alarm ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1292 of 6020

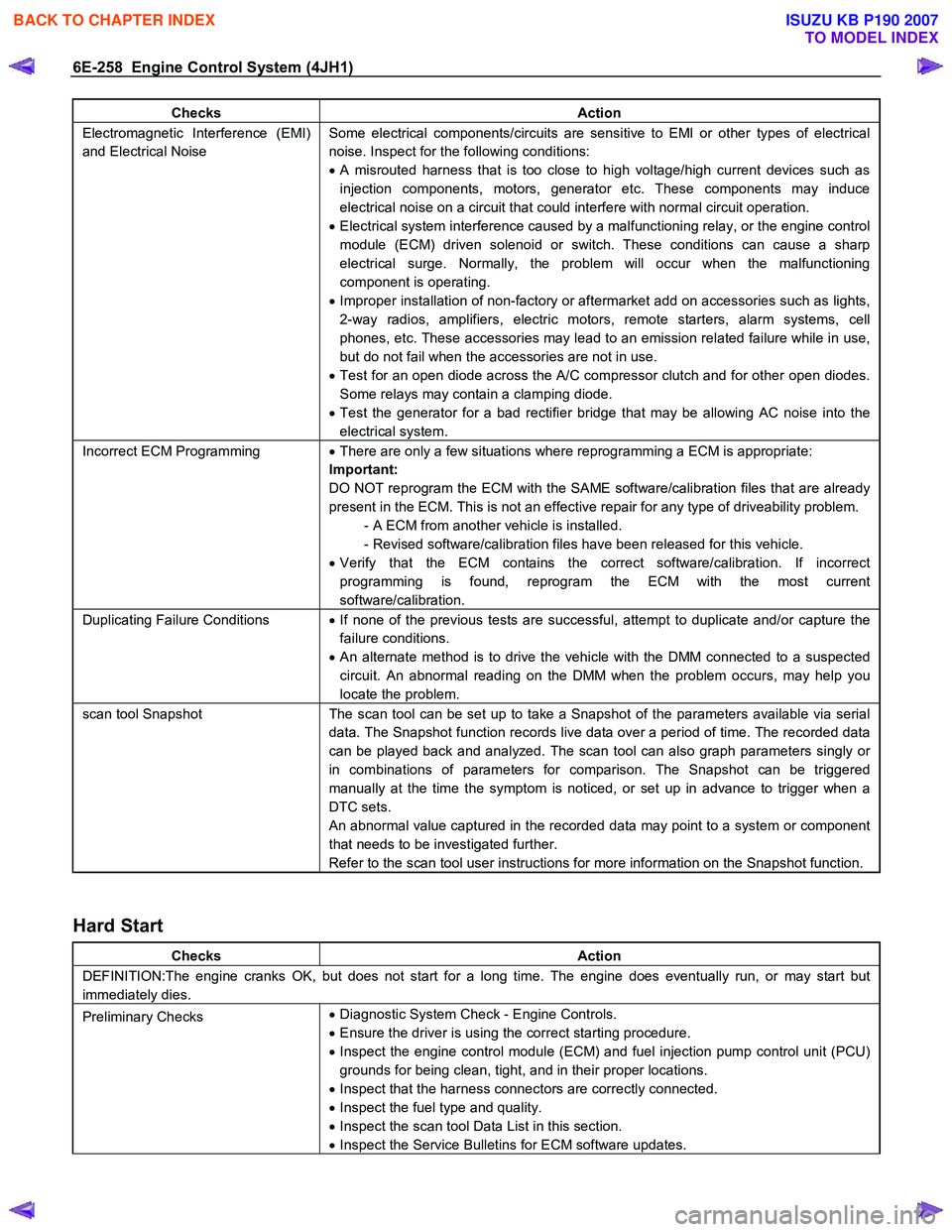

6E-258 Engine Control System (4JH1)

Checks Action

Electromagnetic Interference (EMI)

and Electrical Noise Some electrical components/circuits are sensitive to EMI or other types of electrical

noise. Inspect for the following conditions:

• A misrouted harness that is too close to high voltage/high current devices such as

injection components, motors, generator etc. These components may induce

electrical noise on a circuit that could interfere with normal circuit operation.

• Electrical system interference caused by a malfunctioning relay, or the engine control

module (ECM) driven solenoid or switch. These conditions can cause a sharp

electrical surge. Normally, the problem will occur when the malfunctioning

component is operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights,

2-way radios, amplifiers, electric motors, remote starters, alarm systems, cell

phones, etc. These accessories may lead to an emission related failure while in use,

but do not fail when the accessories are not in use.

• Test for an open diode across the A/C compressor clutch and for other open diodes.

Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the

electrical system.

Incorrect ECM Programming • There are only a few situations where reprogramming a ECM is appropriate:

Important:

DO NOT reprogram the ECM with the SAME software/calibration files that are already

present in the ECM. This is not an effective repair for any type of driveability problem. - A ECM from another vehicle is installed.

- Revised software/calibration files have been released for this vehicle.

• Verify that the ECM contains the correct software/calibration. If incorrect

programming is found, reprogram the ECM with the most current

software/calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/or capture the

failure conditions.

• An alternate method is to drive the vehicle with the DMM connected to a suspected

circuit. An abnormal reading on the DMM when the problem occurs, may help you

locate the problem.

scan tool Snapshot The scan tool can be set up to take a Snapshot of the parameters available via serial

data. The Snapshot function records live data over a period of time. The recorded data

can be played back and analyzed. The scan tool can also graph parameters singly or

in combinations of parameters for comparison. The Snapshot can be triggered

manually at the time the symptom is noticed, or set up in advance to trigger when a

DTC sets.

An abnormal value captured in the recorded data may point to a system or component

that needs to be investigated further.

Refer to the scan tool user instructions for more information on the Snapshot function.

Hard Start

Checks Action

DEFINITION:The engine cranks OK, but does not start for a long time. The engine does eventually run, or may start but

immediately dies.

Preliminary Checks •

Diagnostic System Check - Engine Controls.

• Ensure the driver is using the correct starting procedure.

• Inspect the engine control module (ECM) and fuel injection pump control unit (PCU)

grounds for being clean, tight, and in their proper locations.

• Inspect that the harness connectors are correctly connected.

• Inspect the fuel type and quality.

• Inspect the scan tool Data List in this section.

• Inspect the Service Bulletins for ECM software updates.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1943 of 6020

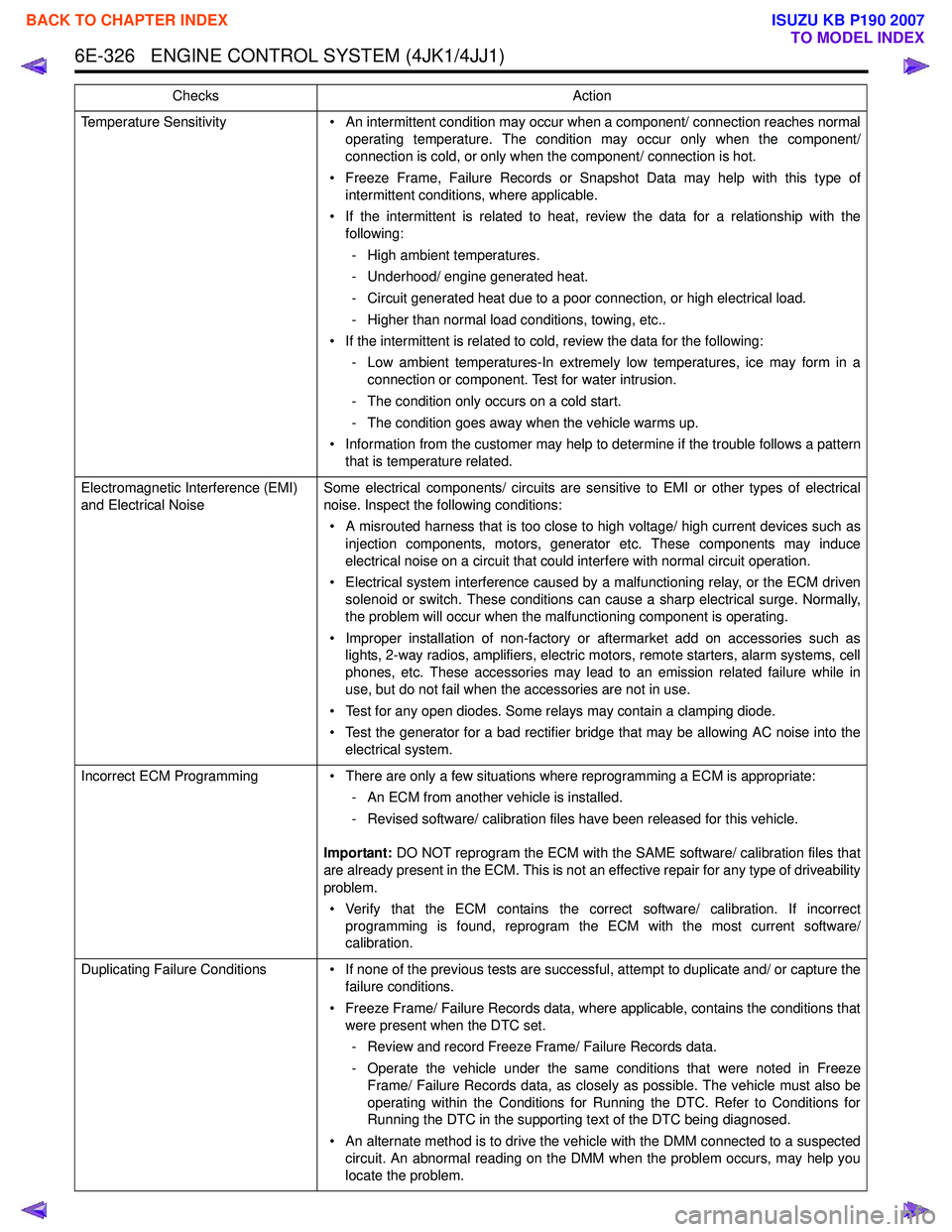

6E-326 ENGINE CONTROL SYSTEM (4JK1/4JJ1)

Temperature Sensitivity• An intermittent condition may occur when a component/ connection reaches normal

operating temperature. The condition may occur only when the component/

connection is cold, or only when the component/ connection is hot.

• Freeze Frame, Failure Records or Snapshot Data may help with this type of intermittent conditions, where applicable.

• If the intermittent is related to heat, review the data for a relationship with the following:

- High ambient temperatures.

- Underhood/ engine generated heat.

- Circuit generated heat due to a poor connection, or high electrical load.

- Higher than normal load conditions, towing, etc..

• If the intermittent is related to cold, review the data for the following: - Low ambient temperatures-In extremely low temperatures, ice may form in aconnection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern that is temperature related.

Electromagnetic Interference (EMI)

and Electrical Noise Some electrical components/ circuits are sensitive to EMI or other types of electrical

noise. Inspect the following conditions:

• A misrouted harness that is too close to high voltage/ high current devices such as injection components, motors, generator etc. These components may induce

electrical noise on a circuit that could interfere with normal circuit operation.

• Electrical system interference caused by a malfunctioning relay, or the ECM driven solenoid or switch. These conditions can cause a sharp electrical surge. Normally,

the problem will occur when the malfunctioning component is operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights, 2-way radios, amplifiers, electric motors, remote starters, alarm systems, cell

phones, etc. These accessories may lead to an emission related failure while in

use, but do not fail when the accessories are not in use.

• Test for any open diodes. Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the electrical system.

Incorrect ECM Programming • There are only a few situations where reprogramming a ECM is appropriate:

- An ECM from another vehicle is installed.

- Revised software/ calibration files have been released for this vehicle.

Important: DO NOT reprogram the ECM with the SAME software/ calibration files that

are already present in the ECM. This is not an effective repair for any type of driveability

problem.

• Verify that the ECM contains the correct software/ calibration. If incorrect programming is found, reprogram the ECM with the most current software/

calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/ or capture the failure conditions.

• Freeze Frame/ Failure Records data, where applicable, contains the conditions that were present when the DTC set.

- Review and record Freeze Frame/ Failure Records data.

- Operate the vehicle under the same conditions that were noted in Freeze Frame/ Failure Records data, as closely as possible. The vehicle must also be

operating within the Conditions for Running the DTC. Refer to Conditions for

Running the DTC in the supporting text of the DTC being diagnosed.

• An alternate method is to drive the vehicle with the DMM connected to a suspected circuit. An abnormal reading on the DMM when the problem occurs, may help you

locate the problem.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3302 of 6020

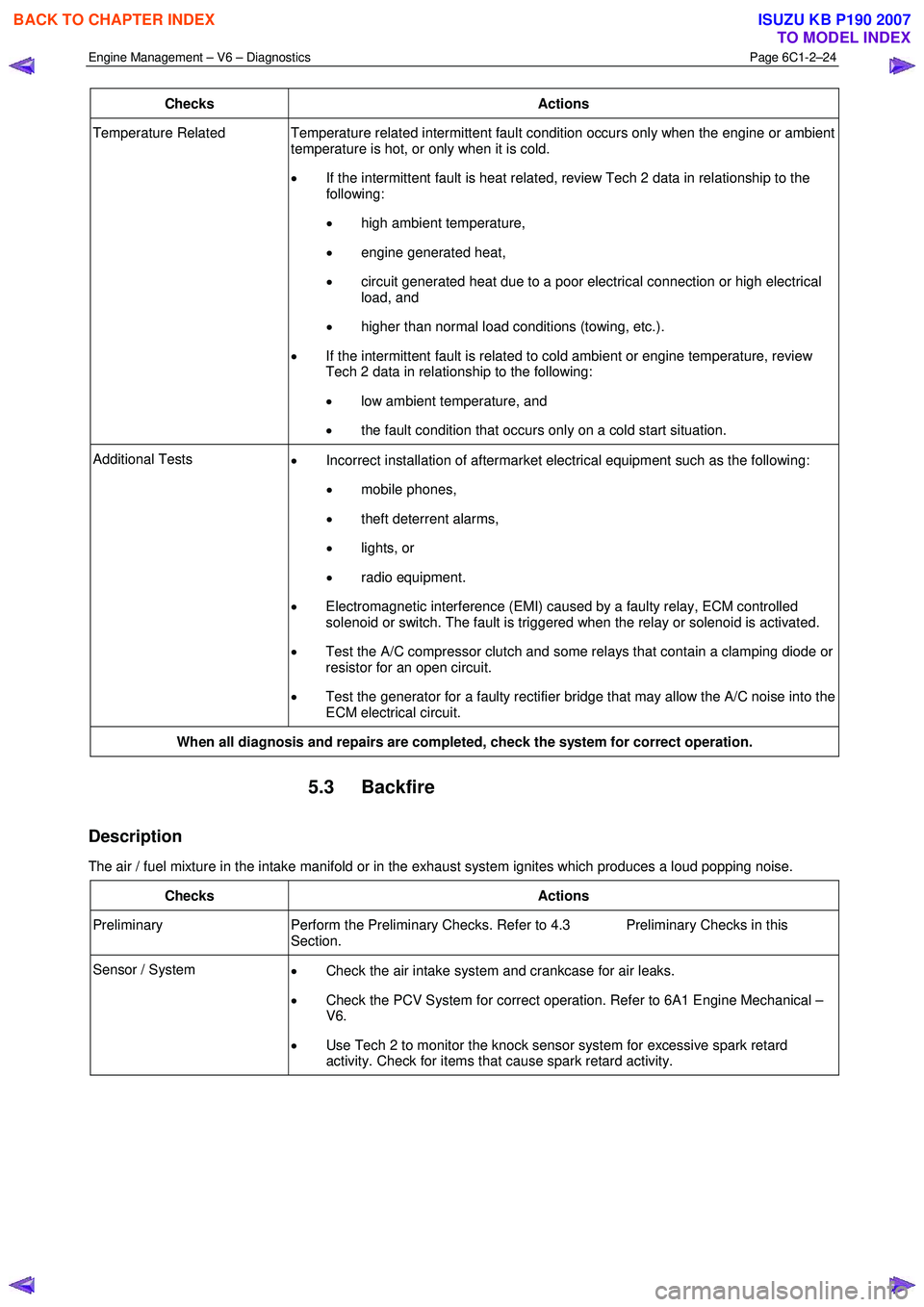

Engine Management – V6 – Diagnostics Page 6C1-2–24

Checks Actions

Temperature Related Temperature related intermittent fault condition occurs only when the engine or ambient

temperature is hot, or only when it is cold.

• If the intermittent fault is heat related, review Tech 2 data in relationship to the

following:

• high ambient temperature,

• engine generated heat,

• circuit generated heat due to a poor electrical connection or high electrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review

Tech 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Electromagnetic interference (EMI) caused by a faulty relay, ECM controlled

solenoid or switch. The fault is triggered when the relay or solenoid is activated.

• Test the A/C compressor clutch and some relays that contain a clamping diode or

resistor for an open circuit.

• Test the generator for a faulty rectifier bridge that may allow the A/C noise into the

ECM electrical circuit.

When all diagnosis and repairs are completed, check the system for correct operation.

5.3 Backfire

Description

The air / fuel mixture in the intake manifold or in the exhaust system ignites which produces a loud popping noise.

Checks Actions

Preliminary Perform the Preliminary Checks. Refer to 4.3 Preliminary Checks in this

Section.

Sensor / System • Check the air intake system and crankcase for air leaks.

• Check the PCV System for correct operation. Refer to 6A1 Engine Mechanical –

V6.

• Use Tech 2 to monitor the knock sensor system for excessive spark retard

activity. Check for items that cause spark retard activity.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3690 of 6020

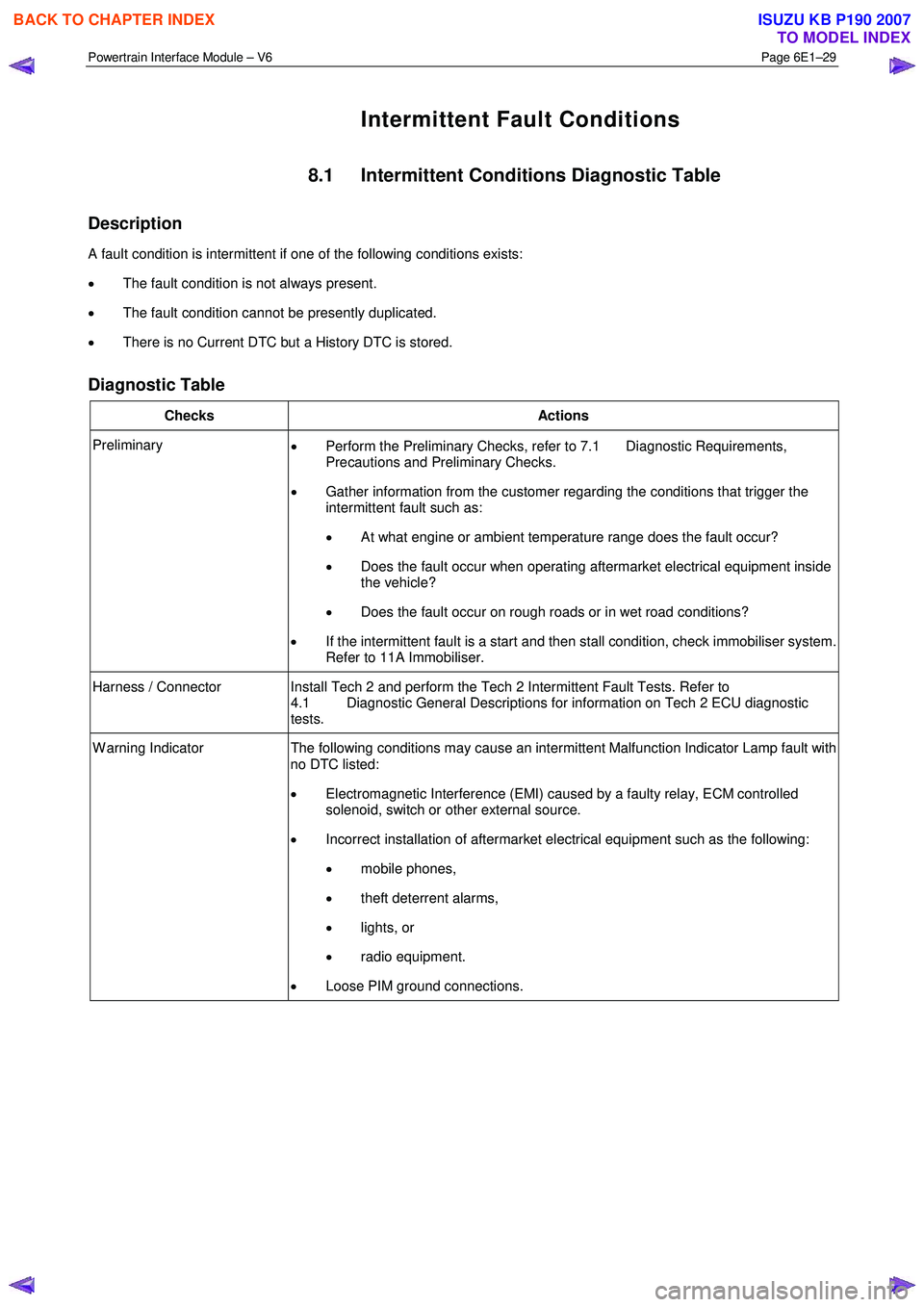

Powertrain Interface Module – V6 Page 6E1–29

Intermittent Fault Conditions

8.1 Intermittent Conditions Diagnostic Table

Description

A fault condition is intermittent if one of the following conditions exists:

• The fault condition is not always present.

• The fault condition cannot be presently duplicated.

• There is no Current DTC but a History DTC is stored.

Diagnostic Table

Checks Actions

Preliminary

• Perform the Preliminary Checks, refer to 7.1 Diagnostic Requirements,

Precautions and Preliminary Checks.

• Gather information from the customer regarding the conditions that trigger the

intermittent fault such as:

• At what engine or ambient temperature range does the fault occur?

• Does the fault occur when operating aftermarket electrical equipment inside

the vehicle?

• Does the fault occur on rough roads or in wet road conditions?

• If the intermittent fault is a start and then stall condition, check immobiliser system.

Refer to 11A Immobiliser.

Harness / Connector Install Tech 2 and perform the Tech 2 Intermittent Fault Tests. Refer to 4.1 Diagnostic General Descriptions for information on Tech 2 ECU diagnostic

tests.

W arning Indicator The following conditions may cause an intermittent Malfunction Indicator Lamp fault with

no DTC listed:

• Electromagnetic Interference (EMI) caused by a faulty relay, ECM controlled

solenoid, switch or other external source.

• Incorrect installation of aftermarket electrical equipment such as the following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Loose PIM ground connections.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3691 of 6020

Powertrain Interface Module – V6 Page 6E1–30

Checks Actions

Temperature Related The Tech 2 Freeze Frame / Failure Records or Snapshot data may be used if applicable

to the fault condition. Refer to 4.1 Diagnostic General Descriptions for information on

Tech 2 ECU diagnostic tests.

• If the intermittent fault is heat related, review the Tech 2 data in relationship to the

following:

• high ambient temperature,

• underhood / engine generated heat,

• circuit generated heat due to a poor electrical connection or high electrical

load, and

• higher than normal load conditions (towing, etc.).

• If the intermittent fault is related to cold ambient or engine temperature, review the

Tech 2 data in relationship to the following:

• low ambient temperature, and

• the fault condition that occurs only on a cold start situation.

Additional Tests

• Check for incorrect installation of aftermarket electrical equipment such as the

following:

• mobile phones,

• theft deterrent alarms,

• lights, or

• radio equipment.

• Check for electromagnetic Interference (EMI) caused by a faulty relay, ECM

controlled solenoid or switch. The fault is triggered when the relay or solenoid is

activated.

• Check the A/C compressor clutch and some relays that contain a clamping diode

or resistor for an open circuit.

• Check the generator for a faulty rectifier bridge that may allow A/C noise into the

PIM electrical circuit.

When all diagnosis and repairs are completed, check the engine management system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4378 of 6020

7A2-94 TRANSMISSION CONTROL SYSTEM (JR405E)

Temperature Sensitivity• An intermittent condition may occur when a component/ connection reaches

normal operating temperature. The condition may occur only when the

component/ connection is cold, or only when the component/ connection is hot.

• If the intermittent is related to heat, review the data for a relationship with the following:

- High ambient temperatures.

- Underhood/ engine generated heat.

- Circuit generated heat due to a poor connection, or high electrical load.

- Higher than normal load conditions, towing, etc.

• If the intermittent is related to cold, review the data for the following: - Low ambient temperatures-In extremely low temperatures, ice may form in a connection or component. Test for water intrusion.

- The condition only occurs on a cold start.

- The condition goes away when the vehicle warms up.

• Information from the customer may help to determine if the trouble follows a pattern that is temperature related.

Electromagnetic Interference (EMI) and

Electrical Noise Some electrical components/ circuits are sensitive to EMI or other types of electrical

noise. Inspect the following conditions:

• A misrouted harness that is too close to high voltage/ high current devices such as injection components, motors, generator etc. These components may

induce electrical noise on a circuit that could interfere with normal circuit

operation.

• Electrical system interference caused by a malfunctioning relay, or the TCM driven solenoid or switch. These conditions can cause a sharp electrical surge.

Normally, the problem will occur when the malfunctioning component is

operating.

• Improper installation of non-factory or aftermarket add on accessories such as lights, 2-way radios, amplifiers, electric motors, remote starters, alarm systems,

cell phones, etc. These accessories may lead to an emission related failure

while in use, but do not fail when the accessories are not in use.

• Test for any open diodes. Some relays may contain a clamping diode.

• Test the generator for a bad rectifier bridge that may be allowing AC noise into the electrical system.

Incorrect TCM Programming • There are only a few situations where reprogramming a TCM is appropriate:

- An ECM from another vehicle is installed.

- Revised software/ calibration files have been released for this vehicle.

Important: DO NOT reprogram the TCM with the SAME software/ calibration files

that are already present in the TCM. This is not an effective repair for any type of

driveability problem.

• Verify that the TCM contains the correct software/ calibration. If incorrect programming is found, reprogram the TCM with the most current software/

calibration.

Duplicating Failure Conditions • If none of the previous tests are successful, attempt to duplicate and/ or capture

the failure conditions.

• An alternate method is to drive the vehicle with the DMM connected to a suspected circuit. An abnormal reading on the DMM when the problem occurs,

may help you locate the problem.

Scan Tool Snapshot The scan tool can be set up to take a Snapshot of the parameters available via serial

data. The Snapshot function records live data over a period of time. The recorded

data can be played back and analyzed. The scan tool can also graph parameters

singly or in combinations of parameters for comparison. The Snapshot can be

triggered manually at the time the symptom is noticed, or set up in advance to trigger

when a DTC sets.

An abnormal value captured in the recorded data may point to a system or

component that needs to be investigated further.

Refer to the scan tool Users Guide for more information.

Checks

Action

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 5522 of 6020

8A-584 ELECTRICAL-BODY AND CHASSIS

RTW 38DLH000101

Menu

The left table shows witch functions are used for the

available equipment versions.

NOTE: Marked items are not applied for keyless entry

system.

DTC

On OBD has three options available in the Tech-2

DTC mode to display the enhanced information

available.

• Read DTC Info Ordered By Priority.

• Read DTC Info As Stored By ECU.

• Clear DTC and Alarm Code Info.

Clear DTC Information

To clear Diagnostic Trouble Codes (DTCs), Use the

diagnostic scan tool “Clear DTC Information” function.

Tech-2 Data Display

The Tech-2 data values represent values that would

be seen on a normally-keyless entry system.

RTW 38DSH001601

Actuator Test

Unlock/Lock Test

Check whether opening and closing of a door lock

can be performed by operation of Tech-2.

1. Turn the key “OFF”.

2. Turn the key “ON”.

3. Check the display and test menu.

4. Operate the Tech-2.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5858 of 6020

IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6) 11A-7

Powertrain Interface Module (PIM)

Legend1. Powertrain interface module (PIM)

Immobilizer Control Unit (ICU) Connector

End View

Connector No. B-109

Connector Color White

Test Adapter No. J-35616-64A

Pin No. Wire Color Pin Function

1 RED/YEL Battery voltage

2-N ot u se d

3 BLK Ground

4-N ot u se d

5 BLU CAN high

6 YEL CAN low

7-N ot u se d

8 VIO Alarm cancel (disarm) signal output (with anti-theft system)

9 YEL Ignition voltage

10 - Not used 11 - Not used

12 - Not used

RTW7BASH000501

123456

789101112

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5896 of 6020

IMMOBILIZER CONTROL SYSTEM (4JK1/4JJ1/HFV6) 11A-45

Description and Operation

Immobilizer System Description

Legend1. Transponder key

2. ICU

3. Controller area network (CAN) communication bus lines 4. Anti-theft control unit (with anti-theft system)

5. Engine control module (ECM) (4JK1/ 4JJ1)

6. Powertrain interface module (PIM)

7. Engine control module (ECM) (HFV6)

The immobilizer controls engine starting along with the

engine control module (ECM). The main system

components are the ICU, the ECM, the PIM (HFV6)

and the transponder key. The immobilizer system is

activated (immobilized) by an incorrectly programmed

or non-programmed transponder key, the ICU or the

ECM. While this system is activated, the ECM controls

the fuel injection system and starter cut relay in order to

fail to engine running. A typical engine starting

sequence is below.

1. When the ignition switch is ON, the ICU begins authentication of the transponder key in the

steering lock. The ICU transmits a specific request

signal to the transponder key and the transponder

key sends back a response signal to the ICU. Both

communication signals are carried out via antenna

coil.

2. Because the anti-theft system alarms if a key or other methods unlock the door, when the

transponder key is correctly authenticated the ICU

transmits an alarm cancel (disarm) signal to the

anti-theft control unit. (With anti-theft system)

3. After the transponder key authentication is completed, the ICU begins authentication of the

ECM. The ECM transmits a specific request signal

to the ICU and the ICU sends back a response

signal to the ECM. Both communication signals

are carried out via a controller area network (CAN)

communication bus. 4. After the ECM authentication is completed, the

ECM enables engine running.

Immobilizer System Componenet

Description

Immobilizer Control Unit (ICU)

RTW7BASH000101

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007

Page 5955 of 6020

ANTITHEFT SYSTEM 11B-1

SECTION 11B

ANTITHEFT SYSTEM

TABLE OF CONTENTS

Service Precaution .................................................. 11B- 2

General Description ................................................ 11B- 2

Diagrams And Schematics ................................. 11B- 5 System W iring Diagrams ................................ 11B- 5

Parts Location ................................................. 11B- 6

Circuit Diagram ..............................................11B-10

Antitheft control unit (A) ...................................11B-24

Pin-outs ...........................................................11B-24

Pin-Assignment ...............................................11B-25

lmportant information on Programming..............11B-26

Tech-2 Scan Tool ...............................................11B-27 Operating Procedure .......................................11B-27

Menu ...............................................................11B-28

DTC .................................................................11B-28

Clear DTC Information ....................................11B-28

Tech-2 Data Display........................................11B-28

Actuator Test ...................................................11B-28

Programming...................................................11B-30

Tech-2 Data List ..............................................11B-35

Diagnosis............................................................11B-36 Diagnostic procedure ......................................11B-36

Clearing Diagnostic Trouble Codes ................11B-36

Verifying Vehicle Repair ..................................11B-36

Diagnostic Aids................................................11B-36

Diagnostic Trouble Code (DTC) list

For Antitheft.....................................................11B-37

Antitheft System Check ...................................11B-38

No Antitheft Lamp ...........................................11B-39

DTC13 Security code not yet programmed .....11B-40

DTC14 No remote key programmed ...............11B-41

DTC16 Door lock actuators short circuit

to ground .........................................................11B-42

DTC20 Broken wire to door lock actuators .....11B-43

DTC21 Remote key 1 with random code

out of capture range ........................................11B-44

DTC22 Remote key 2 with random code

out of capture range ........................................11B-45

DTC23 Remote key 3 with random code

out of capture range ........................................11B-46

DTC24 Remote key 4 with random code

out of capture range ........................................ 11B-47

DTC25 Remote key 5 with random code

out of capture range ........................................ 11B-48

DTC28 Input immobilizer short circuit

to ground ......................................................... 11B-49

DTC29 Broken wire to immobilizer ................. 11B-50

DTC31 Actuator driver door defect ................. 11B-51

DTC32 Actuator passenger door defect ......... 11B-52

DTC36 Broken wire to driver door................... 11B-53

DTC37 Broken wire to passenger door........... 11B-54

DTC41 Driver door Lock switch unlock

defect .............................................................. 11B-55

DTC42 Driver door Lock switch lock defect .... 11B-56

DTC43 Driver door Lock switch Super lock

defect .............................................................. 11B-57

DTC44 Passenger door Lock switch lock

defect .............................................................. 11B-58

DTC45 Passenger door Lock switch unlock

defect .............................................................. 11B-59

DTC47 Battery voltage for door lock actuators

is missing ........................................................ 11B-60

DTC50 A/D converter defect or battery

voltage less than 9 volt.................................... 11B-61

DTC51 EEPROM defect ................................. 11B-62

DTC52 EEPROM not programmed

by ISUZU ......................................................... 11B-63

DTC55 Control unit defect............................... 11B-64

DTC123 Output flasher short circuit to ground

or broken wire ................................................. 11B-65

DTC125 Output alarm horn broken wire ......... 11B-66

BACK TO CHAPTER INDEX TO MODEL INDEX

ISUZU KB P190 2007