lock ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1003 of 6020

6D – 2 ENGINE ELECTRICAL

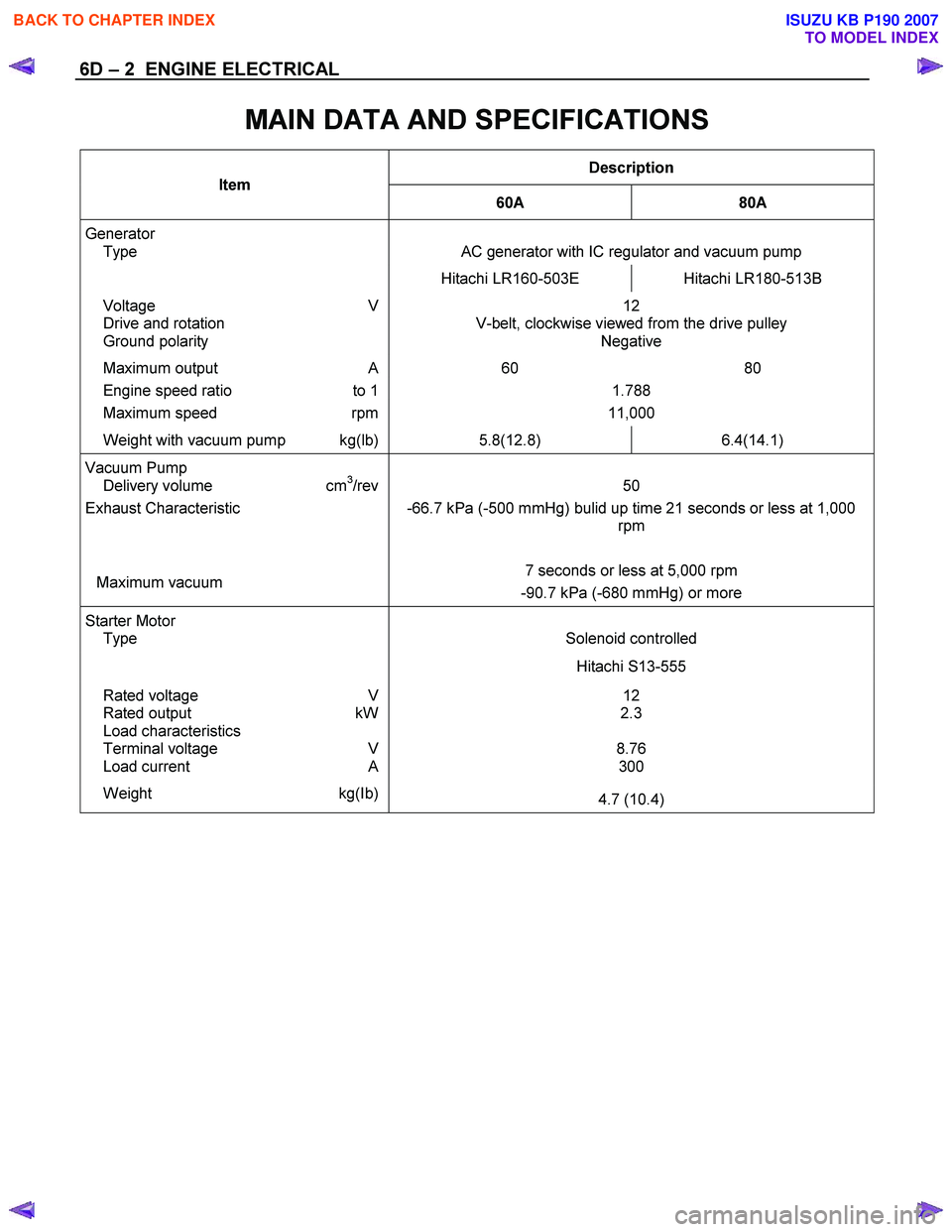

MAIN DATA AND SPECIFICATIONS

Description

Item

60A 80A

Generator

Type

AC generator with IC regulator and vacuum pump

Hitachi LR160-503E Hitachi LR180-513B

Voltage V

Drive and rotation

Ground polarity 12

V-belt, clockwise viewed from the drive pulley Negative

Maximum output A 60 80

Engine speed ratio to 1 1.788

Maximum speed rpm 11,000

Weight with vacuum pump kg(lb) 5.8(12.8) 6.4(14.1)

Vacuum Pump

Delivery volume cm3/rev

Exhaust Characteristic

Maximum vacuum

50

-66.7 kPa (-500 mmHg) bulid up time 21 seconds or less at 1,000 rpm

7 seconds or less at 5,000 rpm

-90.7 kPa (-680 mmHg) or more

Starter Motor

Type

Solenoid controlled

Hitachi S13-555

12

2.3

8.76 300 Rated voltage V

Rated output kW

Load characteristics

Terminal voltage V

Load current A

Weight kg(Ib) 4.7 (10.4)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1029 of 6020

6D – 28 ENGINE ELECTRICAL

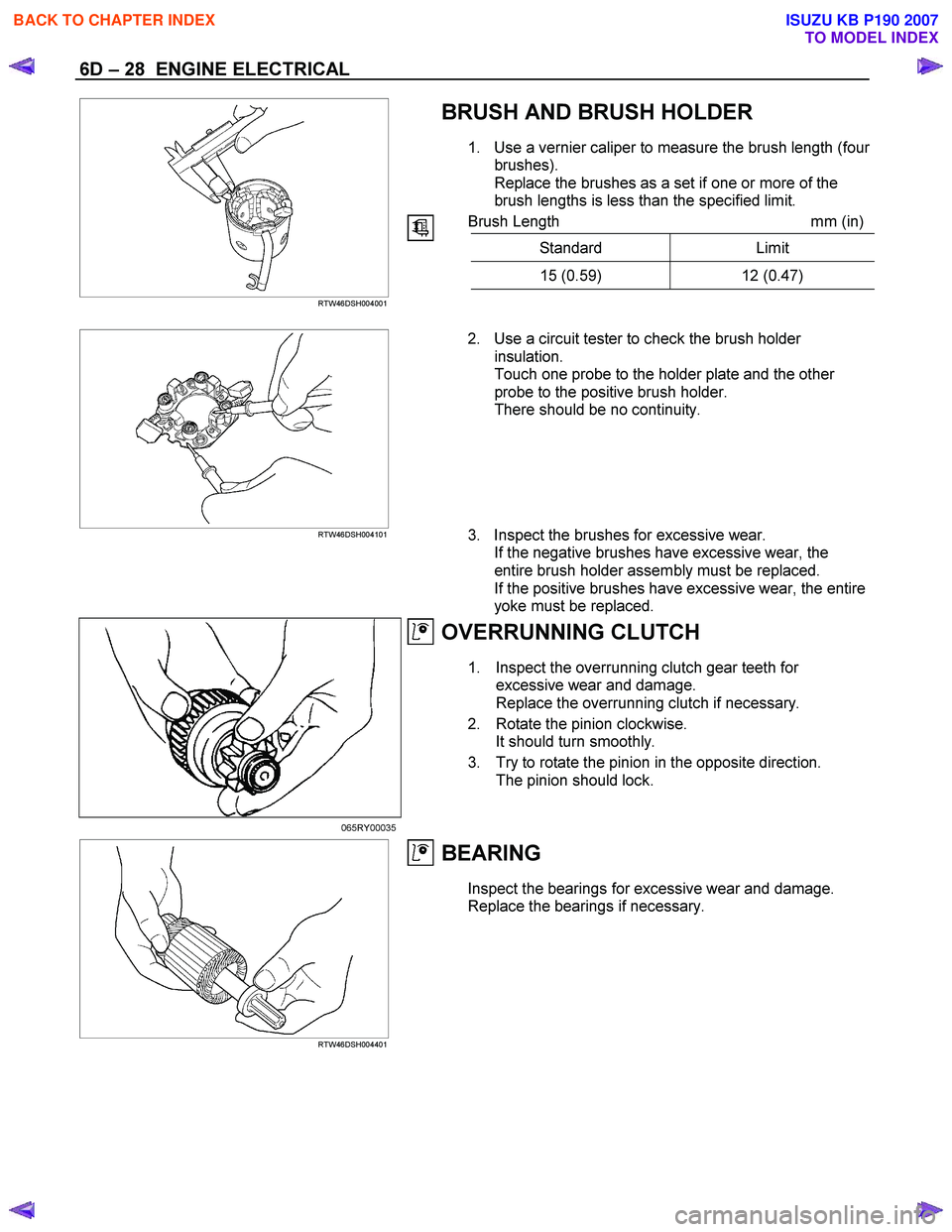

BRUSH AND BRUSH HOLDER

1. Use a vernier caliper to measure the brush length (four

brushes).

Replace the brushes as a set if one or more of the

brush lengths is less than the specified limit.

Brush Length mm (in)

Standard Limit

15 (0.59) 12 (0.47)

RTW46DSH004001

RTW46DSH004101

2. Use a circuit tester to check the brush holder

insulation.

Touch one probe to the holder plate and the other

probe to the positive brush holder.

There should be no continuity.

3. Inspect the brushes for excessive wear. If the negative brushes have excessive wear, the

entire brush holder assembly must be replaced.

If the positive brushes have excessive wear, the entire

yoke must be replaced.

OVERRUNNING CLUTCH

1. Inspect the overrunning clutch gear teeth for excessive wear and damage.

Replace the overrunning clutch if necessary.

2. Rotate the pinion clockwise. It should turn smoothly.

3. Try to rotate the pinion in the opposite direction. The pinion should lock.

065RY00035

RTW46DSH004401

BEARING

Inspect the bearings for excessive wear and damage.

Replace the bearings if necessary.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1077 of 6020

Engine Control System (4JH1) 6E-43

Step Action Value(s) Yes No

8 1. Turn OFF the ignition.

2. Disconnect the ECM C-56 and C-57 harness connectors.

3. Turn ON the ignition, with the engine OFF.

4. Attempt to communicate with the TCM and EHCU.

Does the scan tool communicate with the TCM and

EHCU?

Go to Step 12 Go to Step 9

9 1. Turn OFF the ignition. 2. Reconnect the ECM C-56 and C-57 harness connectors.

3. Disconnect the TCM A and B harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and EHCU.

Does the scan tool communicate with the ECM and

EHCU?

Go to Step 13 Go to Step 10

10 1. Turn OFF the ignition. 2. Reconnect the TCM A and B harness connectors.

3. Disconnect the EHCU C-67 harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and TCM.

Does the scan tool communicate with the ECM and

TCM?

Go to Step 14 Go to Step 11

11 Repair the short to ground or short to voltage on the Keyword 2000 serial data circuit between the DLC

and ECM, TCM and EHCU.

Did you complete the repair?

Go to Step 15

12 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 15

13 Important: Replacement TCM must be

programmed.

Replace the TCM. Refer to Transmission Control

Module (TCM) Replacement in the transmission

section.

Did you complete the replacement?

Go to Step 15

14 Replace the EHCU. Refer to Electronic Hydraulic

Control Unit in the anti-lock brake system section.

Did you complete the replacement?

Go to Step 15

15 Attempt to communicate with the ECM, TCM and

EHCU.

Does the scan tool communicate with the ECM, TCM

and EHCU?

System OK Go to Step 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1086 of 6020

6E-52 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P0180

(B) 15 ON Fuel Temperature

Sensor Circuit •

Ignition switch is

ON.

•

The PCU internal

FT sensor output is

lower than -40°C (-

40°F) for 3 seconds

or higher than

150°C (302°F) for 3

seconds.

•

Faulty PCU.

P0215 (A) 52 ON at

next

ignition cycle Engine Shutoff

(ESO) Solenoid

Control Circuit •

The ignition switch

is OFF.

• The engine speed

is lower than 1500

RPM.

• The vehicle speed

is lower than 1.5

km/h (1 MPH).

•

After the condition

for running the DTC

for 2 seconds, the

engine speed is

higher than 200

RPM when the ESO

solenoid valve is

commanded shutoff

from the PCU.

•

Faulty fuel injection pump.

P0215 (B) 52 ON Engine Shutoff

(ESO) Solenoid

Control Circuit •

The ignition switch

is ON. •

The PCU detects

high voltage

condition on the

ESO solenoid valve

control circuit for

longer than 1

second when the

ECM does not

command shutoff.

•

ESO solenoid valve control

circuit is short to battery or

ignition voltage.

• Faulty PCU.

• Faulty ECM.

P0215 (C) 52 ON Engine Shutoff

(ESO) Solenoid

Control Circuit •

The ignition switch

is OFF.

• The engine speed

is lower than 1500

RPM.

• The vehicle speed

is lower than 1.5

km/h (1 MPH).

•

The engine speed

is higher than 200

RPM within 2

seconds after the

condition for

running the DTC

are met.

•

ESO solenoid valve control

circuit is open circuit, high

resistance or short to ground.

• Faulty PCU.

• Faulty ECM.

P0215 (D) 52 ON Engine Shutoff

(ESO) Solenoid

Control Circuit

•

The ignition switch

is OFF. •

The ECM detects

internal CAN

controller does not

Bus OFF mode.

•

Faulty ECM.

P0216 (A) 54 ON Injection Timing

Control Circuit •

The engine speed

is higher than 700

RPM.

• The fuel injection

quantity is higher

than 4 mg/strk.

•

The PCU monitored

actual fuel injection

timing is advanced

more than desired

by 3°CA for longer

than 12 seconds or

retarded more than

desired by 6°CA for

longer than 12

seconds.

•

Excessive air in the fuel system.

• Loss fuel.

• Fuel suction side looseness,

kinks or blocked.

• Faulty or clogged fuel filter.

• Contaminated fuel.

• Faulty timing device.

• Faulty fuel injection pump CMP

sensor.

P0216 (B) 54 ON Injection Timing

Control Circuit •

The engine speed

is higher than 2014

RPM.

•

The PCU monitored

actual fuel injection

timing is oscillated

higher than desired

by 5.2°CA.

•

Excessive air in the fuel system.

• Loss fuel.

• Fuel suction side looseness,

kinks or blocked.

• Faulty or clogged fuel filter.

• Contaminated fuel.

• Faulty timing device.

• Faulty fuel injection pump CMP

sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1104 of 6020

6E-70 Engine Control System (4JH1)

DTC P0100 (Symptom Code B) (Flash Code 65)

Circuit Description

The mass air flow (MAF) sensor is an air flow meter that

measures the amount of air that enters the engine. It is

fitted between the air cleaner and turbocharger. A small

quantity of air that enters the engine indicates

deceleration or idle speed. A large quantity of air that

enters the engine indicates acceleration or a high load

condition. The MAF sensor has the following circuits.

• Ignition voltage circuit

• 5 volts reference circuit

• Low reference circuit

• MAF sensor signal circuit

The engine control module (ECM) monitors the MAF

sensor signal for voltage outside the normal range o

f

the MAF sensor. If the ECM detects an excessively low

MAF sensor signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The engine is running.

Condition for Setting the DTC

• The ECM calculated MAF is lower than -18.6 kg/h

for 5 seconds. This indicates the ECM detects that

the MAF sensor signal voltage is smaller than a

predetermined range during engine run.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a MAF substitution of 1600 mg/strk

for engine control.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL that the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice: • W rong direction of MAF sensor installation will

cause this DTC to set.

• Contaminated or restricted MAF sensor will cause

this DTC to set.

• The MAF Sensor parameter on the scan tool will

only update with engine running.

Test Description

The number below refers to the step number on the

diagnostic table.

7. If the MAF sensor signal circuit between the ECM

and the sensor is short to ground or any low reference

circuits, the sensor 5 volts reference voltage low DTC

P0100 (Symptom Code 9) will set.

8. If the MAF sensor signal circuit between the ECM

and the sensor is normal, the sensor signal voltage high

DTC P0100 (Symptom Code C) will set.

DTC P0100 (Symptom Code B) (Flash Code 65)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the ECM (10A) fuse (EB-

4) or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1145 of 6020

Engine Control System (4JH1) 6E-111

DTC P0243 (Symptom Code 4) (Flash Code 64)

Circuit Description

The engine control module (ECM) controls the

turbocharger wastegate valve based on the barometric

pressure in order to reduce turbocharger spinning

speeds at high altitude area. The ECM controls the

turbocharger wastegate valve diaphragm by acting the

regulated vacuum pressure via controlling the solenoid

valve. The vacuum pressure sensor monitors the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The ECM calculates desired vacuum

pressure and it compares the calculated desired

vacuum pressure to the actual value to determine the

solenoid valve position. W hen the actual vacuum

pressure is higher than the desired value, the solenoid

valve is closed to decrease the vacuum pressure. If the

ECM detects that an open circuit or short to ground on

the turbocharger solenoid valve control circuit, this DTC

will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the low voltage condition on

the turbocharger solenoid valve control circuit fo

r

longer than 3 seconds when the solenoid valve is

commanded OFF.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses a turbocharger solenoid valve

control substitution of 68%.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0243 (Symptom Code 4) (Flash Code 64)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that fed by the ECM (10A) fuse (EB-4)

or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 15

5 1. Turn OFF the ignition.

2. Disconnect the turbocharger solenoid valve harness connector.

3. Connect a test lamp between the voltage feed circuit of the turbocharger solenoid valve harness

(pin 1 of C-123 connector) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 6 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1170 of 6020

6E-136 Engine Control System (4JH1)

DTC P0380 (Symptom Code 4) (Flash Code 66)

Circuit Description

The engine control module (ECM) controls the glo

w

relay which supplies power to the glow plugs based on

engine coolant temperature. In the after glow phase, the

glow indicator light is not illuminated but glow plugs

remain active for a certain period. If the ECM detects an

open circuit or short to ground on the glow relay control

circuit, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the low voltage condition on

the glow relay control circuit for longer than 3

seconds when the relay is commanded OFF.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Notice:

• The glow relay is commanded OFF with ignition

ON and engine OFF when the engine coolant

temperature is reached at 30°C (86°F).

• The glow relay is commanded OFF with engine

run when the engine coolant temperature is

reached at 60°C (140°F).

DTC P0380 (Symptom Code 4) (Flash Code 66)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Perform the Glow Relay test with the scan tool.

4. Command the Glow Relay ON with the scan tool.

Does the glow relay click when commanded ON with

the scan tool?

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition. 2. Replace the glow relay with the starter relay or replace with a known good relay.

3. Turn ON the ignition, with the engine OFF.

4. Command the Glow Relay ON with the scan tool.

Does the glow relay click when commanded ON with

the scan tool?

Go to Step 12 Go to Step 4

4 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 5 Go to Step 6

5 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the ECM (10A) fuse (EB-

4) or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 16

6 1. Turn OFF the ignition.

2. Remove the glow relay.

3. Connect a test lamp between the voltage feed circuit of the glow relay coil side (pin 2 of X-5

connector) and a known good ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 7 Go to Step 9

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1175 of 6020

Engine Control System (4JH1) 6E-141

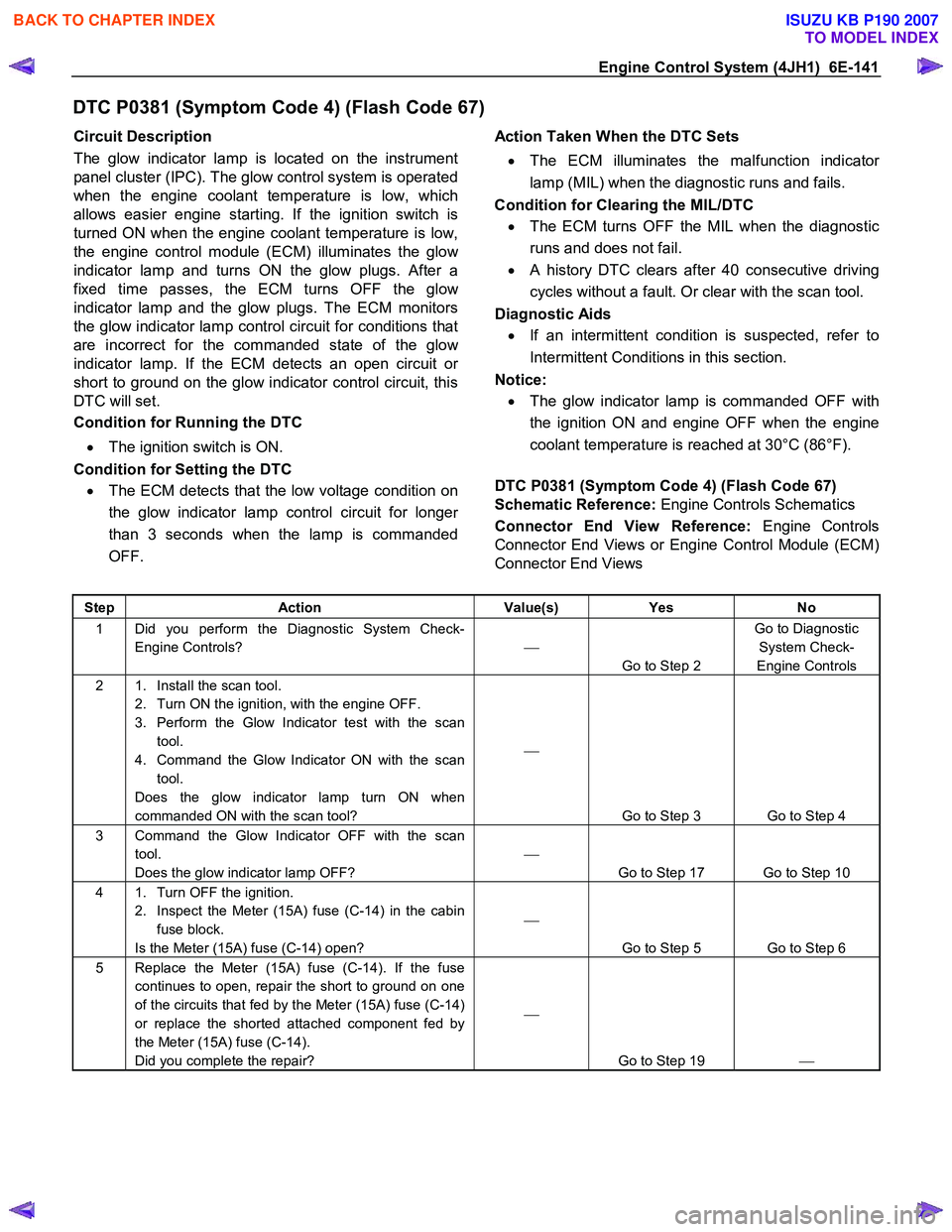

DTC P0381 (Symptom Code 4) (Flash Code 67)

Circuit Description

The glow indicator lamp is located on the instrument

panel cluster (IPC). The glow control system is operated

when the engine coolant temperature is low, which

allows easier engine starting. If the ignition switch is

turned ON when the engine coolant temperature is low,

the engine control module (ECM) illuminates the glo

w

indicator lamp and turns ON the glow plugs. After a

fixed time passes, the ECM turns OFF the glo

w

indicator lamp and the glow plugs. The ECM monitors

the glow indicator lamp control circuit for conditions that

are incorrect for the commanded state of the glo

w

indicator lamp. If the ECM detects an open circuit or

short to ground on the glow indicator control circuit, this

DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the low voltage condition on

the glow indicator lamp control circuit for longe

r

than 3 seconds when the lamp is commanded

OFF.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Notice:

• The glow indicator lamp is commanded OFF with

the ignition ON and engine OFF when the engine

coolant temperature is reached at 30°C (86°F).

DTC P0381 (Symptom Code 4) (Flash Code 67)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Perform the Glow Indicator test with the scan tool.

4. Command the Glow Indicator ON with the scan tool.

Does the glow indicator lamp turn ON when

commanded ON with the scan tool?

Go to Step 3 Go to Step 4

3 Command the Glow Indicator OFF with the scan tool.

Does the glow indicator lamp OFF?

Go to Step 17 Go to Step 10

4 1. Turn OFF the ignition. 2. Inspect the Meter (15A) fuse (C-14) in the cabin fuse block.

Is the Meter (15A) fuse (C-14) open?

Go to Step 5 Go to Step 6

5 Replace the Meter (15A) fuse (C-14). If the fuse continues to open, repair the short to ground on one

of the circuits that fed by the Meter (15A) fuse (C-14)

or replace the shorted attached component fed by

the Meter (15A) fuse (C-14).

Did you complete the repair?

Go to Step 19

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1183 of 6020

Engine Control System (4JH1) 6E-149

DTC P0400 (Symptom Code 4) (Flash Code 32)

Circuit Description

The engine control module (ECM) controls the exhaust

gas recirculation (EGR) flow amount based on the

engine speed, engine coolant temperature, intake ai

r

temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve b

y

controlling the EGR solenoid valve. The mass air flo

w

(MAF) sensor monitors EGR gas flow amount. An

expected MAF amount should be detected while the

engine running. If the ECM detects that an open circuit

or short to ground on the EGR solenoid valve control

circuit, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC • The ECM detects that the low voltage condition on

the EGR solenoid valve control circuit for longe

r

than 3 seconds when the solenoid valve is

commanded OFF.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0400 (Symptom Code 4) (Flash Code 32)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3 Go to Diagnostic

Aids

3 1. Turn OFF the ignition. 2. Inspect the ECM (10A) fuse (EB-4) in the engine room fuse block.

Is the ECM (10A) fuse (EB-4) open?

Go to Step 4 Go to Step 5

4 Replace the ECM (10A) fuse (EB-4). If the fuse continues to open, repair the short to ground on one

of the circuits that fed by the ECM (10A) fuse (EB-4)

or replace the shorted attached component fed by

the ECM (10A) fuse (EB-4).

Did you complete the repair?

Go to Step 15

5 1. Turn OFF the ignition.

2. Disconnect the EGR control solenoid valve harness connector.

3. Connect a test lamp between the voltage feed circuit of the EGR control solenoid valve harness

(pin 1 of C-115 connector) and a known good

ground.

4. Turn ON the ignition, with the engine OFF.

Does the test lamp illuminate?

Go to Step 6 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1196 of 6020

6E-162 Engine Control System (4JH1)

Step Action Value(s) Yes No

11 Replace the IPC (meter assembly). Refer to Meter

Replacement in electrical section.

Did you complete the replacement?

Go to Step 14

12 Important: Replacement TCM must be

programmed.

Replace the TCM. Refer to Transmission Control

Module (TCM) Replacement in the transmission

section.

Did you complete the replacement?

Go to Step 14

13 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 14

14 1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Drive the vehicle.

5. Observe the Vehicle Speed parameter with the scan tool.

Does the Vehicle Speed parameter indicate correct

vehicle speed?

Go to Step 15 Go to Step 2

15 Observe the DTC Information with the scan tool. Are there any DTCs that you have not diagnosed? Go to Diagnostic

Trouble Code (DTC) List System OK

Chart for except 2WD with A/T

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Drive the vehicle.

3. Observe the Vehicle Speed parameter with the scan tool.

Does the Vehicle Speed parameter indicate correct

vehicle speed?

Go to Diagnostic Aids Go to Step 3

3 1. Turn OFF the ignition. 2. Inspect the Meter (15A) fuse (C-14) in the cabin fuse block.

Is the Meter (15A) fuse (C-14) open?

Go to Step 4 Go to Step 5

4 Replace the Meter (15A) fuse (C-14). If the fuse continues to open, repair the short to ground on one

of the circuits that fed by the Meter (15A) fuse (C-14)

or replace the shorted attached component fed by

the Meter (15A) fuse (C-14).

Did you complete the repair?

Go to Step 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007