fuse box location ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4967 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-29

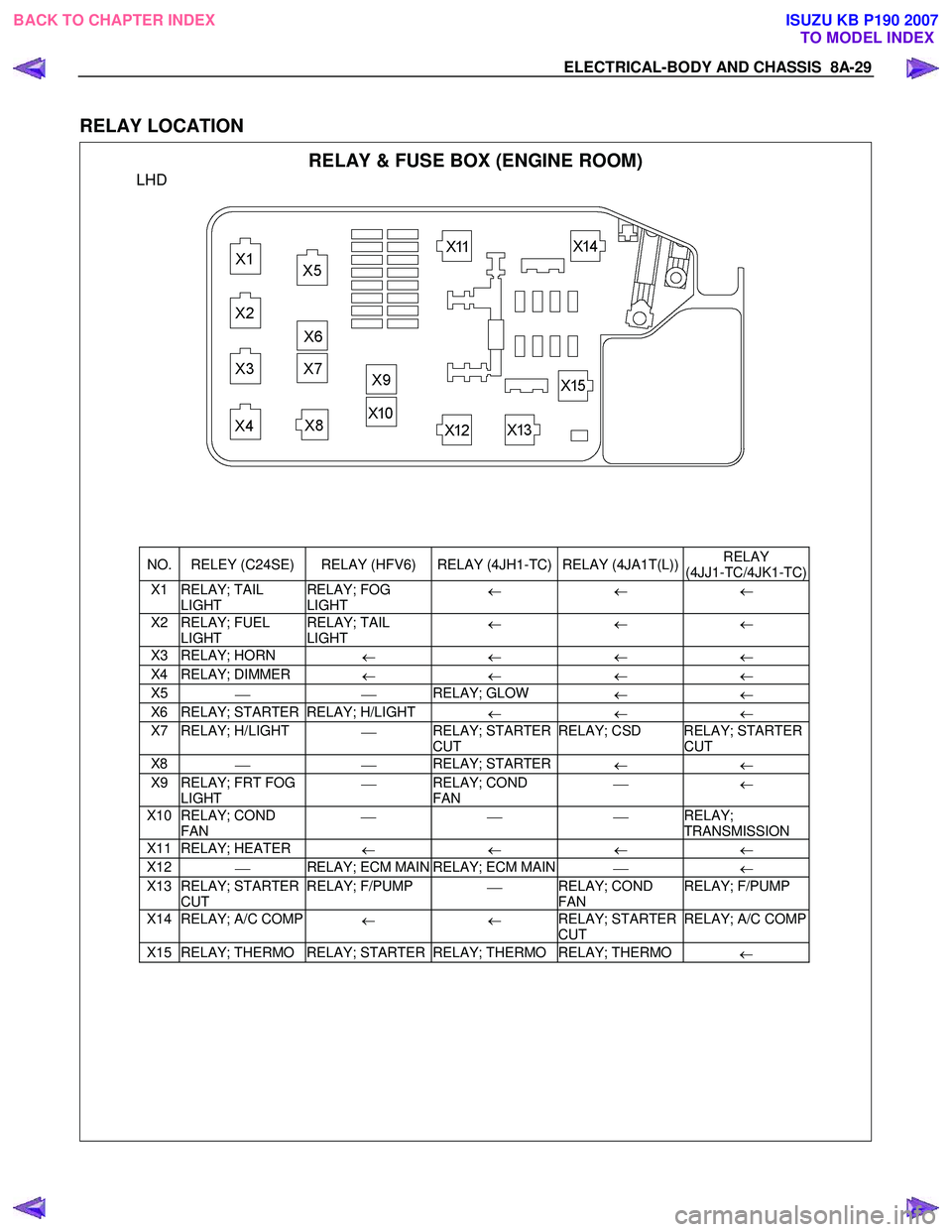

RELAY LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

LHD

NO. RELEY (C24SE) RELAY (HFV6) RELAY (4JH1-TC) RELAY (4JA1T(L)) RELAY

(4JJ1-TC/4JK1-TC)

X1 RELAY; TAIL LIGHT RELAY; FOG

LIGHT ←

← ←

X2 RELAY; FUEL

LIGHT RELAY; TAIL

LIGHT ←

← ←

X3 RELAY; HORN

← ← ← ←

X4 RELAY; DIMMER

← ← ← ←

X5

RELAY; GLOW

← ←

X6 RELAY; STARTER RELAY; H/LIGHT

← ← ←

X7 RELAY; H/LIGHT

RELAY; STARTER

CUT RELAY; CSD RELAY; STARTER

CUT

X8 RELAY; STARTER

← ←

X9 RELAY; FRT FOG

LIGHT

RELAY; COND

FAN

←

X10 RELAY; COND

FAN

RELAY;

TRANSMISSION

X11 RELAY; HEATER ← ← ← ←

X12

RELAY; ECM MAIN RELAY; ECM MAIN

←

X13 RELAY; STARTER

CUT RELAY; F/PUMP

RELAY; COND

FAN RELAY; F/PUMP

X14 RELAY; A/C COMP

← ← RELAY; STARTER

CUT RELAY; A/C COMP

X15 RELAY; THERMO RELAY; STARTER RELAY; THERMO RELAY; THERMO

←

BACK TO CHAPTER INDEXTO MODEL INDEXISUZU KB P190 2007

Page 4968 of 6020

8A-30 ELECTRICAL-BODY AND CHASSIS

RELAY LOCATION

RELAY & FUSE BOX (CABIN)

RELAY

Connector No. B7 B8 B40

Relay name

REAR DEFOGGER POW ER W INDOW (NO RELAY)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4969 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-31

FUSE AND SLOW BLOW FUSE LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

RHD

FUSE ∗1 AUSTRALIA

ENGINE MODEL

FUSE NO. C24SE

HFV6 4JA1T (L) 4JJ1-TC/ 4JK1-TC

EB1 15A ECM

← 10A ACG (S)

←

EB2

15A 02 SENS PRE

10A ECM (B)

EB3 15A FRT FOG 10A ECM (B)

10A F/PUMP

20A TRAILER ∗1

EB4 10A ACG (S)

10A TCM PIM B

10A ENGINE

EB5 10A ILLUMI

10A H/L (RH) HI

← ←

10A H/L (RH) HI ∗1

EB6 10A H/L (LH) HI

← ← ←

EB7 10A H/L (RH) LOW

← ← ←

EB8 10A H/L (LH) LOW

← ← ←

EB9 20A F/PUMP 20A TRAILER

20A TRAIKER

EB10 10A SENSOR 20A COND, FAN

EB11 10A TAIL (RH)

← ← ←

EB12 10A ILLUMI & TAIL-LH

← ← ←

EB13 10A A/C

← ← ←

EB14 10A 4W D

← ← ←

EB15 10A HORN

← ← ←

EB16 10A HAZARD

← ← ←

SLOW BLOW FUSE

ENGINE MODEL

FUSE NO. C24SE

HFV6 4JA1T (L) 4JJ1-TC / 4JK1-TC

SBF1 100A MAIN ←

80A MAIN 120A MAIN

SBF2

20A FRT FOG

40A ABS1 ←

SBF3

60A RAD. FAN

20A ABS2 ←

SBF4 20A COND, FAN 20A F/PUMP

20A COND, FAN 40A ECM

SBF5 40A IG 1

←

← ←

SBF6

30A BLOW ER ←

←

SBF7 20A FRT FOG

40A ABS1 20A FRT FOG ←

SBF8 30A BLOW ER

20A ABS2 50A GLOW 60A GLOW

SBF9

50A IG 2

60A IG 2 50A IG 2 60A IG 2

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 4970 of 6020

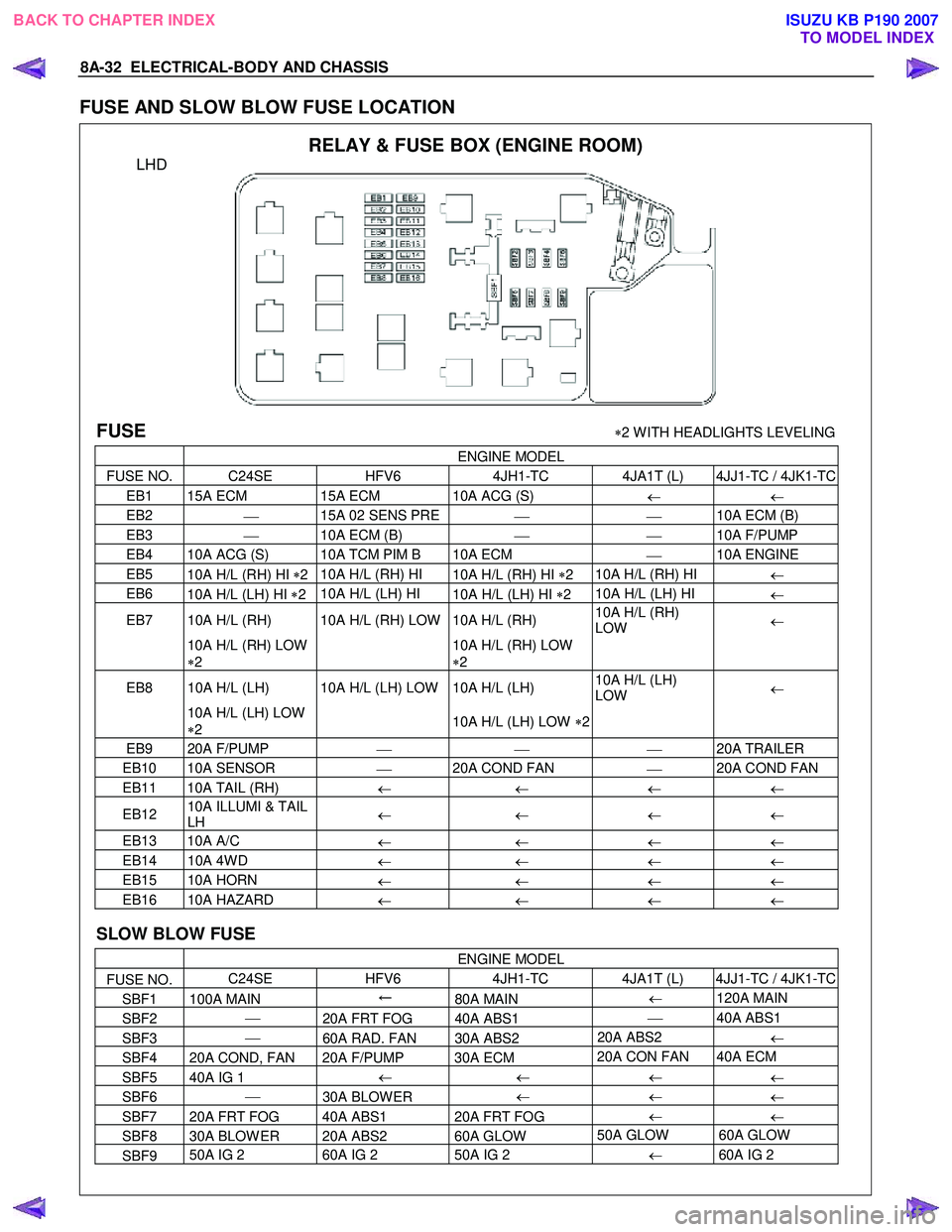

8A-32 ELECTRICAL-BODY AND CHASSIS

FUSE AND SLOW BLOW FUSE LOCATION

RELAY & FUSE BOX (ENGINE ROOM)

LHD

FUSE ∗2 W ITH HEADLIGHTS LEVELING

ENGINE MODEL

FUSE NO. C24SE HFV6 4JH1-TC 4JA1T (L) 4JJ1-TC / 4JK1-TC

EB1 15A ECM 15A ECM 10A ACG (S)

← ←

EB2

15A 02 SENS PRE

10A ECM (B)

EB3

10A ECM (B)

10A F/PUMP

EB4 10A ACG (S) 10A TCM PIM B 10A ECM

10A ENGINE

EB5

10A H/L (RH) HI ∗2 10A H/L (RH) HI

10A H/L (RH) HI ∗2 10A H/L (RH) HI

←

EB6

10A H/L (LH) HI ∗2 10A H/L (LH) HI

10A H/L (LH) HI ∗2 10A H/L (LH) HI

←

EB7 10A H/L (RH) 10A H/L (RH) LOW 10A H/L (RH) 10A H/L (RH)

LOW ←

10A H/L (RH) LOW

∗ 2

10A H/L (RH) LOW

∗ 2

EB8 10A H/L (LH) 10A H/L (LH) LOW 10A H/L (LH)

10A H/L (LH)

LOW ←

10A H/L (LH) LOW

∗ 2

10A H/L (LH) LOW ∗2

EB9 20A F/PUMP

20A TRAILER

EB10 10A SENSOR

20A COND FAN

20A COND FAN

EB11 10A TAIL (RH)

← ← ← ←

EB12 10A ILLUMI & TAIL

LH ←

← ← ←

EB13 10A A/C

← ← ← ←

EB14 10A 4W D

← ← ← ←

EB15 10A HORN

← ← ← ←

EB16 10A HAZARD

← ← ← ←

SLOW BLOW FUSE

ENGINE MODEL

FUSE NO. C24SE

HFV6 4JH1-TC 4JA1T (L) 4JJ1-TC / 4JK1-TC

SBF1 100A MAIN ←

80A MAIN ←

120A MAIN

SBF2

20A FRT FOG 40A ABS1

40A ABS1

SBF3

60A RAD. FAN 30A ABS2 20A ABS2

←

SBF4 20A COND, FAN 20A F/PUMP 30A ECM 20A CON FAN 40A ECM

SBF5 40A IG 1

←

← ←

←

SBF6

30A BLOW ER ←

←

←

SBF7 20A FRT FOG 40A ABS1 20A FRT FOG ←

←

SBF8 30A BLOW ER 20A ABS2 60A GLOW 50A GLOW 60A GLOW

SBF9 50A IG 2

60A IG 2 50A IG 2

← 60A IG 2

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4971 of 6020

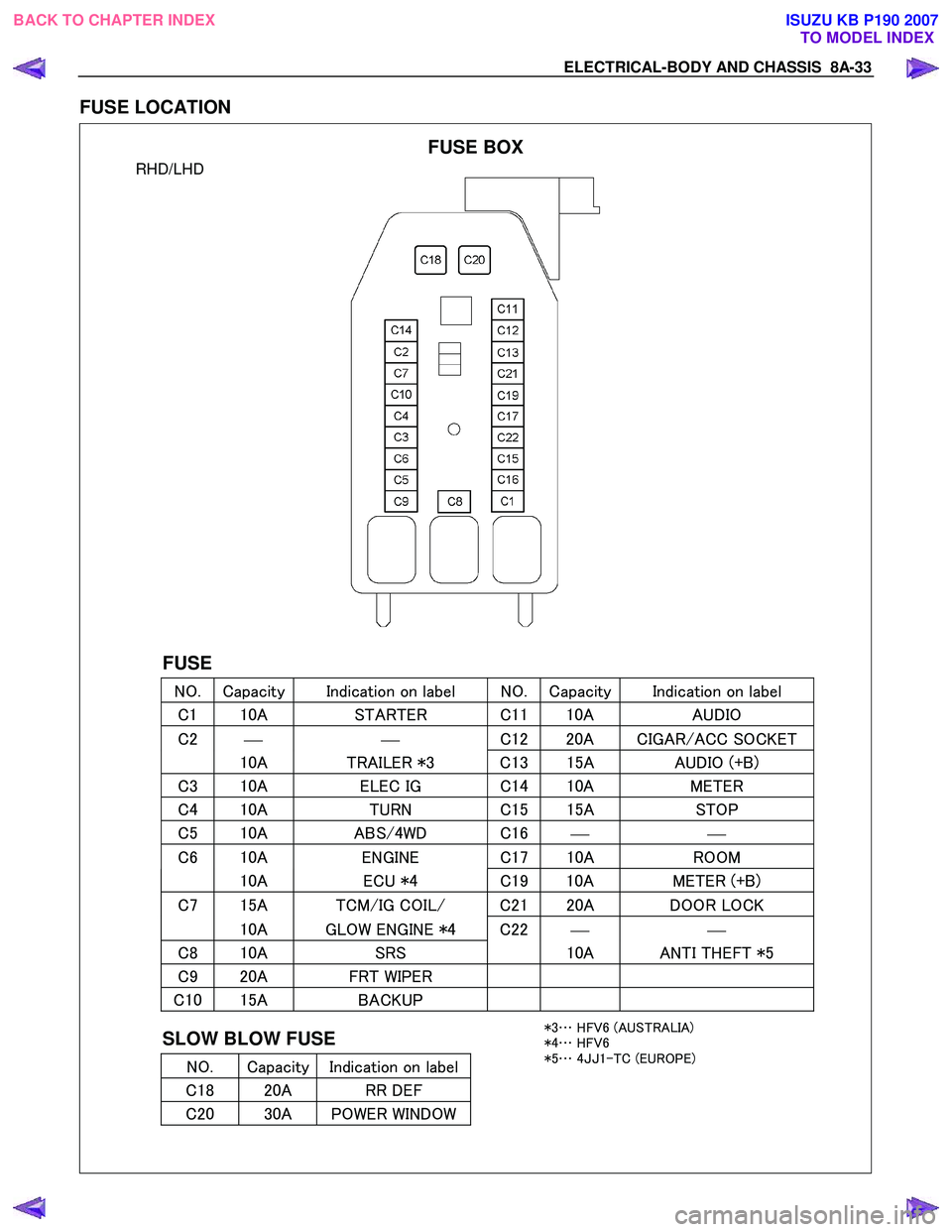

ELECTRICAL-BODY AND CHASSIS 8A-33

FUSE LOCATION

RHD/LHD

FUSE

NO. Capacity Indication on label NO. Capacity Indication on label

C 1 10A STARTER C 1110A AUDIO

C2

C

12 20A CIGAR/ACC SOCKET

10A TRAILER *3 C 13 15A AUDIO (+B)

C3 10A ELEC IG C 14 10A METER

C4 10A TURN C 15 15A STOP

C5 10A ABS/4WD C 16

C6 10A ENGINE C 17 10A ROOM

10A ECU *4 C19 10A METER (+B)

C7 15A TCM/IG COIL/ C2 120A DOOR LOCK

10A GLOW ENGINE *4 C22

C8 10A SRS 10A ANTI THEFT *5

C9 20A FRT WIPER

C10 15A BACKUP

SLOW BLOW FUSE

NO. Capacity Indication on label

C 18 20A RR DEF

C20 30A POWER WINDOW

FUSE BOX

*3 … HFV6 (AUSTRALIA)

*4 … HFV6

*5 … 4JJ 1-TC (EUROPE)

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 4972 of 6020

8A-34 ELECTRICAL-BODY AND CHASSIS

DIODE LOCATION

RELAY & FUSE BOX

DIODE

C24SE HFV6 4JH1-TC4JA1T (L) 4JJ1-TC/4JK1-TC

No. RHD LHD RHD LHD LHD RHD LHD RHD LHD

X16 ― ― DIODE VSV FICD DIODE

X17 ― ― ― ― DIODE

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5667 of 6020

9A-32 SUPPLEMENTAL RESTRAINT SYSTEM

Service Precautions for SRS

Component Service

CAUTION: When fasteners are removed, always

reinstall them at the same location from which

they were removed. If a fastener needs to be

replaced, use the correct part number fastener fo

r

that application. If the correct part number

fastener is not available, a fastener of equal size

and strength (or stronger) may be used. Fasteners

that are not reused, and those requiring a thread

locking compound will be called out. The correct

torque value must be used when installing

fasteners that require it. If the above conditions

are not followed, parts or system damage could

result.

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS

REPAIRS.

The SRS control unit in the Driver–Passenger SRS

can maintain sufficient voltage to cause a deployment

for up to 15 seconds after the ignition switch is turned

“OFF,” the battery is disconnected, or the fuse

powering the SRS control unit is removed.

Many of the service procedures require removal of the

“SRS” fuse, and disconnection of the air bag assembl

y

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected

from the deployment loop as noted in the “Disabling

the SRS” procedure that follows, service can begin

immediately without waiting for the 15 second time

period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “OFF” and turn the steering

wheel so that the vehicle's wheels are pointing straight

ahead.

1. Remove the SRS fuse “SRS” from the left dash side lower fuse block or disconnect the battery.

2. Disconnect the yellow connector at the base o

f

steering column.

3. Remove the glove box assembly; Refer to “Passenger air bag assembly replacement” in this

section.

4. Disconnect the passenger air bag assembly yello

w

connector behind the glove box assembly.

CAUTION: With the “SRS” fuse removed and the

ignition switch to “ON,” the “SRS” warning lamp

will be “ON.” This is normal operation and does

not indicate an SRS malfunction.

Enabling The SRS

Installation

Turn the ignition switch to “LOCK” and remove the

key.

1. Connect the yellow connector passenger air bag assembly.

2. Install the glove box assembly. Refer to “Passenger Air Bag Assembly Replacement” in

this section.

3. Connect the yellow connector at the base of the steering column.

4. Install the “AIR BAG” fuse “SRS” to the left dash side lower fuse block or connect the battery.

Turn the ignition switch to “ON” and verify that the

“SRS” warning lamp flashes seven times and then

turns to “LOCK”. If it does not operate as described,

perform the “SRS Diagnostic System Check” in this

section.

Handling / Installation / Diagnosis

1. Air bag assembly should not be subjected to

temperatures above 65 °C (150 °F).

2.

Air bag assembly, and SRS control unit should not

be used if they have been dropped from a height

of 100 centimeters (3.28 feet) or more.

3. W hen a SRS control unit is replaced, it must be oriented with the arrow on the SRS control unit

pointing toward the front of the vehicle. It is ver

y

important for the SRS control unit to be located flat

on the mounting surface, parallel to the vehicle

datum line. It is important that the SRS control unit

mounting surface is free of any dirt or other foreign

material.

4. Do not apply power to the SRS unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble

code.

5. The “SRS Diagnostic System Check” must be the starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “SRS”

warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and

incorrect parts replacements.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007