key ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1067 of 6020

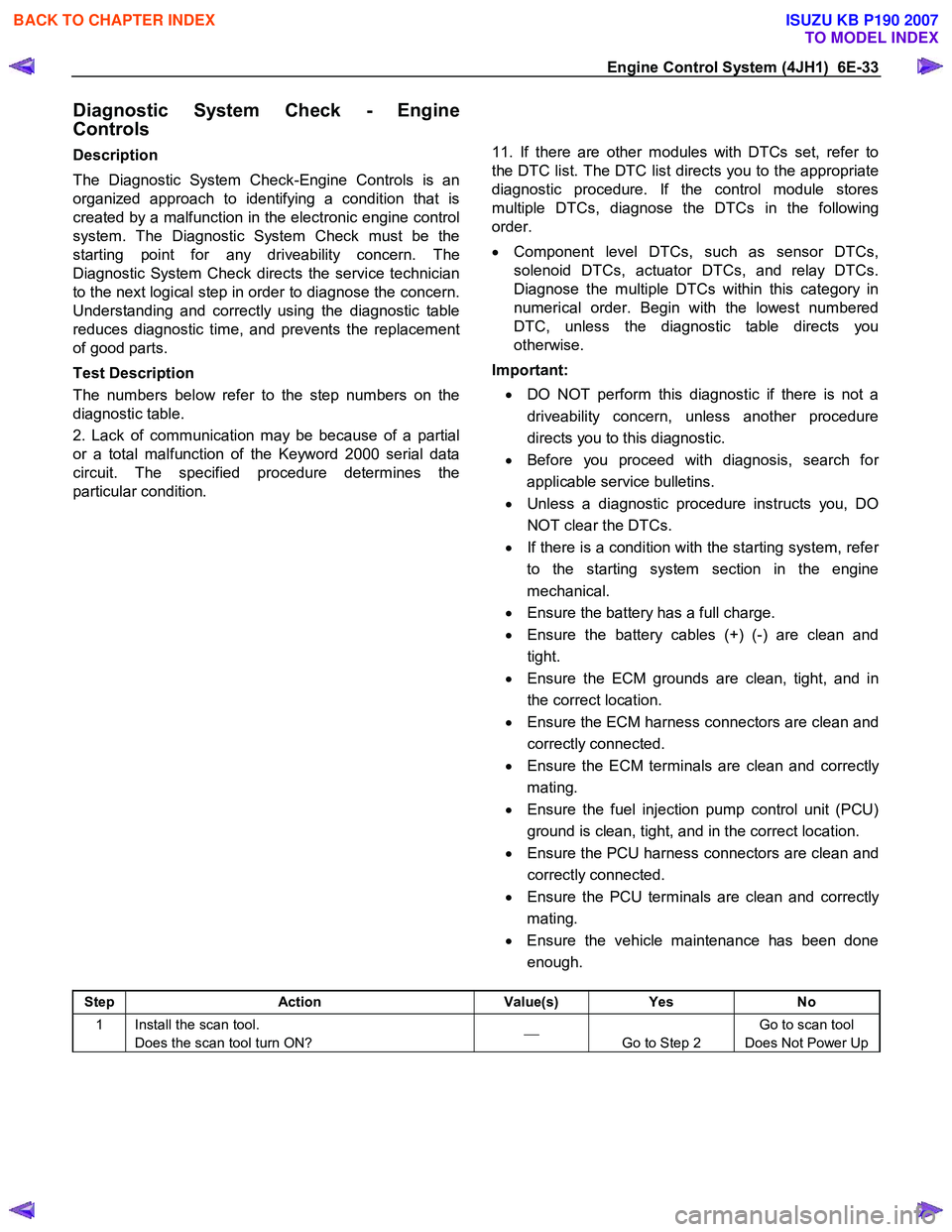

Engine Control System (4JH1) 6E-33

Diagnostic System Check - Engine

Controls

Description

The Diagnostic System Check-Engine Controls is an

organized approach to identifying a condition that is

created by a malfunction in the electronic engine control

system. The Diagnostic System Check must be the

starting point for any driveability concern. The

Diagnostic System Check directs the service technician

to the next logical step in order to diagnose the concern.

Understanding and correctly using the diagnostic table

reduces diagnostic time, and prevents the replacement

of good parts.

Test Description

The numbers below refer to the step numbers on the

diagnostic table.

2. Lack of communication may be because of a partial

or a total malfunction of the Keyword 2000 serial data

circuit. The specified procedure determines the

particular condition.

11. If there are other modules with DTCs set, refer to

the DTC list. The DTC list directs you to the appropriate

diagnostic procedure. If the control module stores

multiple DTCs, diagnose the DTCs in the following

order.

• Component level DTCs, such as sensor DTCs,

solenoid DTCs, actuator DTCs, and relay DTCs.

Diagnose the multiple DTCs within this category in

numerical order. Begin with the lowest numbered

DTC, unless the diagnostic table directs you

otherwise.

Important:

• DO NOT perform this diagnostic if there is not a

driveability concern, unless another procedure

directs you to this diagnostic.

• Before you proceed with diagnosis, search fo

r

applicable service bulletins.

• Unless a diagnostic procedure instructs you, DO

NOT clear the DTCs.

• If there is a condition with the starting system, refe

r

to the starting system section in the engine

mechanical.

• Ensure the battery has a full charge.

• Ensure the battery cables (+) (-) are clean and

tight.

• Ensure the ECM grounds are clean, tight, and in

the correct location.

• Ensure the ECM harness connectors are clean and

correctly connected.

• Ensure the ECM terminals are clean and correctl

y

mating.

• Ensure the fuel injection pump control unit (PCU)

ground is clean, tight, and in the correct location.

• Ensure the PCU harness connectors are clean and

correctly connected.

• Ensure the PCU terminals are clean and correctl

y

mating.

• Ensure the vehicle maintenance has been done

enough.

Step Action Value(s) Yes No

1 Install the scan tool.

Does the scan tool turn ON?

Go to Step 2 Go to scan tool

Does Not Power Up

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1068 of 6020

6E-34 Engine Control System (4JH1)

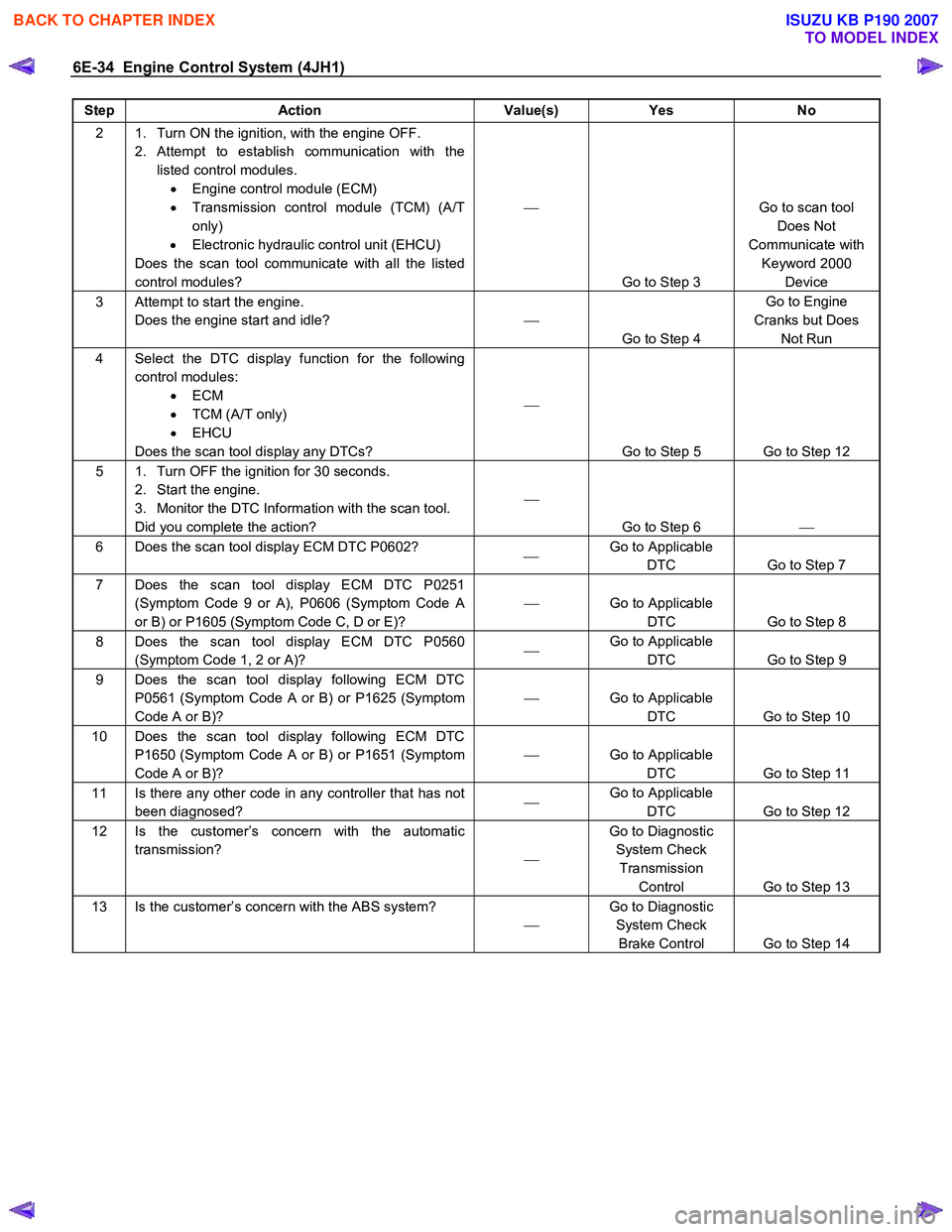

Step Action Value(s) Yes No

2 1. Turn ON the ignition, with the engine OFF.

2. Attempt to establish communication with the listed control modules. • Engine control module (ECM)

• Transmission control module (TCM) (A/T

only)

• Electronic hydraulic control unit (EHCU)

Does the scan tool communicate with all the listed

control modules?

Go to Step 3 Go to scan tool

Does Not

Communicate with Keyword 2000 Device

3 Attempt to start the engine. Does the engine start and idle?

Go to Step 4 Go to Engine

Cranks but Does Not Run

4 Select the DTC display function for the following control modules: • ECM

• TCM (A/T only)

• EHCU

Does the scan tool display any DTCs?

Go to Step 5 Go to Step 12

5 1. Turn OFF the ignition for 30 seconds. 2. Start the engine.

3. Monitor the DTC Information with the scan tool.

Did you complete the action?

Go to Step 6

6 Does the scan tool display ECM DTC P0602?

Go to Applicable

DTC Go to Step 7

7 Does the scan tool display ECM DTC P0251 (Symptom Code 9 or A), P0606 (Symptom Code A

or B) or P1605 (Symptom Code C, D or E)?

Go to Applicable

DTC Go to Step 8

8 Does the scan tool display ECM DTC P0560 (Symptom Code 1, 2 or A)?

Go to Applicable

DTC Go to Step 9

9 Does the scan tool display following ECM DTC

P0561 (Symptom Code A or B) or P1625 (Symptom

Code A or B)?

Go to Applicable

DTC Go to Step 10

10 Does the scan tool display following ECM DTC P1650 (Symptom Code A or B) or P1651 (Symptom

Code A or B)?

Go to Applicable

DTC Go to Step 11

11 Is there any other code in any controller that has not

been diagnosed?

Go to Applicable

DTC Go to Step 12

12 Is the customer’s concern with the automatic

transmission? Go to Diagnostic

System Check Transmission Control Go to Step 13

13 Is the customer’s concern with the ABS system?

Go to Diagnostic

System Check Brake Control Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1076 of 6020

6E-42 Engine Control System (4JH1)

Scan Tool Does Not Communicate with Keyword 2000 Device

Circuit Description

The engine control module (ECM), transmission control

module (TCM) and anti-theft (keyless entry) control unit

(ACU) all communicate with the scan tool over the

Keyword 2000 serial data link. However, the ECM and

fuel injection pump control unit (PCU) communicates

with each other over the controller area network (CAN)

link. The CAN link is not used for communication with

the scan tool and is shared only between the ECM and

PCU.

Diagnostic Aids

The following conditions will cause a loss of Keyword

2000 serial data communication between the TCM and

EHCU or between the scan tool and any control module:

• A Keyword 2000 serial data circuit open.

• A Keyword 2000 serial data circuit shorted to

ground.

• A Keyword 2000 serial data circuit shorted to

voltage.

•

An internal condition within a module or connector

on the Keyword 2000 serial data circuit, that causes

a short to voltage or ground to the Keyword 2000

serial data circuit.

• Open ground circuit (pin 5) at the DLC.

Scan tool Does Not Communicate with Keyword

2000 Device

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Attempt to communicate with the listed control modules. • Engine control module (ECM)

• Transmission control module (TCM) (A/T

only)

• Electronic hydraulic control unit (EHCU)

Does the scan tool communicate with all the listed

control modules?

Go to Step 3 Go to Step 8

3 Does the scan tool communicate with the ECM?

Go to Step 4 Go to Lost

Communication with The ECM

4 Does the scan tool communicate with the TCM?

Go to Step 5 Go to Diagnostic

System Check Transmission Control

5 Does the scan tool communicate with the EHCU?

Go to Step 6 Go to Diagnostic

System Brake

6 Test the Keyword 2000 serial data circuit for an intermittently short to ground or intermittently short to

voltage. Then, test the Keyword 2000 serial data

circuit for an intermittently open (based on which

control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition?

Go to Step 15 System OK

7 Test the data link connector (DLC) ground circuit at terminal 5 for an open circuit or poor connection.

Did you find and correct the condition?

Go to Step 15 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1077 of 6020

Engine Control System (4JH1) 6E-43

Step Action Value(s) Yes No

8 1. Turn OFF the ignition.

2. Disconnect the ECM C-56 and C-57 harness connectors.

3. Turn ON the ignition, with the engine OFF.

4. Attempt to communicate with the TCM and EHCU.

Does the scan tool communicate with the TCM and

EHCU?

Go to Step 12 Go to Step 9

9 1. Turn OFF the ignition. 2. Reconnect the ECM C-56 and C-57 harness connectors.

3. Disconnect the TCM A and B harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and EHCU.

Does the scan tool communicate with the ECM and

EHCU?

Go to Step 13 Go to Step 10

10 1. Turn OFF the ignition. 2. Reconnect the TCM A and B harness connectors.

3. Disconnect the EHCU C-67 harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and TCM.

Does the scan tool communicate with the ECM and

TCM?

Go to Step 14 Go to Step 11

11 Repair the short to ground or short to voltage on the Keyword 2000 serial data circuit between the DLC

and ECM, TCM and EHCU.

Did you complete the repair?

Go to Step 15

12 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 15

13 Important: Replacement TCM must be

programmed.

Replace the TCM. Refer to Transmission Control

Module (TCM) Replacement in the transmission

section.

Did you complete the replacement?

Go to Step 15

14 Replace the EHCU. Refer to Electronic Hydraulic

Control Unit in the anti-lock brake system section.

Did you complete the replacement?

Go to Step 15

15 Attempt to communicate with the ECM, TCM and

EHCU.

Does the scan tool communicate with the ECM, TCM

and EHCU?

System OK Go to Step 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1078 of 6020

6E-44 Engine Control System (4JH1)

Lost Communication with The Engine Control Module (ECM)

Circuit Description

The engine control module (ECM), transmission control

module (TCM) and electronic hydraulic control unit

(EHCU) all communicate with the scan tool over the

Keyword 2000 serial data link. However, the ECM and

fuel injection pump control unit (PCU) communicates

with each other over the controller area network (CAN)

link. The CAN link is not used for communication with

the scan tool and is shared only between the ECM and

PCU.

Lost Communication with The Engine Control

Module (ECM)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 Attempt to establish engine control module (ECM) communications with the scan tool.

Does the ECM communicate with the scan tool?

Go to Intermittent

Conditions Go to Step 3

3 Check the ECM C-56 and C-57 connectors for poor connections.

Did you find and correct the condition?

Go to Step 17 Go to Step 4

4 Check the electronic hydraulic control unit (EHCU)

C-67 connector for poor connection.

Did you find and correct the condition?

Go to Step 17 Go to Step 5

5 1. Turn ON the ignition, with the engine OFF. 2. Check the ECM (30A) (SFB-4), ECM (10A) fuse (EB-4) and Engine (15A) fuse (C-6).Replace and

retest if open. If any fuse continues to open,

check for a short to ground on each circuit fed by

that fuse.

3. Turn OFF the ignition.

4. Disconnect the ECM C-56 harness connector.

5. Turn ON the ignition, with the engine OFF.

6. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at the

ECM (pin 39 of C-56 connector).

Does the test lamp illuminate?

Go to Step 6 Go to Step 14

6 1. Turn OFF the ignition. 2. Connect a DMM between the Keyword 2000 serial data circuit at the ECM (pin 35 of C-56

connector) and the EHCU (pin 11 of C-67

connector).

3. Test the circuits for an open circuit or high resistance.

4. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 7

7 1. Turn OFF the ignition. 2. Connect a DMM between the Keyword 2000 serial data circuit at the EHCU (pin 11 of C-67

connector) and the DLC (pin 7 of B-58

connector).

3. Test the circuits for an open circuit or high resistance.

4. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1081 of 6020

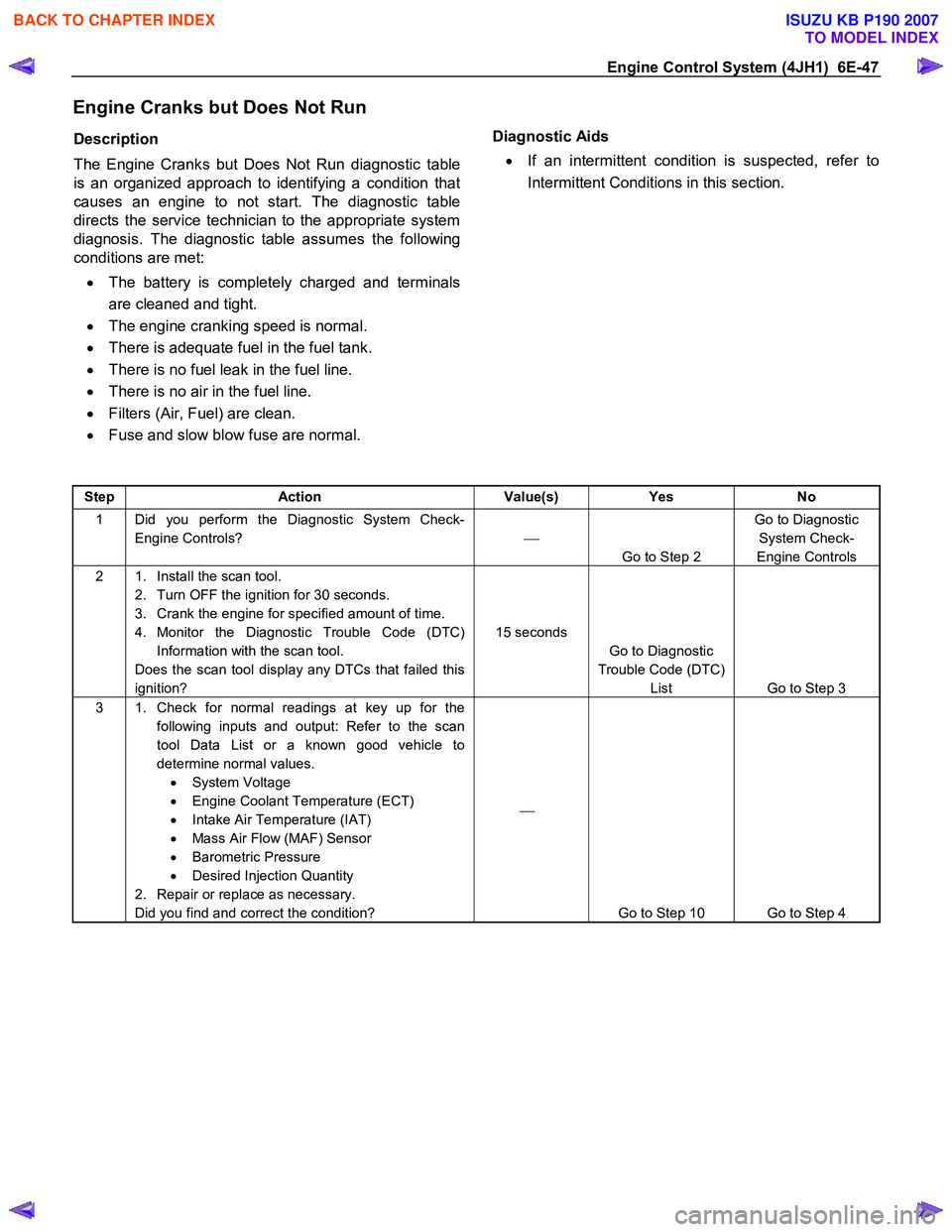

Engine Control System (4JH1) 6E-47

Engine Cranks but Does Not Run

Description

The Engine Cranks but Does Not Run diagnostic table

is an organized approach to identifying a condition that

causes an engine to not start. The diagnostic table

directs the service technician to the appropriate system

diagnosis. The diagnostic table assumes the following

conditions are met:

• The battery is completely charged and terminals

are cleaned and tight.

• The engine cranking speed is normal.

• There is adequate fuel in the fuel tank.

• There is no fuel leak in the fuel line.

• There is no air in the fuel line.

• Filters (Air, Fuel) are clean.

• Fuse and slow blow fuse are normal.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Crank the engine for specified amount of time.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Does the scan tool display any DTCs that failed this

ignition? 15 seconds

Go to Diagnostic

Trouble Code (DTC) List Go to Step 3

3 1. Check for normal readings at key up for the

following inputs and output: Refer to the scan

tool Data List or a known good vehicle to

determine normal values. • System Voltage

• Engine Coolant Temperature (ECT)

• Intake Air Temperature (IAT)

• Mass Air Flow (MAF) Sensor

• Barometric Pressure

• Desired Injection Quantity

2. Repair or replace as necessary.

Did you find and correct the condition?

Go to Step 10 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1096 of 6020

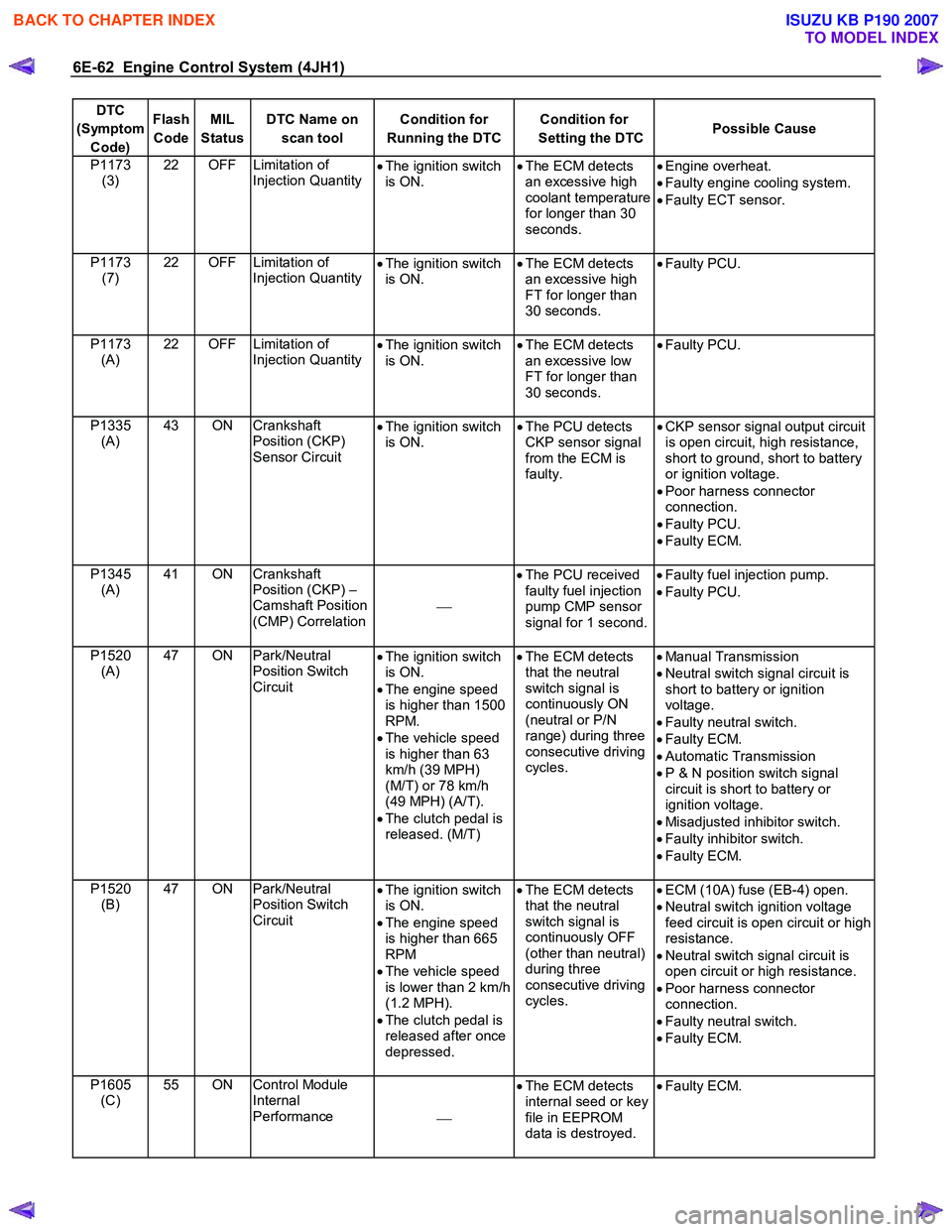

6E-62 Engine Control System (4JH1)

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1173

(3) 22 OFF Limitation of

Injection Quantity •

The ignition switch

is ON. •

The ECM detects

an excessive high

coolant temperature

for longer than 30

seconds.

•

Engine overheat.

• Faulty engine cooling system.

• Faulty ECT sensor.

P1173 (7) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive high

FT for longer than

30 seconds.

•

Faulty PCU.

P1173 (A) 22 OFF Limitation of

Injection Quantity

•

The ignition switch

is ON. •

The ECM detects

an excessive low

FT for longer than

30 seconds.

•

Faulty PCU.

P1335 (A) 43 ON Crankshaft

Position (CKP)

Sensor Circuit •

The ignition switch

is ON. •

The PCU detects

CKP sensor signal

from the ECM is

faulty.

•

CKP sensor signal output circuit

is open circuit, high resistance,

short to ground, short to battery

or ignition voltage.

• Poor harness connector

connection.

• Faulty PCU.

• Faulty ECM.

P1345 (A) 41 ON Crankshaft

Position (CKP) –

Camshaft Position

(CMP) Correlation

•

The PCU received

faulty fuel injection

pump CMP sensor

signal for 1 second.

•

Faulty fuel injection pump.

• Faulty PCU.

P1520 (A) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 1500

RPM.

• The vehicle speed

is higher than 63

km/h (39 MPH)

(M/T) or 78 km/h

(49 MPH) (A/T).

• The clutch pedal is

released. (M/T)

•

The ECM detects

that the neutral

switch signal is

continuously ON

(neutral or P/N

range) during three

consecutive driving

cycles.

•

Manual Transmission

• Neutral switch signal circuit is

short to battery or ignition

voltage.

• Faulty neutral switch.

• Faulty ECM.

• Automatic Transmission

• P & N position switch signal

circuit is short to battery or

ignition voltage.

• Misadjusted inhibitor switch.

• Faulty inhibitor switch.

• Faulty ECM.

P1520 (B) 47 ON Park/Neutral

Position Switch

Circuit •

The ignition switch

is ON.

• The engine speed

is higher than 665

RPM

• The vehicle speed

is lower than 2 km/h

(1.2 MPH).

• The clutch pedal is

released after once

depressed.

•

The ECM detects

that the neutral

switch signal is

continuously OFF

(other than neutral)

during three

consecutive driving

cycles.

•

ECM (10A) fuse (EB-4) open.

• Neutral switch ignition voltage

feed circuit is open circuit or high

resistance.

• Neutral switch signal circuit is

open circuit or high resistance.

• Poor harness connector

connection.

• Faulty neutral switch.

• Faulty ECM.

P1605 (C) 55 ON Control Module

Internal

Performance •

The ECM detects

internal seed or key

file in EEPROM

data is destroyed.

•

Faulty ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1097 of 6020

Engine Control System (4JH1) 6E-63

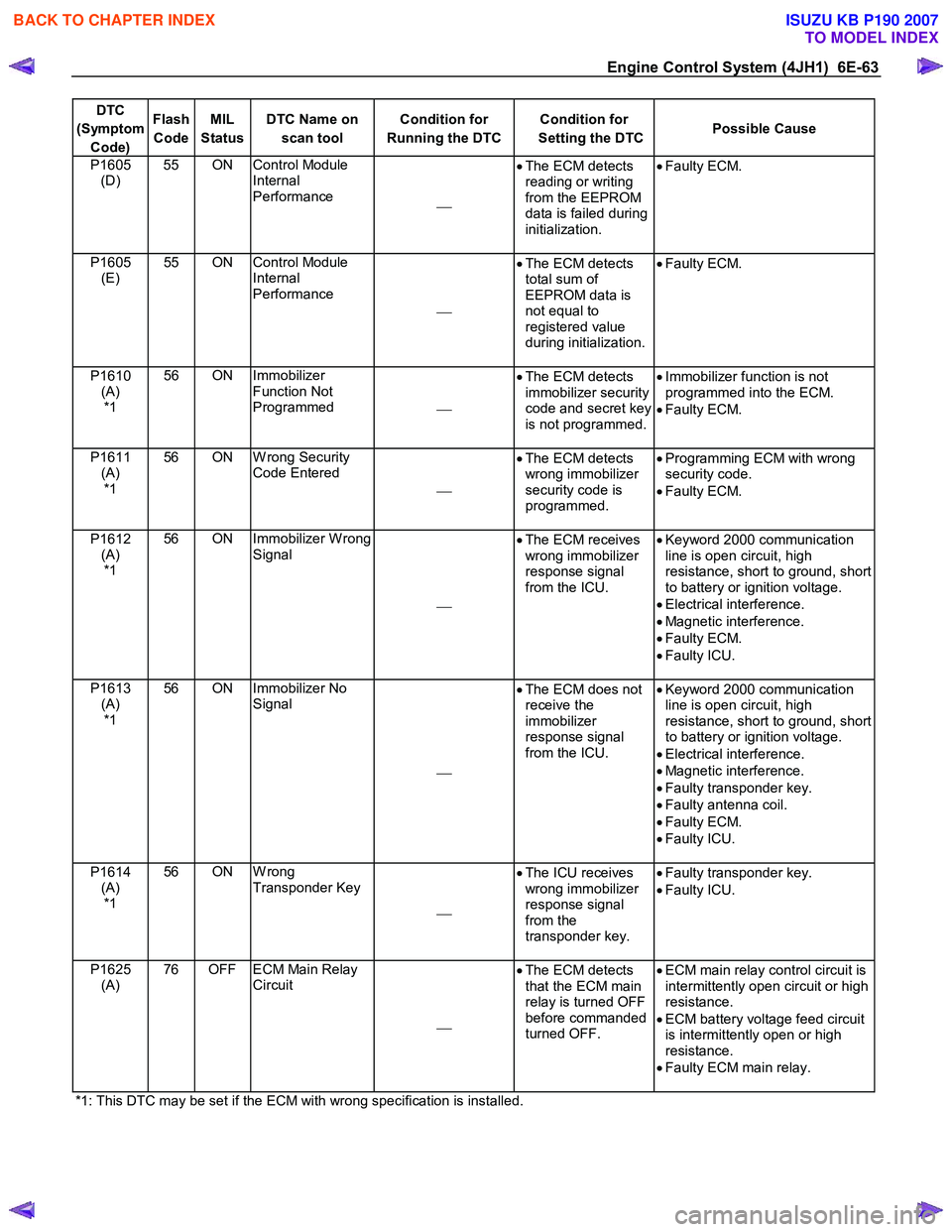

DTC

(Symptom Code) Flash

Code MIL

Status DTC Name on

scan tool Condition for

Running the DTC Condition for

Setting the DTC Possible Cause

P1605

(D) 55 ON Control Module

Internal

Performance •

The ECM detects

reading or writing

from the EEPROM

data is failed during

initialization.

•

Faulty ECM.

P1605

(E) 55 ON Control Module

Internal

Performance

•

The ECM detects

total sum of

EEPROM data is

not equal to

registered value

during initialization.

•

Faulty ECM.

P1610

(A) *1 56 ON Immobilizer

Function Not

Programmed •

The ECM detects

immobilizer security

code and secret key

is not programmed.

•

Immobilizer function is not

programmed into the ECM.

• Faulty ECM.

P1611 (A) *1 56 ON W rong Security

Code Entered

•

The ECM detects

wrong immobilizer

security code is

programmed.

•

Programming ECM with wrong

security code.

• Faulty ECM.

P1612 (A) *1 56 ON Immobilizer W rong

Signal

•

The ECM receives

wrong immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty ECM.

• Faulty ICU.

P1613 (A) *1 56 ON Immobilizer No

Signal

•

The ECM does not

receive the

immobilizer

response signal

from the ICU.

•

Keyword 2000 communication

line is open circuit, high

resistance, short to ground, short

to battery or ignition voltage.

• Electrical interference.

• Magnetic interference.

• Faulty transponder key.

• Faulty antenna coil.

• Faulty ECM.

• Faulty ICU.

P1614 (A) *1 56 ON W rong

Transponder Key

•

The ICU receives

wrong immobilizer

response signal

from the

transponder key.

•

Faulty transponder key.

• Faulty ICU.

P1625 (A) 76 OFF ECM Main Relay

Circuit

•

The ECM detects

that the ECM main

relay is turned OFF

before commanded

turned OFF.

•

ECM main relay control circuit is

intermittently open circuit or high

resistance.

• ECM battery voltage feed circuit

is intermittently open or high

resistance.

• Faulty ECM main relay.

*1: This DTC may be set if the ECM with wrong specification is installed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1141 of 6020

Engine Control System (4JH1) 6E-107

DTC P0243 (Symptom Code 3) (Flash Code 64)

Circuit Description

The engine control module (ECM) controls the

turbocharger wastegate valve based on the barometric

pressure in order to reduce turbocharger spinning

speeds at high altitude area. The ECM controls the

turbocharger wastegate valve diaphragm by acting the

regulated vacuum pressure via controlling the solenoid

valve. The vacuum pressure sensor monitors the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The ECM calculates desired vacuum

pressure and it compares the calculated desired

vacuum pressure to the actual value to determine the

solenoid valve position. W hen the actual vacuum

pressure is higher than the desired value, the solenoid

valve is closed to decrease the vacuum pressure. An

expected vacuum pressure amount should be detected

while the engine running. If the ECM detects the actual

vacuum pressure amount is higher than desired

vacuum pressure amount, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The barometric pressure (BARO) is between 0

hPa and 3500 hPa.

• The intake air temperature (IAT) is between -50°C

(-58 °F) and 200°C (392°F).

• The engine coolant temperature (ECT) is between

-50°C (-58 °F) and 150°C (302°F)

Condition for Setting the DTC

• The ECM detects that the vacuum pressure is 50

hPa higher than the desired vacuum pressure for

3 seconds. This indicates excessive high vacuum

pressure.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• Misrouted vacuum hoses will cause this DTC to

set.

Test Description

The numbers below refer to the step number on the

diagnostic table.

4. A skewed vacuum pressure sensor value (shifted to

a high pressure) can set this DTC. The Vacuum

Pressure on the scan tool should read near doubled

barometric pressure (BARO) with the key ON and

engine OFF.

5. A skewed BARO sensor value (shifted to a lowe

r

pressure) may set this DTC. The BARO on the scan

tool should read near surrounding barometric pressure.

DTC P0243 (Symptom Code 3) (Flash Code 64)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Is DTC P0105 (Symptom Code 1, 2, 7 or 9) or

P0243 (Symptom Code 4 or 8) set?

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1148 of 6020

6E-114 Engine Control System (4JH1)

DTC P0243 (Symptom Code 5) (Flash Code 64)

Circuit Description

The engine control module (ECM) controls the

turbocharger wastegate valve based on the barometric

pressure in order to reduce turbocharger spinning

speeds at high altitude area. The ECM controls the

turbocharger wastegate valve diaphragm by acting the

regulated vacuum pressure via controlling the solenoid

valve. The vacuum pressure sensor monitors the

regulated vacuum pressure to the turbocharge

r

wastegate valve. The ECM calculates desired vacuum

pressure and it compares the calculated desired

vacuum pressure to the actual value to determine the

solenoid valve position. W hen the actual vacuum

pressure is higher than the desired value, the solenoid

valve is closed to decrease the vacuum pressure. An

expected vacuum pressure amount should be detected

while the engine running. If the ECM detects the actual

vacuum pressure amount is lower than desired vacuum

pressure amount, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

• The barometric pressure (BARO) is between 0

hPa and 3500 hPa.

• The intake air temperature (IAT) is between -50°C

(-58 °F) and 200°C (392°F).

• The engine coolant temperature (ECT) is between

-50°C (-58 °F) and 150°C (302°F)

Condition for Setting the DTC

• The ECM detects that the vacuum pressure is 50

hPa lower than the desired vacuum pressure for 3

seconds. This indicates excessive low vacuum

pressure.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicato

r

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses an EGR solenoid valve control

substitution of 10%.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

• Misrouted vacuum hoses may set this DTC.

• A vacuum pump problem will cause this DTC.

Test Description

The numbers below refer to the step number on the

diagnostic table.

4. A skewed vacuum pressure sensor value (shifted to

a low pressure) can set this DTC. The Vacuum

Pressure on the scan tool should read near doubled

barometric pressure (BARO) with the key ON and

engine OFF.

5. A skewed BARO sensor value (shifted to a highe

r

pressure) may set this DTC. The BARO on the scan

tool should read near surrounding barometric pressure.

DTC P0243 (Symptom Code 5) (Flash Code 64)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn OFF the ignition for 30 seconds.

3. Start the engine and let idle for 30 seconds.

4. Monitor the Diagnostic Trouble Code (DTC) Information with the scan tool.

Is DTC P0105 (Symptom Code 1, 2, 7 or 9) or

P0243 (Symptom Code 4 or 8) set?

Go to Applicable DTC Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007