ISUZU KB P190 2007 Workshop Repair Manual

KB P190 2007

ISUZU

ISUZU

https://www.carmanualsonline.info/img/61/57177/w960_57177-0.png

ISUZU KB P190 2007 Workshop Repair Manual

Page 819 of 6020

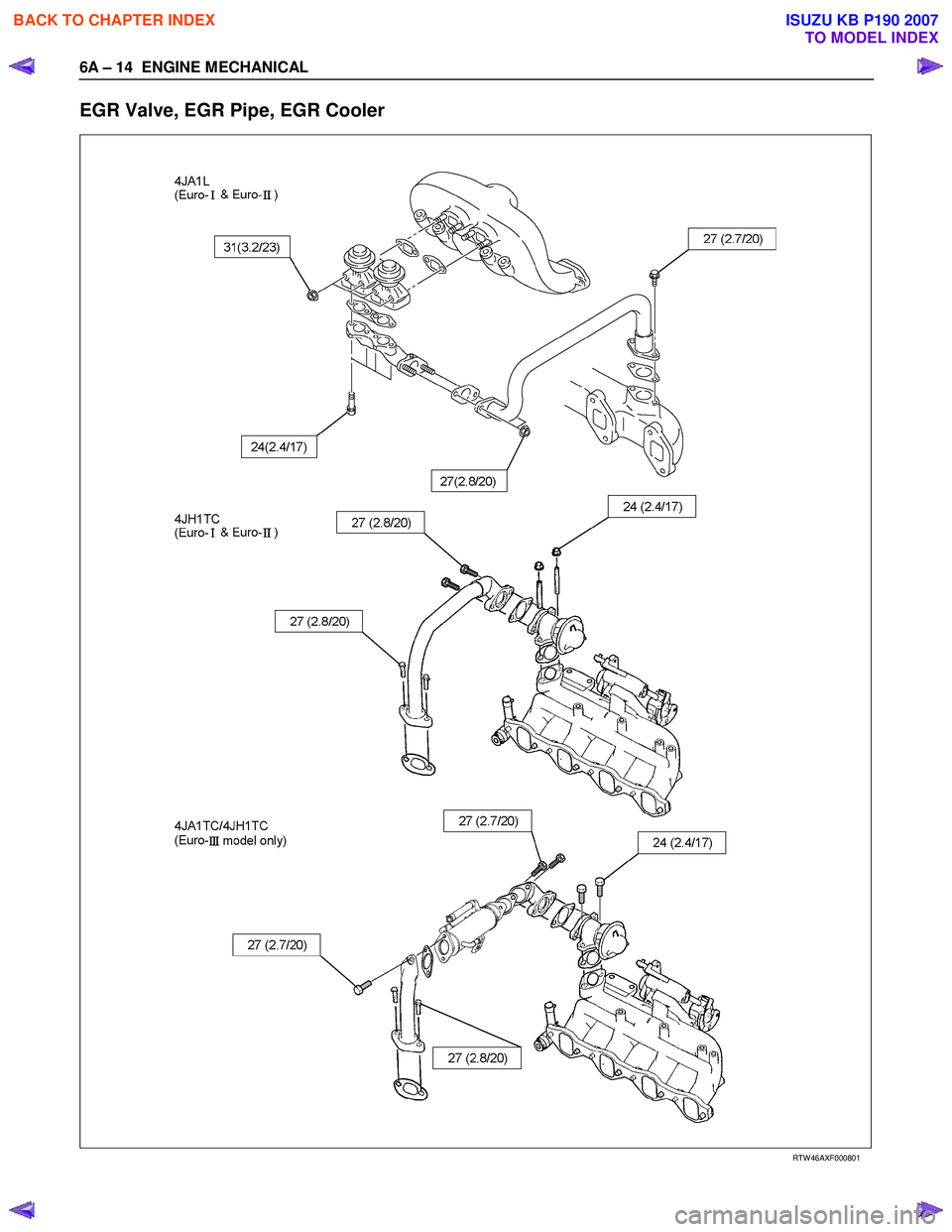

6A – 14 ENGINE MECHANICAL

EGR Valve, EGR Pipe, EGR Cooler

RTW 46AXF000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 820 of 6020

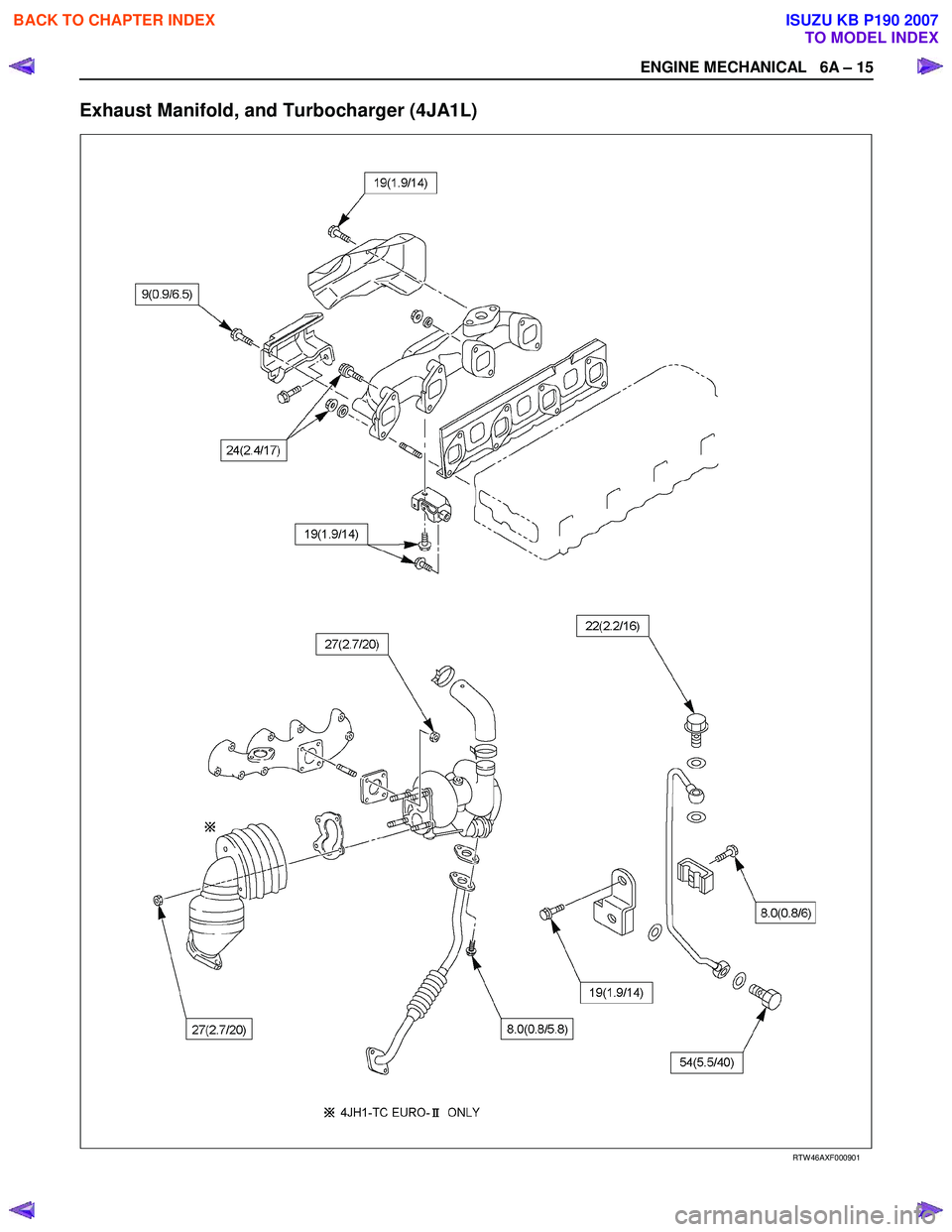

ENGINE MECHANICAL 6A – 15

Exhaust Manifold, and Turbocharger (4JA1L)

RTW 46AXF000901

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 821 of 6020

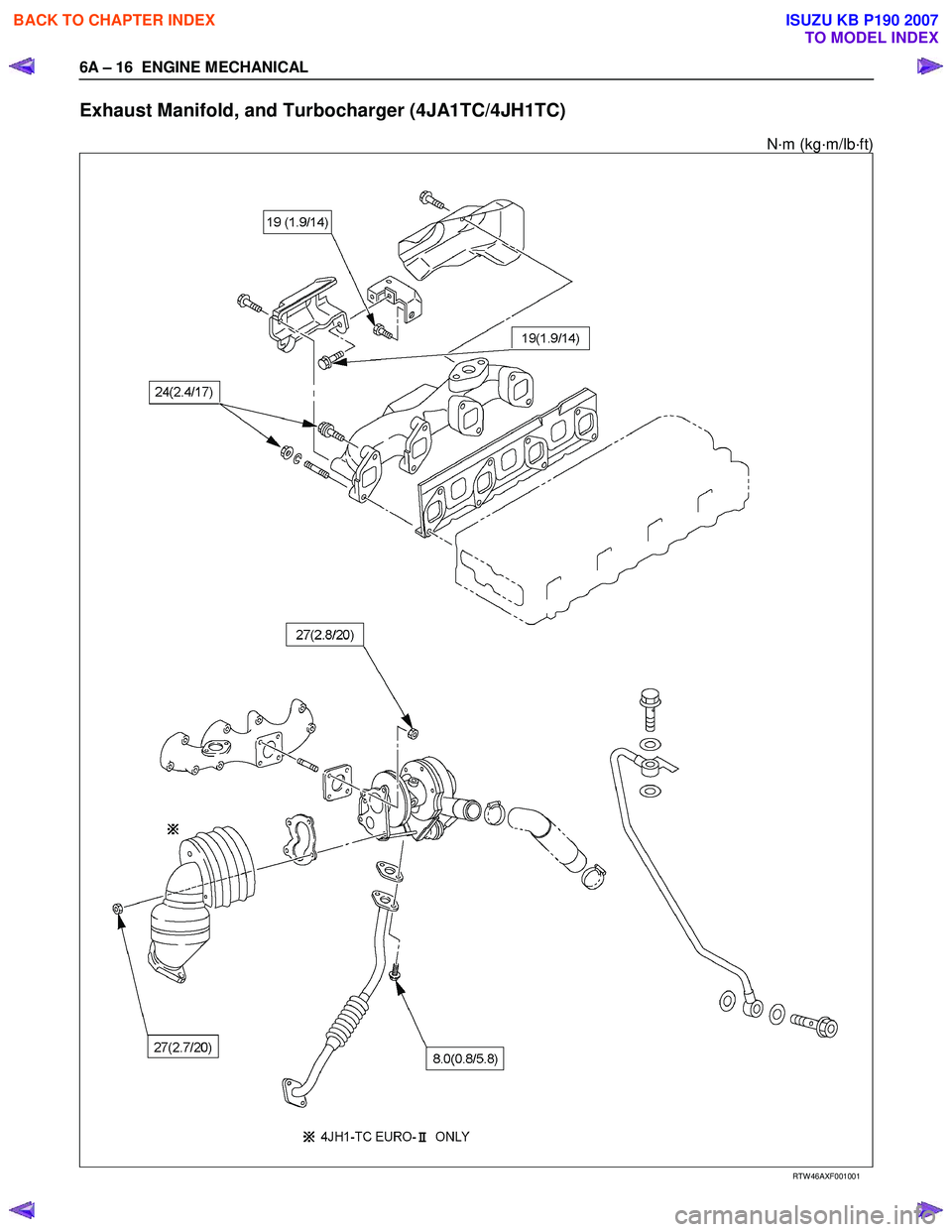

6A – 16 ENGINE MECHANICAL

Exhaust Manifold, and Turbocharger (4JA1TC/4JH1TC)

N·m (kg·m/lb·ft)

RTW 46AXF001001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 822 of 6020

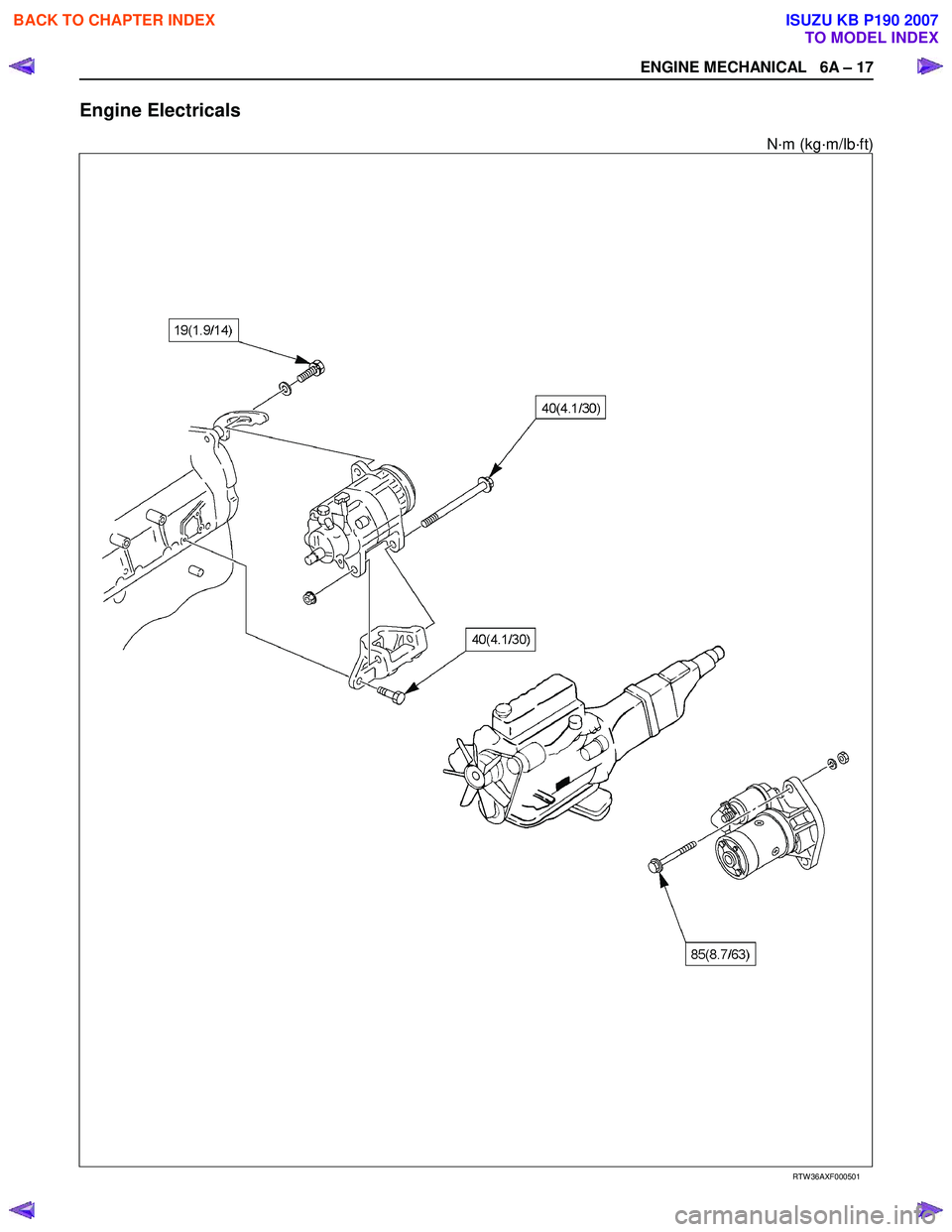

ENGINE MECHANICAL 6A – 17

Engine Electricals

N·m (kg·m/lb·ft)

RTW 36AXF000501

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 823 of 6020

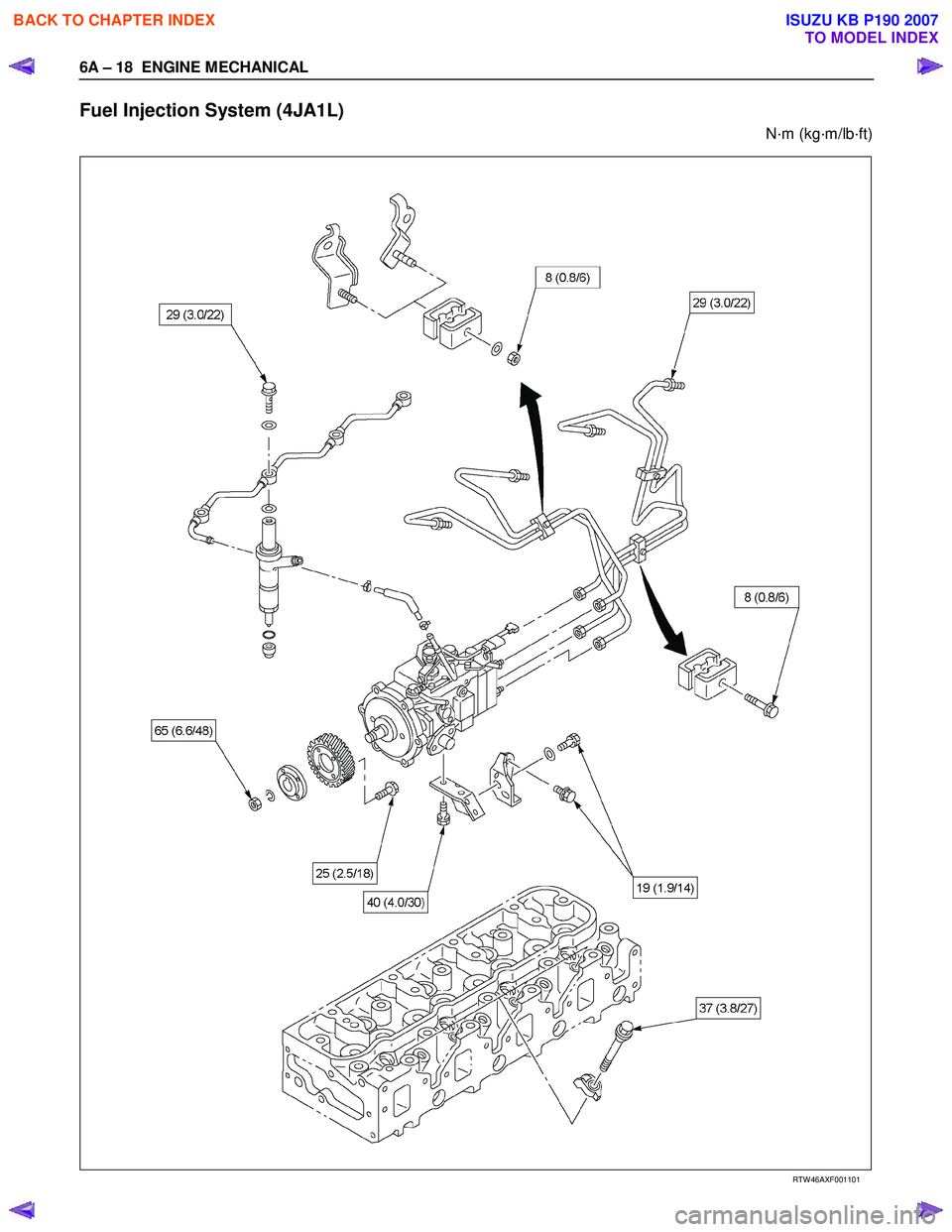

6A – 18 ENGINE MECHANICAL

Fuel Injection System (4JA1L)

N·m (kg·m/lb·ft)

RTW 46AXF001101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 824 of 6020

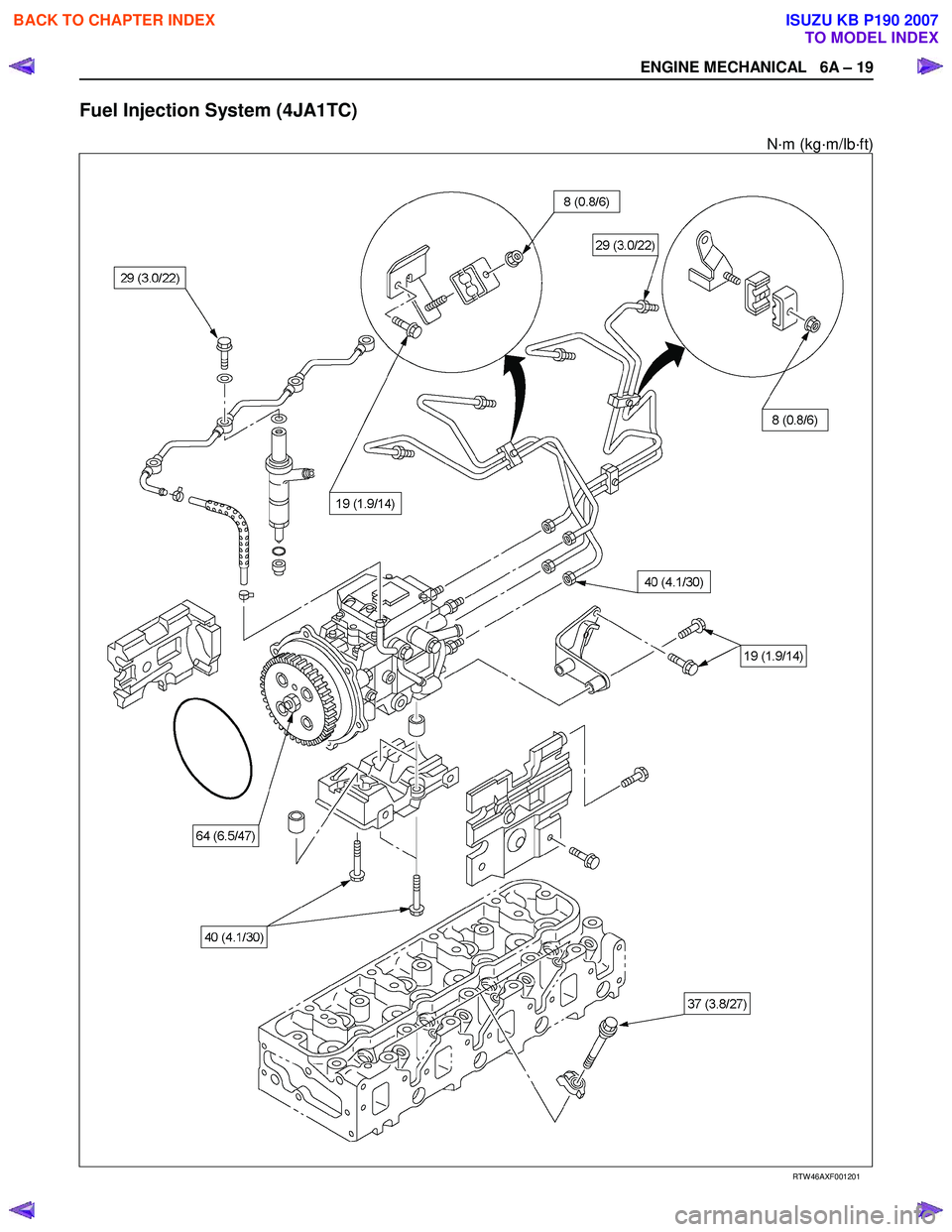

ENGINE MECHANICAL 6A – 19

Fuel Injection System (4JA1TC)

N·m (kg·m/lb·ft)

RTW 46AXF001201

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 825 of 6020

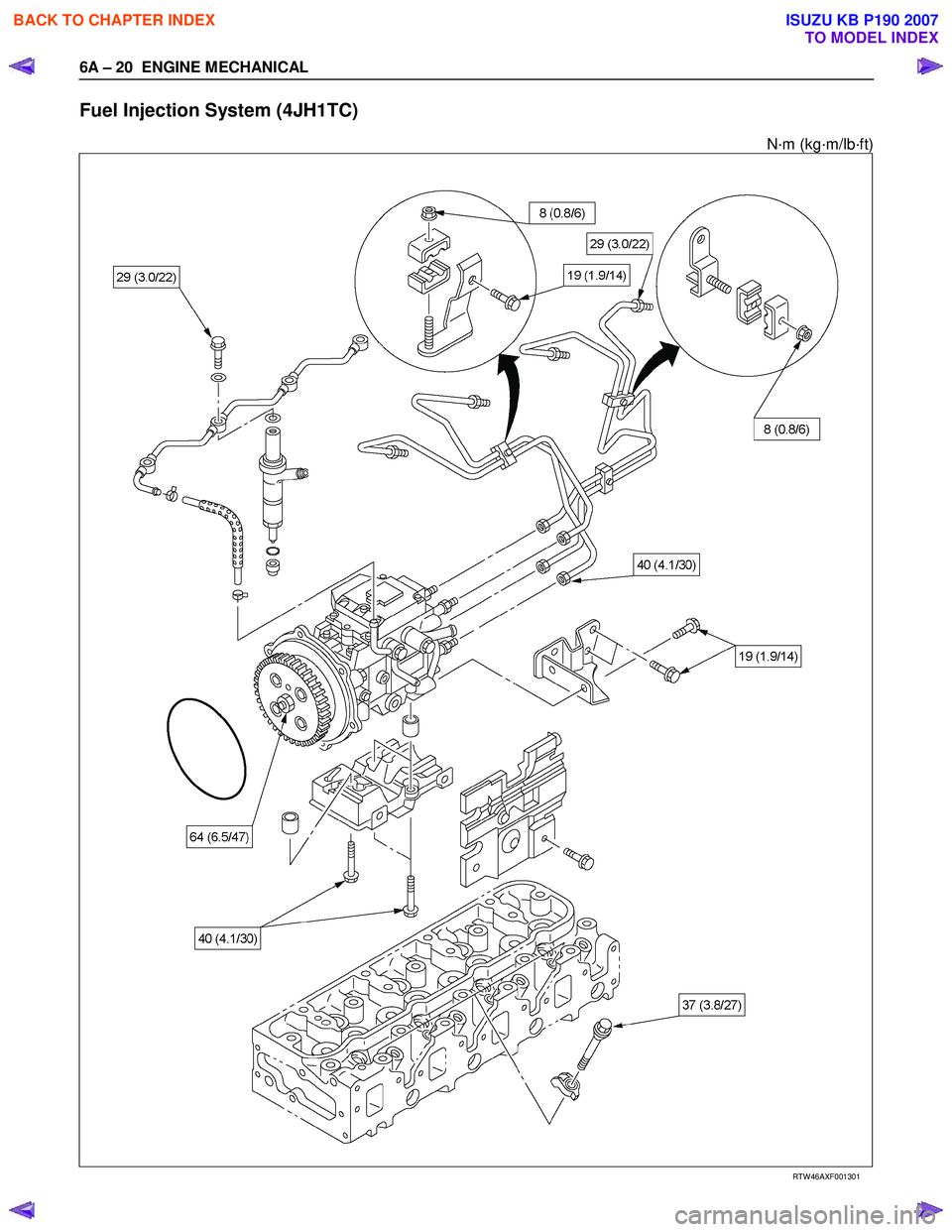

6A – 20 ENGINE MECHANICAL

Fuel Injection System (4JH1TC)

N·m (kg·m/lb·ft)

RTW 46AXF001301

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 826 of 6020

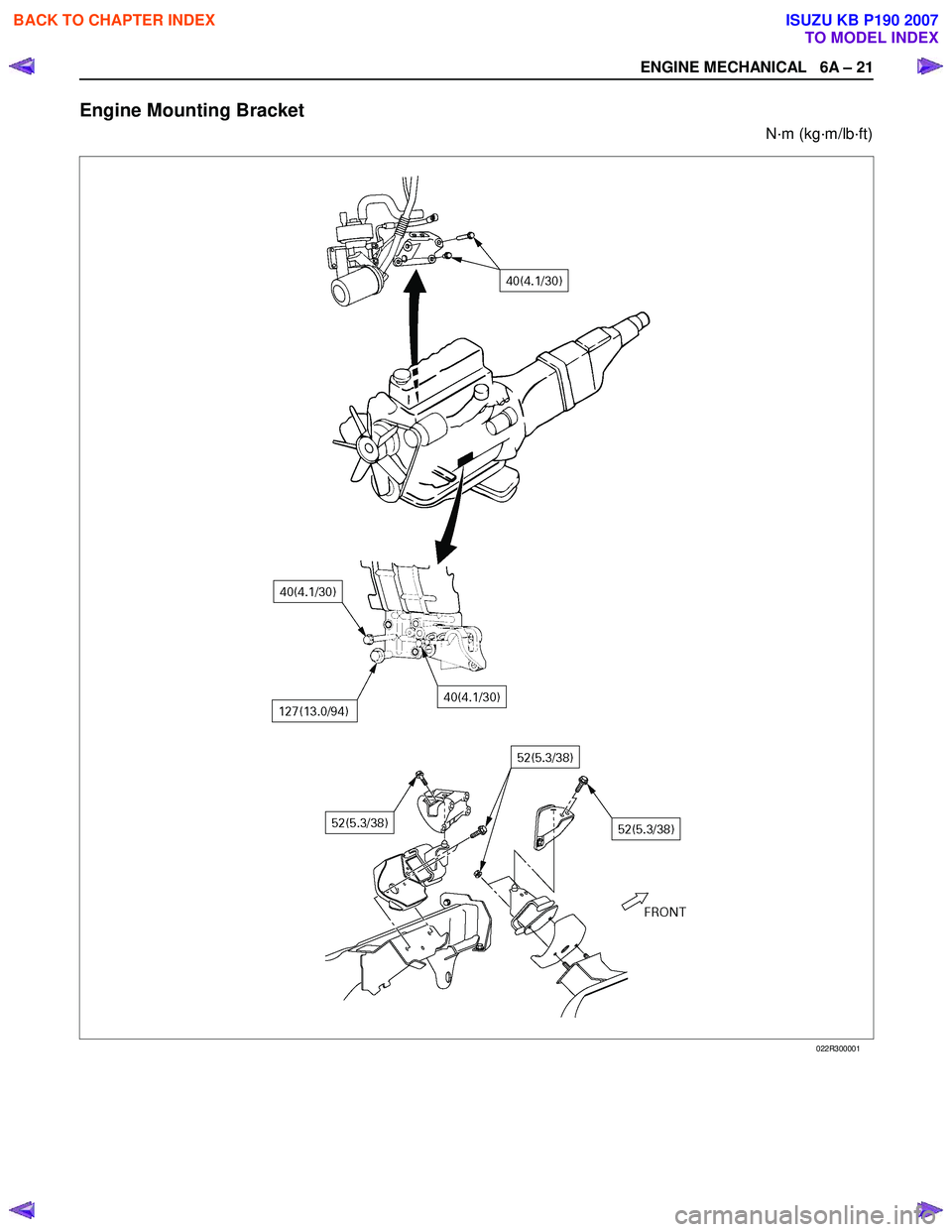

ENGINE MECHANICAL 6A – 21

Engine Mounting Bracket

N·m (kg·m/lb·ft)

022R300001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 827 of 6020

6A – 22 ENGINE MECHANICAL

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacturer Remarks

RTV*

Silicon Base ThreeBond 1207B

ThreeBond 1207C Three Bond

Three Bond

W ater Base

ThreeBond 1141E

ThreeBond 1215 Three Bond

Three Bond

Solvent

ThreeBond 1104

Belco Bond 4

Belco Bond 401

Belco Bond 402 Three Bond

Isuzu

Isuzu

Isuzu

Anaerobic

LOCTITE 515

LOCTITE 518

LOCTITE 262 Loctite

Loctite

Loctite Recommended for

transaxle repairs

* RTV : Room Temperature Vulcanizer

Note:

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the vehicle.

2. Be careful to use the specified amount of liquid gasket. Follow the manufacturer’s instructions at all times.

3. Be absolutely sure to remove all lubricants and moisture from the connecting surfaces before applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface. Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance of

greater than 0.25 mm (0.01 in). Poor adhesion will result.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 828 of 6020

ENGINE MECHANICAL 6A – 23

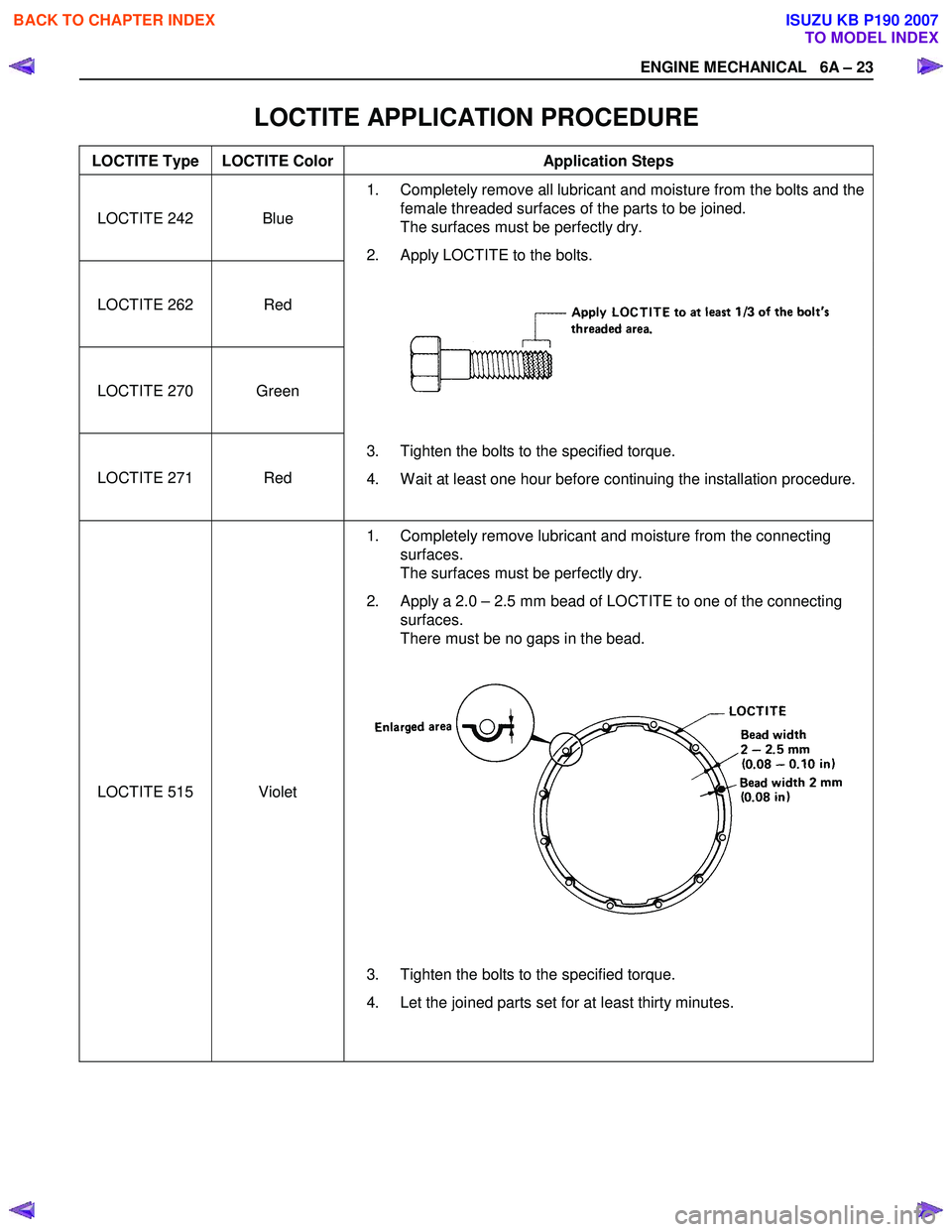

LOCTITE APPLICATION PROCEDURE

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242 Blue

LOCTITE 262 Red

LOCTITE 270 Green

LOCTITE 271 Red 1. Completely remove all lubricant and moisture from the bolts and the

female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2. Apply LOCTITE to the bolts.

3. Tighten the bolts to the specified torque.

4. W ait at least one hour before continuing the installation procedure.

LOCTITE 515 Violet 1. Completely remove lubricant and moisture from the connecting

surfaces.

The surfaces must be perfectly dry.

2. Apply a 2.0 – 2.5 mm bead of LOCTITE to one of the connecting surfaces.

There must be no gaps in the bead.

3. Tighten the bolts to the specified torque.

4. Let the joined parts set for at least thirty minutes.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007