lock ISUZU KB P190 2007 Workshop Service Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 351 of 6020

3C-30 FRONT SUSPENSION

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNECESSARY SRS

SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (paints, greases,

or other corrosion inhibitors) on threaded fasteners

or fastener joint interfaces. Generally, such

coatings adversely affect the fastener torque and

the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specifications.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 418 of 6020

4A-2 PROPELLER SHAFT

Service Precaution

WARNING: THIS VEHICLE HAS A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS).

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON

OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING

SERVICE ON OR NEAR THE SRS COMPONENTS

OR THE SRS WIRING, REFER TO THE SRS

SERVICE INFORMATION. FAILURE TO FOLLOW

WARNING COULD RESULT IN POSSIBLE AIR

BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION : Always use the correct fastener in the

proper location. When you replace a fastener,

use ONLY the exact part number for that

application. ISUZU/GM will call out those

fasteners that require a replacement afte

r

removal. ISUZU/GM will also call out the

fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do

not use supplemental coatings (Paints, greases,

or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastene

r

torque and the joint clamping force, and may

damage the fastener. When you install fasteners,

use the correct tightening sequence and

specifications. Following these instructions can

help you avoid damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 434 of 6020

4A-18 PROPELLER SHAFT

Rear Propeller Shaft Assembly

(4×2, 4×4)

RTW 54ALF000101

Legend

1. Splined Yoke

2. Journal Assembly

3. 1st Tube Assembly

4. Center Bearing

5. Plain W asher

6. Center Yoke

7. Lock Nut

8. 2nd Tube Assembly

9. Flange Yoke

10. Snap Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 435 of 6020

PROPELLER SHAFT 4A-19

Disassembly

1. Disassembly the three portions of the journal assemblies.

2. Remove the splined yoke, the 1st tube assembly with cente

r

bearing, the 2nd tube assembly and the flange yoke.

3. Remove the lock nut.

4. Remove the center yoke, the plain washer the cente

r

bearing and the 1st tube assembly.

Reassembly

1. Install the center bearing on the 1st tube assembly.

Clean the bearing fitting face.

Repack the grease.

Amount of grease

required g(oz) Approx. 12 (0.42)

2. Install the plain washer and the center yoke.

3. Install the lock nut and tighten it to the specified torque.

Lock nut Torque : 118 N ⋅

⋅⋅

⋅

m (12.0 kgf ⋅

⋅⋅

⋅

m/87lb ⋅

⋅⋅

⋅

ft)

(1) Discard the flange nut and install a new one.

(2) Stake the outer face of the flange nut against the slot in the shaft.

4. Install the splined yoke, the 1st tube assembly with cente

r

bearing, the 2nd tube assembly and the flange yoke by

assembling the universal joint.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 442 of 6020

4A-26 PROPELLER SHAFT

401RS027

Propeller Shaft Run-out

Support the ends of the propeller shaft on V-blocks (2) and

check for run-out by holding the probe of a dial indicator (1) in

contact with the center part of the shaft. If the amount of run-

out is beyond the standard value for assembly, correct with a

bench press or replace the shaft with a new propeller shaft

assembly.

Standard: 0.3 mm (0.012 in)

Limit: 0.5 mm (0.02 in)

401RS009

Play in Splines in Normal Direction of Rotation

Check the amount of play between the sleeve yoke (1) and the

propeller shaft spline (2) in the direction of rotation, using a

pointed feeler gauge.

Standard: 0.073-0.156 mm (0.003-0.006 in)

Limit: 0.3 mm (0.012 in)

401RS010

Play in Universal Joint

Limit: Less than 0.1 mm (0.004 in)

401RS011

Reassembly

1. Install spider to flange yoke. Be sure to install the spider by

aligning the setting marks made during disassembly.

2. Apply a molybdenum-disulfide grease or multi-purpose type grease NLGI No. 2 to inside of the bearing cap.

Grease Amount: Approx. 1.2 g (0.042 oz)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 445 of 6020

REAR AXLE 4B-1

SECTION 4B

REAR AXLE

TABLE OF CONTENTS

PAGE

Main Data and Specifications ........................................................................................... 4B- 3

Torque Specifications .............................................................................................................. 4B- 4

Recommended Liquid Gasket .......................................................................................... 4B- 6

Recommended Thread Locking Agents .......................................................................... 4B- 6

Rear Axle Assembly .......................................................................................................... 4B- 7

General Description...................................................................................................... 4B- 7

Servicing ...................................................................................................................... ...... 4B- 8

Rear Axle ...................................................................................................................... ...... 4B- 9

Disassembly .................................................................................................................. 4B - 10

Inspection and Repair .................................................................................................. 4B- 14

Reassembly ................................................................................................................... 4B - 15

Differential Assembly ..................................................................................................................... 4B- 20

Disassembly .................................................................................................................. 4B - 21

Reassembly ................................................................................................................... 4B - 24

Differential Cage Assembly .......................................................................................................... 4B- 34

Disassembly .................................................................................................................. 4B - 35

Inspection and Repair .............................................................................................................. 4B- 35

Reassembly ................................................................................................................................. 4B- 37

Limited Slip Differential (LSD) .......................................................................................... 4B- 38

Disassembly ............................................................................................................................... .4B- 39

Inspection and Repair .................................................................................................. 4B- 40

Reassembly ................................................................................................................... 4B - 42

Troubleshooting............................................................................................................ 4B- 45

Special Service Tool ................................................................................................................. 4B- 56

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 446 of 6020

4B-2 REAR AXLE

Service Precaution

WARNING:

THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE REFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE

TO FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS

SYSTEM REPAIRS.

CAUTION:

Always use the correct fastener in the prope

r

location. When you replace a fastener, use ONLY

the exact part number for that application.

ISUZU/GM will call out those fasteners that require

a replacement after removal. ISUZU/GM will also

call out the fasteners that require thread lockers o

r

thread sealant. UNLESS OTHERWISE SPECIFIED,

do not use supplemental coatings (Paints,

greases, or other corrosion inhibitors) on threaded

fasteners or fastener joint interfaces. Generally,

such coatings adversely affect the fastener torque

and the joint clamping force, and may damage the

fastener. When you install fasteners, use the

correct tightening sequence and specification.

Following these instructions can help you avoid

damage to parts and systems.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 450 of 6020

4B-6 REAR AXLE

RECOMMENDED LIQUID GASKET

Type Brand Name Manufacture Remarks

RTV* Silicon Base ThreeBond 1207B

ThreeBond 1207C

ThreeBond 1215

Three Bond

Three Bond

Three Bond

For Engine Repairs

For Axle Case

Repairs, T/M

W ater Base ThreeBond 1141E Three Bond For Engine Repairs

Solvent ThreeBond 1104

BelcoBond 4

BelcoBond 401

BelcoBond 402 Three bond

Isuzu

Isuzu

Isuzu

For Engine Repairs

Anaerobic LOCTITE 515

LOCTITE 518 Loctite

Loctite All

* RTV : Room Temperature Vulcanizer

Note :

1. It is very important that the liquid gaskets listed above or their exact equivalent be used on the

vehicle.

2. Be careful to use the specified amount of liquid gasket.

Follow the manufacture's instructions at all times.

3. Be absolutely sure to remove all lubricants and

moisture from the connecting surfaces before

applying the liquid gasket.

The connecting surfaces must be perfectly dry.

4. LOCTITE 515 and LOCTITE 518 harden upon contact with a metal surface.

Do not apply LOCTITE 515 or LOCTITE 518 between two metal surfaces having a clearance

of greater than 0.25 mm (0.01 in). Poo

r

adhesion will result.

RECOMMENDED THREAD LOCKING AGENTS

LOCTITE Type LOCTITE Color Application Steps

LOCTITE 242

Blue 1. Completely remove all lubricant and moisture from the bolts and

the female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

LOCTITE 262

Red 2. Apply LOCTITE to the bolts.

LOCTITE 270

Green

LOCTITE 271

Red

3. Tighten the bolts to the specified torque.

4. W ait at least one hour before continuing the installation procedure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 456 of 6020

4B-12 REAR AXLE

9. Use offset box wrench to compress locking lugs

on the cable, then remove parking brake oute

r

cable from back plate.

311RS012

Legend

1. Offset Box W rench

10. Remove wheel cylinder.

11. Remove bearing holder fixing nuts.

12. Take out axle shaft assembly with back plate and

set it on a bench press as following illustration.

W hen axle shaft is extracted, since axle case oil

seal is damaged, replace the axle case oil seal.

13. Remove snap ring. Use snap ring pliers to

remove. Snap ring is prohibition of reuse.

14. Remove shim (If so equipped)

15. Grind the retainer surfaces using a grinder, then chisel them out with a chisel.

16. Position remover 5-8840-2831-0 on the bearing

holder with 4 nuts.

RTW 54BSH000801

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 469 of 6020

REAR AXLE 4B-25

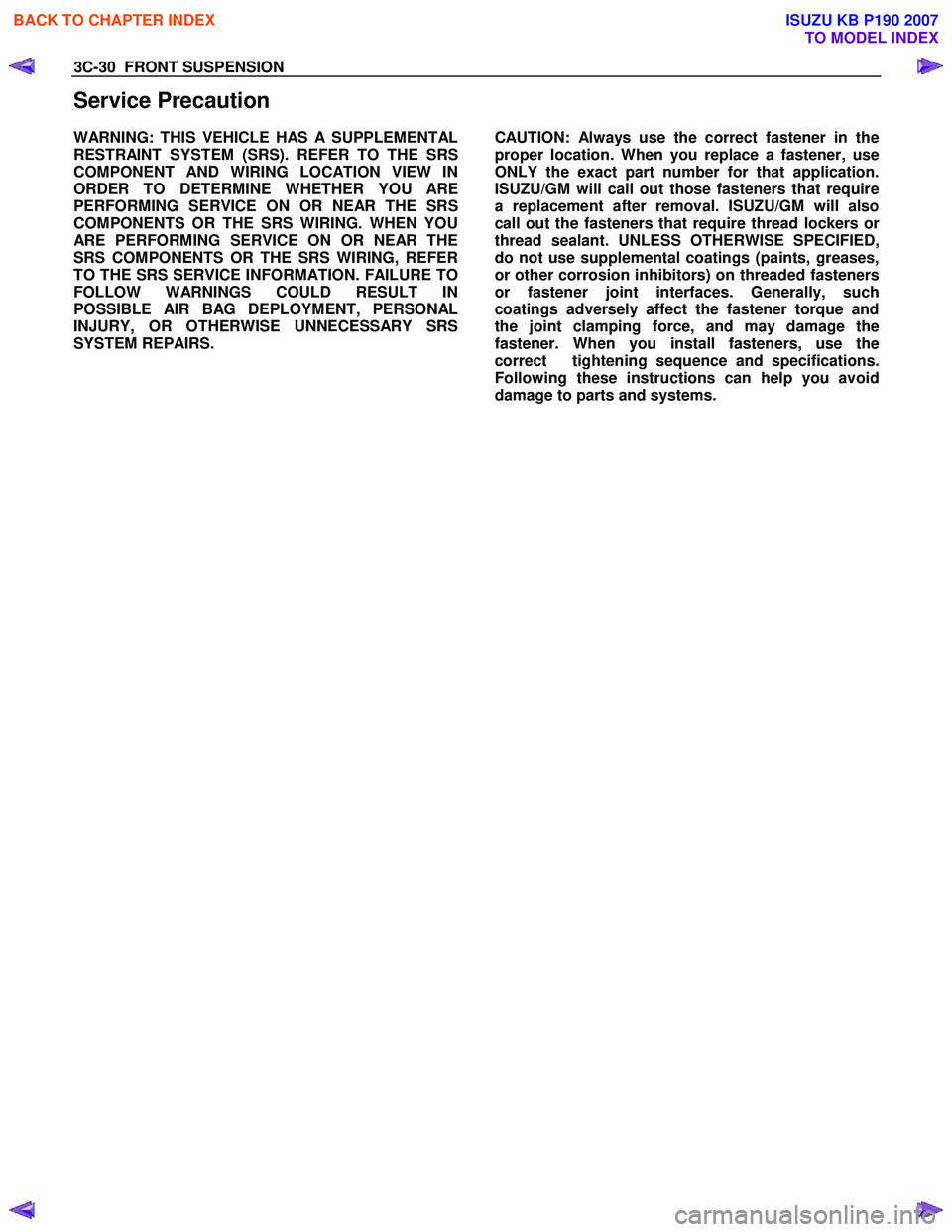

b. Tighten the nut to the specified torque.

Torque:

φ220mm : 2.7 N ⋅m (0.28 kgf ⋅m/24 lb ⋅in)

φ194mm : 2.3 N ⋅m (0.23 kgf ⋅m/20 lb ⋅in)

425RW 030

c. Clean the side bearing bores. Place discs and

dial indicator on to arbor, and place tool into

position in side bearing bores. Install and

tighten the bearing caps to the specified

torque.

Torque : φ220mm : 108N ⋅m (11 kgf ⋅m/80 lb ⋅ft)

φ194mm : 94N ⋅m (10 kgf ⋅m/72 lb ⋅ft)

425RW 031

Legend

φ

φφ

φ

220mm

1. Dial Indicator : 5-8840-0126-0

2. Gauge Plate : 5-8840-2166-0

3. Disc (2 pcs.) : 5-8840-2167-0

4. Arbor : 5-8840-0128-0

φ

φφ

φ

194mm

1. Dial Indicator : 5-8840-0126-0

2. Gauge Plate : 5-8840-2087-0

3. Disc (2 pcs.) : 5-8840-2088-0

4. Arbor : 5-8840-0128-0

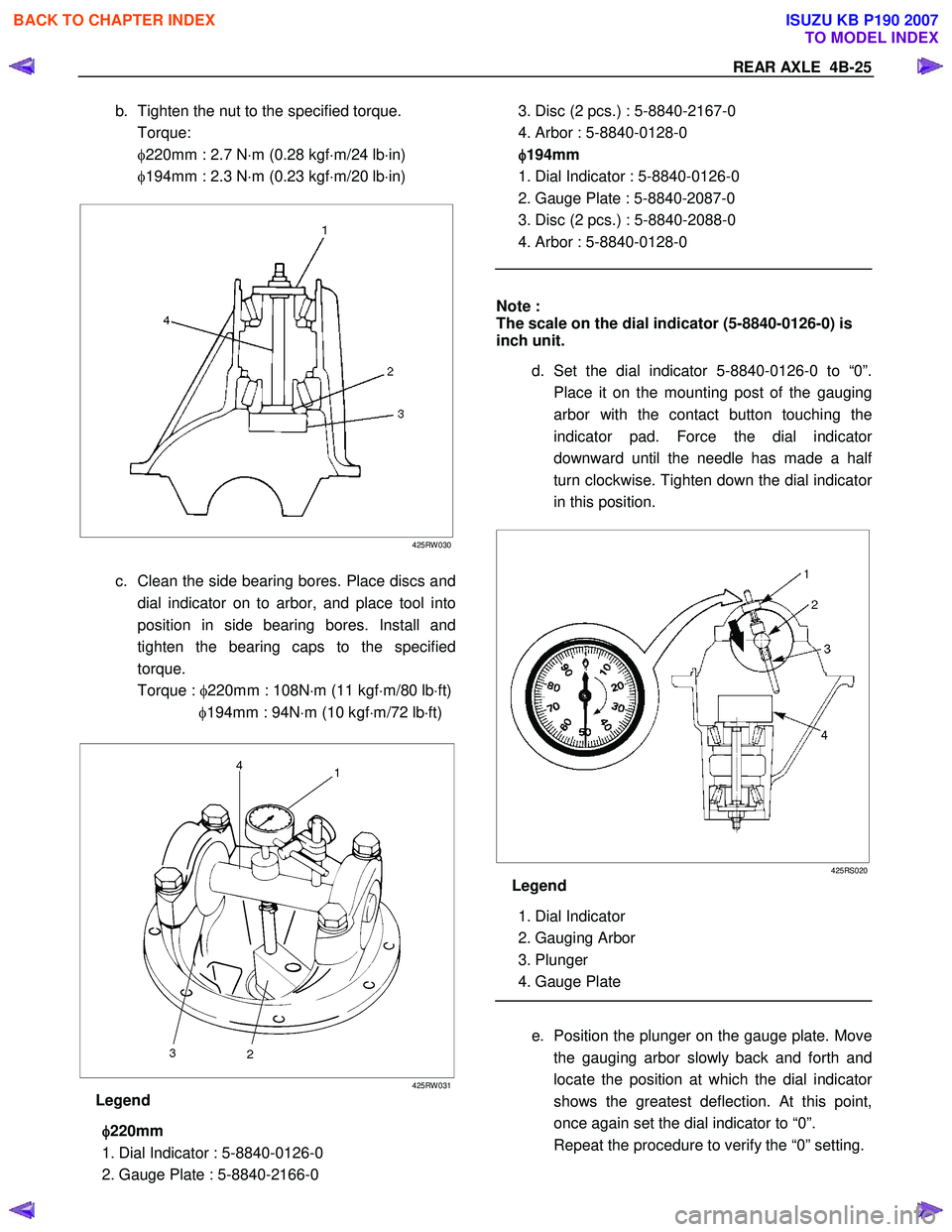

Note :

The scale on the dial indicator (5-8840-0126-0) is

inch unit.

d. Set the dial indicator 5-8840-0126-0 to “0”.

Place it on the mounting post of the gauging

arbor with the contact button touching the

indicator pad. Force the dial indicato

r

downward until the needle has made a hal

f

turn clockwise. Tighten down the dial indicato

r

in this position.

425RS020

Legend

1. Dial Indicator

2. Gauging Arbor

3. Plunger

4. Gauge Plate

e. Position the plunger on the gauge plate. Move

the gauging arbor slowly back and forth and

locate the position at which the dial indicato

r

shows the greatest deflection. At this point,

once again set the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007