fuel pump ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 851 of 6020

6A – 46 ENGINE MECHANICAL

13. Injection Pump

Refer to section 6C-19 (Injection Pump)

14. Starter Motor

15. Oil Pressure Warning Switch

16. Fuel Leak Off Pipe

17. Oil Cooler Water Pipe

18. Cooling Fan Pulley

19. Heat Protector

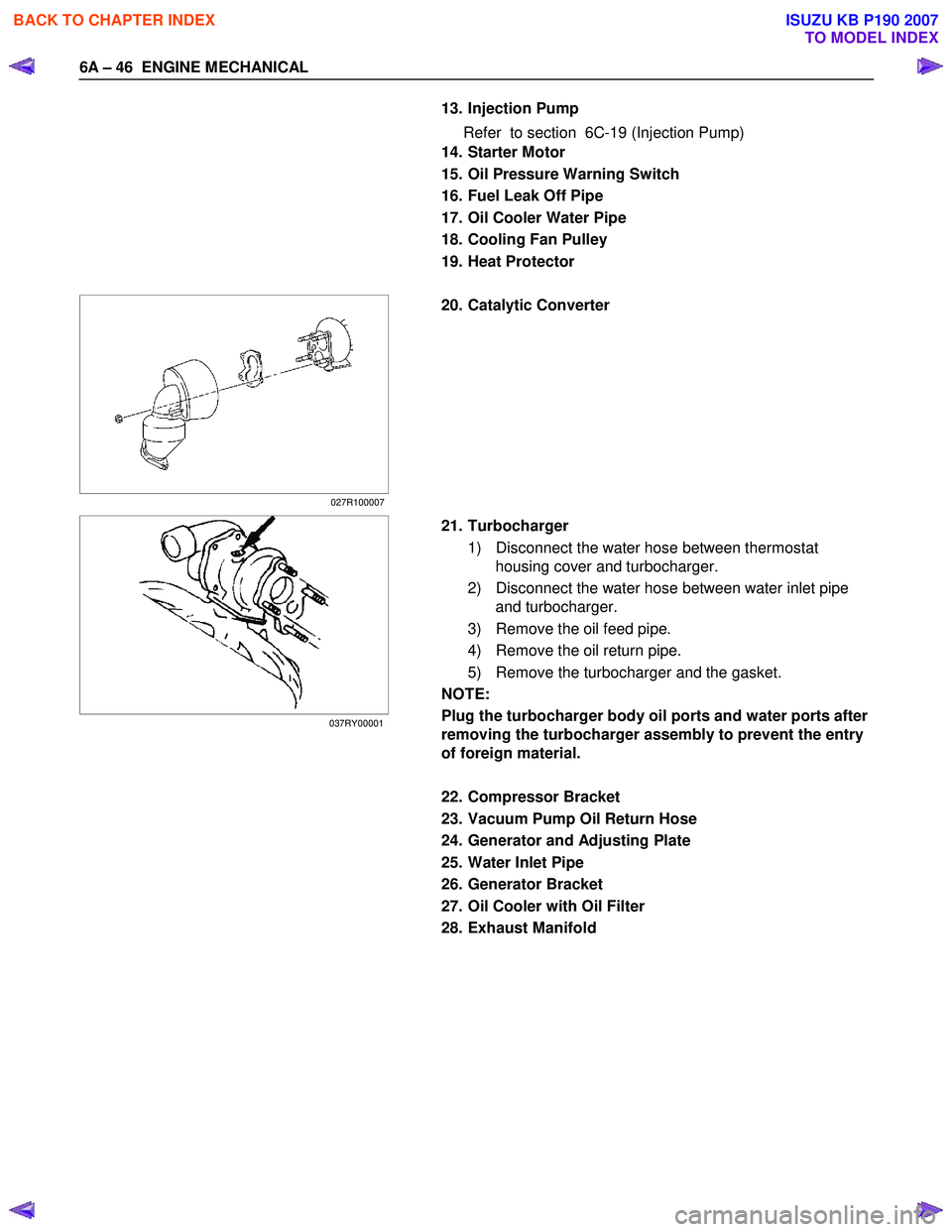

20. Catalytic Converter

21. Turbocharger 1) Disconnect the water hose between thermostat housing cover and turbocharger.

2) Disconnect the water hose between water inlet pipe and turbocharger.

3) Remove the oil feed pipe.

4) Remove the oil return pipe.

5) Remove the turbocharger and the gasket.

NOTE:

Plug the turbocharger body oil ports and water ports after

removing the turbocharger assembly to prevent the entry

of foreign material.

22. Compressor Bracket

23. Vacuum Pump Oil Return Hose

24. Generator and Adjusting Plate

25. Water Inlet Pipe

26. Generator Bracket

27. Oil Cooler with Oil Filter

28. Exhaust Manifold

027R100007

037RY00001

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 923 of 6020

6A – 118 ENGINE MECHANICAL

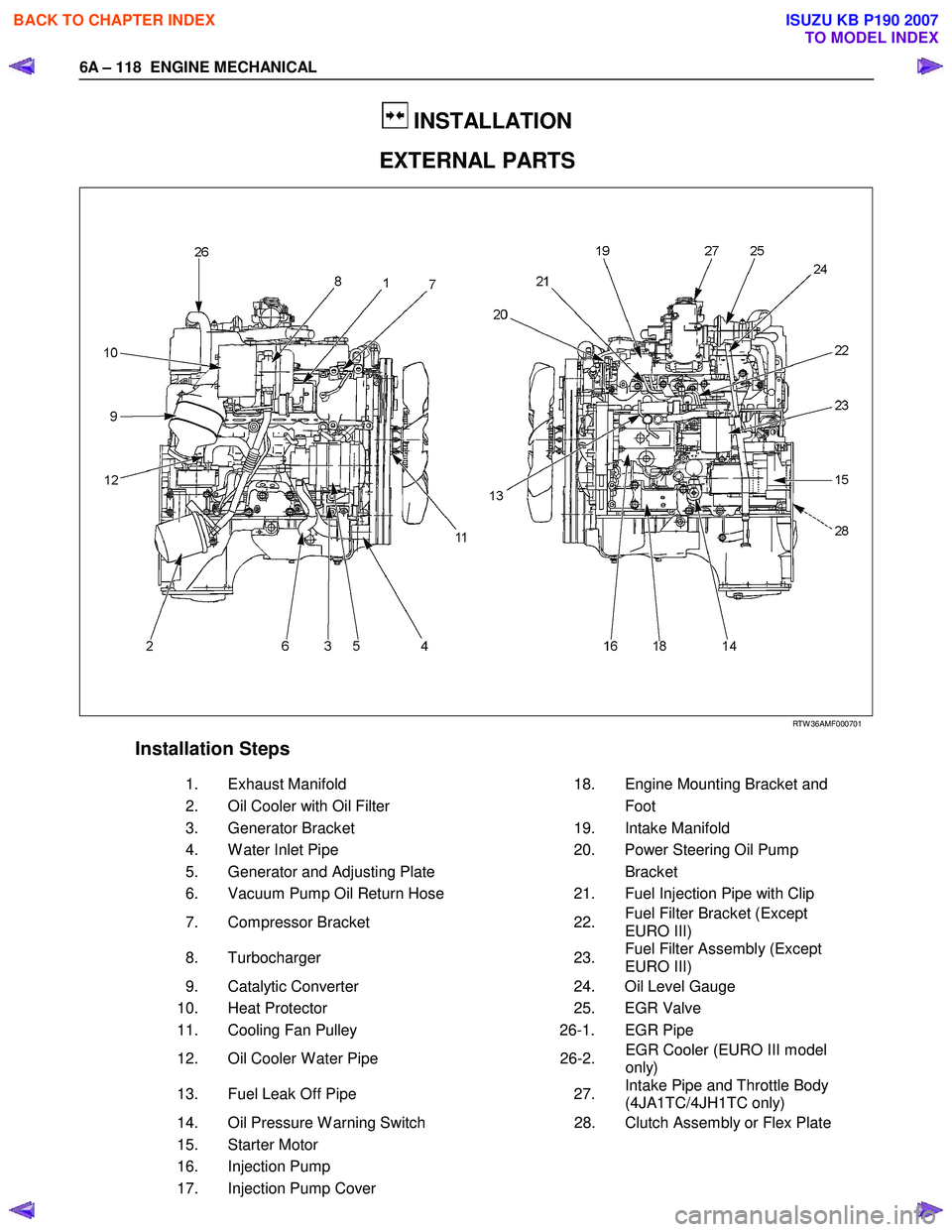

INSTALLATION

EXTERNAL PARTS

RTW 36AMF000701

Installation Steps

1.

Exhaust Manifold 18. Engine Mounting Bracket and

2.

Oil Cooler with Oil Filter Foot

3. Generator Bracket 19. Intake Manifold

4. W ater Inlet Pipe 20. Power Steering Oil Pump

5.

Generator and Adjusting Plate Bracket

6.

Vacuum Pump Oil Return Hose 21. Fuel Injection Pipe with Clip

7.

Compressor Bracket 22. Fuel Filter Bracket (Except

EURO III)

8. Turbocharger 23. Fuel Filter Assembly (Except

EURO III)

9. Catalytic Converter 24. Oil Level Gauge

10. Heat Protector 25. EGR Valve

11. Cooling Fan Pulley 26-1. EGR Pipe

12. Oil Cooler W ater Pipe 26-2. EGR Cooler (EURO III model

only)

13. Fuel Leak Off Pipe 27. Intake Pipe and Throttle Body

(4JA1TC/4JH1TC only)

14. Oil Pressure W arning Switch 28. Clutch Assembly or Flex Plate

15. Starter Motor

16. Injection Pump

17. Injection Pump Cover

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 927 of 6020

6A – 122 ENGINE MECHANICAL

RTW 46ASH001601

9) Install the water feed adapter (1) with the gaskets to

turbocharger and tighten to the specified torque.

Adapter Torque N·m(kg·m/Ib ft)

39 (4.0/29)

10) Install the water feed pipe with the gaskets and tighten to the specified torque.

W ater Return Pipe Torque N·m(kg·m/Ib ft)

39 (4.0/29)

11) Install the water return pipe with the gaskets and tighten to the specified torque.

W ater Return Torque N·m(kg·m/Ib ft)

39 (4.0/29)

12) Clamp the water feed pipe to the oil return pipe of the turbocharger.

Fixing Bolt (3) Torque N·m(kg·m/Ib ft)

8 (0.8/6)

13) Install the hoses for the water feed and return.

9. Catalytic Converter

Install the catalytic converter with gasket and tighten the

nut to the specified torque.

Catalytic converter Nut Torque N·m(kg·m/Ib ft)

27 (2.7/20)

Do not install the catalytic converter, if drop down it.

10. Heat Protector Install the heat protector and tighten the bolt to the

specified torque.

Heat Protector Bolt Torque N·m(kg·m/Ib ft)

9 (0.9/6.5 Ib in)

033R300002

11. Cooling Fan Pulley

1) Install the cooling fan pulley to the water pump.

2) Tighten the cooling fan pulley nuts to the specified torque.

Pulley Nut Torque N·m(kg·m/Ib ft)

8 (0.8/6)

12. Oil Cooler Water Pipe

13. Fuel Leak Off Pipe

14. Oil Pressure Warning Switch

027R100007

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 929 of 6020

6A – 124 ENGINE MECHANICAL

20. Power Steering Oil Pump Bracket

Oil Pump Braket Nut and Bolt Torque N·m(kg·m/Ib ft)

1M10 ×1.25

37 (3.8/28)

2

3M8×1.25

18 (1.8/13) (Bolt ID:8)

040R300005

21. Fuel Injection Pipe with Clip

1) Temporarily tighten the injection pipe sleeve nut.

2) Set the clip in the illustrated position. Note:

Make absolutely sure that the clip is correctly

positioned.

An improperly positioned clip will result in injection

pipe breakage and fuel pulsing noise.

3) Tighten the injection pipe sleeve nut to the specified torque.

Torque

Injection Pump Side (4JA1TC/4JH1TC) N·m(kg·m/Ib ft)

40 (4.1/30)

Injection Pipe Sleeve Nuts N·m(kg·m/Ib ft)

29 (3.0/22)

Injection Pipe Clip Nuts N·m(kg·m/Ib ft)

8 (0.8/6)

22. Fuel Filter Bracket (Except EURO III model)

Install the fuel filter bracket and tighten fixing bolts to the

specified torque.

Fuel Filter Bracket Bolt Torque N·m(kg·m/Ib ft)

21 (2.1/15)

23. Fuel Filter Assembly (Except EURO III model)

Install the fuel filter assembly and tighten fixing bolts to the

specified torque.

Fuel Filter Assembly Bolt Torque N·m(kg·m/Ib ft)

21 (2.1/15)

24. Oil Level Gauge

Install the oil level gauge and tighten fixing bolts to the

specified torque.

Oil Level Gauge Bolt Torque N·m(kg·m/Ib ft)

M8 19 (1.9/14)

M6 8 (0.8/6)

431RY00013

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 965 of 6020

SECTION 6C

FUEL SYSTEM

TABLE OF CONTENTS

PAGE

Main Data and Specifications ....................................................................................... 6C - 2

General Description ...................................................................................................... 6C - 3

Fuel Flow.................................................................................................................... 6 C - 3

Fuel Filter and Water Separator ............................................................................... 6C - 4

Injection Pump........................................................................................................... 6C - 6

Injection Nozzle ......................................................................................................... 6C - 7

Fuel Tank...................................................................................................................... .. 6C - 8

Removal .................................................................................................................... 6 C - 9

Installation ................................................................................................................ 6C - 9

Fuel Gauge Unit ............................................................................................................. 6C - 11

Removal ..................................................................................................................... 6 C - 12

Installation ................................................................................................................. 6C - 12

Fuel Tube / Quick - Connector Fittings........................................................................ 6C - 14

Filler Neck .................................................................................................................... .. 6C - 16

Removal ..................................................................................................................... 6 C - 16

Installation ................................................................................................................. 6C - 16

Fuel Filler Cap................................................................................................................ 6C - 17

Injection Pump ............................................................................................................... 6 C - 18

Removal and Installation .......................................................................................... 6C - 18

Removal ..................................................................................................................... 6C - 18

Installation ................................................................................................................. 6 C - 21

Injection Nozzle (4JA1L) ............................................................................................... 6C - 25

Disassembly .............................................................................................................. 6C - 25

Reassembly ............................................................................................................... 6C - 26

Special tools .................................................................................................................. 6C - 37

FU

EL SY STEM 6C – 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 966 of 6020

6C – 2 FUEL SYSTEM

MAIN DATA AND SPECIFICATIONS

Description Item

4JA1T (L) 4JA1TC 4JH1TC

Injection pump type Bosch distributor

VE type Bosch distributor VP44 type

Governor type

Mechanical variable

(Half speed oil pressure) Electrical controled

Timer type

Oil pressure Electrical controled

Fuel feed pump type Vane with input shaft

Injection nozzle type Hole type

Number of injection nozzle orifices 5

Injection nozzle orifices

Inside diameter mm (in) 0.19 (0.0075) 0.17 (0.0067) 0.21 (0.0083)

19.1 (195) 19.0 (194) 19.5 (199) Injection nozzle designed operating

pressure MPa (kg/cm2) 1st

2nd 25.0 (255)

33.5 (328) 33.8 (331)

Main fuel filter type Disposable cartridge paper element

Precautions

When working on the fuel system, there are several things

to keep in mind:

•

Any time the fuel system is being worked on,

disconnect the negative battery cable except fo

r

those tests where battery voltage is required.

•

Always keep a dry chemical (Class B) fire

extinguisher near the work area.

• Replace all pipes with the same pipe and fittings that

were removed.

• Clean and inspect “O” rings. Replace if required.

•

Always relieve the line pressure before servicing any

fuel system components.

• Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

• Adhere to all Notices and Cautions.

NOTE:

Injection nozzle adjustment is possible only on the 4JA1L

engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 967 of 6020

FUEL SYSTEM 6C – 3

GENERAL DESCRIPTION

FUEL FLOW

RTW 66CMF000101

The fuel system consists of the fuel tank, the fuel filter, the water separator, the injection pump, and the injection

nozzle.

The fuel from the fuel tank passes through the water separator and the fuel filter where water particles and other

foreign material are removed from the fuel.

Fuel, fed by the injection pump plunger, is delivered to the injection nozzle in the measured volume at the optimum

timing for efficient engine operation.

NOTE:

1 If it find abnormal condition on the fuel injector, refer to section 6E ENGINE DRIVEABILITY AND EMISSIONS.

2 Do not contain "Additive for water drain" with fuel.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 968 of 6020

6C – 4 FUEL SYSTEM

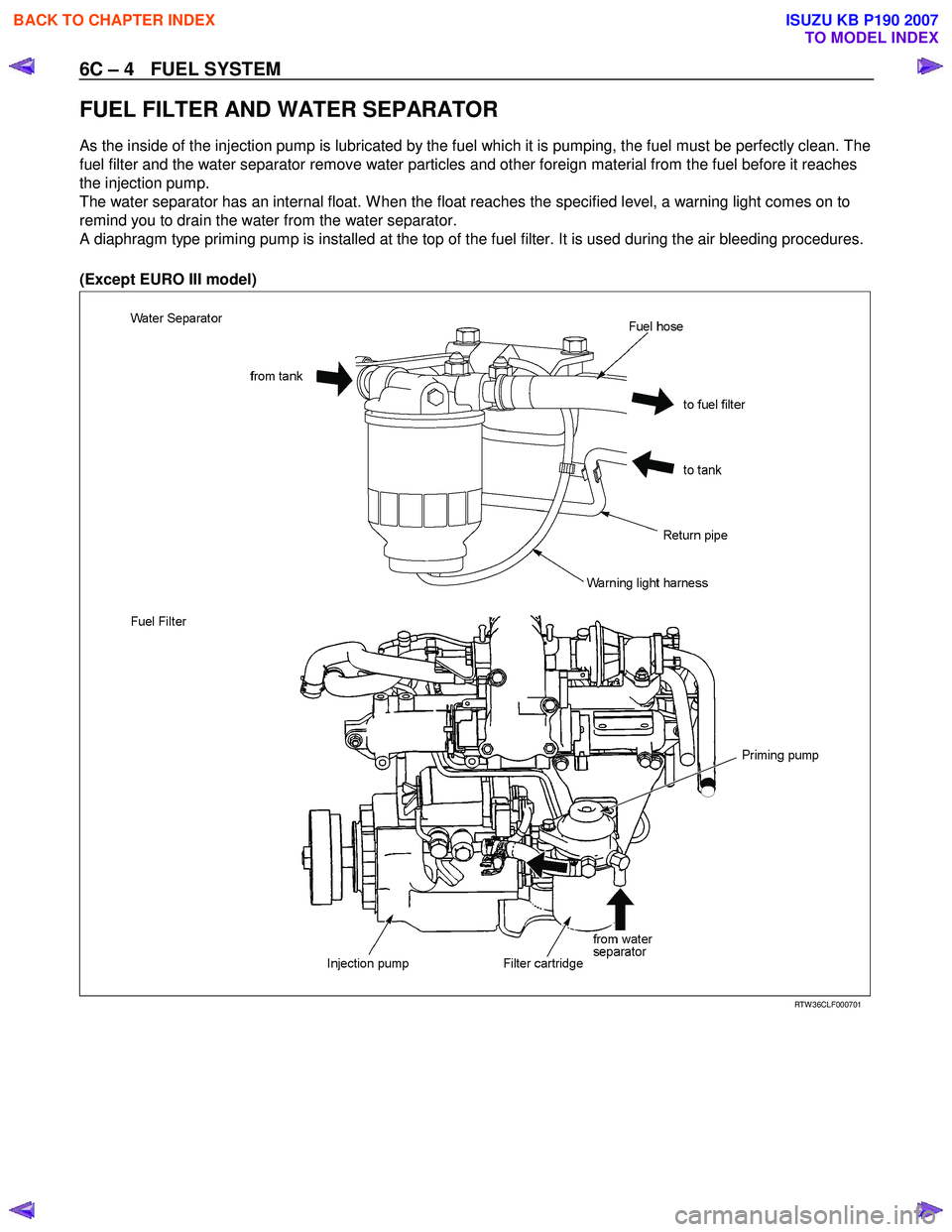

FUEL FILTER AND WATER SEPARATOR

As the inside of the injection pump is lubricated by the fuel which it is pumping, the fuel must be perfectly clean. The

fuel filter and the water separator remove water particles and other foreign material from the fuel before it reaches

the injection pump.

The water separator has an internal float. W hen the float reaches the specified level, a warning light comes on to

remind you to drain the water from the water separator.

A diaphragm type priming pump is installed at the top of the fuel filter. It is used during the air bleeding procedures.

(Except EURO III model)

RTW 36CLF000701

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 970 of 6020

6C – 6 FUEL SYSTEM

INJECTION PUMP

RTW 46CLF000201

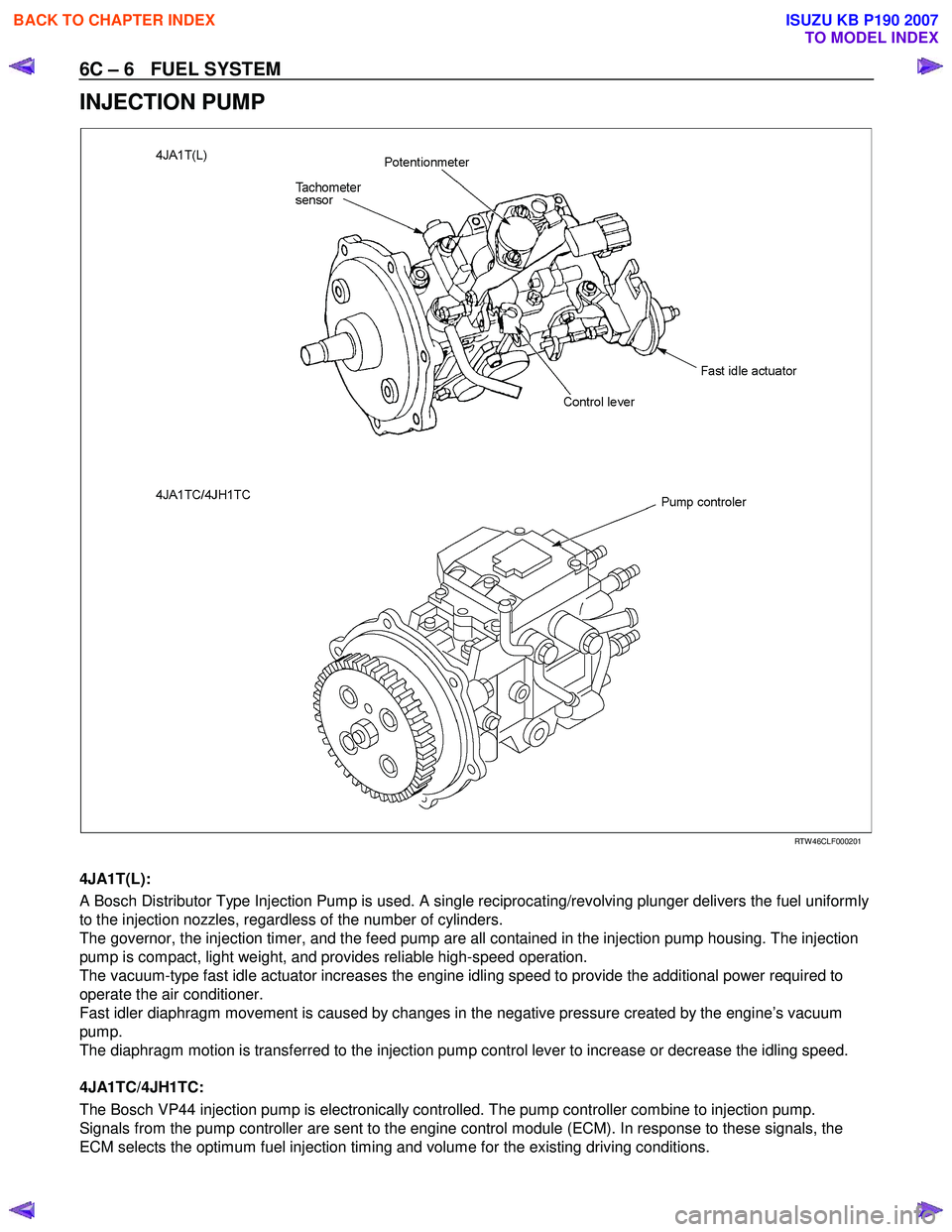

4JA1T(L):

A Bosch Distributor Type Injection Pump is used. A single reciprocating/revolving plunger delivers the fuel uniformly

to the injection nozzles, regardless of the number of cylinders.

The governor, the injection timer, and the feed pump are all contained in the injection pump housing. The injection

pump is compact, light weight, and provides reliable high-speed operation.

The vacuum-type fast idle actuator increases the engine idling speed to provide the additional power required to

operate the air conditioner.

Fast idler diaphragm movement is caused by changes in the negative pressure created by the engine’s vacuum

pump.

The diaphragm motion is transferred to the injection pump control lever to increase or decrease the idling speed.

4JA1TC/4JH1TC:

The Bosch VP44 injection pump is electronically controlled. The pump controller combine to injection pump.

Signals from the pump controller are sent to the engine control module (ECM). In response to these signals, the

ECM selects the optimum fuel injection timing and volume for the existing driving conditions.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 971 of 6020

FUEL SYSTEM 6C – 7

INJECTION NOZZLE (4JA1L)

RTW 76CMF000301

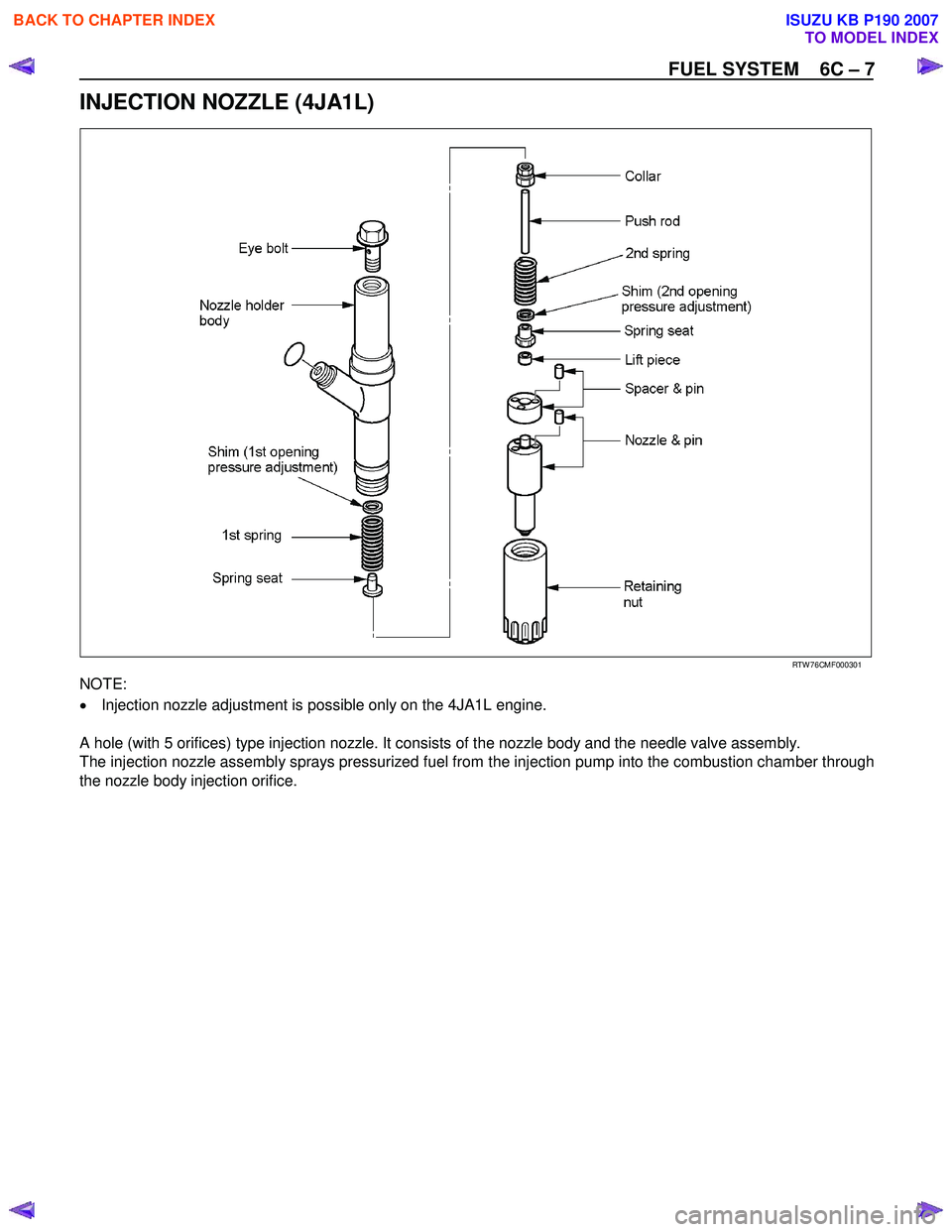

NOTE:

• Injection nozzle adjustment is possible only on the 4JA1L engine.

A hole (with 5 orifices) type injection nozzle. It consists of the nozzle body and the needle valve assembly.

The injection nozzle assembly sprays pressurized fuel from the injection pump into the combustion chamber through

the nozzle body injection orifice.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007