Fuel line ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 811 of 6020

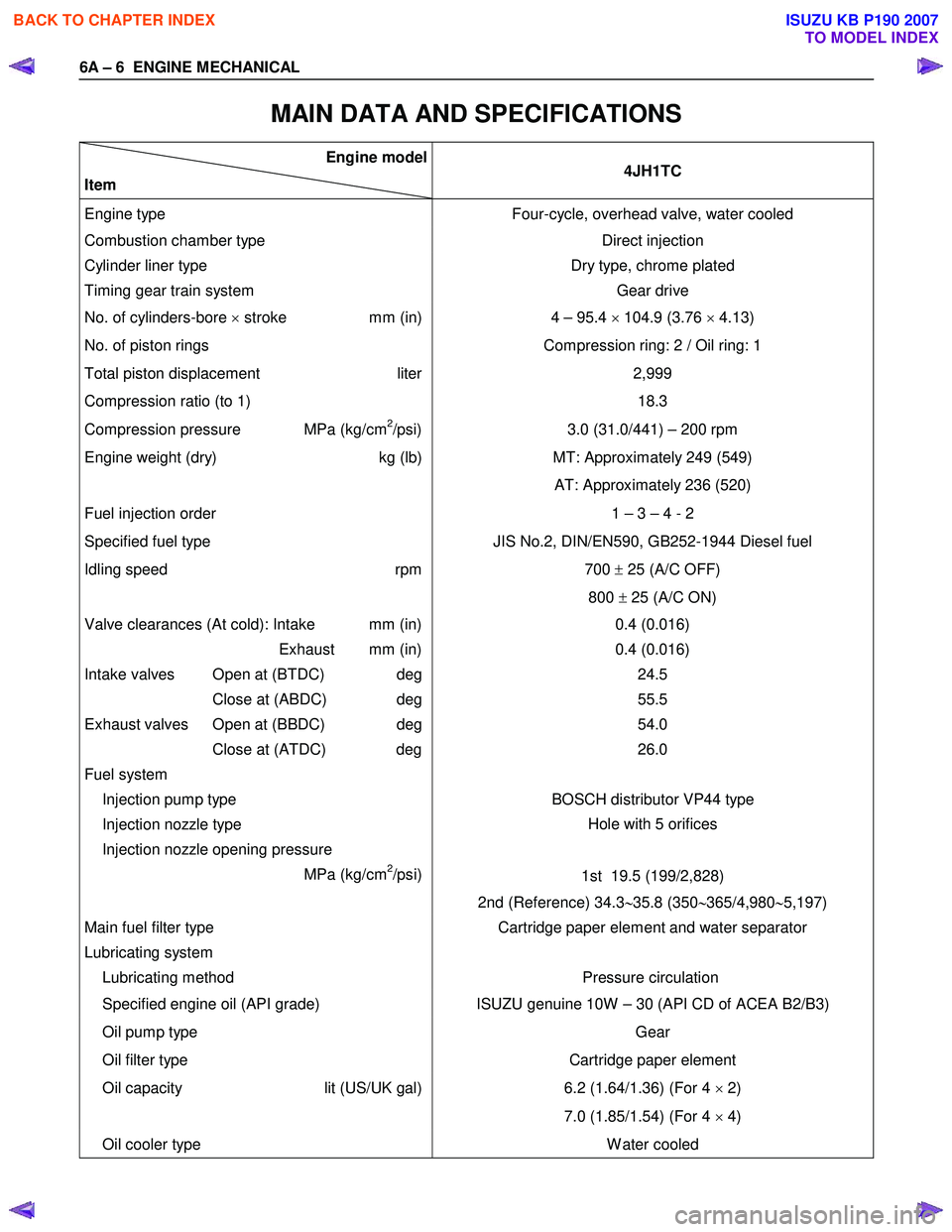

6A – 6 ENGINE MECHANICAL

MAIN DATA AND SPECIFICATIONS

Engine model

Item 4JH1TC

Engine type

Four-cycle, overhead valve, water cooled

Combustion chamber type Direct injection

Cylinder liner type

Timing gear train system Dry type, chrome plated

Gear drive

No. of cylinders-bore × stroke mm (in) 4 – 95.4 × 104.9 (3.76 × 4.13)

No. of piston rings Compression ring: 2 / Oil ring: 1

Total piston displacement liter

Compression ratio (to 1) 2,999

18.3

Compression pressure MPa (kg/cm2/psi) 3.0 (31.0/441) – 200 rpm

Engine weight (dry) kg (lb)MT: Approximately 249 (549)

AT: Approximately 236 (520)

Fuel injection order 1 – 3 – 4 - 2

Specified fuel type JIS No.2, DIN/EN590, GB252-1944 Diesel fuel

Idling speed rpm

700 ± 25 (A/C OFF)

800 ± 25 (A/C ON)

Valve clearances (At cold): Intake mm (in)

Exhaust mm (in)

Intake valves Open at (BTDC) deg

Close at (ABDC) deg

Exhaust valves Open at (BBDC) deg

Close at (ATDC) deg

Fuel system

Injection pump type 0.4 (0.016)

0.4 (0.016) 24.5

55.5

54.0

26.0

BOSCH distributor VP44 type

Injection nozzle type

Injection nozzle opening pressure

MPa (kg/cm

2/psi) Hole with 5 orifices

1st 19.5 (199/2,828)

2nd (Reference) 34.3 ∼35.8 (350 ∼365/4,980 ∼5,197)

Main fuel filter type

Lubricating system

Lubricating method Cartridge paper element and water separator

Pressure circulation

Specified engine oil (API grade) ISUZU genuine 10W – 30 (API CD of ACEA B2/B3)

Oil pump type

Oil filter type Gear

Cartridge paper element

Oil capacity lit (US/UK gal)

6.2 (1.64/1.36) (For 4

× 2)

7.0 (1.85/1.54) (For 4 × 4)

Oil cooler type W ater cooled

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 841 of 6020

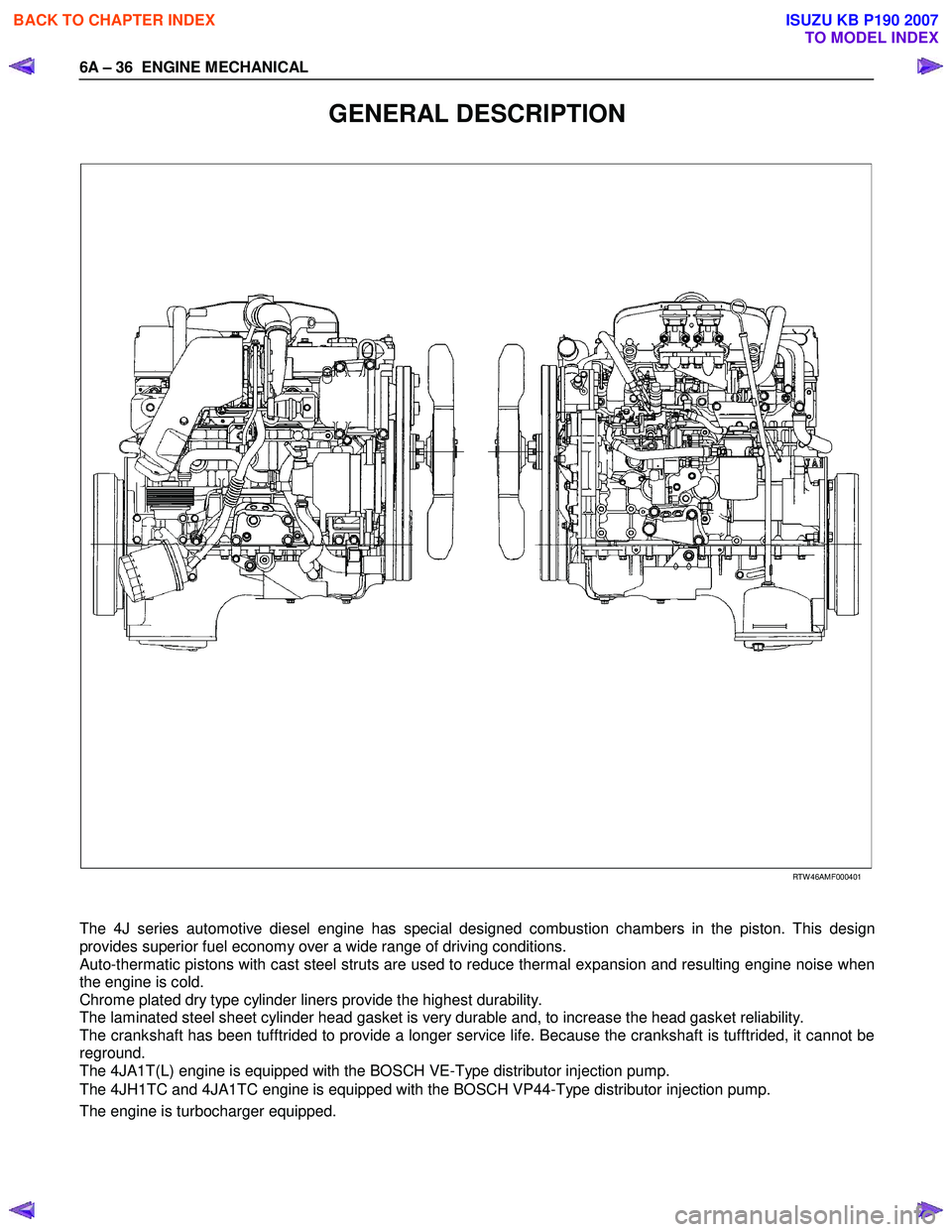

6A – 36 ENGINE MECHANICAL

GENERAL DESCRIPTION

RTW 46AMF000401

The 4J series automotive diesel engine has special designed combustion chambers in the piston. This design

provides superior fuel economy over a wide range of driving conditions.

Auto-thermatic pistons with cast steel struts are used to reduce thermal expansion and resulting engine noise when

the engine is cold.

Chrome plated dry type cylinder liners provide the highest durability.

The laminated steel sheet cylinder head gasket is very durable and, to increase the head gasket reliability.

The crankshaft has been tufftrided to provide a longer service life. Because the crankshaft is tufftrided, it cannot be

reground.

The 4JA1T(L) engine is equipped with the BOSCH VE-Type distributor injection pump.

The 4JH1TC and 4JA1TC engine is equipped with the BOSCH VP44-Type distributor injection pump.

The engine is turbocharger equipped.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 966 of 6020

6C – 2 FUEL SYSTEM

MAIN DATA AND SPECIFICATIONS

Description Item

4JA1T (L) 4JA1TC 4JH1TC

Injection pump type Bosch distributor

VE type Bosch distributor VP44 type

Governor type

Mechanical variable

(Half speed oil pressure) Electrical controled

Timer type

Oil pressure Electrical controled

Fuel feed pump type Vane with input shaft

Injection nozzle type Hole type

Number of injection nozzle orifices 5

Injection nozzle orifices

Inside diameter mm (in) 0.19 (0.0075) 0.17 (0.0067) 0.21 (0.0083)

19.1 (195) 19.0 (194) 19.5 (199) Injection nozzle designed operating

pressure MPa (kg/cm2) 1st

2nd 25.0 (255)

33.5 (328) 33.8 (331)

Main fuel filter type Disposable cartridge paper element

Precautions

When working on the fuel system, there are several things

to keep in mind:

•

Any time the fuel system is being worked on,

disconnect the negative battery cable except fo

r

those tests where battery voltage is required.

•

Always keep a dry chemical (Class B) fire

extinguisher near the work area.

• Replace all pipes with the same pipe and fittings that

were removed.

• Clean and inspect “O” rings. Replace if required.

•

Always relieve the line pressure before servicing any

fuel system components.

• Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

• Adhere to all Notices and Cautions.

NOTE:

Injection nozzle adjustment is possible only on the 4JA1L

engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 973 of 6020

FUEL SYSTEM 6C – 9

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system for

loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission".

1. Disconnect battery ground cable.

2. Loosen slowly the fuel filler cap.

NOTE: Be careful not to spouting out fuel because of change

the pressure in the fuel tank.

NOTE: Cover opening of the filler neck to prevent any dust

entering.

3. Jack up the vehicle.

4. Support underneath of the fuel tank with a lifter.

5. Remove the inner liner of the wheel house at rear left side.

6. Remove fixing bolt of the filler neck from the body.

7. Disconnect the quick connector (3) of the fuel tube from the

fuel pipe.

NOTE: Cover the quick connector to prevent any dust entering

and fuel leakage.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in this

section when performing any repairs.

8. Remove fixing bolt (1) of the tank band and remove the tank band (2).

9. Disconnect the pump and sender connector on the fuel

pump and remove the harness from weld clip on the fuel

tank.

10. Lower the fuel tank (5).

NOTE: W hen lower the fuel tank from the vehicle, don’t scratch

each hose and tube by around other parts.

Installation

1. Raise the fuel tank.

NOTE: W hen raise the fuel tank to the vehicle, don’t scratch

each hose and tube by around other parts.

2. Connect the pump and sender connector to the fuel pump and install the harness to weld clip on the tank.

NOTE: The connector must be certainly connected against

stopper.

3. Install the tank band and fasten bolt.

Torque N·m (kg·m / lb ft)

68 (6.9 / 50)

NOTE: The anchor of the tank band must be certainly installed

to guide hole on frame.

4. Connect the quick connector of the fuel tube to the fuel pipe and the evapo tube from evapo joint connector.

NOTE: Pull off the left checker on the fuel pipe.

NOTE: Refer to “Fuel Tube/Quick Connector Fittings” in this

section when performing any repairs.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 974 of 6020

6C – 10 FUEL SYSTEM

5. Install the filler neck to the body with bolt.

6. Install the inner liner of the wheel house at rear left side.

7. Remove lifter from the fuel tank.

8. Lower the vehicle.

9. Tigten the filler cap until at least three clicks.

10. Connect the battery ground cable.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 984 of 6020

6C – 20 FUEL SYSTEM

020L200017

RTW 46CSH000201

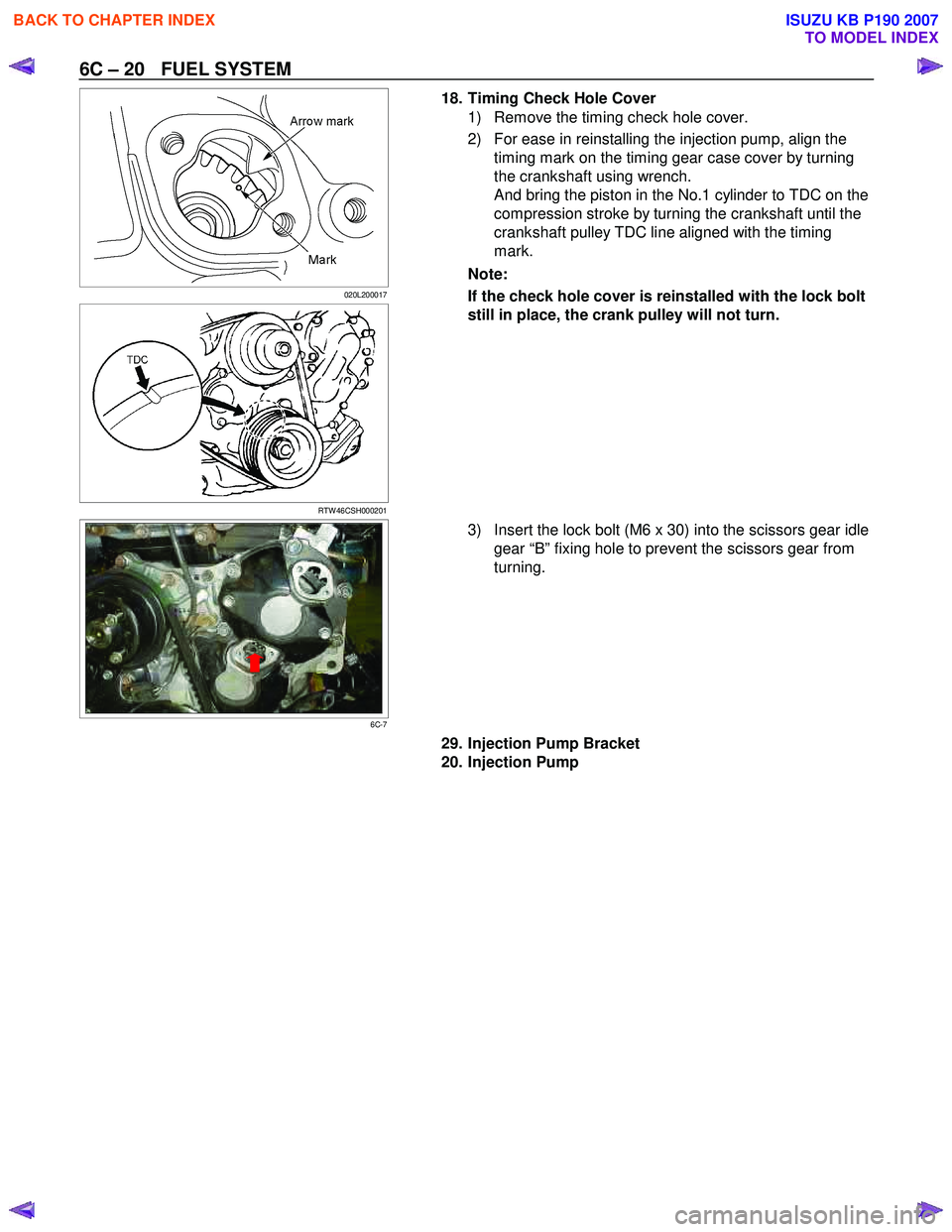

18. Timing Check Hole Cover

1) Remove the timing check hole cover.

2) For ease in reinstalling the injection pump, align the timing mark on the timing gear case cover by turning

the crankshaft using wrench.

And bring the piston in the No.1 cylinder to TDC on the

compression stroke by turning the crankshaft until the

crankshaft pulley TDC line aligned with the timing

mark.

Note:

If the check hole cover is reinstalled with the lock bolt

still in place, the crank pulley will not turn.

6C-7

3) Insert the lock bolt (M6 x 30) into the scissors gear idle

gear “B” fixing hole to prevent the scissors gear from

turning.

29. Injection Pump Bracket

20. Injection Pump

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 985 of 6020

FUEL SYSTEM 6C – 21

RTW 46CSH000201

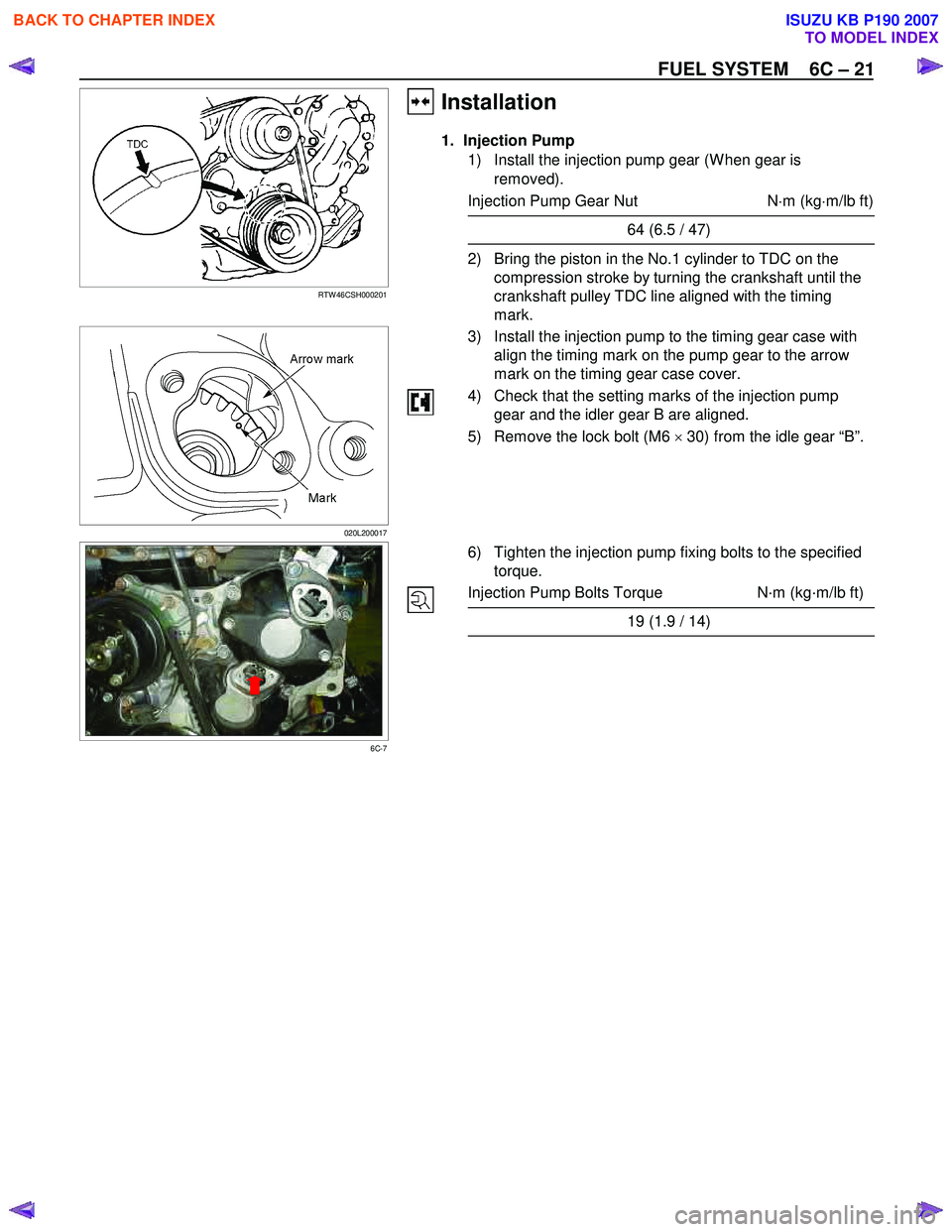

Installation

1. Injection Pump

1) Install the injection pump gear (W hen gear is removed).

Injection Pump Gear Nut N⋅m (kg ⋅m/lb ft)

64 (6.5 / 47)

2) Bring the piston in the No.1 cylinder to TDC on the

compression stroke by turning the crankshaft until the

crankshaft pulley TDC line aligned with the timing

mark.

020L200017

3) Install the injection pump to the timing gear case with

align the timing mark on the pump gear to the arrow

mark on the timing gear case cover.

4) Check that the setting marks of the injection pump gear and the idler gear B are aligned.

5) Remove the lock bolt (M6 × 30) from the idle gear “B”.

6C-7

6) Tighten the injection pump fixing bolts to the specified

torque.

Injection Pump Bolts Torque N·m (kg·m/lb ft)

19 (1.9 / 14)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 996 of 6020

6C – 32 FUEL SYSTEM

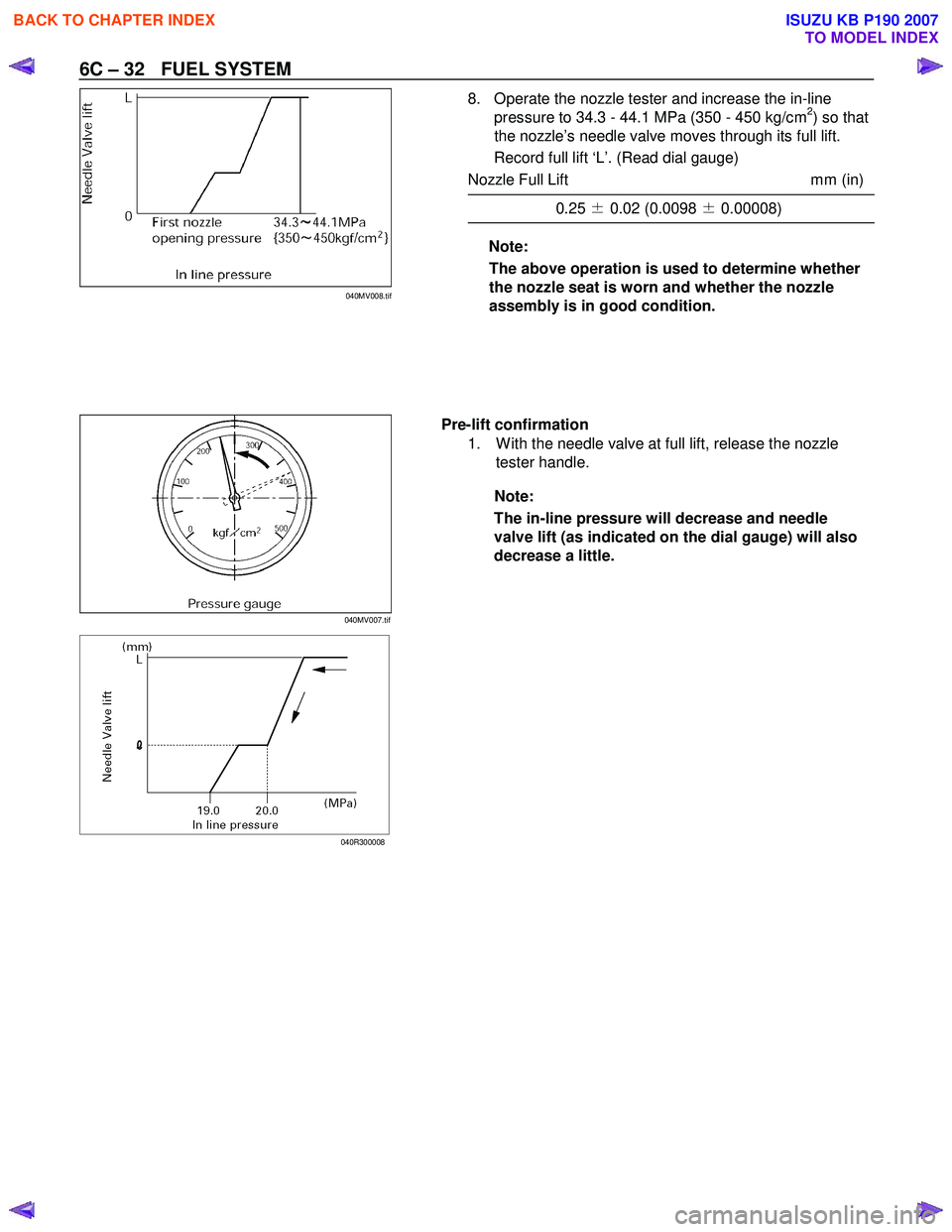

8. Operate the nozzle tester and increase the in-line

pressure to 34.3 - 44.1 MPa (350 - 450 kg/cm2) so that

the nozzle’s needle valve moves through its full lift.

Record full lift ‘L’. (Read dial gauge)

Nozzle Full Lift mm (in)

0.25 ± 0.02 (0.0098 ± 0.00008)

Note:

The above operation is used to determine whether

the nozzle seat is worn and whether the nozzle

assembly is in good condition.

Pre-lift confirmation 1. W ith the needle valve at full lift, release the nozzle tester handle.

Note:

The in-line pressure will decrease and needle

valve lift (as indicated on the dial gauge) will also

decrease a little.

040R300008

040MV007.tif040MV008.tif

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 997 of 6020

FUEL SYSTEM 6C – 33

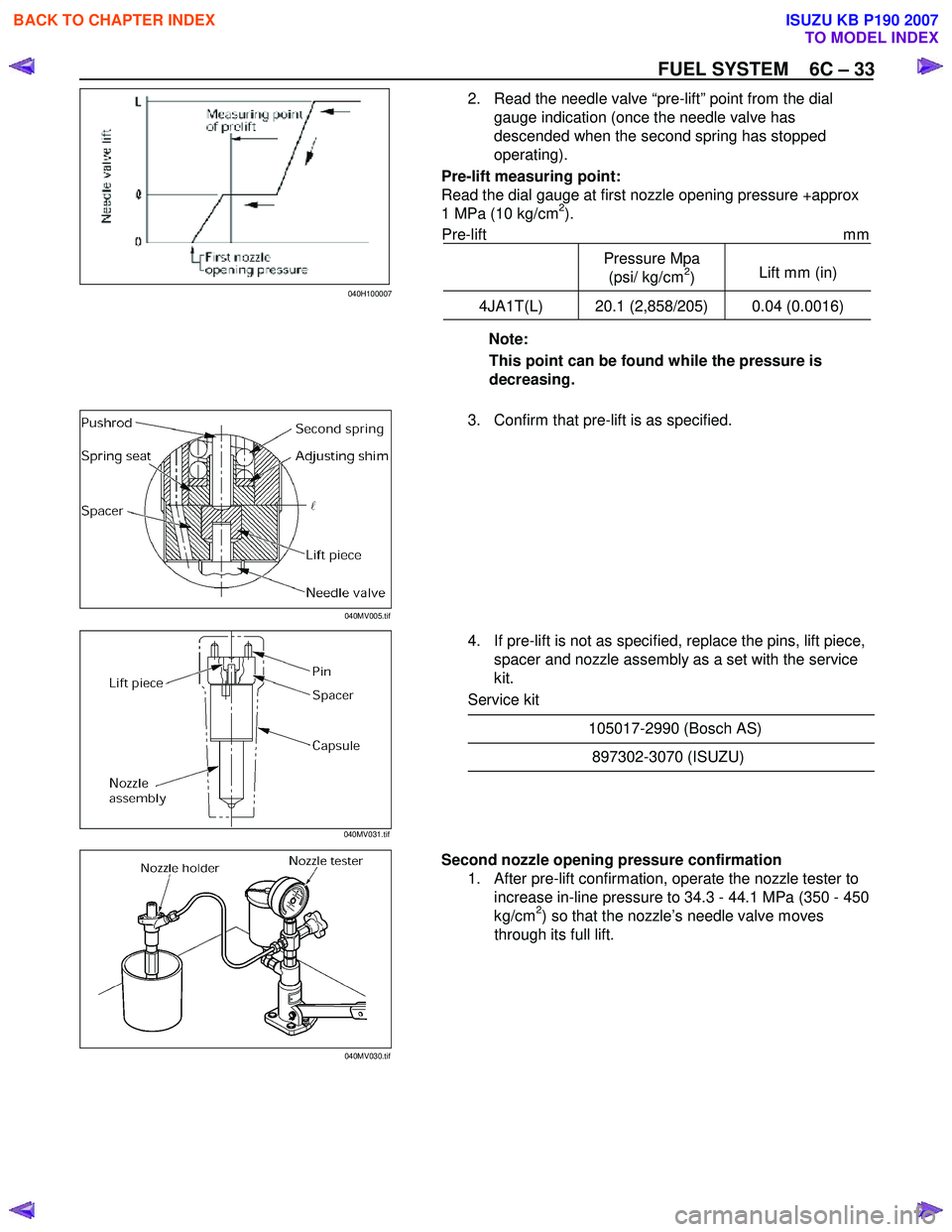

2. Read the needle valve “pre-lift” point from the dial gauge indication (once the needle valve has

descended when the second spring has stopped

operating).

Pre-lift measuring point:

Read the dial gauge at first nozzle opening pressure +approx

1 MPa (10 kg/cm

2).

Pre-lift mm

Pressure Mpa

(psi/ kg/cm

2) Lift mm (in)

4JA1T(L) 20.1 (2,858/205) 0.04 (0.0016)

Note:

This point can be found while the pressure is

decreasing.

3. Confirm that pre-lift is as specified.

4. If pre-lift is not as specified, replace the pins, lift piece, spacer and nozzle assembly as a set with the service

kit.

Service kit

105017-2990 (Bosch AS)

897302-3070 (ISUZU)

Second nozzle opening pressure confirmation

1. After pre-lift confirmation, operate the nozzle tester to increase in-line pressure to 34.3 - 44.1 MPa (350 - 450

kg/cm

2) so that the nozzle’s needle valve moves

through its full lift.

040MV005.tif

040MV031.tif

040MV030.tif 040H100007

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 998 of 6020

6C – 34 FUEL SYSTEM

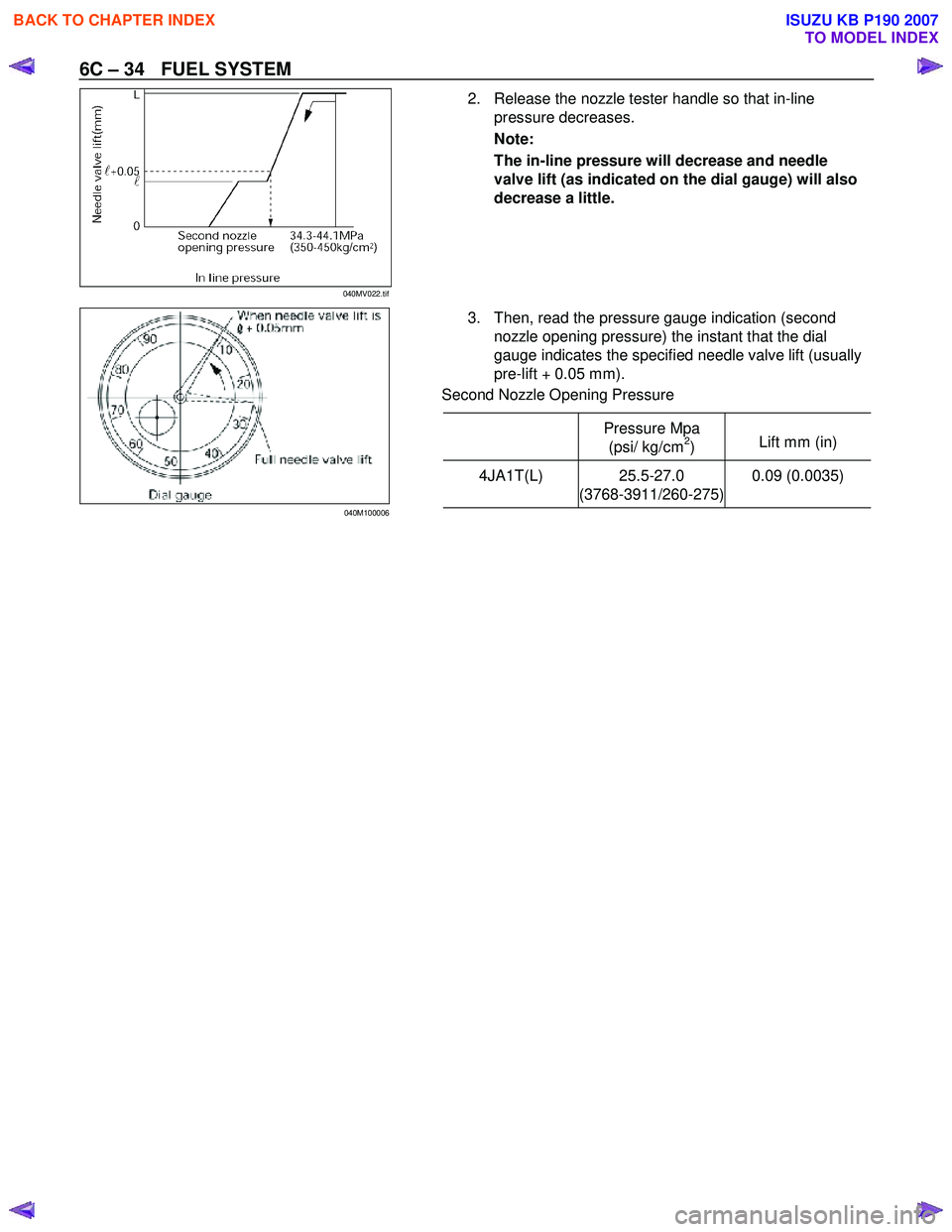

2. Release the nozzle tester handle so that in-line

pressure decreases.

Note:

The in-line pressure will decrease and needle

valve lift (as indicated on the dial gauge) will also

decrease a little.

3. Then, read the pressure gauge indication (second

nozzle opening pressure) the instant that the dial

gauge indicates the specified needle valve lift (usually

pre-lift + 0.05 mm).

Second Nozzle Opening Pressure

Pressure Mpa

(psi/ kg/cm

2) Lift mm (in)

4JA1T(L) 25.5-27.0

(3768-3911/260-275) 0.09 (0.0035)

040MV022.tif

040M100006

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007