cooling ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 125 of 6020

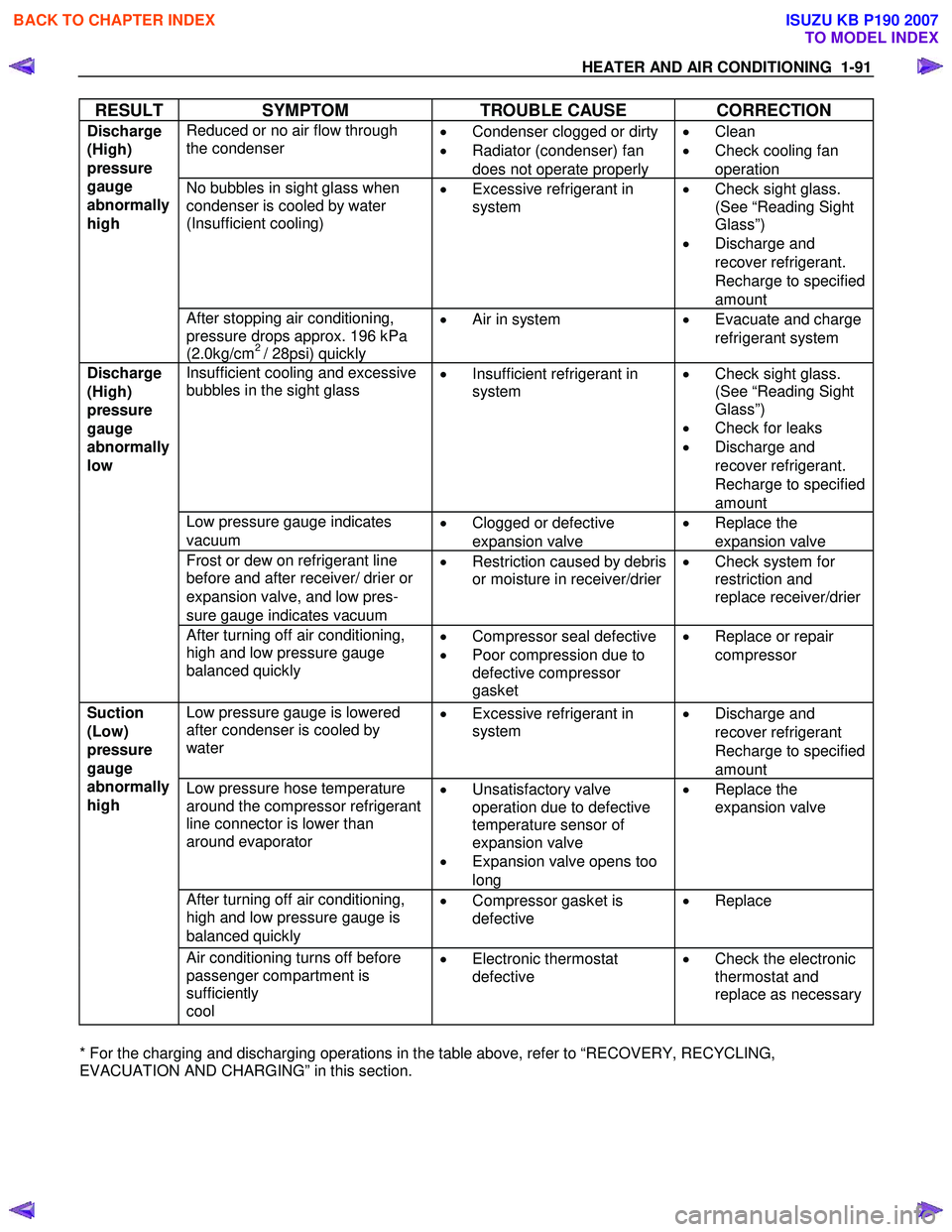

HEATER AND AIR CONDITIONING 1-91

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Reduced or no air flow through

the condenser

•

Condenser clogged or dirty

• Radiator (condenser) fan

does not operate properly •

Clean

• Check cooling fan

operation

No bubbles in sight glass when

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Discharge

(High)

pressure

gauge

abnormally

high

After stopping air conditioning,

pressure drops approx. 196 kPa

(2.0kg/cm

2 / 28psi) quickly •

Air in system

•

Evacuate and charge

refrigerant system

Insufficient cooling and excessive

bubbles in the sight glass

•

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Low pressure gauge indicates

vacuum •

Clogged or defective

expansion valve •

Replace the

expansion valve

Frost or dew on refrigerant line

before and after receiver/ drier or

expansion valve, and low pres-

sure gauge indicates vacuum •

Restriction caused by debris

or moisture in receiver/drier

•

Check system for

restriction and

replace receiver/drier

Discharge

(High)

pressure

gauge

abnormally

low

After turning off air conditioning,

high and low pressure gauge

balanced quickly

•

Compressor seal defective

• Poor compression due to

defective compressor

gasket •

Replace or repair

compressor

Low pressure gauge is lowered

after condenser is cooled by

water

•

Excessive refrigerant in

system

•

Discharge and

recover refrigerant

Recharge to specified

amount

Low pressure hose temperature

around the compressor refrigerant

line connector is lower than

around evaporator

•

Unsatisfactory valve

operation due to defective

temperature sensor of

expansion valve

• Expansion valve opens too

long •

Replace the

expansion valve

After turning off air conditioning,

high and low pressure gauge is

balanced quickly •

Compressor gasket is

defective

•

Replace

Suction

(Low)

pressure

gauge

abnormally

high

Air conditioning turns off before

passenger compartment is

sufficiently

cool •

Electronic thermostat

defective

•

Check the electronic

thermostat and

replace as necessary

* For the charging and discharging operations in the table above, refer to “RECOVERY, RECYCLING,

EVACUATION AND CHARGING” in this section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 126 of 6020

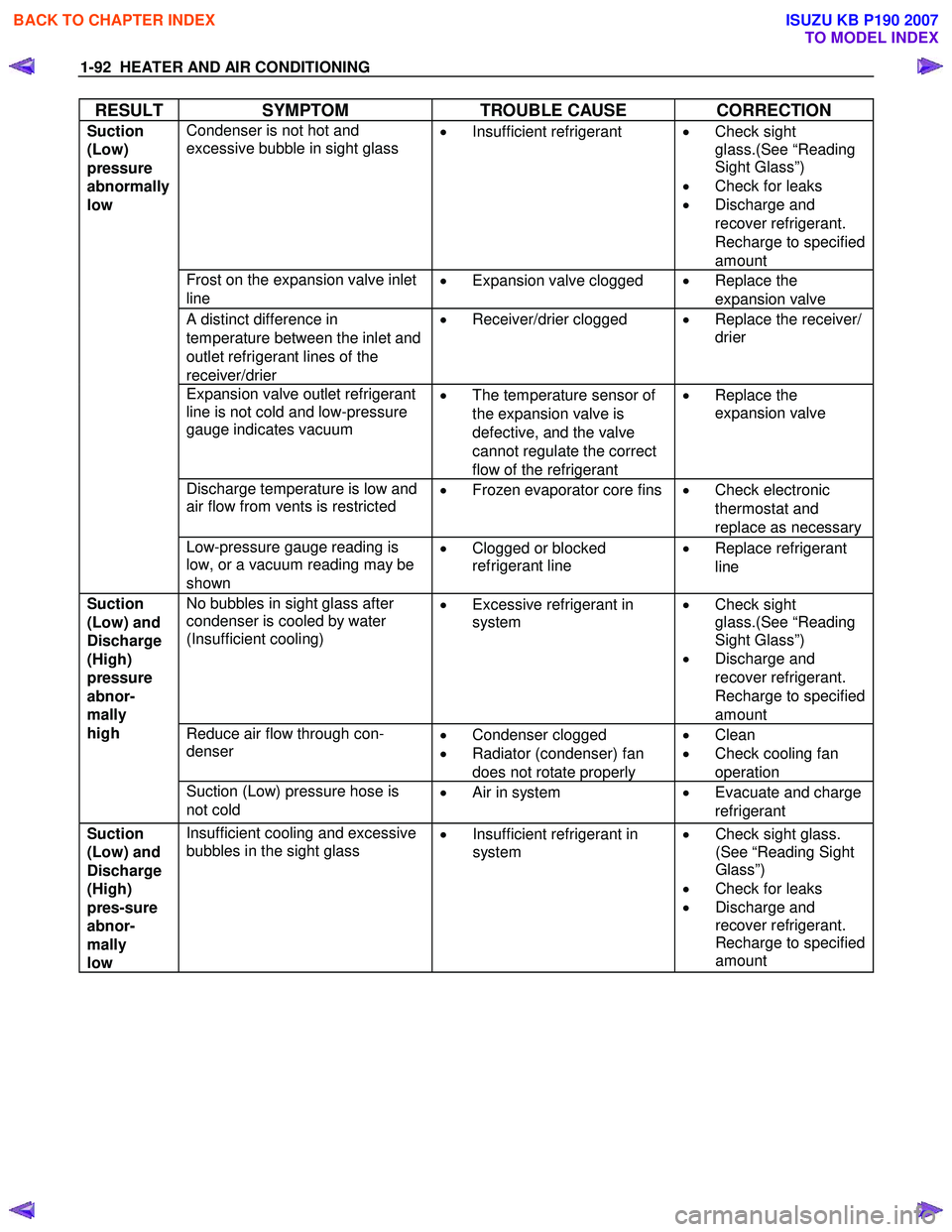

1-92 HEATER AND AIR CONDITIONING

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Condenser is not hot and

excessive bubble in sight glass

•

Insufficient refrigerant

•

Check sight

glass.(See “Reading

Sight Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Frost on the expansion valve inlet

line •

Expansion valve clogged

•

Replace the

expansion valve

A distinct difference in

temperature between the inlet and

outlet refrigerant lines of the

receiver/drier •

Receiver/drier clogged

•

Replace the receiver/

drier

Expansion valve outlet refrigerant

line is not cold and low-pressure

gauge indicates vacuum

•

The temperature sensor of

the expansion valve is

defective, and the valve

cannot regulate the correct

flow of the refrigerant •

Replace the

expansion valve

Discharge temperature is low and

air flow from vents is restricted

•

Frozen evaporator core fins

•

Check electronic

thermostat and

replace as necessary

Suction

(Low)

pressure

abnormally

low

Low-pressure gauge reading is

low, or a vacuum reading may be

shown •

Clogged or blocked

refrigerant line

•

Replace refrigerant

line

No bubbles in sight glass after

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight

glass.(See “Reading

Sight Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Reduce air flow through con-

denser

•

Condenser clogged

• Radiator (condenser) fan

does not rotate properly •

Clean

• Check cooling fan

operation

Suction

(Low) and

Discharge

(High)

pressure

abnor-

mally

high

Suction (Low) pressure hose is

not cold •

Air in system • Evacuate and charge

refrigerant

Suction

(Low) and

Discharge

(High)

pres-sure

abnor-

mally

low Insufficient cooling and excessive

bubbles in the sight glass •

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

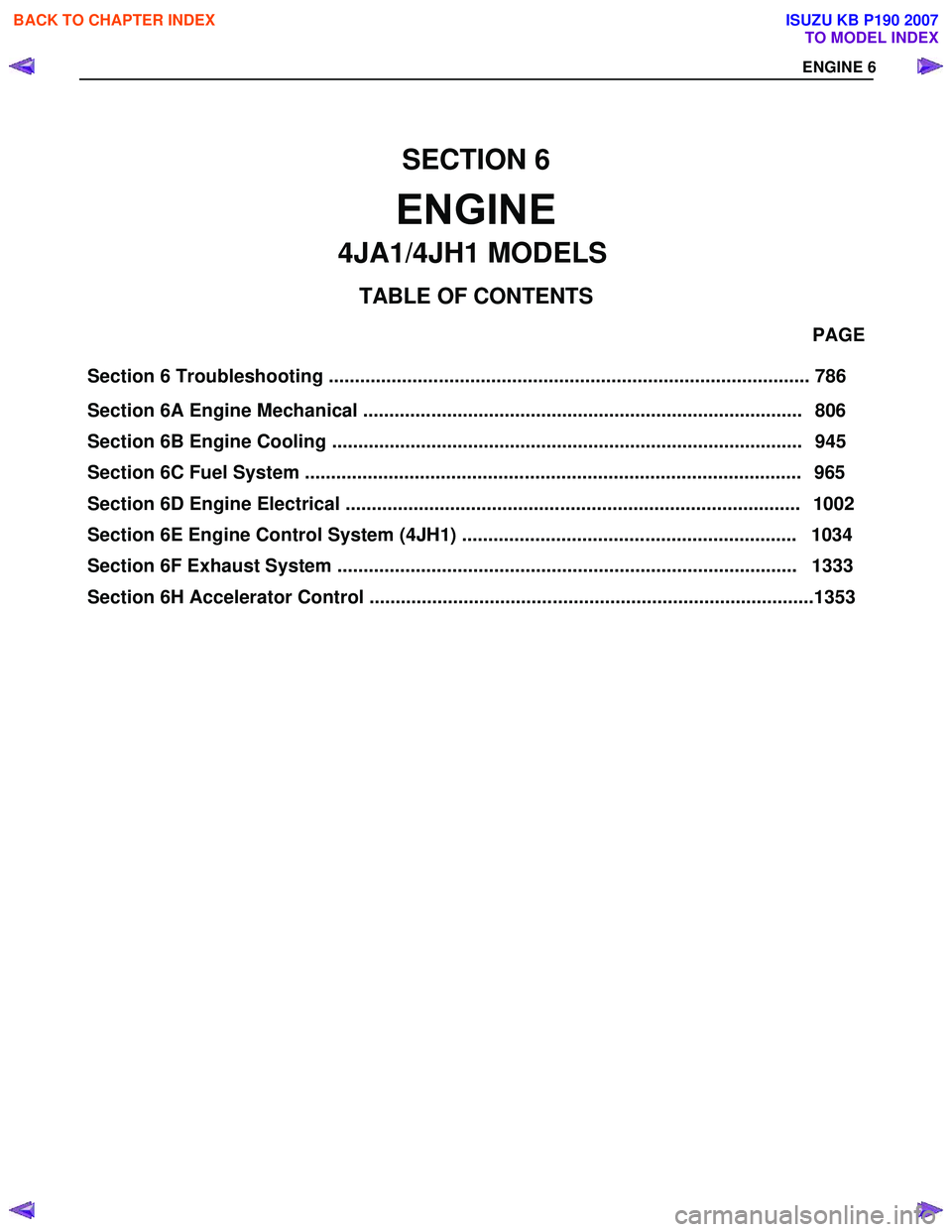

Page 785 of 6020

Section 6 Troubleshooting ....................................................................................... ..... 786

PAGE

Section 6A Engine Mechanical .................................................................................... 806

Section 6B Engine Cooling .......................................................................... ................ 945

Section 6C Fuel System .......................................................................... ..................... 96 5

Section 6D Engine Electrical ................................................................ ....................... 1002

Section 6E Engine Control System (4JH1) ....................................................... ......... 1034

Section 6F Exhaust System ....................................................... .............................. ... 1333

Section 6H Accelerator Control ....................................................... ..............................135 3

SECTION 6

ENGINE

TA BLE OF CONTENTS

ENGINE 6

4JA1/4JH1 MODELS

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 794 of 6020

TROUBLESHOOTING 6 – 9

6. Overheating

Step Action Value(s) Yes No

1 Was the engine coolant level OK? —

Go to Step 2 Replenish the

coolant

2 Was the water leakage or the radiator restriction found? (Include radiator cap) —

Repair or

replace the

leakage part. Go to Step 3

3 Was the fan belt slippage found? — Tension or

replace the fan belt. Go to Step 4

4 Was the fan clutch working completely? —

Go to Step 5 Replace the fan

clutch

assembly.

5 Was the oil leakage found from fan clutch? — Replace the fan

clutch

assembly Go to Step 6

6 Was the thermostat working normally? —

Go to Step 7 Replace the

thermostat.

7 Was the water pump working OK? —

Go to Step 8 Replace the

water pump assembly.

8 Was the restriction by the foreign materials in the cooling system found? For example, clog the water

hose between the cylinder body and radiator etc.. —

Clean or

replace the clog part. Go to Step 9

9 Was the water leakage found from the sealing cap

on the cylinder body? —

Replace the

sealing cap or replace the

cylinder body. Go to Step 10

10 Are any DTC stored? — Go to indicated

DTC. Solved

7. White Exhaust Smoke

Step Action Value(s) Yes No

1 Was the compression pressure OK? 3.0 MPa

(31.0 kg/cm2,

441 psi) at 200 rpm

Go to Step 2 Readjust the

valve clearance or replace the cylinder head gasket or

cylinder liner or

piston or piston ring or valve and relation parts.

2 Was the PCV (Positive Crankcase Ventilation) valve working completely? —

Go to Step 3 Repair or

replace the

PCV valve.

3 Was the turbocharger working completely? —

Go to Step 4 Replace the

turbocharger.

4 Are any DTC stored? — Go to indicated

DTC Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 798 of 6020

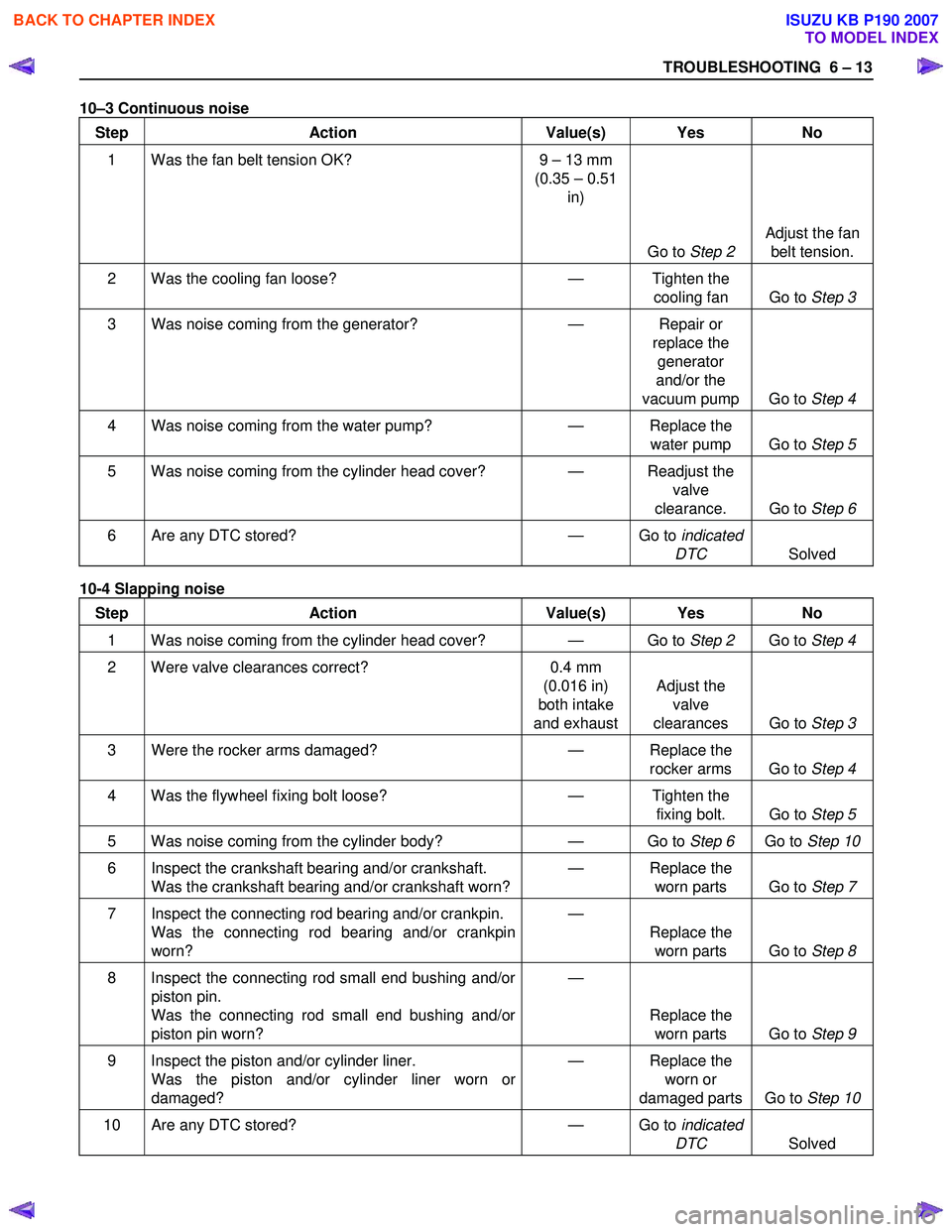

TROUBLESHOOTING 6 – 13

10–3 Continuous noise

Step Action Value(s) Yes No

1 Was the fan belt tension OK? 9 – 13 mm

(0.35 – 0.51

in)

Go to Step 2 Adjust the fan

belt tension.

2 Was the cooling fan loose? — Tighten the

cooling fan Go to Step 3

3 Was noise coming from the generator? — Repair or

replace the generator

and/or the

vacuum pump Go to Step 4

4 Was noise coming from the water pump? — Replace the

water pump Go to Step 5

5 Was noise coming from the cylinder head cover? — Readjust the

valve

clearance. Go to Step 6

6 Are any DTC stored? — Go to indicated

DTC Solved

10-4 Slapping noise

Step Action Value(s) Yes No

1 Was noise coming from the cylinder head cover? — Go to Step 2 Go to Step 4

2 Were valve clearances correct? 0.4 mm

(0.016 in)

both intake

and exhaust Adjust the

valve

clearances Go to Step 3

3 Were the rocker arms damaged? — Replace the

rocker arms Go to Step 4

4 Was the flywheel fixing bolt loose? — Tighten the

fixing bolt. Go to Step 5

5 Was noise coming from the cylinder body? — Go to Step 6 Go to Step 10

6 Inspect the crankshaft bearing and/or crankshaft.

Was the crankshaft bearing and/or crankshaft worn? —

Replace the

worn parts Go to Step 7

7 Inspect the connecting rod bearing and/or crankpin.

Was the connecting rod bearing and/or crankpin

worn? —

Replace the worn parts Go to Step 8

8 Inspect the connecting rod small end bushing and/or

piston pin.

Was the connecting rod small end bushing and/or

piston pin worn? —

Replace the worn parts Go to Step 9

9 Inspect the piston and/or cylinder liner.

Was the piston and/or cylinder liner worn or

damaged? —

Replace the

worn or

damaged parts Go to Step 10

10 Are any DTC stored? — Go to indicated

DTC Solved

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 806 of 6020

SECTION 6A

ENGINE MECHANICAL

TABLE OF CONTENTS

PAGE

4 8

Standard Bolts ........................................................................................................... 6A - 8

Special Parts Fixing Nuts and Bolts ........................................................................ 6A - 9

Recommended Liquid Gasket ...................................................................................... 6A - 22

LOCTITE Application Procedure .................................................................................. 6A - 23

Servicing ...................................................................................................................... .. 6A - 24

Model Identification ................................................................................................... 6A - 24

Air Cleaner .................................................................................................................. 6 A - 24

Lubricating System.................................................................................................... 6A - 24

Fuel System ................................................................................................................ 6A - 25

Cooling System .......................................................................................................... 6A - 2 7

Valve Clearance Adjustment ..................................................................................... 6A - 31

Compression Pressure Measurement ..................................................................... 6A - 32

General Description ...................................................................................................... 6A- 3 6

Removal and Installation .............................................................................................. 6A- 37 Removal ...................................................................................................................... 6 A- 37

Installation .................................................................................................................. 6A- 40

Coolant Replenishment ......................................................................................... 6A- 41

Engine Warm-Up .................................................................................................... 6A- 41

Engine Repair Kit........................................................................................................... 6A - 42

Engine Overhaul ............................................................................................................ 6A- 43

Removal ...................................................................................................................... 6 A- 43

External Parts ......................................................................................................... 6A- 43

E N GINE MECHA NICA L 6A – 1

Main Dat a and Specif ications ....................................................................................... 6A -

Torque Specif ications ................................................................................................... 6A -

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 810 of 6020

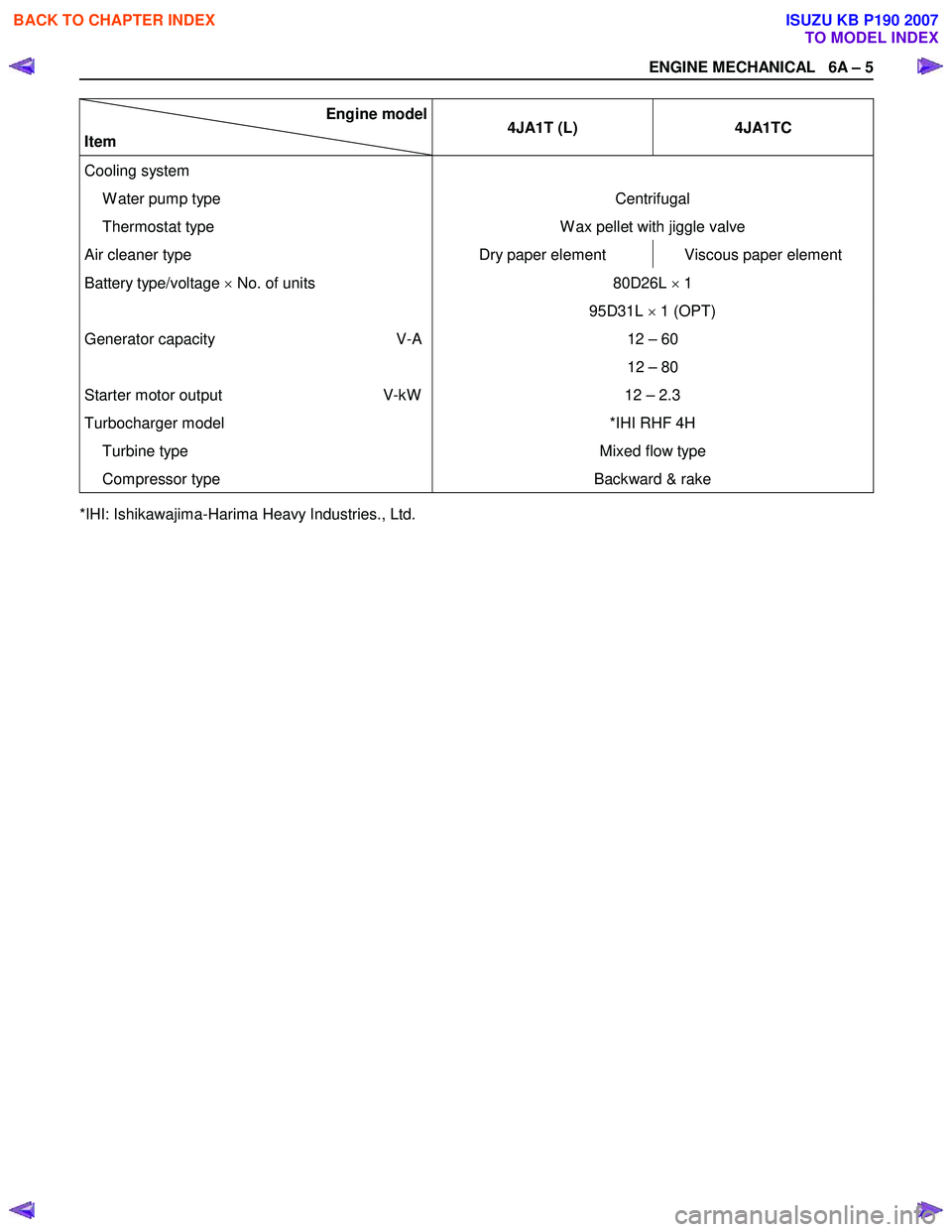

ENGINE MECHANICAL 6A – 5

Engine model

Item 4JA1T (L)

4JA1TC

Cooling system

W ater pump type Centrifugal

Thermostat type W ax pellet with jiggle valve

Air cleaner type Dry paper element Viscous paper element

Battery type/voltage × No. of units 80D26L × 1

95D31L × 1 (OPT)

Generator capacity V-A12 – 60

12 – 80

Starter motor output V-kW12 – 2.3

Turbocharger model

Turbine type

Compressor type *IHI RHF 4H

Mixed flow type

Backward & rake

*IHI: Ishikawajima-Harima Heavy Industries., Ltd.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

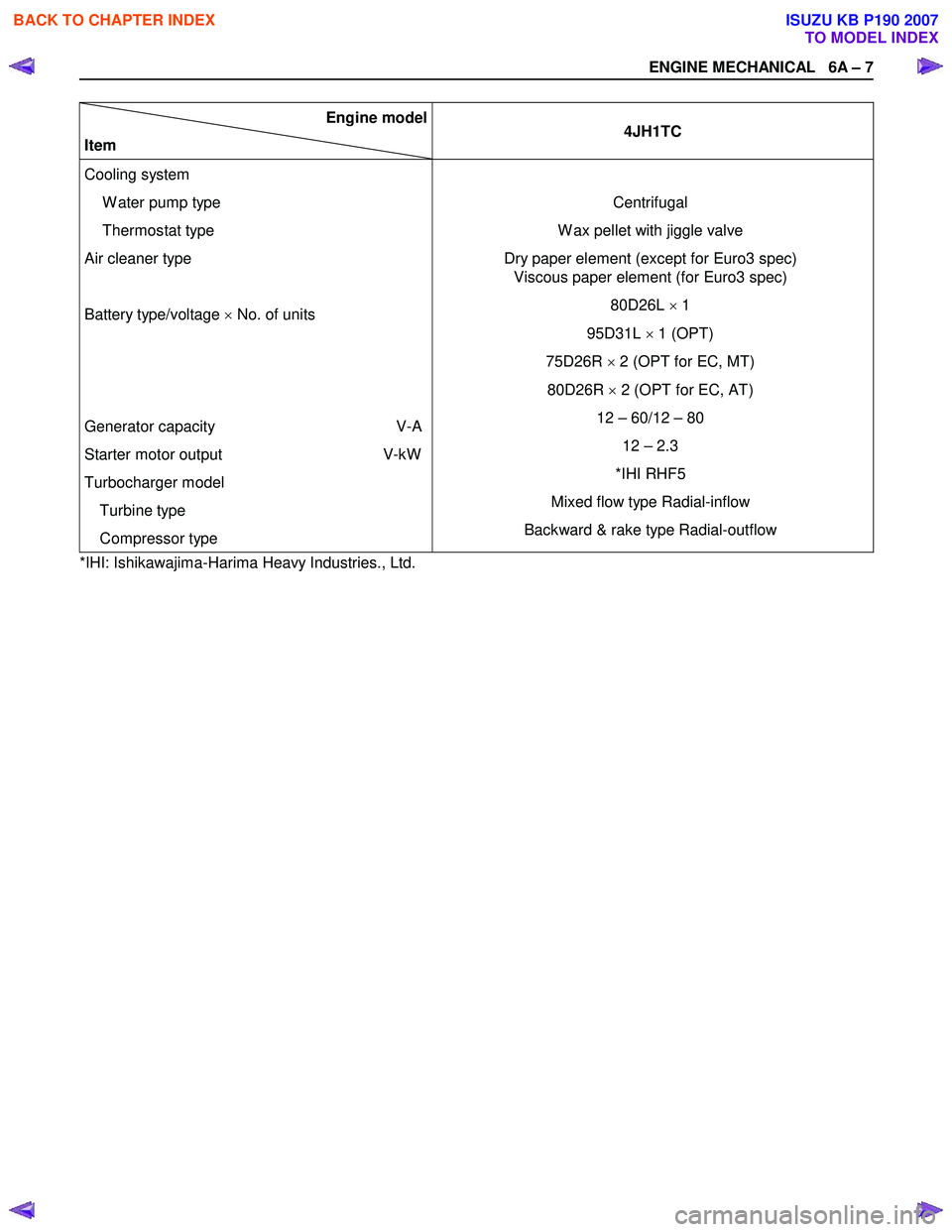

Page 812 of 6020

ENGINE MECHANICAL 6A – 7

Engine model

Item 4JH1TC

Cooling system

W ater pump type

Thermostat type

Air cleaner type

Battery type/voltage × No. of units

Generator capacity V-A

Starter motor output V-kW

Turbocharger model Turbine type

Compressor type

Centrifugal

W ax pellet with jiggle valve

Dry paper element (except for Euro3 spec) Viscous paper element (for Euro3 spec)

80D26L × 1

95D31L × 1 (OPT)

75D26R × 2 (OPT for EC, MT)

80D26R × 2 (OPT for EC, AT)

12 – 60/12 – 80 12 – 2.3

*IHI RHF5

Mixed flow type Radial-inflow

Backward & rake type Radial-outflow

*IHI: Ishikawajima-Harima Heavy Industries., Ltd.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 817 of 6020

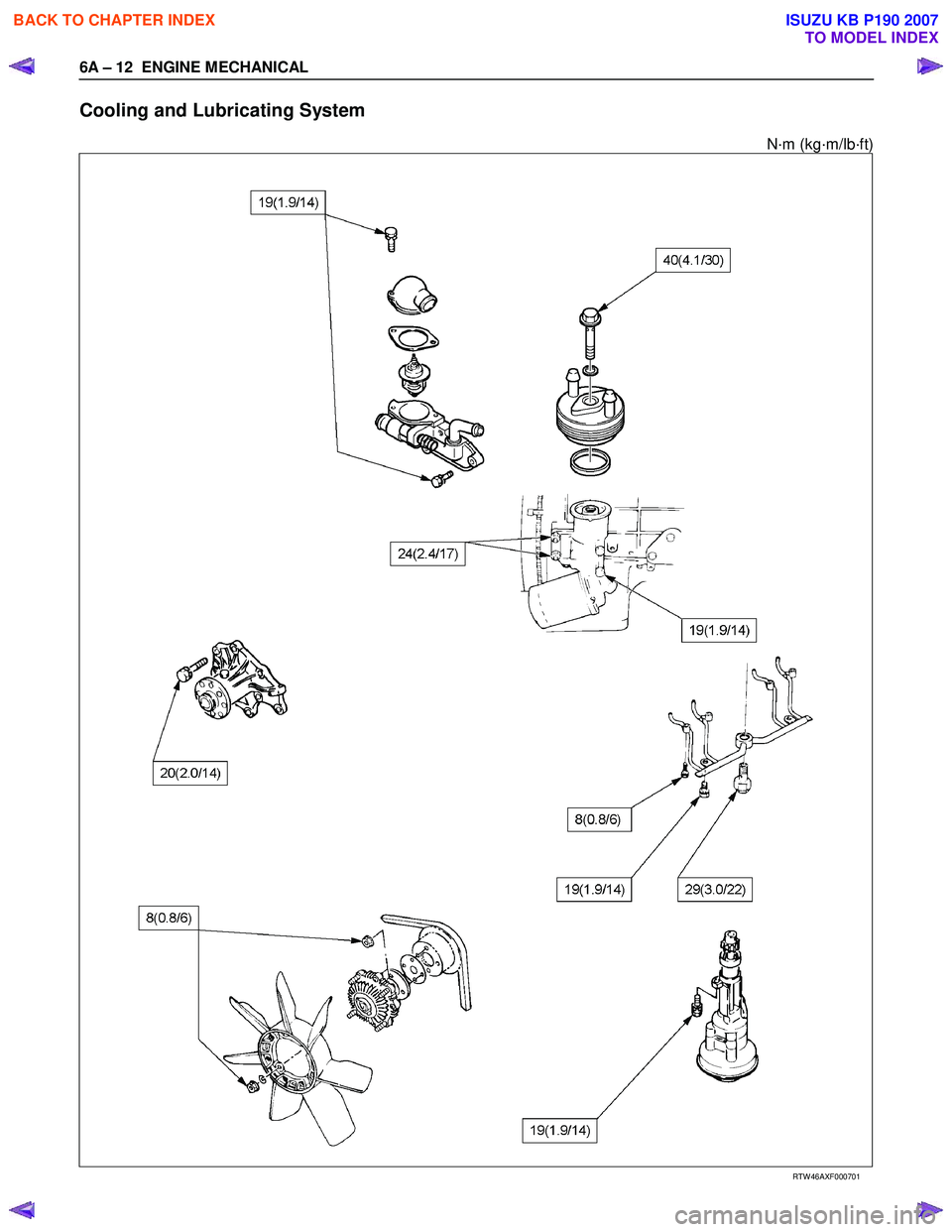

6A – 12 ENGINE MECHANICAL

Cooling and Lubricating System

N·m (kg·m/lb·ft)

RTW 46AXF000701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 832 of 6020

ENGINE MECHANICAL 6A – 27

111R300001

COOLING SYSTEM

Coolant Level

Check the coolant level and replenish the radiator reserve

tank as necessary.

If the coolant level falls below the “MIN” line, carefully

check the cooling system for leakage. Then add enough

coolant to bring the level up to the “MAX” line.

Engine coolant Filling up procedure

1. Make sure that the engine is cool.

Warning:

When the coolant is heated to a high temperature, be

sure not to loosen or remove the rediator cap.

Otherwise you might get scalded by hot vapor or

boiling water.

To open the radiator cap, put a piece of thick cloth on

the cap and loosen the cap slowly to reduce the

pressure when the coolant has become cooler.

2. Open rediator cap pour coolant up to filler neck

3. Pour coolant into reservoir tank up to “MAX” line

4. Tighten radiator cap and start the engine. After idling for 2 to 3 minutes, stop the engine and reopen radiator

cap. If the water level is lower, replenish.

5. After replenish the coolant tighten radiator cap, warm up the engine at about 2000 rpm. Set heater

adjustment to the highest temperature position, and let

the coolant circulate also into heater water system.

6. Check to see the thermometer, continuously idling 5 minutes and stop the engine.

7. W hen the engine has been cooled, check filler neck for water level and replenish if required. Should

extreme shortage of coolant is found, check the

coolant system and reservoir tank hose for leakage.

8. Pour coolant into the reservoir tank up to “MAX” line.

Engine Coolant Total Capacity Lit (U.S / UK gal)

4JA1 / TC 9.4 (2.5 / 2.1)

4JH1TC M/T: 10.1 (2.7 / 2.2)

A/T: 10.0 (2.6 / 2.2)

Mixing Ratio (Anti-Freeze Solution/W ater)

50 %

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007