engine ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3726 of 6020

Powertrain Interface Module – V6 Page 6E1–65

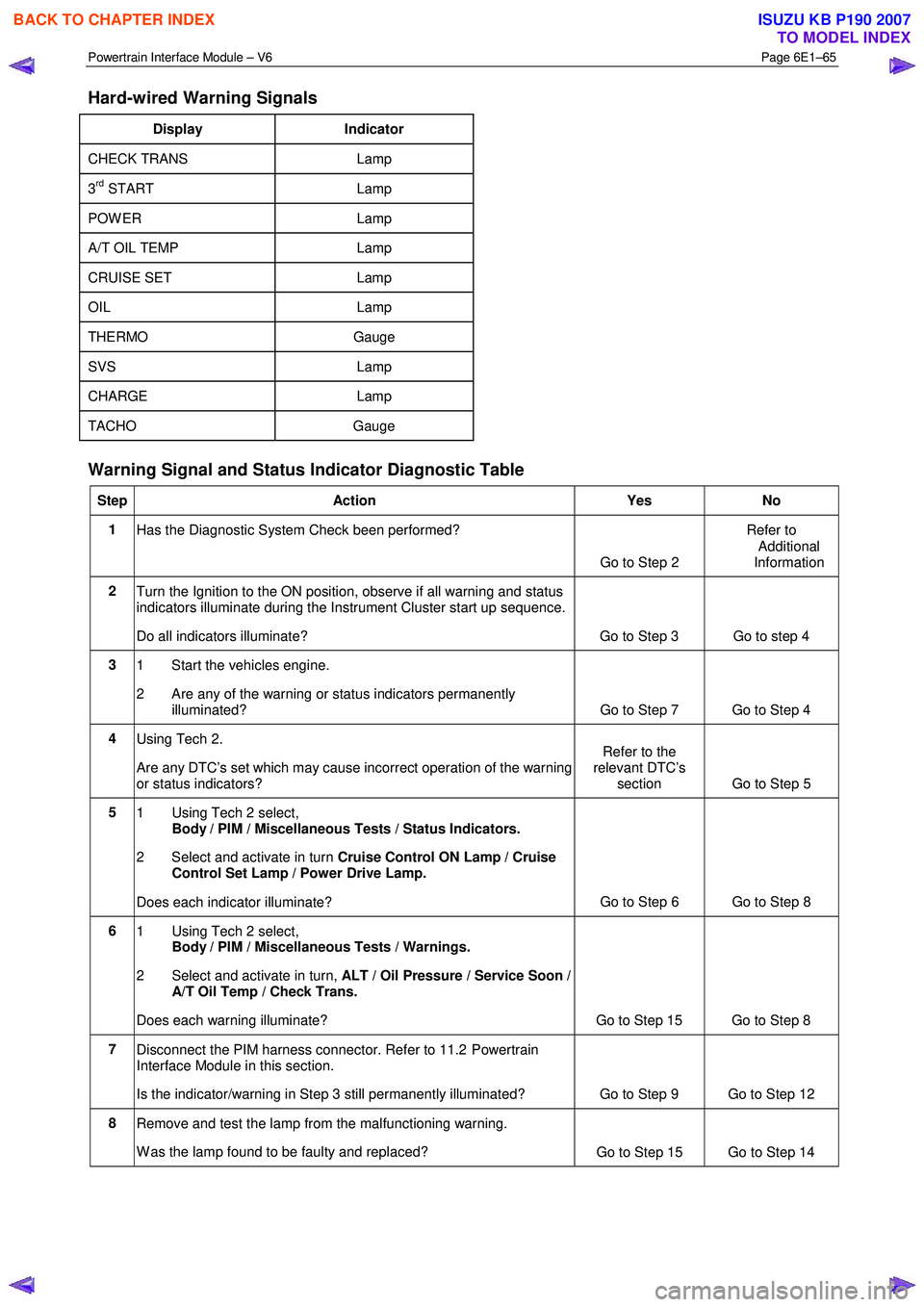

Hard-wired Warning Signals

Display Indicator

CHECK TRANS Lamp

3rd START Lamp

POW ER Lamp

A/T OIL TEMP Lamp

CRUISE SET Lamp

OIL Lamp

THERMO Gauge

SVS Lamp

CHARGE Lamp

TACHO Gauge

Warning Signal and Status Indicator Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

Additional

Information

2 Turn the Ignition to the ON position, observe if all warning and status

indicators illuminate during the Instrument Cluster start up sequence.

Do all indicators illuminate? Go to Step 3 Go to step 4

3 1 Start the vehicles engine.

2 Are any of the warning or status indicators permanently illuminated? Go to Step 7 Go to Step 4

4 Using Tech 2.

Are any DTC’s set which may cause incorrect operation of the warning

or status indicators? Refer to the

relevant DTC’s section Go to Step 5

5

1 Using Tech 2 select,

Body / PIM / Miscellaneous Tests / Status Indicators.

2 Select and activate in turn Cruise Control ON Lamp / Cruise

Control Set Lamp / Power Drive Lamp.

Does each indicator illuminate? Go to Step 6 Go to Step 8

6

1 Using Tech 2 select,

Body / PIM / Miscellaneous Tests / Warnings.

2 Select and activate in turn, ALT / Oil Pressure / Service Soon /

A/T Oil Temp / Check Trans.

Does each warning illuminate? Go to Step 15 Go to Step 8

7 Disconnect the PIM harness connector. Refer to 11.2 Powertrain

Interface Module in this section.

Is the indicator/warning in Step 3 still permanently illuminated? Go to Step 9 Go to Step 12

8 Remove and test the lamp from the malfunctioning warning.

W as the lamp found to be faulty and replaced? Go to Step 15 Go to Step 14

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3728 of 6020

Powertrain Interface Module – V6 Page 6E1–67

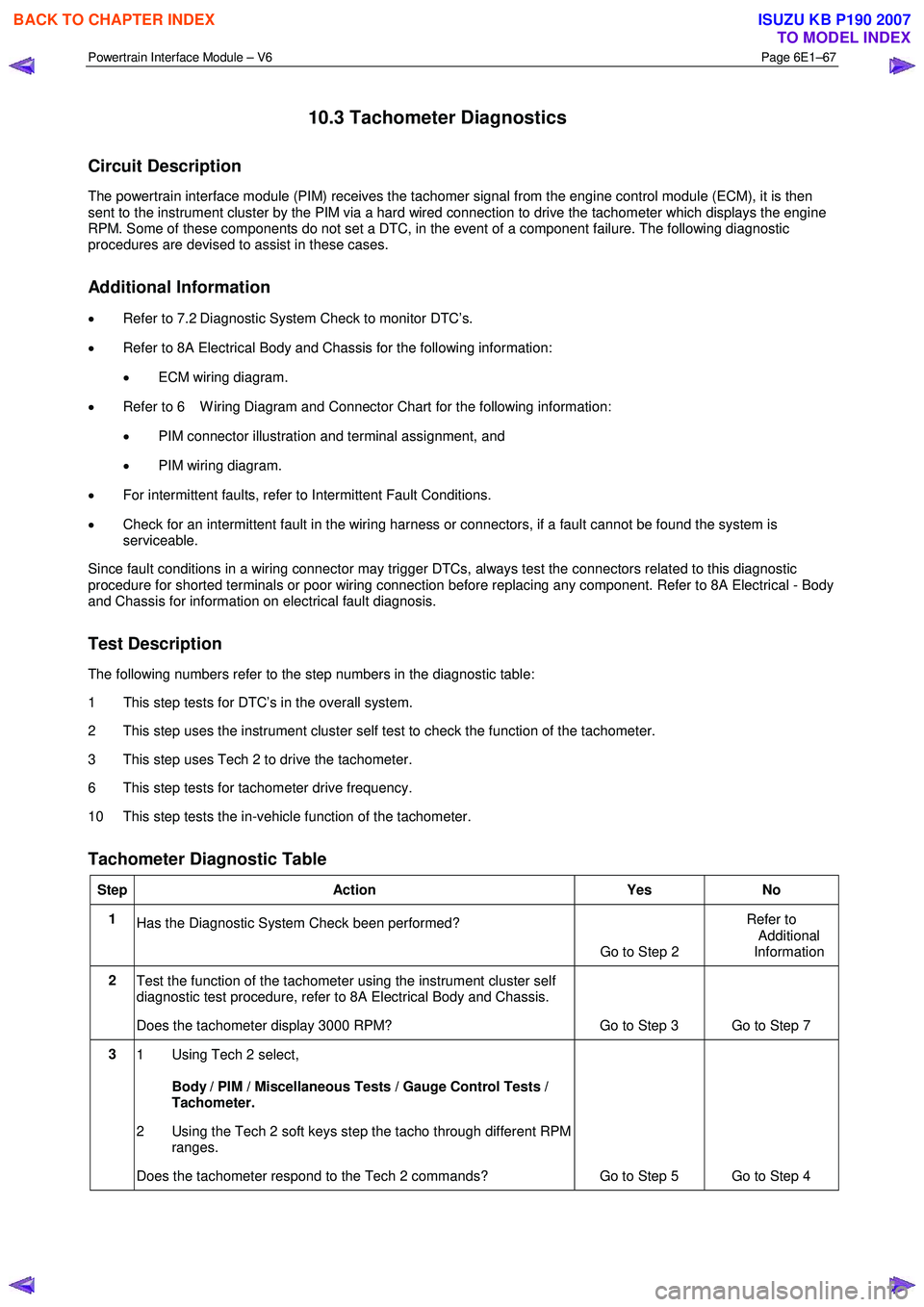

10.3 Tachometer Diagnostics

Circuit Description

The powertrain interface module (PIM) receives the tachomer signal from the engine control module (ECM), it is then

sent to the instrument cluster by the PIM via a hard wired connection to drive the tachometer which displays the engine

RPM. Some of these components do not set a DTC, in the event of a component failure. The following diagnostic

procedures are devised to assist in these cases.

Additional Information

• Refer to 7.2 Diagnostic System Check to monitor DTC’s.

• Refer to 8A Electrical Body and Chassis for the following information:

• ECM wiring diagram.

• Refer to 6 W iring Diagram and Connector Chart for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• For intermittent faults, refer to Intermittent Fault Conditions.

• Check for an intermittent fault in the wiring harness or connectors, if a fault cannot be found the system is

serviceable.

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step tests for DTC’s in the overall system.

2 This step uses the instrument cluster self test to check the function of the tachometer.

3 This step uses Tech 2 to drive the tachometer.

6 This step tests for tachometer drive frequency.

10 This step tests the in-vehicle function of the tachometer.

Tachometer Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

Additional

Information

2 Test the function of the tachometer using the instrument cluster self

diagnostic test procedure, refer to 8A Electrical Body and Chassis.

Does the tachometer display 3000 RPM? Go to Step 3 Go to Step 7

3 1 Using Tech 2 select,

Body / PIM / Miscellaneous Tests / Gauge Control Tests /

Tachometer.

2 Using the Tech 2 soft keys step the tacho through different RPM ranges.

Does the tachometer respond to the Tech 2 commands? Go to Step 5 Go to Step 4

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3729 of 6020

Powertrain Interface Module – V6 Page 6E1–68

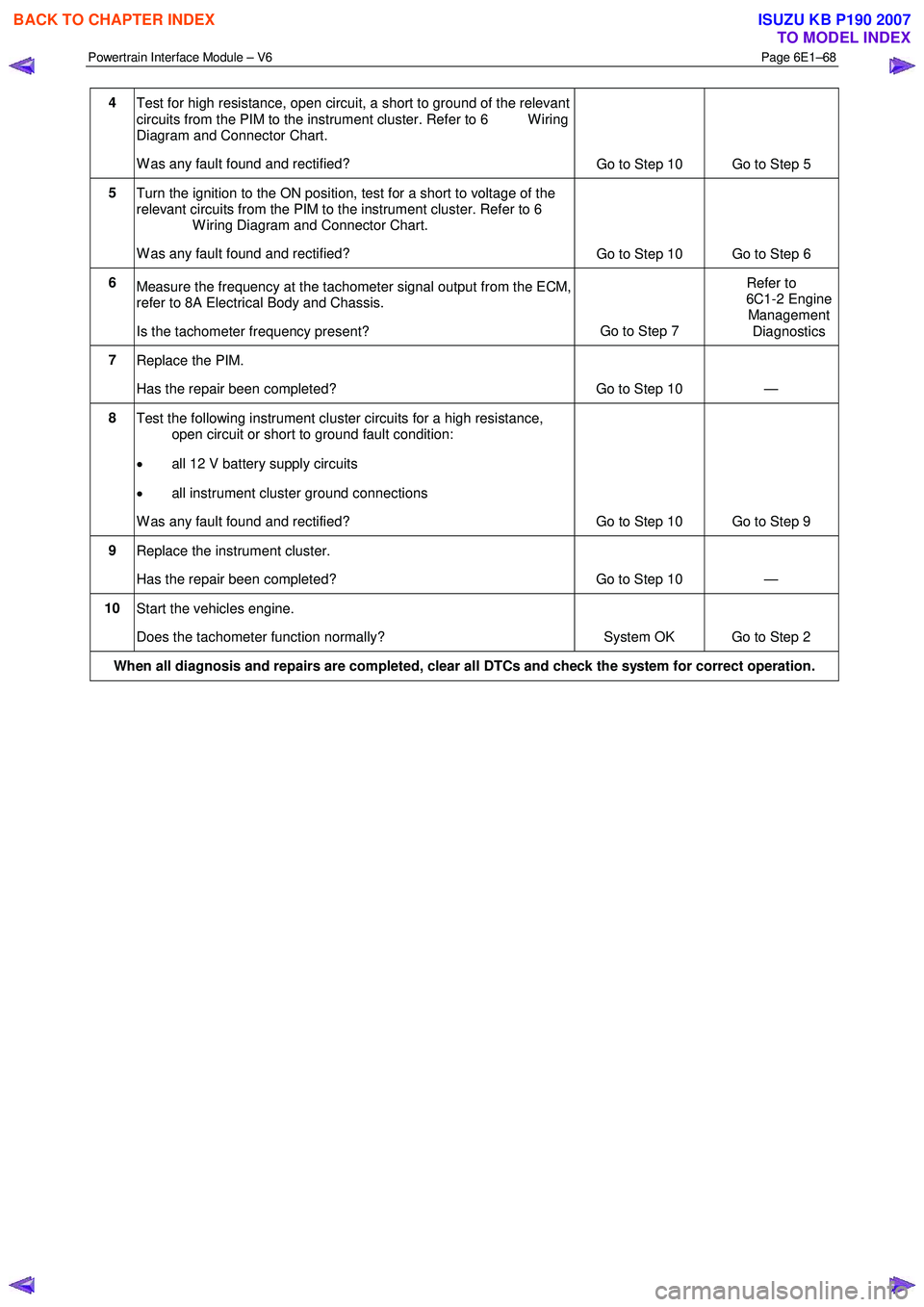

4

Test for high resistance, open circuit, a short to ground of the relevant

circuits from the PIM to the instrument cluster. Refer to 6 W iring

Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 10 Go to Step 5

5

Turn the ignition to the ON position, test for a short to voltage of the

relevant circuits from the PIM to the instrument cluster. Refer to 6

W iring Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 10 Go to Step 6

6

Measure the frequency at the tachometer signal output from the ECM,

refer to 8A Electrical Body and Chassis.

Is the tachometer frequency present? Go to Step 7 Refer to

6C1-2 Engine Management

Diagnostics

7 Replace the PIM.

Has the repair been completed? Go to Step 10 —

8 Test the following instrument cluster circuits for a high resistance,

open circuit or short to ground fault condition:

• all 12 V battery supply circuits

• all instrument cluster ground connections

W as any fault found and rectified? Go to Step 10 Go to Step 9

9 Replace the instrument cluster.

Has the repair been completed? Go to Step 10 —

10 Start the vehicles engine.

Does the tachometer function normally? System OK Go to Step 2

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3730 of 6020

Powertrain Interface Module – V6 Page 6E1–69

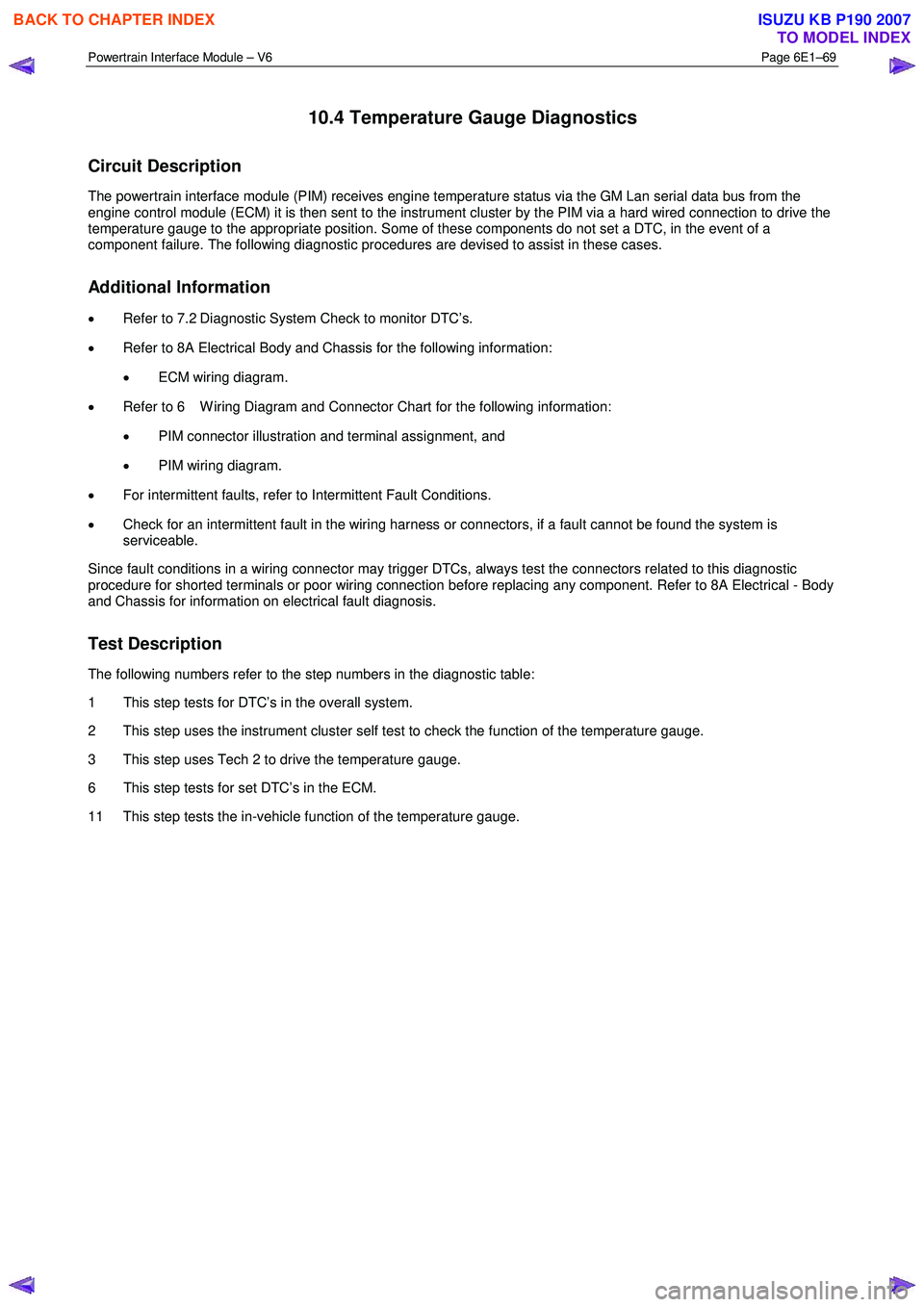

10.4 Temperature Gauge Diagnostics

Circuit Description

The powertrain interface module (PIM) receives engine temperature status via the GM Lan serial data bus from the

engine control module (ECM) it is then sent to the instrument cluster by the PIM via a hard wired connection to drive the

temperature gauge to the appropriate position. Some of these components do not set a DTC, in the event of a

component failure. The following diagnostic procedures are devised to assist in these cases.

Additional Information

• Refer to 7.2 Diagnostic System Check to monitor DTC’s.

• Refer to 8A Electrical Body and Chassis for the following information:

• ECM wiring diagram.

• Refer to 6 W iring Diagram and Connector Chart for the following information:

• PIM connector illustration and terminal assignment, and

• PIM wiring diagram.

• For intermittent faults, refer to Intermittent Fault Conditions.

• Check for an intermittent fault in the wiring harness or connectors, if a fault cannot be found the system is

serviceable.

Since fault conditions in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 This step tests for DTC’s in the overall system.

2 This step uses the instrument cluster self test to check the function of the temperature gauge.

3 This step uses Tech 2 to drive the temperature gauge.

6 This step tests for set DTC’s in the ECM.

11 This step tests the in-vehicle function of the temperature gauge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3731 of 6020

Powertrain Interface Module – V6 Page 6E1–70

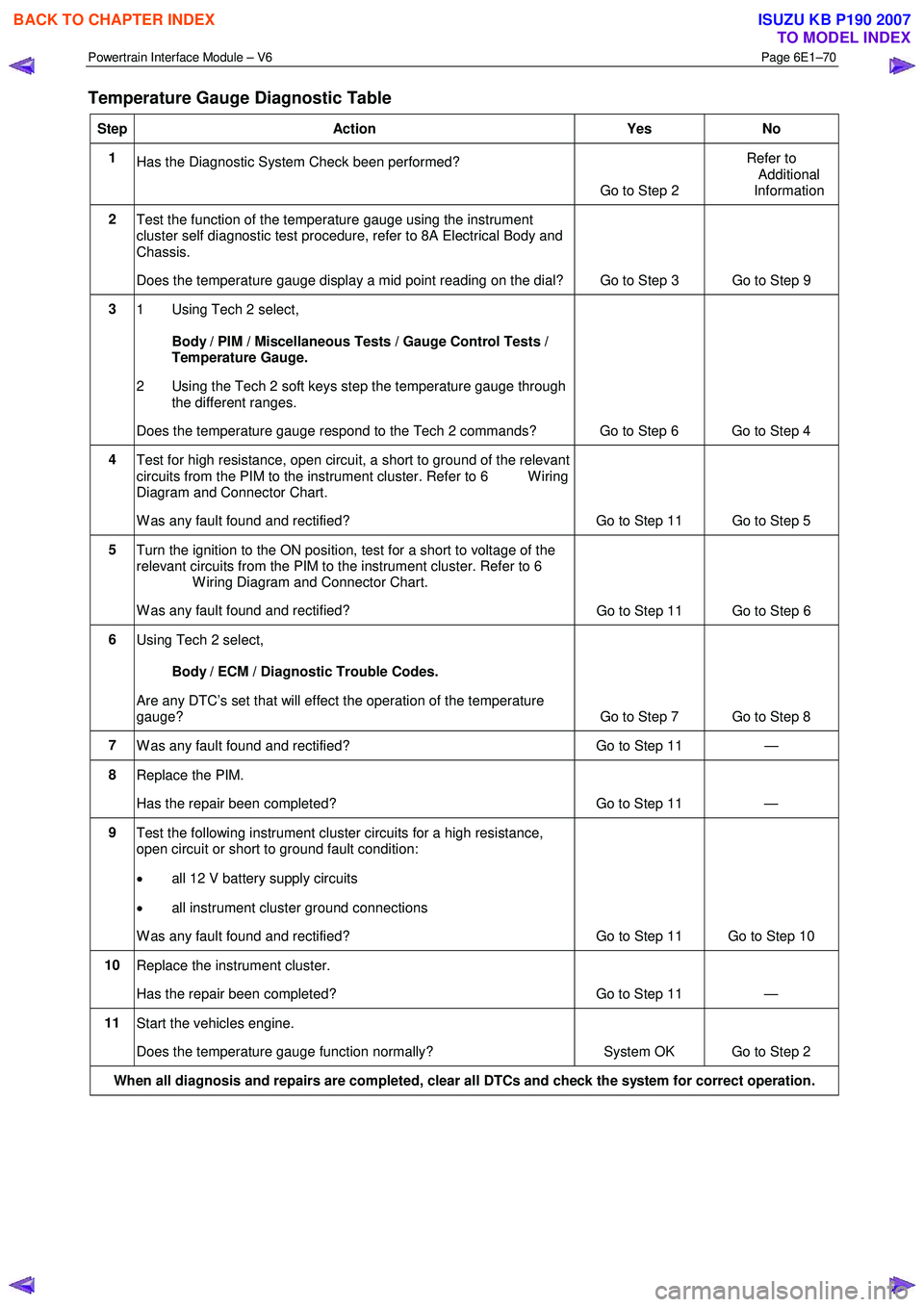

Temperature Gauge Diagnostic Table

Step Action Yes No

1

Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

Additional

Information

2 Test the function of the temperature gauge using the instrument

cluster self diagnostic test procedure, refer to 8A Electrical Body and

Chassis.

Does the temperature gauge display a mid point reading on the dial? Go to Step 3 Go to Step 9

3

1 Using Tech 2 select,

Body / PIM / Miscellaneous Tests / Gauge Control Tests /

Temperature Gauge.

2 Using the Tech 2 soft keys step the temperature gauge through the different ranges.

Does the temperature gauge respond to the Tech 2 commands? Go to Step 6 Go to Step 4

4 Test for high resistance, open circuit, a short to ground of the relevant

circuits from the PIM to the instrument cluster. Refer to 6 W iring

Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 11 Go to Step 5

5 Turn the ignition to the ON position, test for a short to voltage of the

relevant circuits from the PIM to the instrument cluster. Refer to 6

W iring Diagram and Connector Chart.

W as any fault found and rectified? Go to Step 11 Go to Step 6

6

Using Tech 2 select,

Body / ECM / Diagnostic Trouble Codes.

Are any DTC’s set that will effect the operation of the temperature

gauge? Go to Step 7 Go to Step 8

7 W as any fault found and rectified? Go to Step 11 —

8 Replace the PIM.

Has the repair been completed? Go to Step 11 —

9 Test the following instrument cluster circuits for a high resistance,

open circuit or short to ground fault condition:

• all 12 V battery supply circuits

• all instrument cluster ground connections

W as any fault found and rectified? Go to Step 11 Go to Step 10

10 Replace the instrument cluster.

Has the repair been completed? Go to Step 11 —

11 Start the vehicles engine.

Does the temperature gauge function normally? System OK Go to Step 2

When all diagnosis and repairs are completed, clear all DTCs and check the system for correct operation.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3732 of 6020

Powertrain Interface Module – V6 Page 6E1–71

11 Service Operations

11.1 Safety and Precautionary Measures

The following safety and precautionary

measures must be followed when servicing

and diagnosing the powertrain interface

module (PIM) System. Otherwise, personal

injury and / or improper braking system

operation may occur:

• W hen using electric welding equipment, disconnect the wiring harness connector from the PIM.

• Never disconnect or reconnect the PIM wiring harness connector when the ignition is switched ON.

• Do not touch the PIM connector pins or soldered components on the PIM circuit board to prevent possible

Electrostatic Discharge damage.

• To avoid wiring connector terminal damage, always use suitable wiring harness test leads (such as those in Tool

No, J35616) when performing tests on the PIM wiring connector.

• The PIM is extremely sensitive to Electro Magnetic Interference (EMI). Ensure the PIM wiring harness is routed

correctly and securely fitted to mounting clips when performing service procedures.

• Due to the sensitive nature of the PIM circuitry, specific wiring repair procedures have been developed. These

procedures and instructions are detailed in 8A Electrical - Body and Chassis and are the only recommended and

approved wiring repair methods.

• Ensure that all wiring harness connectors are seated correctly.

• Never disconnect the battery from the vehicle electrical system while the engine is running.

• Always disconnect the battery from the vehicle electrical system before charging.

• Do not use a fast charger for starting the vehicle.

• Ensure the battery cable terminals are secure.

• Before installing a new PIM, ensure the correct type is fitted. Always refer to the latest spare parts information.

11.2 Powertrain Interface Module

Do not touch the powertrain interface module

pins as Electrostatic Discharge (ESD) damage

may result. For further information on ESD,

refer to 1.2 Warning Caution and Notes.

When replacing the PIM, the PIM must be

reset prior to removal. Failure to perform this

procedure will result in the inability to:

• Test the PIM for warranty purposes.

• Install the PIM into other vehicles.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3736 of 6020

Powertrain Interface Module – V6 Page 6E1–75

NOTE

The Tech 2 PIM Security Information Data List

typical display values are obtained from a

correctly operating vehicle under the following

conditions:

• ignition switched on,

• engine not running, and

• vehicle is stationary.

Tech 2 Parameter Units Displayed Typical Display Values

ICU / PIM Status Yes / No Yes

Security Code Programmed Yes / No Yes

Security W ait Time Inactive / Active Inactive

Security W ait Time Inactive / 0:00:00 Inactive

Security Code Correct Enter Yes / No Yes

Security Code Reset Counter 0 0

12.2 PIM Reset Procedure

Do not perform the reset procedure within

sixty seconds of turning the ignition switch

on. Failure to comply may result in the PIM

failing to reset.

W hen a PIM has been installed into a vehicle, it is security linked to the immobiliser control unit (ICU) and engine control

module (ECM). Once this linking has been performed, the PIM cannot be installed in any other vehicle, unless the

security linking between the ICU and the ECM has been reset using the following procedure:

1 Prior to resetting the PIM, obtain the Security Code. For further information, refer to 12.1 Security and Programming Information.

2 Connect Tech 2 to the data link connector (DLC) and turn the ignition switch on.

3 On Tech 2 select: Body / Powertrain Interface Module / Security / Reset PIM .

NOTE

When Tech 2 requests programming approval,

obtain TIS approval.

NOTE

If a Tech 2 screen displaying Security Wait Time

Active, Please Wait! appears after selecting the

Reset PIM option, an incorrect security code has

been previously entered. Refer to 12.1

Security and Programming Information for further

information.

4 W hen Tech 2 displays Enter Security Code, enter the security code, press the Enter key and then the Okay soft

key.

The engine will not start after the PIM has

been reset.

5 W hen Tech 2 displays Do you really want to Reset? , press the Reset soft key.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3738 of 6020

Powertrain Interface Module – V6 Page 6E1–77

Do not turn the ignition switch off within 60

seconds of programming the VIN. Failure to

comply may result in the changes failing to be

programmed into the PIM.

5 W hen notified that the programming was successful, press the Confirm soft key to return to the Tech 2 Program

screen.

12.4 Immobiliser Link to ECM / PIM

Do not perform the Immobiliser Link to ECM /

PIM procedure within sixty seconds of turning

the ignition switch on. Failure to comply may

result in the PIM failing to link.

W hen the powertrain interface module (PIM) has been replaced, it is necessary to security link the PIM to the immobiliser

control unit (ICU) and engine control module (ECM) before the vehicle will start.

NOTE

This linking procedure between the ECM and PIM

is also known as the Immobiliser Function

Programming.

1 Prior to performing the linking procedure, obtain the security code. For further information, refer to 12.1Security and Programming Information.

2 Connect Tech 2 to the data link connector (DLC).

3 On Tech 2 select: Body / Powertrain Interface Module / Security / Immobiliser Link to ECM / PIM .

4 W hen Tech 2 displays Immobiliser Replaced, press the No soft key.

5 W hen Tech 2 displays PIM or ECM Replaced?, press the Yes soft key.

NOTE

When Tech 2 requests programming approval,

obtain TIS approval.

6 W hen Tech 2 displays Enter Security Code, enter the security code and press the Enter key and then the Okay

soft key.

7 W hen Tech 2 displays Confirm Security Code, re-enter the security code, press the Enter key and then the Okay

soft key.

8 W hen Tech 2 displays Select Immobiliser Programming Routine , use the up or down arrow selection keys, to

select the PIM Replaced option and press the Enter key.

9 W hen Tech 2 displays Stop Engine – Turn Off Ignition , turn the ignition switch off and press the Confirm soft key.

10 W hen Tech 2 displays Turn Ignition On, turn the ignition switch on and press the Confirm soft key.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3740 of 6020

Powertrain Interface Module – V6 Page 6E1–79

13 Powertrain Interface Module –

Tech 2 Functions

13.1 Introduction

Do not use a Tech 2 that displays faulty data;

have the Tech 2 repaired. The use of a faulty

Tech 2 can result in misdiagnosis and the

unnecessary replacement of parts.

From the Main Menu, having selected Diagnostics / 2006 / RA Rodeo / Body , the Tech 2 functions for the Powertrain

Interface, include:

F0: Diagnostic Trouble Codes

F1: Diagnostic Data Display

F2: Snapshot

F3: Miscellaneous Tests

F4: Additional Functions

F5: Program

F6: Security

13.2 Tech 2 Functions

F0: Diagnostic Trouble Codes

W hen this test mode is initiated, DTCs stored by the ECM can be displayed or cleared. W hen entered, there are two

additional modes for selection:

F0: Read DTC Info Ordered By Priority : All DTCs stored in the ECM will be displayed.

F1: Clear DTC Information : Clears all current DTCs in the ECM and TCM memories.

F1: Diagnostic Data Display

• Use the Tech 2 Data List under the following conditions:

• The Diagnostic System Check – V6 Engine has been completed.

• The On-Board Diagnostics are functioning correctly.

• No DTCs are present.

NOTE

The values quoted in the following data list are

only intended to provide the Technician with an

indication of the values to be expected.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3742 of 6020

Powertrain Interface Module – V6 Page 6E1–81

13.3 Powertrain Interface Module Data List

Diagnostic Data Display

Tech 2 Display Units Displayed Switch On Switch Off

AC Switch On/Off On Off

Cruise Cancel Switch Active/Inactive Active Inactive

Cruise Resume Switch Active/Inactive Active Inactive

Cruise Set Switch Active/Inactive Active Inactive

Cruise Main Switch Active/Inactive Active Inactive

Cruise Control Set Lamp On/Off On Off

Cruise Control On Lamp On/Off On Off

Power Drive Switch On/Off On Off

Power Drive Lamp On/Off On Off

3rd Start Switch On/Off On Off

3rd Start Lamp On/Off On Off

4W D Low Gear Active/Inactive Active Inactive

G-Sensor V 2.43 2.43

G-Sensor Pa 0.027 0.027

Engine Speed RPM 152 1093

Coolant temperature Input °C 35 25

Coolant Temperature % 70 70

Fuel Level Input % 26 26

Fuel Level % 43 43

Alternator Lamp On/Off On Off

Oil Pressure Lamp On/Off On Off

SVS Lamp (Service Vehicle soon) On/Off On Off

Check transmission MIL On/Off On Off

Transmission Oil Temperature Lamp On/Off On Off

LED [ - P - ] On/Off On Off

LED [ - R - ] On/Off On Off

LED [ - N - ] On/Off On Off

LED [ - D - ] On/Off On Off

LED [ - 3 - ] On/Off On Off

LED [ - 2 - ] On/Off On Off

LED [ - 1 - ] On/Off On Off

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007