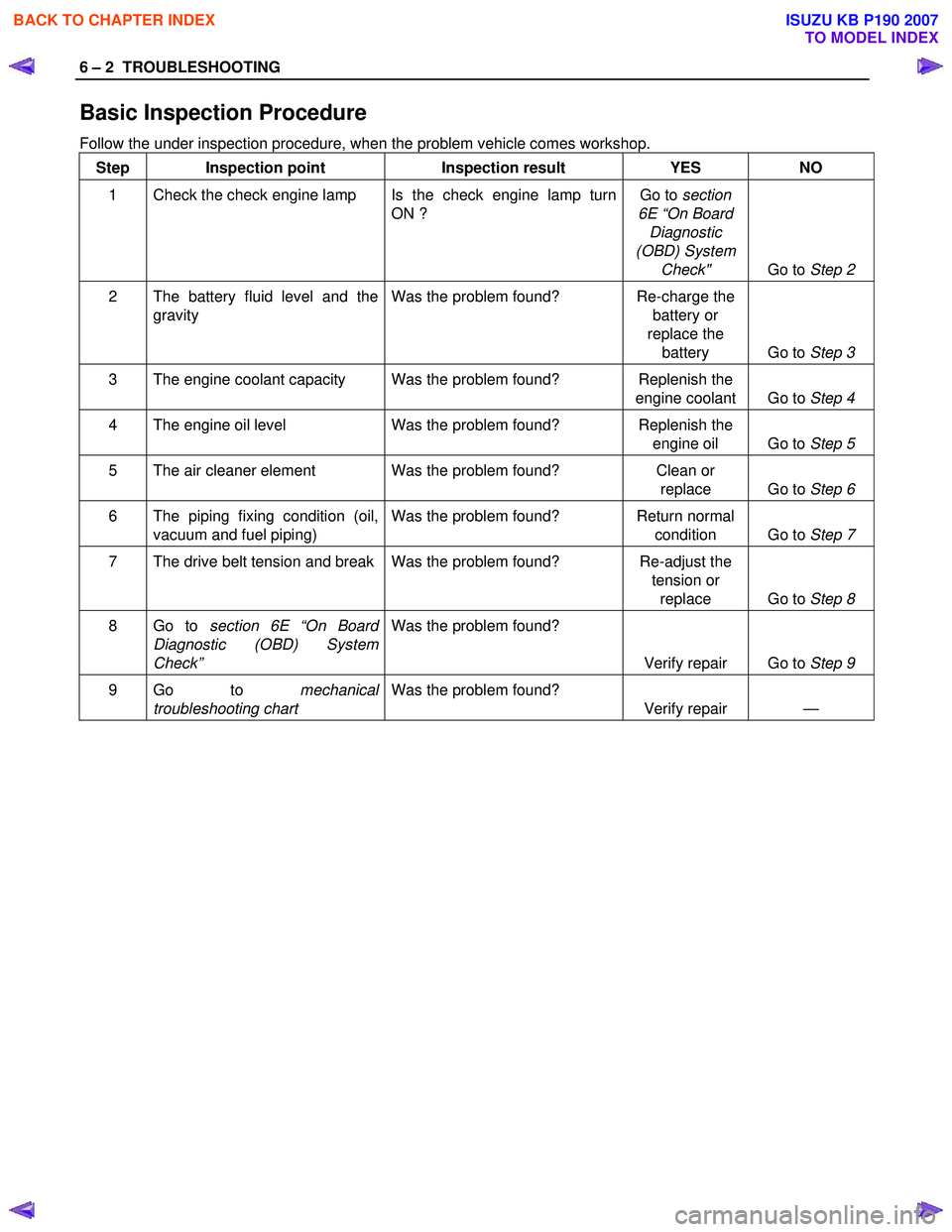

Basic Inspection Procedure

Follow the under inspection procedure, when the problem vehicle comes workshop. Step Inspection point Inspection result YES NO

1 Check the check engine lamp Is the check engine lamp turn ON ? Go to

section

6E “On Board Diagnostic

(OBD) System Check" Go to Step 2

2 The battery fluid level and the

gravity Was the problem found? Re-charge the

battery or

replace the battery Go to Step 3

3 The engine coolant capacity Was the problem found? Replenish the

engine coolant Go to Step 4

4 The engine oil level Was the problem found? Replenish the

engine oil Go to Step 5

5 The air cleaner element Was the problem found? Clean or

replace Go to Step 6

6 The piping fixing condition (oil,

vacuum and fuel piping) Was the problem found? Return normal

condition Go to Step 7

7 The drive belt tension and break Was the problem found? Re-adjust the

tension or replace Go to Step 8

8 Go to section 6E “On Board

Diagnostic (OBD) System

Check” Was the problem found?

Verify repair Go to Step 9

9 Go to mechanical

troubleshooting chart Was the problem found?

Verify repair —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 802 of 6020

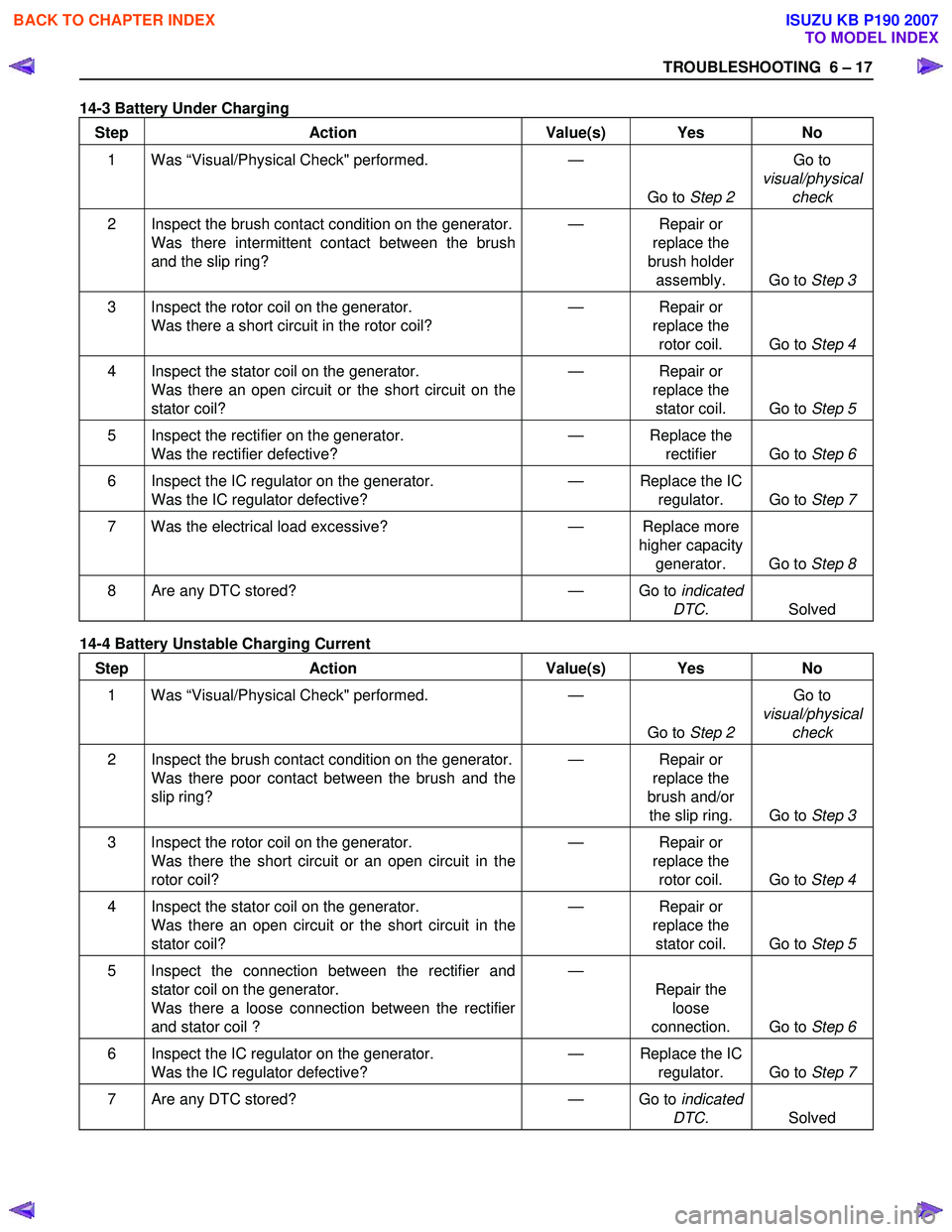

TROUBLESHOOTING 6 – 17

14-3 Battery Under Charging

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there intermittent contact between the brush

and the slip ring? —

Repair or

replace the

brush holder assembly. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there a short circuit in the rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit on the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the rectifier on the generator.

Was the rectifier defective? —

Replace the

rectifier Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Was the electrical load excessive? — Replace more

higher capacity generator. Go to Step 8

8 Are any DTC stored? — Go to indicated

DTC. Solved

14-4 Battery Unstable Charging Current

Step Action Value(s) Yes No

1 Was “Visual/Physical Check" performed.

—

Go to Step 2 Go to

visual/physical check

2 Inspect the brush contact condition on the generator.

Was there poor contact between the brush and the

slip ring? —

Repair or

replace the

brush and/or the slip ring. Go to Step 3

3 Inspect the rotor coil on the generator.

Was there the short circuit or an open circuit in the

rotor coil? —

Repair or

replace the rotor coil. Go to Step 4

4 Inspect the stator coil on the generator.

Was there an open circuit or the short circuit in the

stator coil? —

Repair or

replace the stator coil. Go to Step 5

5 Inspect the connection between the rectifier and

stator coil on the generator.

Was there a loose connection between the rectifier

and stator coil ? —

Repair the loose

connection. Go to Step 6

6 Inspect the IC regulator on the generator.

Was the IC regulator defective? —

Replace the IC

regulator. Go to Step 7

7 Are any DTC stored? — Go to indicated

DTC. Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 811 of 6020

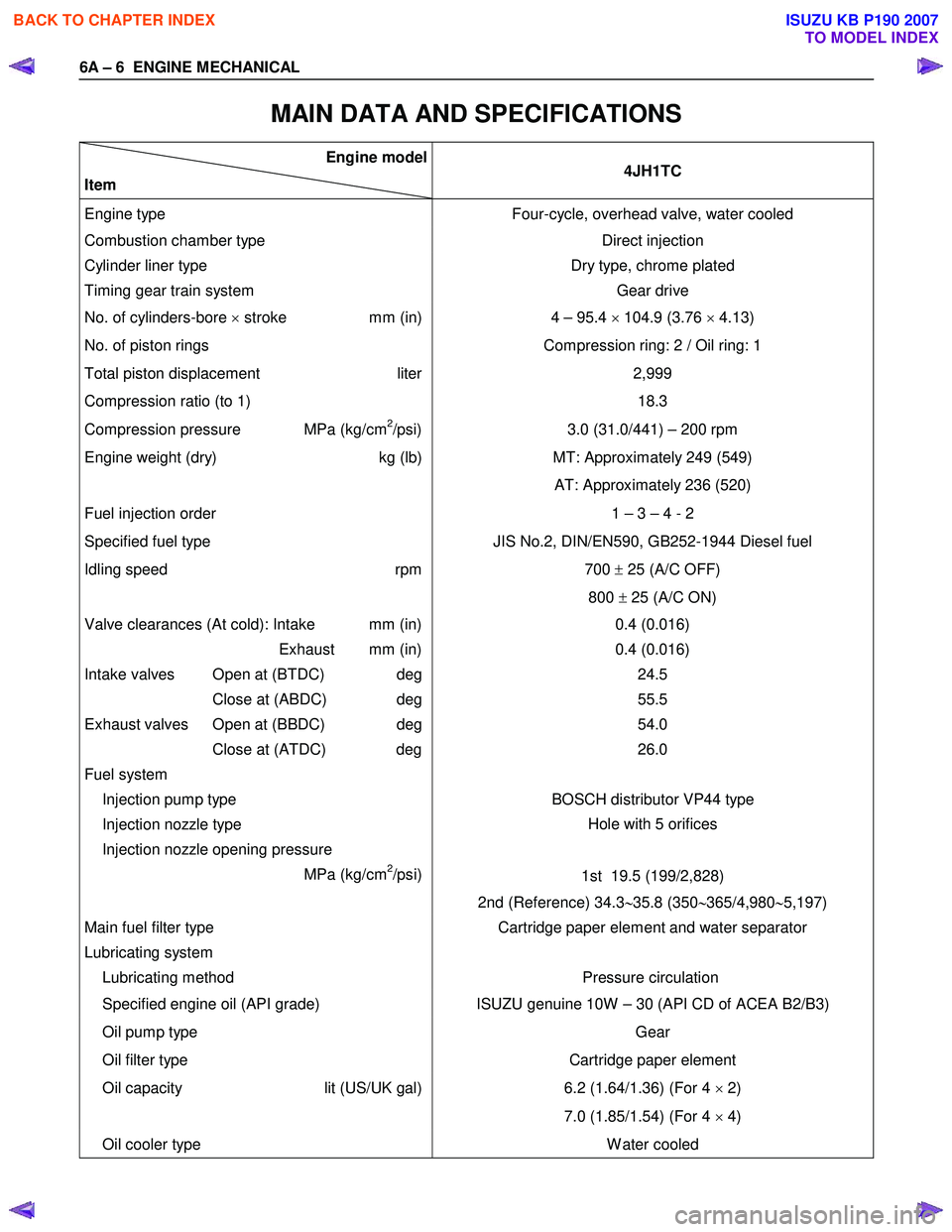

6A – 6 ENGINE MECHANICAL

MAIN DATA AND SPECIFICATIONS

Engine model

Item 4JH1TC

Engine type

Four-cycle, overhead valve, water cooled

Combustion chamber type Direct injection

Cylinder liner type

Timing gear train system Dry type, chrome plated

Gear drive

No. of cylinders-bore × stroke mm (in) 4 – 95.4 × 104.9 (3.76 × 4.13)

No. of piston rings Compression ring: 2 / Oil ring: 1

Total piston displacement liter

Compression ratio (to 1) 2,999

18.3

Compression pressure MPa (kg/cm2/psi) 3.0 (31.0/441) – 200 rpm

Engine weight (dry) kg (lb)MT: Approximately 249 (549)

AT: Approximately 236 (520)

Fuel injection order 1 – 3 – 4 - 2

Specified fuel type JIS No.2, DIN/EN590, GB252-1944 Diesel fuel

Idling speed rpm

700 ± 25 (A/C OFF)

800 ± 25 (A/C ON)

Valve clearances (At cold): Intake mm (in)

Exhaust mm (in)

Intake valves Open at (BTDC) deg

Close at (ABDC) deg

Exhaust valves Open at (BBDC) deg

Close at (ATDC) deg

Fuel system

Injection pump type 0.4 (0.016)

0.4 (0.016) 24.5

55.5

54.0

26.0

BOSCH distributor VP44 type

Injection nozzle type

Injection nozzle opening pressure

MPa (kg/cm

2/psi) Hole with 5 orifices

1st 19.5 (199/2,828)

2nd (Reference) 34.3 ∼35.8 (350 ∼365/4,980 ∼5,197)

Main fuel filter type

Lubricating system

Lubricating method Cartridge paper element and water separator

Pressure circulation

Specified engine oil (API grade) ISUZU genuine 10W – 30 (API CD of ACEA B2/B3)

Oil pump type

Oil filter type Gear

Cartridge paper element

Oil capacity lit (US/UK gal)

6.2 (1.64/1.36) (For 4

× 2)

7.0 (1.85/1.54) (For 4 × 4)

Oil cooler type W ater cooled

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007