check engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 20 of 6020

0B-2 MAINTENANCE AND LUBRICATION

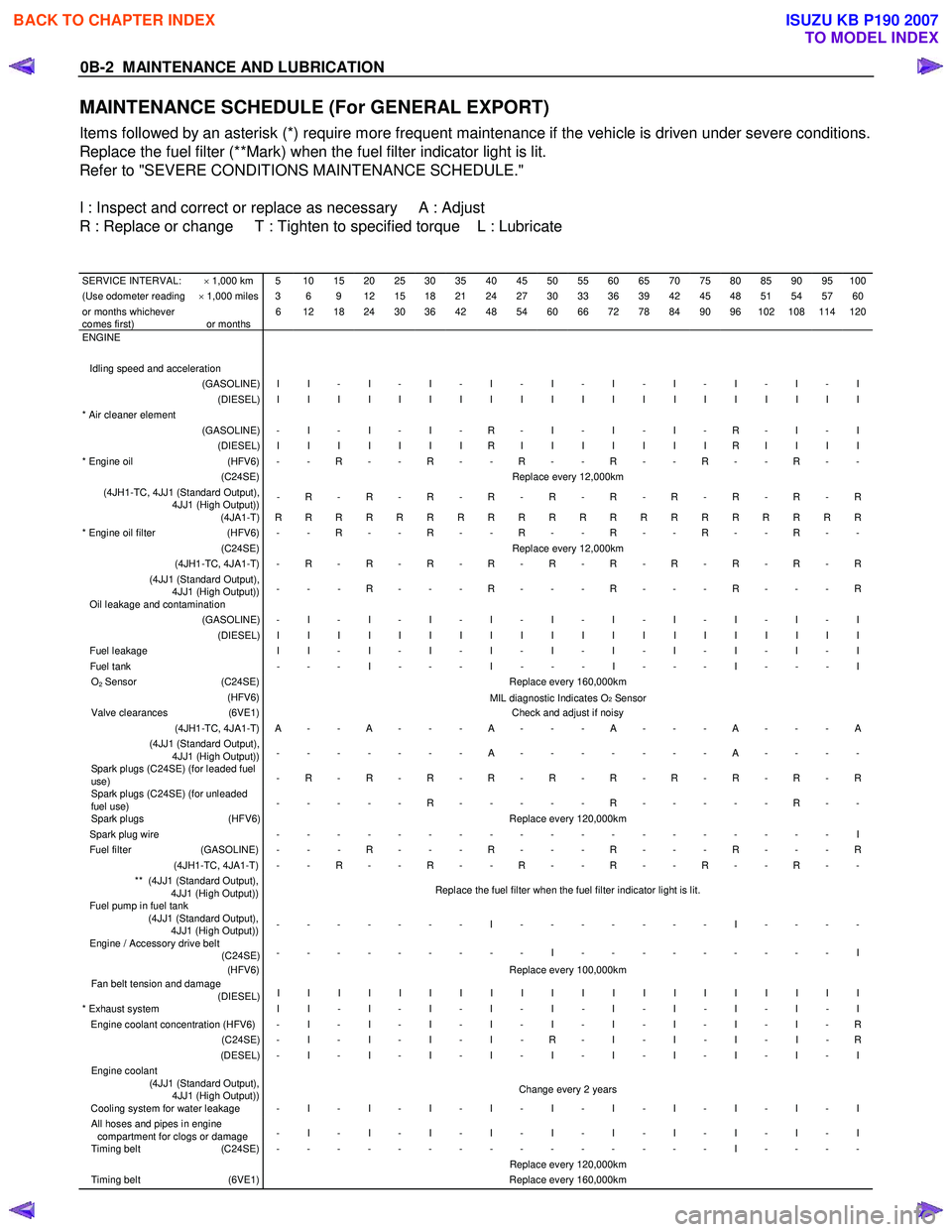

MAINTENANCE SCHEDULE (For GENERAL EXPORT)

Items followed by an asterisk (*) require more frequent maintenance if the vehicle is driven under severe conditions.

Replace the fuel filter (**Mark) when the fuel filter indicator light is lit.

Refer to "SEVERE CONDITIONS MAINTENANCE SCHEDULE."

I : Inspect and correct or replace as necessary A : Adjust

R : Replace or change T : Tighten to specified torque L : Lubricate

SERVICE INTERVAL: × 1,000 km 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100(Use odometer reading × 1,000 miles 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60or months whichever

comes first)

or months 6 12 18 24 30 36 42 48 54 60 66 72 78 84 90 96 102 108 114 120

ENGINE

Idling speed and acceleration

(GASOLINE) I I - I - I - I - I - I - I - I - I - I (DIESEL) I I I I I I I I I I I I I I I I I I I I * Air cleaner element

(GASOLINE) - I - I - I - R - I - I - I - R - I - I (DIESEL) I I I I I I I R I I I I I I I R I I I I * Engine oil (HFV6) - - R - - R - - R - - R - - R - - R - - (C24SE) Replace every 12,000km (4JH1-TC, 4JJ1 (Standard Output),

4JJ1 (High Output)) - R - R - R - R - R - R - R - R - R - R

(4JA1-T) R R R R R R R R R R R R R R R R R R R R * Engine oil filter (HFV6) - - R - - R - - R - - R - - R - - R - - (C24SE) Replace every 12,000km (4JH1-TC, 4JA1-T) - R - R - R - R - R - R - R - R - R - R (4JJ1 (Standard Output),

4JJ1 (High Output)) - - - R - - - R - - - R - - - R - - - R

Oil leakage and contamination (GASOLINE) - I - I - I - I - I - I - I - I - I - I (DIESEL) I I I I I I I I I I I I I I I I I I I I Fuel leakage

I I - I - I - I - I - I - I - I - I - I Fuel tank - - - I - - - I - - - I - - - I - - - I O2 Sensor (C24SE) Replace every 160,000km (HFV6)

MIL diagnostic Indicates O2 Sensor Valve clearances (6VE1) Check and adjust if noisy (4JH1-TC, 4JA1-T) A - - A - - - A - - - A - - - A - - - A (4JJ1 (Standard Output),

4JJ1 (High Output)) - - - - - - - A - - - - - - - A - - - -

Spark plugs (C24SE) (for leaded fuel

use) - R - R - R - R - R - R - R - R - R - R

Spark plugs (C24SE) (for unleaded

fuel use) - - - - - R - - - - - R - - - - - R - -

Spark plugs

(HFV6) Replace every 120,000km Spark plug wire - - - - - - - - - - - - - - - - - - - I Fuel filter (GASOLINE) - - - R - - - R - - - R - - - R - - - R (4JH1-TC, 4JA1-T) - - R - - R - - R - - R - - R - - R - - ** (4JJ1 (Standard Output),

4JJ1 (High Output)) Replace the fuel filter when the fuel filter indicator light is lit.

Fuel pump in fuel tank

(4JJ1 (Standard Output),

4JJ1 (High Output)) - - - - - - - I - - - - - - - I - - - -

Engine / Accessory drive belt

(C24SE) - - - - - - - - - I - - - - - - - - - I

(HFV6) Replace every 100,000km Fan belt tension and damage

(DIESEL) I I I I I I I I I I I I I I I I I I I I

* Exhaust system

I I - I - I - I - I - I - I - I - I - I Engine coolant concentration (HFV6) - I - I - I - I - I - I - I - I - I - R (C24SE) - I - I - I - I - R - I - I - I - I - R (DESEL) - I - I - I - I - I - I - I - I - I - I Engine coolant

(4JJ1 (Standard Output),

4JJ1 (High Output)) Change every 2 years

Cooling system for water leakage - I - I - I - I - I - I - I - I - I - I All hoses and pipes in engine

compartment for clogs or damage - I - I - I - I - I - I - I - I - I - I

Timing belt

(C24SE) - - - - - - - - - - - - - - - I - - - - Replace every 120,000km Timing belt (6VE1) Replace every 160,000km

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 64 of 6020

1-30 HEATER AND AIR CONDITIONING

ON-VEHICLE SERVICE

PRECAUTIONS FOR REPLACEMENT OR

REPAIR OF AIR CONDITIONING PARTS

There are certain procedures, practices and precautions that

should be followed when servicing air conditioning systems:

• Keep your work area clean.

• Always wear safety goggle and protective gloves when

working on refrigerant systems.

• Beware of the danger of carbon monoxide fumes caused by

running the engine.

• Beware of discharged refrigerant in enclosed or improperly

ventilated garages.

•

Always disconnect the negative battery cable and discharge

and recover the refrigerant whenever repairing the air

conditioning system.

• W hen discharging and recovering the refrigerant, do not

allow refrigerant to discharge too fast; it will draw

compressor oil out of the system.

• Keep moisture and contaminants out of the system. W hen

disconnecting or removing any lines or parts, use plugs or

caps to close the fittings immediately.

Never remove the caps or plugs until the lines or parts are reconnected or installed.

• W hen disconnecting or reconnecting the lines, use two

wrenches to support the line fitting, to prevent from twisting

or other damage.

• Always install new O-rings whenever a connection is

disassembled.

• Before connecting any hoses or lines, apply new specified

compressor oil to the O-rings.

• W hen removing and replacing any parts which require

discharging the refrigerant circuit, the operations described

in this section must be performed in the following sequence:

1) Using the ACR

4 (HFC-134a Refrigerant Recovery/

Recycling/Recharging/System) or equivalent to

thoroughly discharge and recover the refrigerant.

ACR

4 (115V 60Hz) : 5-8840-0629-0 (J-39500-A)

ACR4 (220-240V 50/60Hz)

: 5-8840-0630-0 (J-39500-220A)

ACR

4 (220-240V 50/60Hz Australian model)

: 5-8840-0631-0 (J-39500-220ANZ)

2) Remove and replace the defective part.

3)

After evacuation, charge the air conditioning system and

check for leaks.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 71 of 6020

HEATER AND AIR CONDITIONING 1-37

refrigerant container.

1) Make sure the evacuation process is correctly completed.

2) Connect the center-hose of the manifold gauge to the refrigerant container. •

••

•

Turn the charge valve handle counterclockwise to purge

to the charging line and purge any air exiting in the

center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the refrigerant about 200 g (0.44 lbs.). •

••

•

Make sure the high-pressure hand valve is closed.

•

••

•

Avoid charging the refrigerant by turning the refrigerant

container upside down.

4) Close the low-pressure hand valve of the manifold gauge. •

••

•

Check to ensure that the degree of pressure does not

change.

5) Check the refrigerant leaks by using a HFC-134a leak detector. •

••

•

If a leak occurs, repair the leak connection, and start all

over again from the first step of evacuation.

6) If no leaks are found, open the low-pressure hand valve of the manifold gauge. Then continue charging refrigerant to

the system. •

••

•

W hen charging the system becomes difficult:

(1) Run the engine at Idling and close the all vehicle doors.

(2) A/C switch is "ON".

(3) Set the fan control knob (fan switch) to its highest position.

(4) Set air source selector lever to “RECIRC”

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE REFRIGERANT

CONTAINER TO BURST.

7) W hen the refrigerant container is emptied, use the following procedure to replace it with a new refrigerant container.

(1) Close the low-pressure hand valve.

(2) Raise the needle upward and remove the charge valve.

(3) Reinstall the charge valve to the new refrigerant container.

(4) Purge any air existing in the center hose of the manifold gauge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 72 of 6020

1-38 HEATER AND AIR CONDITIONING

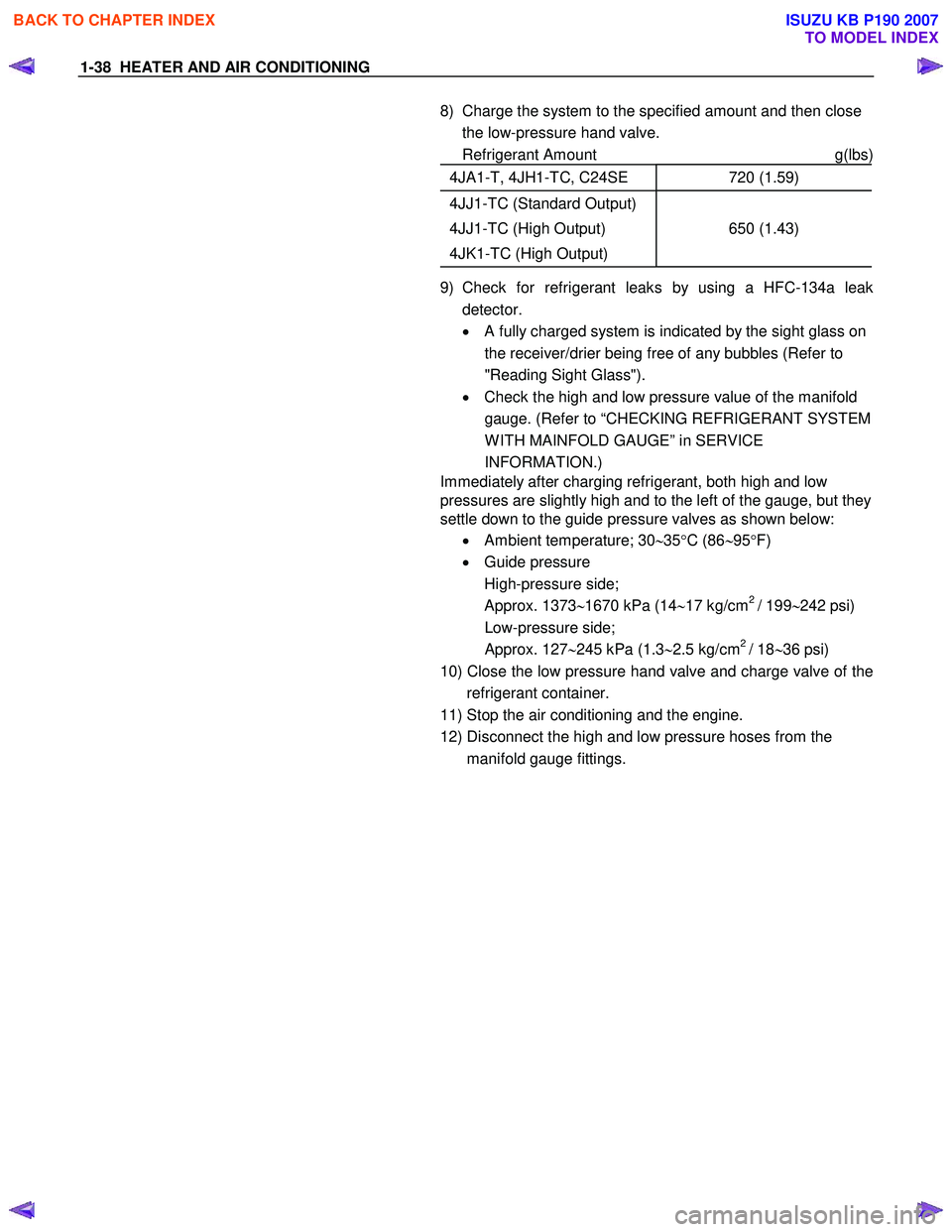

8) Charge the system to the specified amount and then close the low-pressure hand valve.

Refrigerant Amount g(lbs)

4JA1-T, 4JH1-TC, C24SE 720 (1.59)

4JJ1-TC (Standard Output)

4JJ1-TC (High Output)

4JK1-TC (High Output)

650 (1.43)

9) Check for refrigerant leaks by using a HFC-134a leak detector.

• A fully charged system is indicated by the sight glass on

the receiver/drier being free of any bubbles (Refer to

"Reading Sight Glass").

• Check the high and low pressure value of the manifold

gauge. (Refer to “CHECKING REFRIGERANT SYSTEM

W ITH MAINFOLD GAUGE” in SERVICE

INFORMATION.)

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but they

settle down to the guide pressure valves as shown below:

• Ambient temperature; 30 ∼35 °C (86 ∼95 °F)

• Guide pressure

High-pressure side;

Approx. 1373 ∼1670 kPa (14 ∼17 kg/cm

2 / 199 ∼242 psi)

Low-pressure side;

Approx. 127 ∼245 kPa (1.3 ∼2.5 kg/cm

2 / 18 ∼36 psi)

10) Close the low pressure hand valve and charge valve of the refrigerant container.

11) Stop the air conditioning and the engine.

12) Disconnect the high and low pressure hoses from the manifold gauge fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 73 of 6020

HEATER AND AIR CONDITIONING 1-39

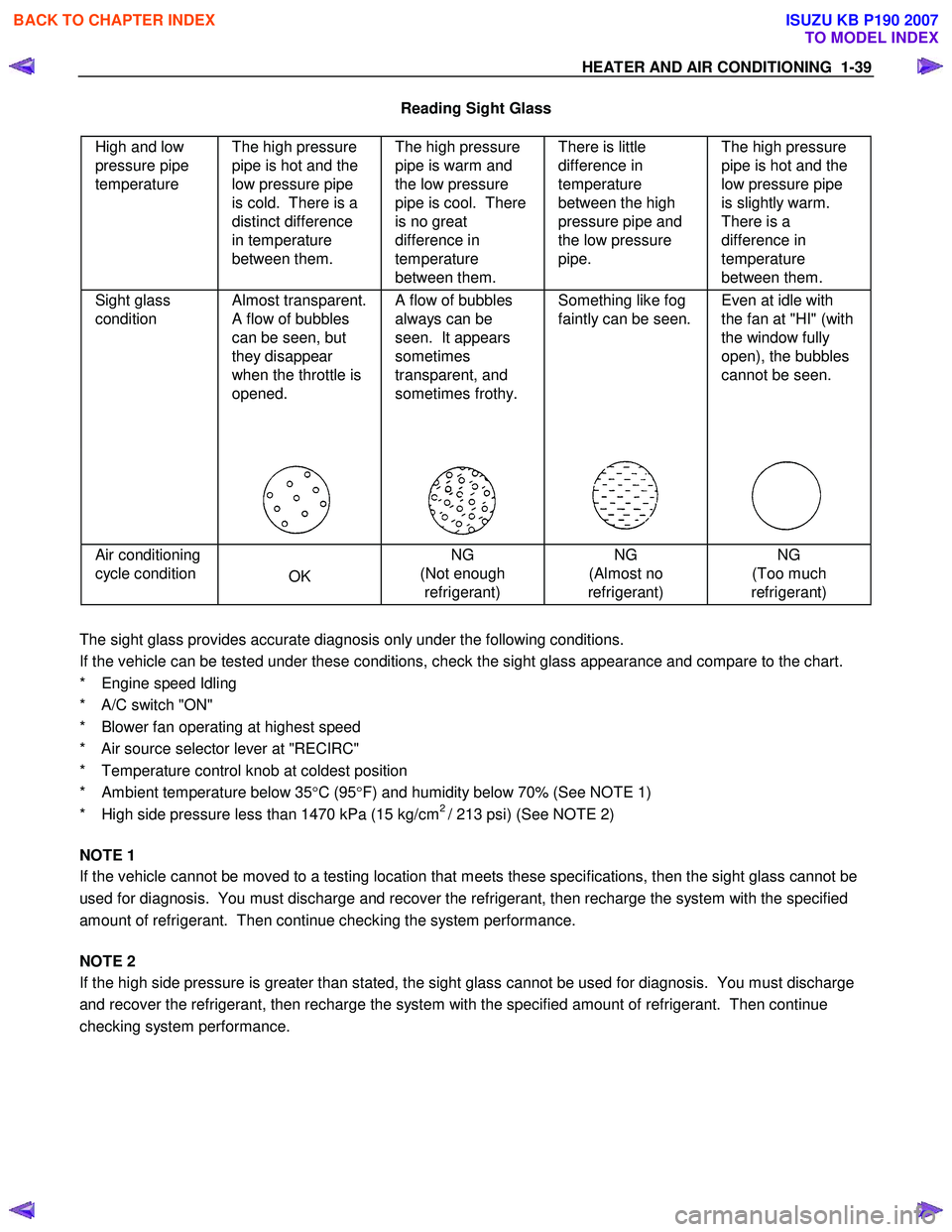

Reading Sight Glass

High and low

pressure pipe

temperature The high pressure

pipe is hot and the

low pressure pipe

is cold. There is a

distinct difference

in temperature

between them. The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great

difference in

temperature

between them. There is little

difference in

temperature

between the high

pressure pipe and

the low pressure

pipe. The high pressure

pipe is hot and the

low pressure pipe

is slightly warm.

There is a

difference in

temperature

between them.

Sight glass

condition Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

A flow of bubbles

always can be

seen. It appears

sometimes

transparent, and

sometimes frothy.

Something like fog

faintly can be seen.

Even at idle with

the fan at "HI" (with

the window fully

open), the bubbles

cannot be seen.

Air conditioning

cycle condition

OK NG

(Not enough refrigerant) NG

(Almost no

refrigerant) NG

(Too much

refrigerant)

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the chart.

* Engine speed Idling

* A/C switch "ON"

* Blower fan operating at highest speed

* Air source selector lever at "RECIRC"

* Temperature control knob at coldest position

* Ambient temperature below 35 °C (95 °F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1470 kPa (15 kg/cm

2 / 213 psi) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass cannot be

used for diagnosis. You must discharge and recover the refrigerant, then recharge the system with the specified

amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must discharge

and recover the refrigerant, then recharge the system with the specified amount of refrigerant. Then continue

checking system performance.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 87 of 6020

HEATER AND AIR CONDITIONING 1-53

Checking and Adjusting for Compressor

Replacement

180 cm3 (5.07 lmp fl oz) of oil is charged in compressor

(service parts). So it is necessary to drain the proper amount

of oil from the new compressor.

1) Perform oil return operation.

2) Discharge refrigerant and remove the compressor.

3) Drain the compressor oil and measure the extracted oil.

4) Check the compressor oil for contamination.

5) Adjust oil level as required.

Amount of oil drained

From used compressor Draining amount of oil

From new compressor

less than

90 cm

3 (2.53 lmp fl oz) Some as drained

amount

more than

90 cm

3 (2.53 lmp fl oz) 90 cm

3 (2.53 lmp fl oz)

6) Evacuate, charge and perform oil return operation.

7) Check system operation.

CONTAMINATION OF COMPRESSOR OIL

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even is the compressor runs for a long period

of time (approximately 1 season), the oil never becomes

contaminated as long as there is nothing wrong with the

compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

• The capacity of the oil has increased.

• The oil has changed color to red.

• Foreign substances, metal powder, etc., are present in the

oil.

If any of these conditions exists, compressor oil is

contaminated. Whenever contaminated compressor oil is

discovered, the receiver/drier must be replaced.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 88 of 6020

1-54 HEATER AND AIR CONDITIONING

OIL RETURN OPERATION

There is close affinity between the oil and the refrigerant.

During normal operation, part of the oil recirculates with the

refrigerant in the system.

W hen checking the amount of oil in the system, or replacing

any component of the system, the compressor must be run in

advance for oil return operation. The procedure is as follows:

1) Open the all doors and engine hood.

2) Start the engine and A/C switch is "ON" and Set the fan control knob at its highest position.

3) Run the compressor for more than 20 minutes between 800 and 1,000 rpm in order to operate the system.

4) Stop the engine.

REPLACEMENT OF COMPONENT PARTS

W hen replacing system component parts, supply the following

amount of oil to the component parts to be installed.

Component parts to be installed Amount of oil

Evaporator 50 cm3 (1.41 lmp fl oz)

Condenser 30 cm3 (0.84 lmp fl oz)

Receiver/drier 30 cm3 (0.84 lmp fl oz)

Refrigerant line (One piece) 10 cm3 (0.28 lmp fl oz)

Refrigeration oil must be replenished if more than two parts

are removed at the same time. After installing these

components, check compressor oil.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 120 of 6020

1-86 HEATER AND AIR CONDITIONING

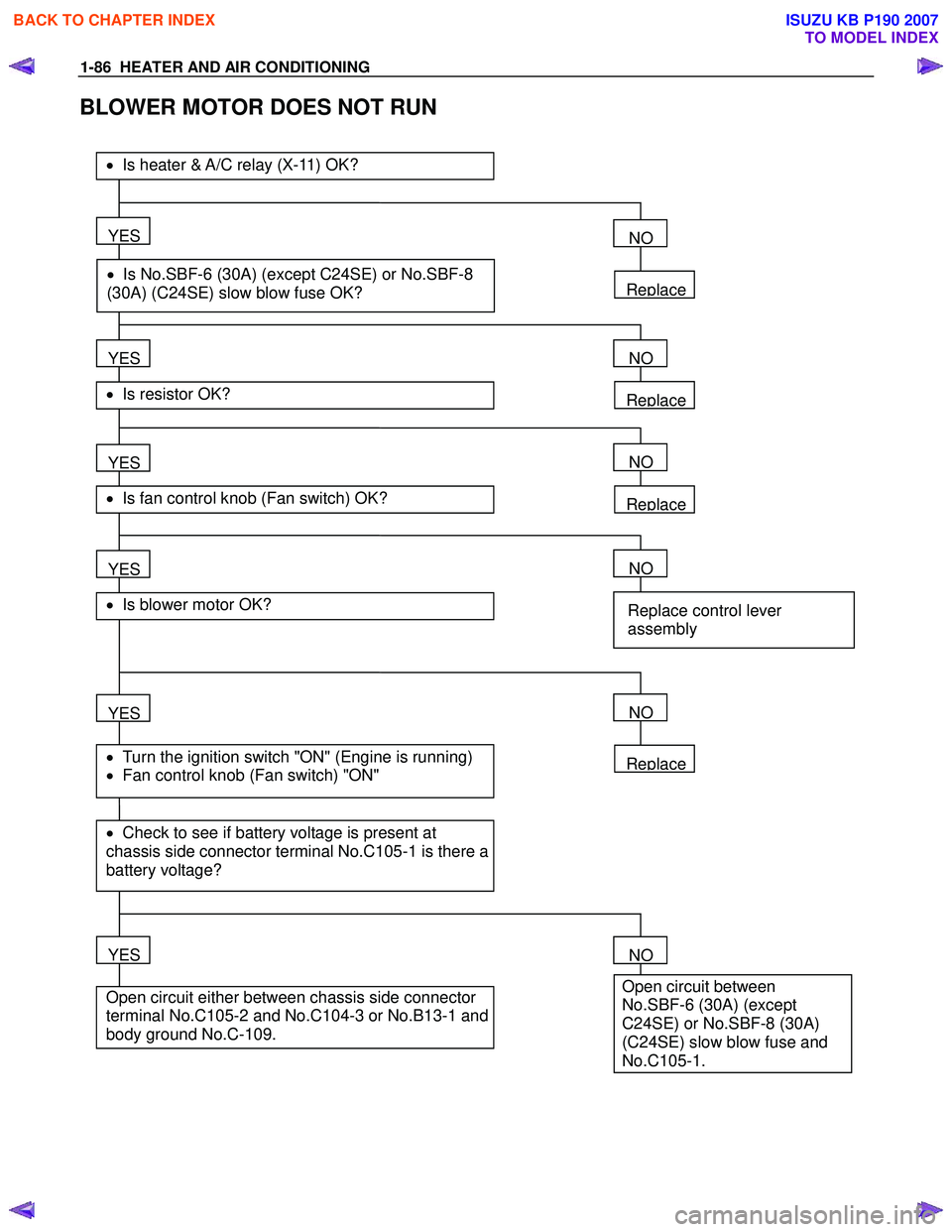

BLOWER MOTOR DOES NOT RUN

Replace

YES

• Is No.SBF-6 (30A) (except C24SE) or No.SBF-8

(30A) (C24SE) slow blow fuse OK?

• Is heater & A/C relay (X-11) OK?

YES

• Is resistor OK?

YES

• Is fan control knob (Fan switch) OK?

YES

YES

• Check to see if battery voltage is present at

chassis side connector terminal No.C105-1 is there a

battery voltage?

• Turn the ignition switch "ON" (Engine is running)

• Fan control knob (Fan switch) "ON"

• Is blower motor OK?

YES

Open circuit either between chassis side connector

terminal No.C105-2 and No.C104-3 or No.B13-1 and

body ground No.C-109.

NO

Replace

NO

Replace

NO

NO

Replace control lever

assembly

Replace

NO

NO

Open circuit between

No.SBF-6 (30A) (except

C24SE) or No.SBF-8 (30A)

(C24SE) slow blow fuse and

No.C105-1.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 124 of 6020

1-90 HEATER AND AIR CONDITIONING

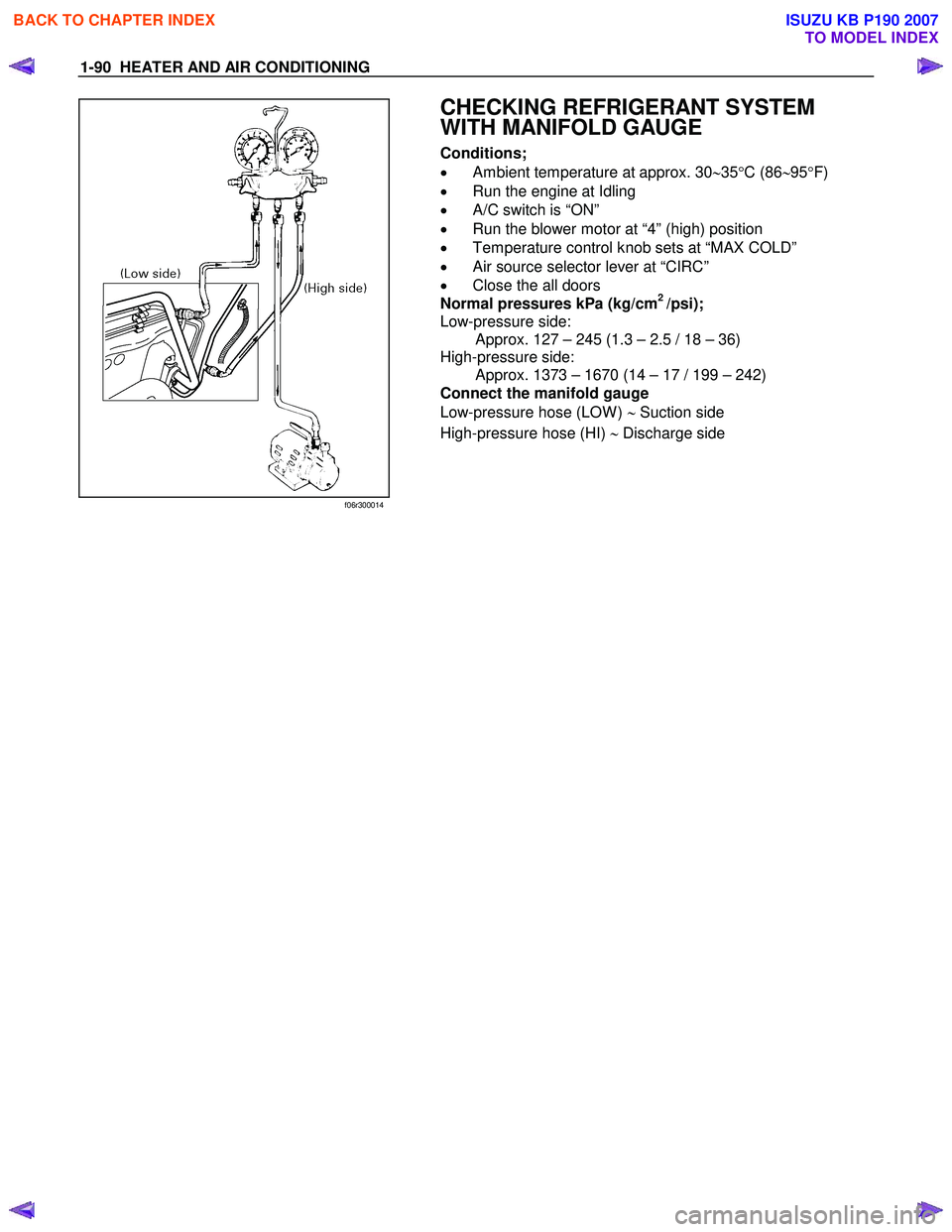

f06r300014

CHECKING REFRIGERANT SYSTEM

WITH MANIFOLD GAUGE

Conditions;

• Ambient temperature at approx. 30 ∼35 °C (86 ∼95 °F)

• Run the engine at Idling

• A/C switch is “ON”

• Run the blower motor at “4” (high) position

• Temperature control knob sets at “MAX COLD”

• Air source selector lever at “CIRC”

• Close the all doors

Normal pressures kPa (kg/cm

2 /psi);

Low-pressure side: Approx. 127 – 245 (1.3 – 2.5 / 18 – 36)

High-pressure side: Approx. 1373 – 1670 (14 – 17 / 199 – 242)

Connect the manifold gauge

Low-pressure hose (LOW ) ∼ Suction side

High-pressure hose (HI) ∼ Discharge side

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 200 of 6020

SHEET METAL 2B-3

RUW 52BSH002501

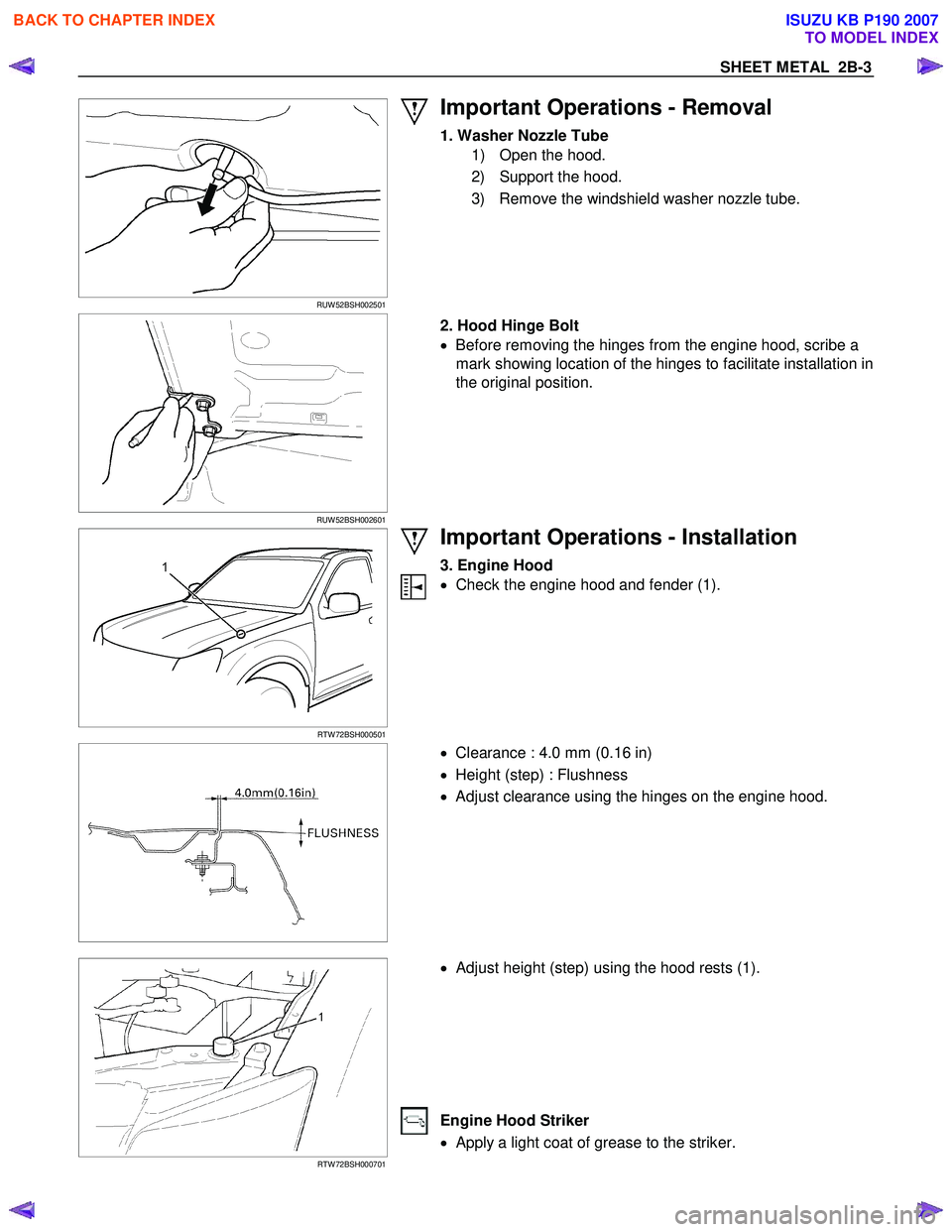

Important Operations - Removal

1. Washer Nozzle Tube

1) Open the hood.

2) Support the hood.

3) Remove the windshield washer nozzle tube.

RUW 52BSH002601

2. Hood Hinge Bolt

• Before removing the hinges from the engine hood, scribe a

mark showing location of the hinges to facilitate installation in

the original position.

RTW 72BSH000501

Important Operations - Installation

3. Engine Hood

• Check the engine hood and fender (1).

• Clearance : 4.0 mm (0.16 in)

• Height (step) : Flushness

• Adjust clearance using the hinges on the engine hood.

RTW 72BSH000701

• Adjust height (step) using the hood rests (1).

Engine Hood Striker

• Apply a light coat of grease to the striker.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007