lock ISUZU KB P190 2007 Workshop User Guide

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 126 of 6020

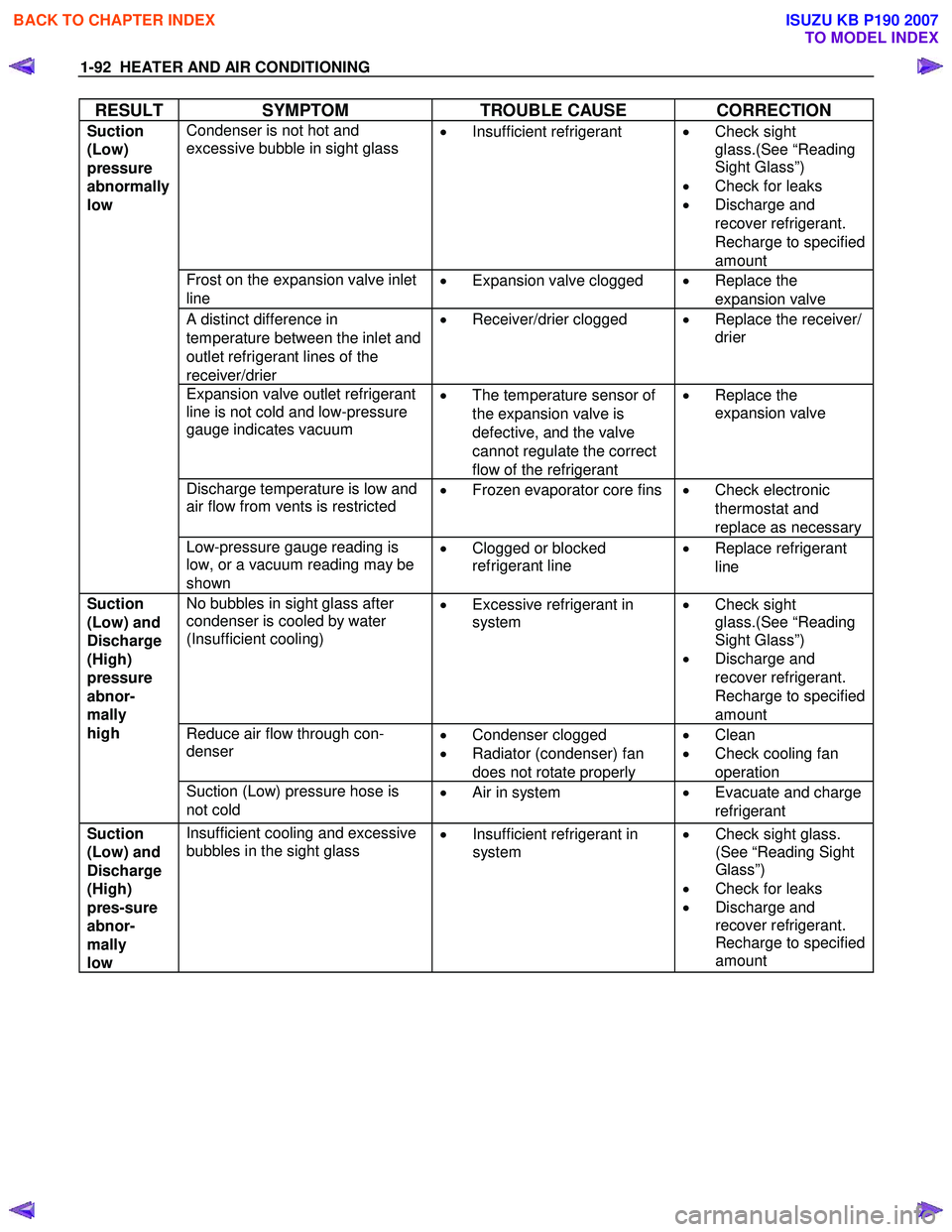

1-92 HEATER AND AIR CONDITIONING

RESULT SYMPTOM TROUBLE CAUSE CORRECTION

Condenser is not hot and

excessive bubble in sight glass

•

Insufficient refrigerant

•

Check sight

glass.(See “Reading

Sight Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

Frost on the expansion valve inlet

line •

Expansion valve clogged

•

Replace the

expansion valve

A distinct difference in

temperature between the inlet and

outlet refrigerant lines of the

receiver/drier •

Receiver/drier clogged

•

Replace the receiver/

drier

Expansion valve outlet refrigerant

line is not cold and low-pressure

gauge indicates vacuum

•

The temperature sensor of

the expansion valve is

defective, and the valve

cannot regulate the correct

flow of the refrigerant •

Replace the

expansion valve

Discharge temperature is low and

air flow from vents is restricted

•

Frozen evaporator core fins

•

Check electronic

thermostat and

replace as necessary

Suction

(Low)

pressure

abnormally

low

Low-pressure gauge reading is

low, or a vacuum reading may be

shown •

Clogged or blocked

refrigerant line

•

Replace refrigerant

line

No bubbles in sight glass after

condenser is cooled by water

(Insufficient cooling)

•

Excessive refrigerant in

system

•

Check sight

glass.(See “Reading

Sight Glass”)

• Discharge and

recover refrigerant.

Recharge to specified

amount

Reduce air flow through con-

denser

•

Condenser clogged

• Radiator (condenser) fan

does not rotate properly •

Clean

• Check cooling fan

operation

Suction

(Low) and

Discharge

(High)

pressure

abnor-

mally

high

Suction (Low) pressure hose is

not cold •

Air in system • Evacuate and charge

refrigerant

Suction

(Low) and

Discharge

(High)

pres-sure

abnor-

mally

low Insufficient cooling and excessive

bubbles in the sight glass •

Insufficient refrigerant in

system

•

Check sight glass.

(See “Reading Sight

Glass”)

• Check for leaks

• Discharge and

recover refrigerant.

Recharge to specified

amount

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 198 of 6020

SHEET METAL 2B-1

SECTION 2B

SHEET METAL

This section includes items of front end sheet metal that are attached by bolts, screws or clips and related

accessory components.

Anticorrosion materials have been applied to the interior surfaces of some metal panels to provide rust resistance.

W hen servicing these panels, areas on which this material has been disturbed, should be properly recoated with

service-type anticorrosion material.

TABLE OF CONTENTS

PAGE

Engine Hood Assembly (A type) ...................................................................................... 2B- 2

Engine Hood Assembly (B type) ..................................................................................... 2B- 8

Engine Hood Lock (A type) .............................................................................................. 2B- 11

Engine Hood Lock (B type) .............................................................................................. 2B- 13

Front Fender Panel (A type) ............................................................................................. 2B- 15

Front Fender Panel (B type) ............................................................................................. 2B- 18

Radiator Grille (A type) ..................................................................................................... 2 B- 21

Radiator Grille (B type) .................................................................................................... 2B - 22

Rear Body...................................................................................................................... ..... 2B- 23

Body Mounting .................................................................................................................. 2B- 26

Body Dimensions .............................................................................................................. 2B - 32

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 208 of 6020

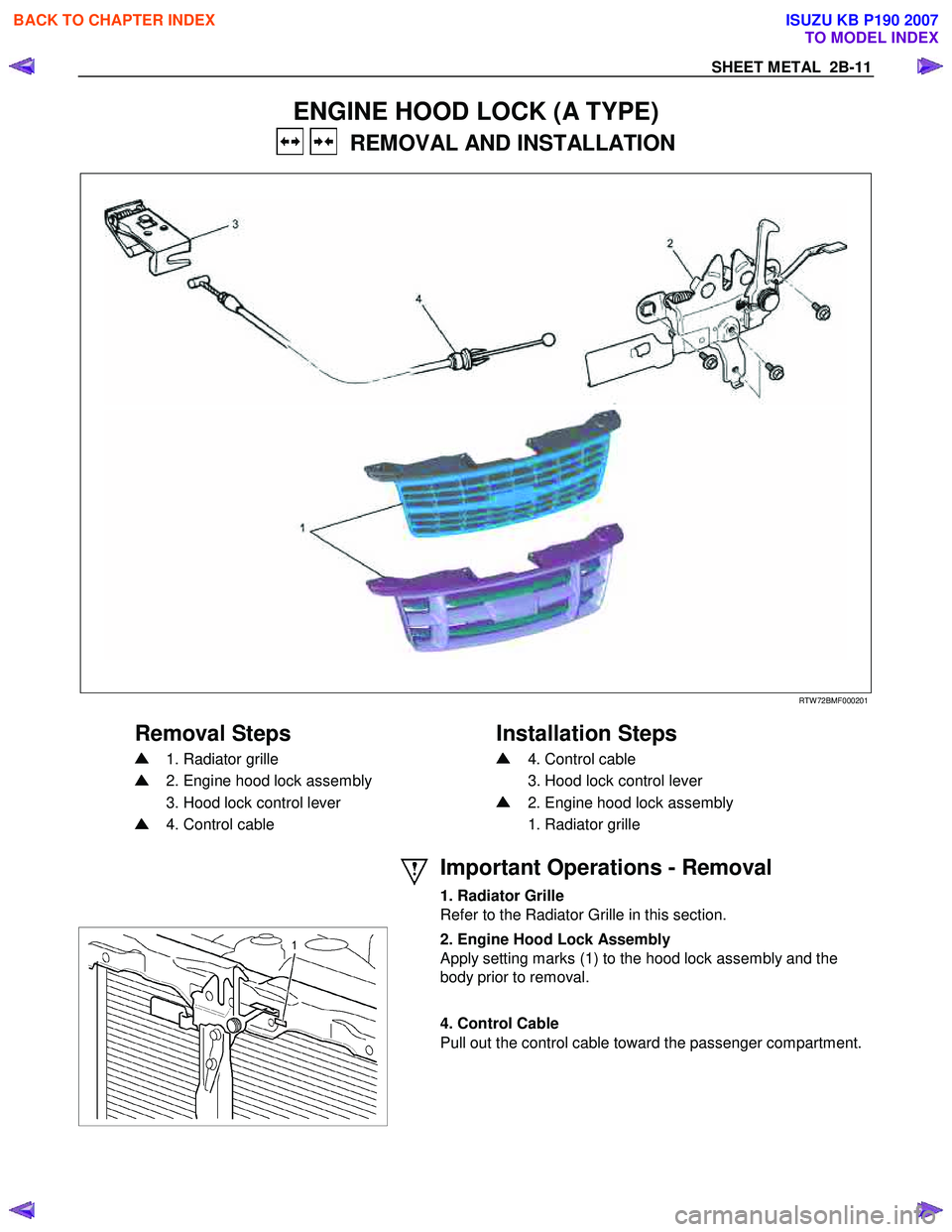

SHEET METAL 2B-11

ENGINE HOOD LOCK (A TYPE)

REMOVAL AND INSTALLATION

RTW 72BMF000201

Removal Steps

Installation Steps

1. Radiator grille 4. Control cable

2. Engine hood lock assembly 3. Hood lock control lever

3. Hood lock control lever

2. Engine hood lock assembly

4. Control cable 1. Radiator grille

Important Operations - Removal

1. Radiator Grille

Refer to the Radiator Grille in this section.

2. Engine Hood Lock Assembly

Apply setting marks (1) to the hood lock assembly and the

body prior to removal.

4. Control Cable

Pull out the control cable toward the passenger compartment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 209 of 6020

2B-12 SHEET METAL

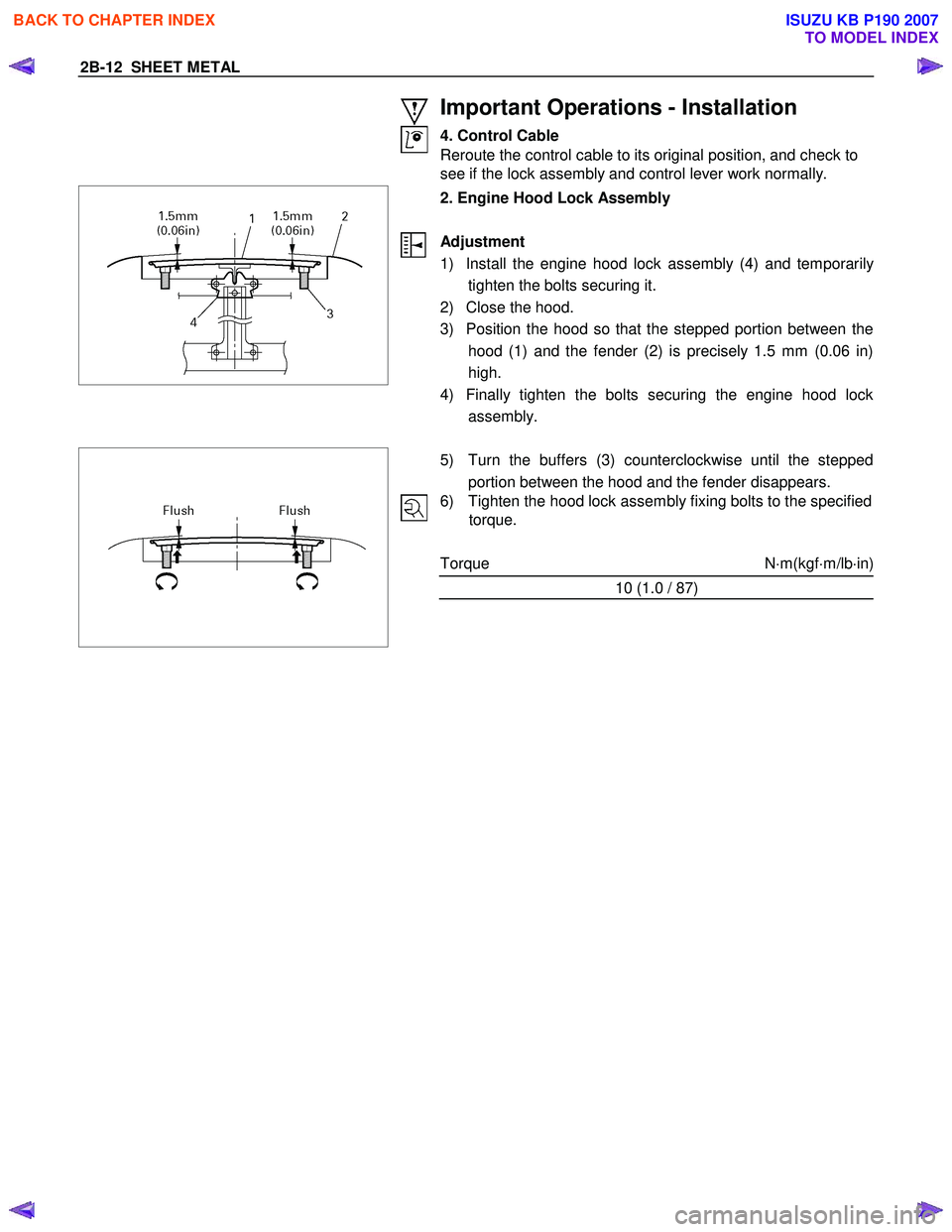

Important Operations - Installation

4. Control Cable

Reroute the control cable to its original position, and check to

see if the lock assembly and control lever work normally.

2. Engine Hood Lock Assembly

Adjustment

1) Install the engine hood lock assembly (4) and temporaril

y

tighten the bolts securing it.

2) Close the hood.

3) Position the hood so that the stepped portion between the hood (1) and the fender (2) is precisely 1.5 mm (0.06 in)

high.

4) Finally tighten the bolts securing the engine hood lock assembly.

5) Turn the buffers (3) counterclockwise until the stepped

portion between the hood and the fender disappears.

6) Tighten the hood lock assembly fixing bolts to the specified torque.

Torque N ⋅m(kgf ⋅m/lb ⋅in)

10 (1.0 / 87)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 210 of 6020

SHEET METAL 2B-13

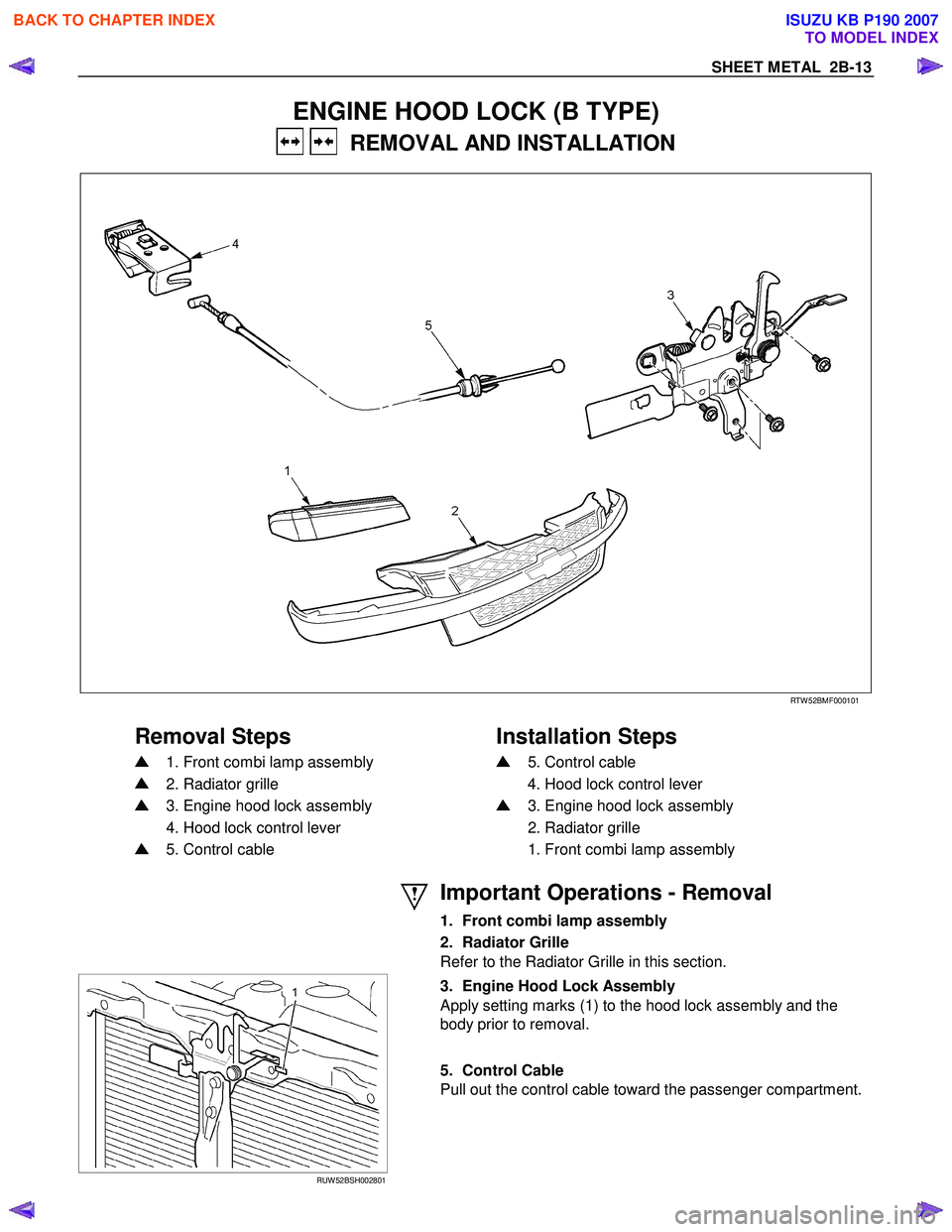

ENGINE HOOD LOCK (B TYPE)

REMOVAL AND INSTALLATION

RTW 52BMF000101

Removal Steps Installation Steps

1. Front combi lamp assembly

2. Radiator grille

3. Engine hood lock assembly

4. Hood lock control lever

5. Control cable

5. Control cable

4. Hood lock control lever

3. Engine hood lock assembly

2. Radiator grille

1. Front combi lamp assembly

Important Operations - Removal

1. Front combi lamp assembly

2. Radiator Grille

Refer to the Radiator Grille in this section.

RUW 52BSH002801

3. Engine Hood Lock Assembly

Apply setting marks (1) to the hood lock assembly and the

body prior to removal.

5. Control Cable

Pull out the control cable toward the passenger compartment.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 211 of 6020

2B-14 SHEET METAL

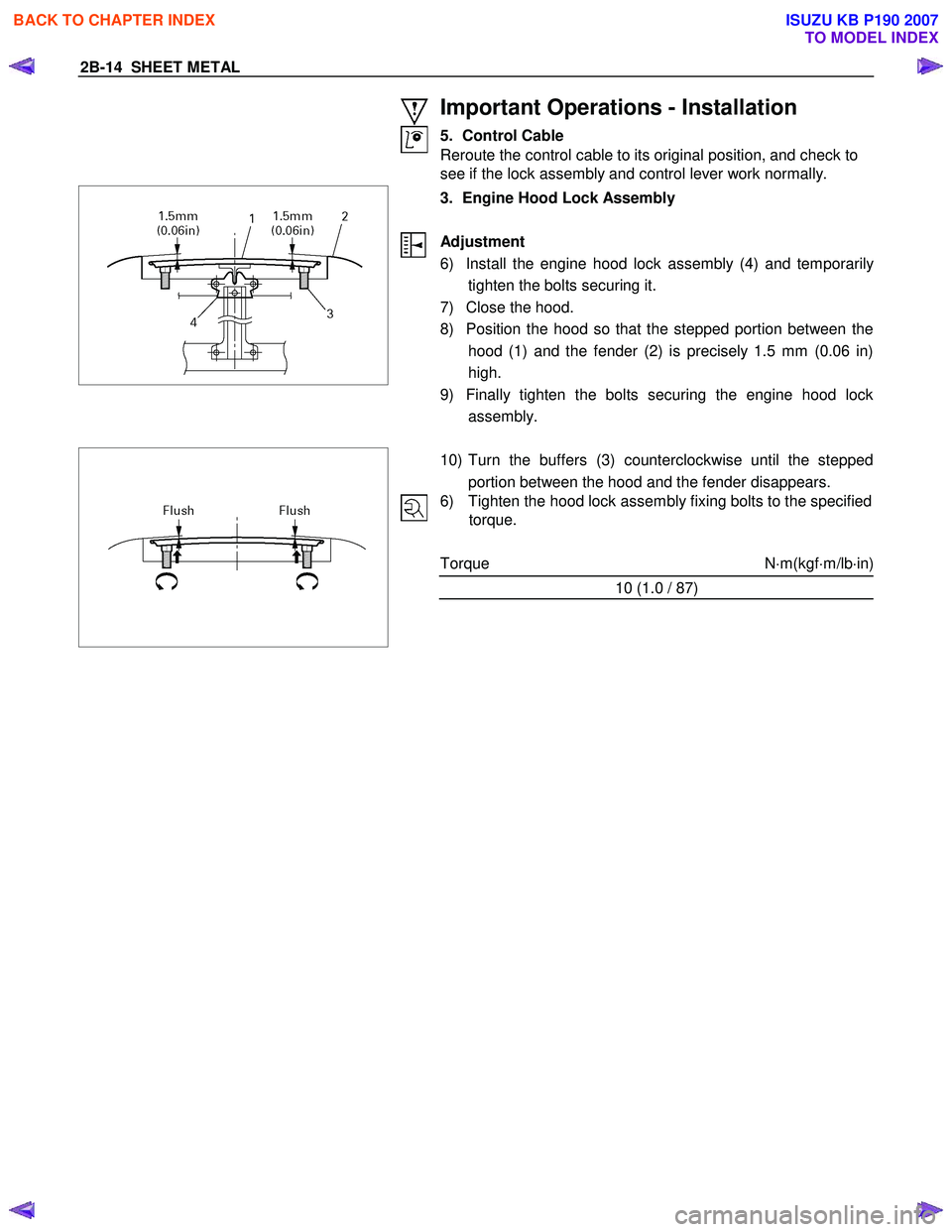

Important Operations - Installation

5. Control Cable

Reroute the control cable to its original position, and check to

see if the lock assembly and control lever work normally.

3. Engine Hood Lock Assembly

Adjustment

6) Install the engine hood lock assembly (4) and temporaril

y

tighten the bolts securing it.

7) Close the hood.

8) Position the hood so that the stepped portion between the hood (1) and the fender (2) is precisely 1.5 mm (0.06 in)

high.

9) Finally tighten the bolts securing the engine hood lock assembly.

10) Turn the buffers (3) counterclockwise until the stepped

portion between the hood and the fender disappears.

6) Tighten the hood lock assembly fixing bolts to the specified torque.

Torque N ⋅m(kgf ⋅m/lb ⋅in)

10 (1.0 / 87)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 256 of 6020

3A-8 FRONT ALIGNMENT

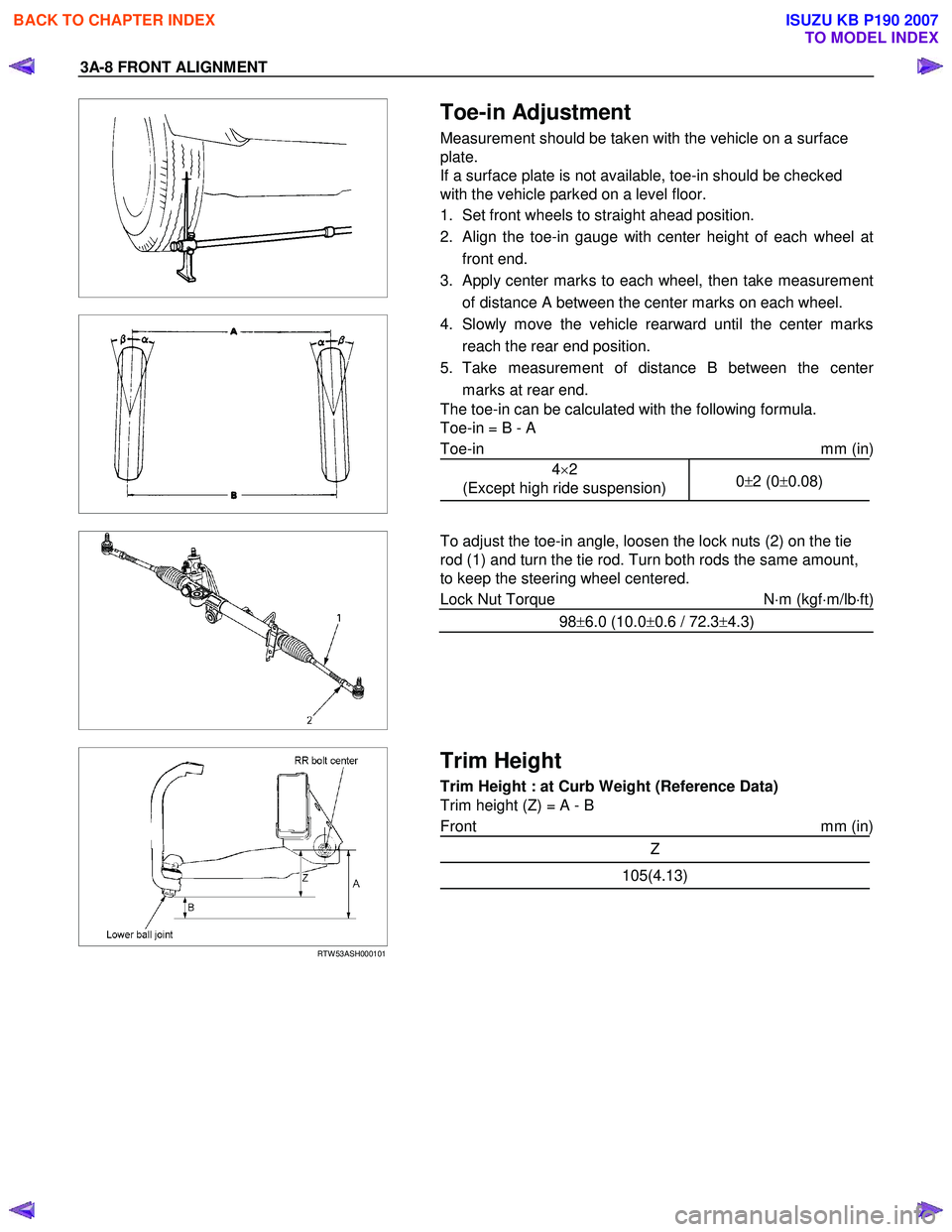

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at front end.

3.

Apply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with the following formula.

Toe-in = B - A

Toe-in mm (in)

4×2

(Except high ride suspension) 0

±2 (0 ±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

98 ±6.0 (10.0 ±0.6 / 72.3 ±4.3)

RTW 53ASH000101

Trim Height

Trim Height : at Curb Weight (Reference Data)

Trim height (Z) = A - B

Front mm (in)

Z

105(4.13)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 260 of 6020

3A-12 FRONT ALIGNMENT

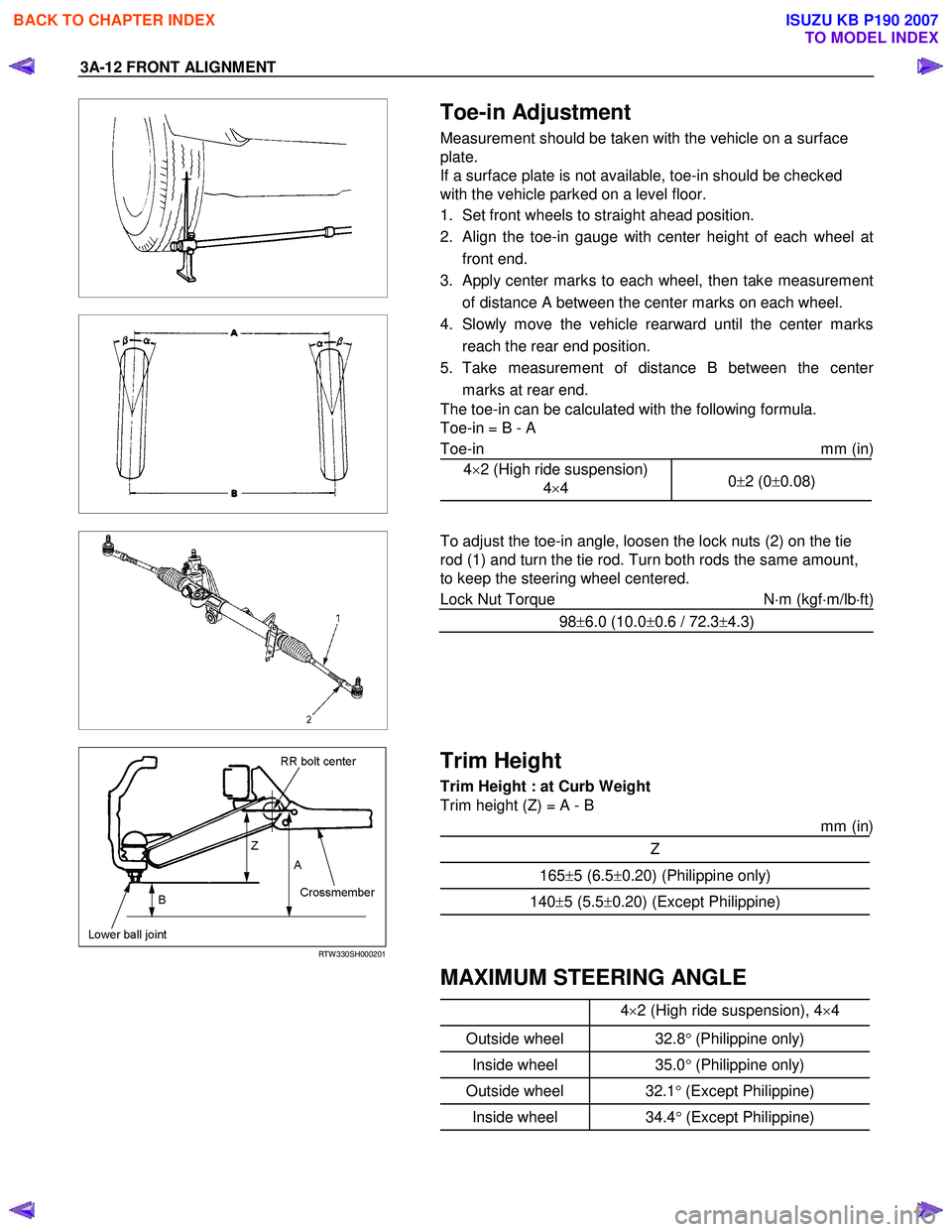

Toe-in Adjustment

Measurement should be taken with the vehicle on a surface

plate.

If a surface plate is not available, toe-in should be checked

with the vehicle parked on a level floor.

1. Set front wheels to straight ahead position.

2. Align the toe-in gauge with center height of each wheel at front end.

3.

Apply center marks to each wheel, then take measurement

of distance A between the center marks on each wheel.

4. Slowly move the vehicle rearward until the center marks reach the rear end position.

5. Take measurement of distance B between the cente

r

marks at rear end.

The toe-in can be calculated with the following formula.

Toe-in = B - A

Toe-in mm (in)

4×2 (High ride suspension)

4×4 0

±2 (0 ±0.08)

To adjust the toe-in angle, loosen the lock nuts (2) on the tie

rod (1) and turn the tie rod. Turn both rods the same amount,

to keep the steering wheel centered.

Lock Nut Torque N⋅m (kgf ⋅m/lb ⋅ft)

98 ±6.0 (10.0 ±0.6 / 72.3 ±4.3)

RTW 330SH000201

Trim Height

Trim Height : at Curb Weight

Trim height (Z) = A - B

mm (in)

Z

165±5 (6.5 ±0.20) (Philippine only)

140 ±5 (5.5 ±0.20) (Except Philippine)

MAXIMUM STEERING ANGLE

4

×2 (High ride suspension), 4 ×4

Outside wheel 32.8° (Philippine only)

Inside wheel 35.0° (Philippine only)

Outside wheel 32.1° (Except Philippine)

Inside wheel 34.4° (Except Philippine)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 263 of 6020

3B-2 POWER-ASSISTED STEERING SYSTEM

PAGE

Power Steering Pump (4JJ1-TC, 4JK1-TC) .................................................................... 3B – 22 Power Steering Pump and Associated Parts............................................................ 3B – 22

Removal ....................................................................................................................... 3B – 22

Installation ................................................................................................................... 3B – 22

Power Steering Pump Disassembled View .............................................................. 3B – 23

Disassembly ................................................................................................................ 3B – 24

Inspection and Repair................................................................................................. 3B – 24

Reassembly ................................................................................................................. 3B – 25

Main Data and Specifications .................................................................................... 3B – 25

Supplemental Restraint System Steering Wheel & Column ........................................ 3B – 27 Service Precaution ...................................................................................................... 3B – 2 7

SRS Connectors .......................................................................................................... 3B – 2 7

Inflator Module ................................................................................................................ . 3B – 28

Inflator Module and Associated Parts ....................................................................... 3B – 28

Removal ....................................................................................................................... 3B – 29

Inspection and Repair (with SRS air bag) ................................................................. 3B – 31

Installation ................................................................................................................... 3B – 31

Steering Wheel................................................................................................................. 3B – 33

Steering Wheel and Associated Parts ....................................................................... 3B – 33

Removal ....................................................................................................................... 3B – 33

Installation ................................................................................................................... 3B – 36

The adjustment method in case a mark has not been applied .................................... 3B – 38

Combination Switch ........................................................................................................ 3B – 39

Combination Switch and Associated Parts .............................................................. 3B – 39

Removal ....................................................................................................................... 3B – 39

Installation ................................................................................................................... 3B – 42

Lock Cylinder .................................................................................................................. . 3B – 45

Lock Cylinder and Associated Parts ......................................................................... 3B – 45

Removal ....................................................................................................................... 3B – 45

Installation ................................................................................................................... 3B – 48

System Inspection (with SRS air bag) ....................................................................... 3B – 50

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 267 of 6020

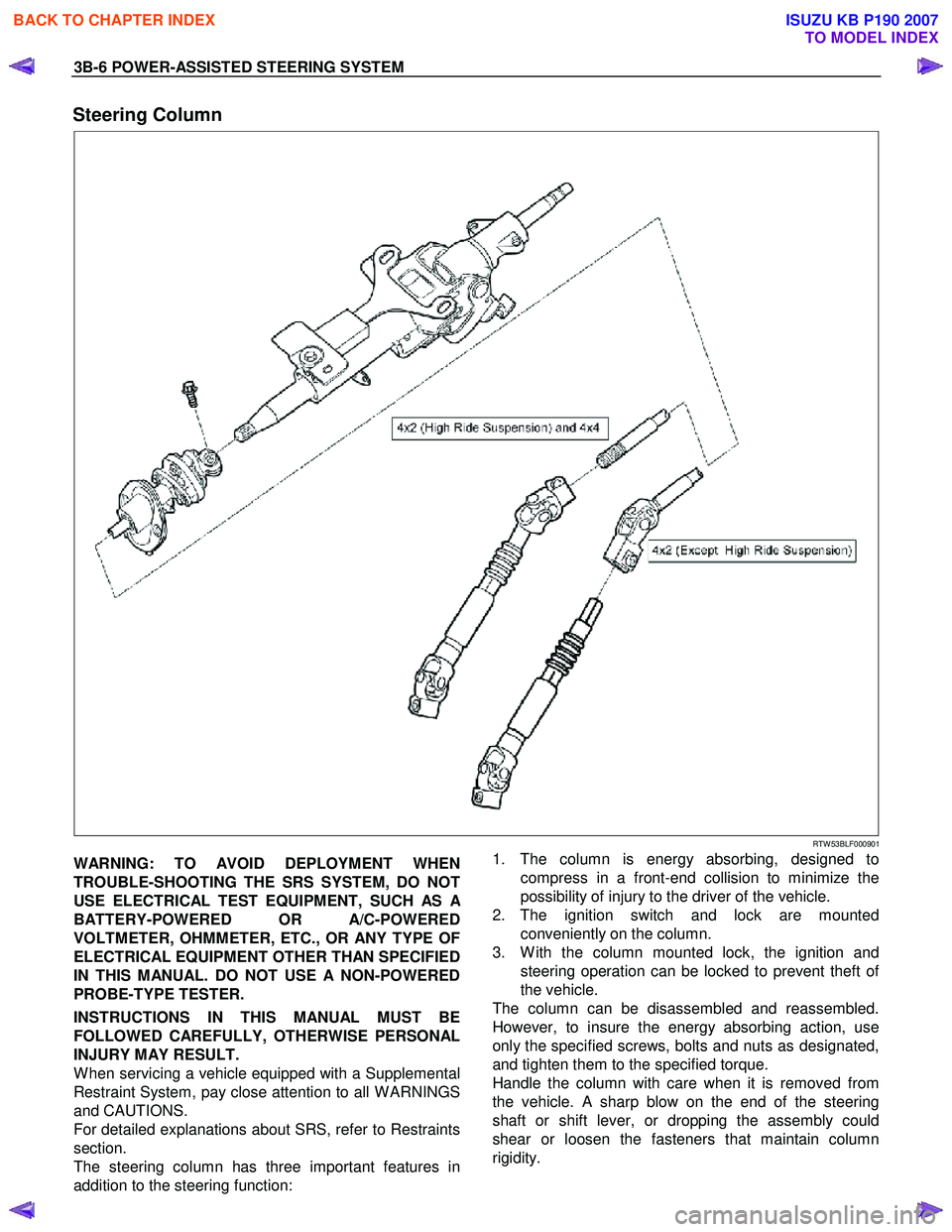

3B-6 POWER-ASSISTED STEERING SYSTEM

Steering Column

RTW 53BLF000901

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLE-SHOOTING THE SRS SYSTEM, DO NOT

USE ELECTRICAL TEST EQUIPMENT, SUCH AS

A

BATTERY-POWERED OR A/C-POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN SPECIFIED

IN THIS MANUAL. DO NOT USE A NON-POWERED

PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

W hen servicing a vehicle equipped with a Supplemental

Restraint System, pay close attention to all W ARNINGS

and CAUTIONS.

For detailed explanations about SRS, refer to Restraints

section.

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of injury to the driver of the vehicle.

2. The ignition switch and lock are mounted conveniently on the column.

3. W ith the column mounted lock, the ignition and steering operation can be locked to prevent theft o

f

the vehicle.

The column can be disassembled and reassembled.

However, to insure the energy absorbing action, use

only the specified screws, bolts and nuts as designated,

and tighten them to the specified torque.

Handle the column with care when it is removed from

the vehicle. A sharp blow on the end of the steering

shaft or shift lever, or dropping the assembly could

shear or loosen the fasteners that maintain column

rigidity.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007